Helioscreen Vario-Pergola User manual

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

VARIO-PERGOLA

self supporting sunroof

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

VARIO-PERGOLA

CONTENTS

1.SAFETY...................................................................................................................................................................... 3

1.1EXPLANATIONOFTHESAFETYNOTES.......................................................................................................... 3

1.2GENERALSAFETYINFORMATION.................................................................................................................... 4

2.INSTALLATION........................................................................................................................................................... 4

2.1.TOOLS,RESOURCESANDMATERIALS........................................................................................................... 4

2.2.PREPARINGTHEINSTALLATION...................................................................................................................... 4

2.3.MOUNTINGSITUATIONS:WALLANDCEILINGINSTALLATION...................................................................... 5

2.4.MOUNTINGHEIGHTANDPOSITIONOFTHEBRACKETS.............................................................................. 6

2.5.MOUNTINGTECHNIQUE................................................................................................................................... 7

2.6.MOUNTINGTHECASING.................................................................................................................................. 7

2.7.MOUNTINGRAILSANDPOSTS........................................................................................................................ 8

2.8.MOUNTINGTHEDISTANCETUBE(S).............................................................................................................. 10

2.9.ALIGNMENTOFTHESYSTEM........................................................................................................................ 11

3.LINESYSTEMS........................................................................................................................................................ 12

4.INITIALOPERATION................................................................................................................................................ 13

5.DISMOUNTING........................................................................................................................................................ 14

6.TROUBLESHOOTING.............................................................................................................................................. 14

7.ANNEX...................................................................................................................................................................... 15

INSTALLATION INSTRUCTIONS

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 3

1.SAFETYNOTES,WARNINGSANDMOUNTINGINFORMATION

1.1 EXPLANATION OF THE SAFETY NOTES

Safety notes and important information are integrated in the text as appropriate. The following symbols are used to alert the

reader/user of the instructions.

This symbol means that the relevant note is important for the safety of persons or for the function of the awning.

This symbol highlights important product information for the installation engineer or user.

1.2 GENERAL SAFETY INFORMATION

!Only qualified and duly specialised companies or trained specialist personnel may be permitted to mount the awning.

!Always observe the information and notes in the installation and operation instructions. A failure to observe the relevant

information will render the manufacturer’s liability null and void.

iThe safety-at-work and accident prevention regulations specific to each country must be complied with. In particular, a

person performing special work at height must be suitably secured. The notes on the product and its packaging must be

observed

i

!

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 4

2.INSTALLATION

2.1 TOOLS, RESOURCES AND MATERIALS

•Measuringtape10m

•(Percussion)drillingmachine

•Cordlessscrewdriver

•Drillbits,suitableforthedrillingsubstrateandthemountingpieces

•SW4,SW5;SW6andSW8Allenkeys

•TorxbitTx25

•Ratchetwithextensionandsockets,respectivelyringspannersSW13andSW17

•Steeldrillbits,diameter4.5mmand5.5mm

•Spiritlevelandstringforalignmentofthebrackets

•Testcable,resp.adjustmentset(forinitialoperation)

•Aluminiumchopsawtoshortentheposts

2.2. PREPARING THE INSTALLATION

! Securetheinstallationzone(thesecuredzonemustbeatleastequivalenttothesizeofthefullydeployedawning).Ifthe

awningishoistedtohigherinstallationpositionswithropes,theawningmustberemovedfromthepackaging.When

attaching the hoisting ropes, ensure that the awning is properly fastened, but not damaged. Hoist the awning exclusively in

horizontal position and evenly.

!If the information above is not observed, the awning system may fall down and put the health of persons at risk!

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 5

Valid from February 2010 Literal mistakes and technical changes excepted © bei WO&WO Art.-Nr.: 930059 Page 5

InstallatIon InstructIons

Pergoline

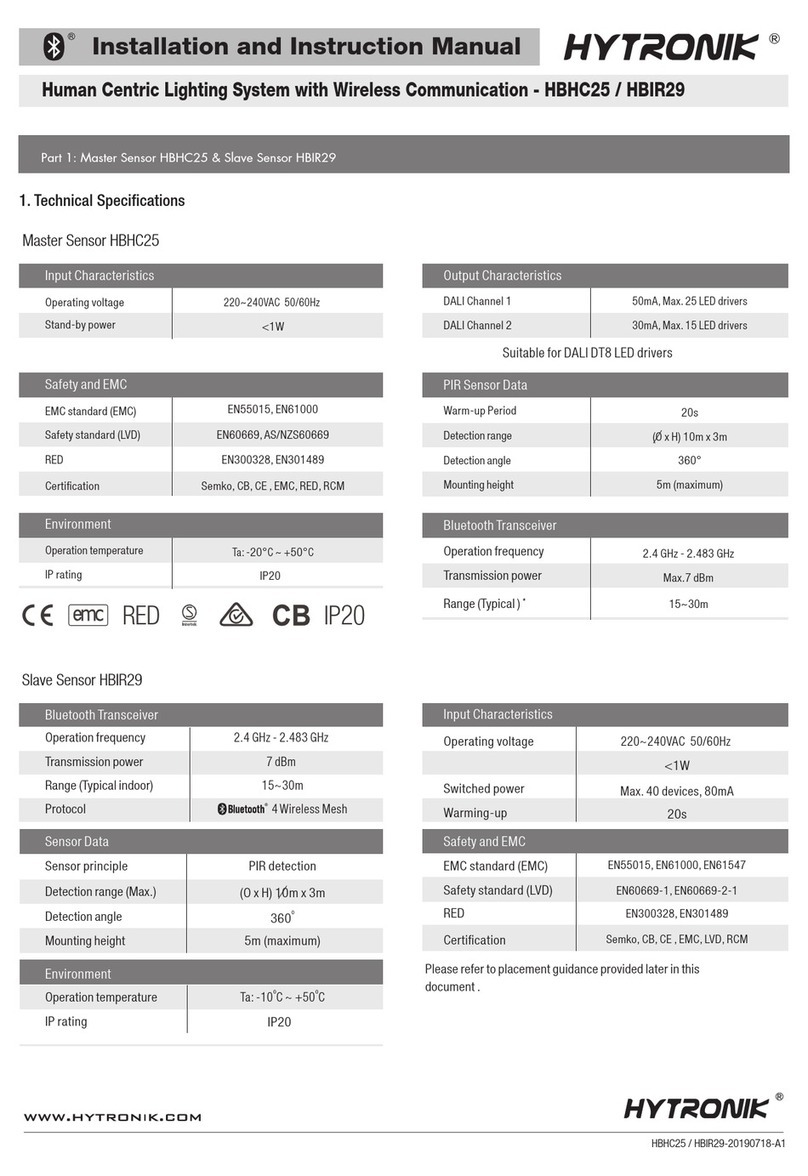

2.4. mounting SituationS

Wall installation of PERGOLINE

Ceiling installation of PERGOLINE with angle

towards the back or towards the front

Headroom

approx. 35 mm

Headroom

approx.

75 mm

approx.

130 mm approx.

130 mm

approx.

175 mm

100 mm 100 mm

200 mm

200 mm

2.3.MOUNTINGSITUATIONS

WallinstallationofVARIOPERGOLA

Ceiling installation of VARIO PERGOLA with angle towards the back or towards the front

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 6

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 6

InstallatIon InstructIons

PERGOLINE

2.5. MOUNTING HEIGHT AND POSITION OF THE BRACKETS

Mounting height: The awning can produce crushing forces and shear stresses, for instance between the fall bar and

the distance tube or casing and at the rollers of the moving fall bar. To protect human safety, the mounting height

must be at least 2,50m. If the situation requires a mounting height less than the stated minimum height, the awning

must be operated exclusively with a switch mounted at a location from where the moving parts can be observed.

Do not exceed the maximum fixing positions of the brackets! This could lead to damages to,

respectively malfunctions of, the awning.

Drilling holes for the brackets:

Transfer the drilling outlines of the brackets to

the determined bracket positions.

Select the appropriate drill bit for the respective

base material and mounting method.

Position of the brackets:

Distance between axes

system width

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 6

InstallatIon InstructIons

PERGOLINE

2.5. MOUNTING HEIGHT AND POSITION OF THE BRACKETS

Mounting height: The awning can produce crushing forces and shear stresses, for instance between the fall bar and

the distance tube or casing and at the rollers of the moving fall bar. To protect human safety, the mounting height

must be at least 2,50m. If the situation requires a mounting height less than the stated minimum height, the awning

must be operated exclusively with a switch mounted at a location from where the moving parts can be observed.

Do not exceed the maximum fixing positions of the brackets! This could lead to damages to,

respectively malfunctions of, the awning.

Drilling holes for the brackets:

Transfer the drilling outlines of the brackets to

the determined bracket positions.

Select the appropriate drill bit for the respective

base material and mounting method.

Position of the brackets:

Distance between axes

system width

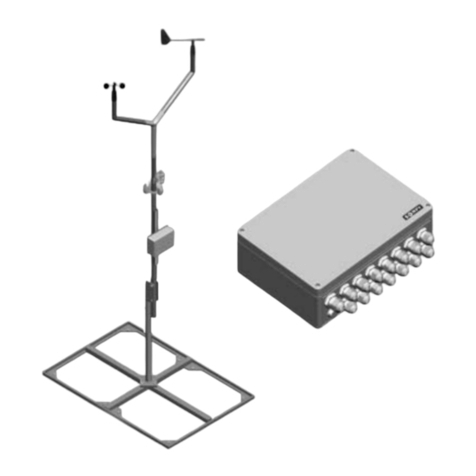

2.4.MOUNTINGHEIGHTANDPOSITIONOFTHEBRACKETS

!Mounting height: The awning can produce crushing forces and shear stresses, for instance between the fall bar and the

distance tube or casing and at the rollers of the moving fall bar. To protect human safety, the mounting height must be at

least2,50m.Ifthesituationrequiresamountingheightlessthanthestatedminimumheight,theawningmustbeoperated

exclusively with a switch mounted at a location from where the moving parts can be observed.

Position of the brackets:

!Do not exceed the maximum fixing positions of the brackets! This could lead to damages to, respectively malfunctions of, the

awning.

Drilling holes for the brackets: Transfer the drilling outlines of the brackets to the determined bracket positions.

iSelect the appropriate drill bit for the respective base material and mounting method.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Page 7 Helioscreen Australia Pty Ltd

Valid from February 2010 Literal mistakes and technical changes excepted © bei WO&WO Art.-Nr.: 930059 Page 7

InstallatIon InstructIons

PERGOLINE

Ensure that sufficient personnel is available to lift the

awning.Theawningweighsupto85kg;theweightsare

defined on the packaging.

At first ensure that both brackets have the same inclination.

Then hook up the awning (slightly tilted upwards) in the rear

locking element of the bracket and lower it down.

Secure the casing with round head screws and the square

nuts inserted in the front clamping channel of the casing.

If the installation is made with ceiling angles,

the brackets must be tilted to hook up the box.

2.6. MOUNTING TECHNIQUE

Due to the own weight of the awning and the maximum

windload,thedowelscanbesubjectedtopullingforces

up to 650N (approximately 65kg).

If the supporting capacity of the base material is less than

thatofconcreteandifinjectionanchorsareused,please

consult a qualified mounting engineer.

Mounting on thermally insulated facades

Insulating plaster and full multi-layer thermal insulation are not

pressure stable. Therefore, it is necessary to use backing for

the entire surface, or at least distancers for the area around the

screws. The picture on the right illustrates one possible variant.

Bracket mounting

Loosely fasten all brackets and achieve true alignment. Even

out irregularities of the base by using suitable spacers. Then

tighten all screws and check that brackets are firmly attached.

2.7. MOUNTING THE CASING

Pre-adjusting the inclination:

• Loosenthetwosidescrewsofthebrackets

with SW 8 Allen key.

• Adjusttheinclinationbyturningthescrewinthe

pivoting part with SW 6 Allen key.

To lower the awning →turn clockwise

To raise the awning →turn counter-clockwise

• Iftheinclinationiscorrectedsignicantly,

adjustthebracketsalternately.

Insulation protection taken out

Distance tube

2.5.MOUNTINGTECHNIQUE

Bracket mounting

Loosely fasten all brackets and achieve true alignment. Even out

irregularities of the base by using suitable spacers. Then tighten all

screws and check that brackets are firmly attached.

2.6.MOUNTINGTHECASING

iEnsure that sufficient personnel is available to lift the awning.

At first ensure that both brackets have the same inclination. Then

hookuptheawning(slightlytiltedupwards)intherearlocking

element of the bracket and lower it down. Secure the casing

with round head screws and the square nuts inserted in the front

clamping channel of the casing.

iIf the installation is made with ceiling angles, the brackets must be

tilted to hook up the box.

Pre-adjusting the inclination:

•LoosenthetwosidescrewsofthebracketswithSW8Allenkey.

•Adjusttheinclinationbyturningthescrewinthepivotingpartwith

SW6Allenkey.

To lower the awning turn clockwise

To raise the awning turn counter-clockwise

•Iftheinclinationiscorrectedsignicantly,adjustthebrackets

alternately.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 8

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 8

InstallatIon InstructIons

Pergoline

2.8. mounting railS anD PoStS

Profile edge

• Ifnecessary,adjusttheheightofthepoststothe

situation on site. For this purpose, shorten the post

profile on the side opposite the pivot.

• Demountthecoveroftheguidingrail.

• Insertthepivotingbearingwiththeclampingplatesin

the guiding rail. Ensure that the acute side of the post

profile points forward. If required, slightly fix the pivot.

• Insertthepostprolewiththepivotingbearingintothe

base plate.

• Re-installthecoveroftheguidingrail.

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 8

InstallatIon InstructIons

Pergoline

2.8. mounting railS anD PoStS

Profile edge

• Ifnecessary,adjusttheheightofthepoststothe

situation on site. For this purpose, shorten the post

profile on the side opposite the pivot.

• Demountthecoveroftheguidingrail.

• Insertthepivotingbearingwiththeclampingplatesin

the guiding rail. Ensure that the acute side of the post

profile points forward. If required, slightly fix the pivot.

• Insertthepostprolewiththepivotingbearingintothe

base plate.

• Re-installthecoveroftheguidingrail.

2.7.MOUNTINGRAILSANDPOSTS

•Ifnecessary,adjusttheheightofthepoststothesituation

on site. For this purpose, shorten the post profile on the side

opposite the pivot.

•Demountthecoveroftheguidingrail.

•Insertthepivotingbearingwiththeclampingplatesinthe

guiding rail. Ensure that the acute side of the post profile

points forward. If required, slightly fix the pivot.

•Insertthepostprolewiththepivotingbearingintothebase

plate.

•Re-installthecoveroftheguidingrail.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 9

•Attachtheguiderailstothepegsofthecasingend

caps. Ensure that the end with the sink hole bore

points to the pegs!

! •Donotmovetheguiderailtoomuchtothesideand

up because the peg could be torn off due to the

lever effect!

•Usingthecord,pullthefallbarononeside

approximately100mminextendeddirectionand

insert a screwdriver or other suitable tool between

the fall bar and the casing to prevent the fall bar from

retracting. Repeat the procedure on the second side.

•Unwindpullingstrapfromtheendcoveroftheguide

rail and ensure that it is not twisted. Remove the

strap securing clips.

! •Securingclipsthatarenotremovedcan

cause damages!

•Insertendcapsintheguiderails(ensurethepulling

strapisnottwisted!)andholdinposition.

•Pullthestrapstoexertslighttensiononthefallbar,

then remove the screwdriver, then let fall bar return to

its home position. Check again that the pulling straps

are not twisted or caught and that they also run over

the deflection pulley in the casing end cap.

•Removepullingcordsforthefallbar.Adjustthe

inclinationofthebrackets(thegapbetweenthe

guiderailandthecasingendcapmustbeuniform)

Valid from February 2010 Literal mistakes and technical changes excepted © bei WO&WO Art.-Nr.: 930059 Page 9

InstallatIon InstructIons

Pergoline

• Attachtheguiderailstothepegsofthecasingend

caps. Ensure that the end with the sink hole bore

points to the pegs!

Do not move the guide rail too much to the side

and up because the peg could be torn off due

to the lever effect!

• Usingthecord,pullthefallbarononeside

approximately 100 mm in extended direction and insert

a screwdriver or other suitable tool between the fall bar

and the casing to prevent the fall bar from retracting.

Repeat the procedure on the second side.

• Unwindpullingstrapfromtheendcoverofthe

guide rail and ensure that it is not twisted.

Remove the strap securing clips.

Securing clips that are not removed can cause damages!

• Insertendcapsintheguiderails(ensurethepulling

strap is not twisted!) and hold in position.

• Pullthestrapstoexertslighttensiononthefallbar,then

remove the screwdriver, then let fall bar return to its home

position. Check again that the pulling straps are not

twisted or caught and that they also run over the

deflection pulley in the casing end cap.

• Removepullingcordsforthefallbar.

Adjusttheinclinationofthebrackets(thegapbetween

the guide rail and the casing end cap must be uniform)

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 10

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 10

InstallatIon InstructIons

Pergoline

2.9. mounting the DiStanCe tube(S):

2.10. a lignment oF the SyStem

• Alignthesystembymovingthecasinginthebracketsor

sideways movement of the two posts in the diagonal.

Deviations of the diagonal measurements by more than

5 mm may result in malfunctions.

• Verticallyaligntheposts

To stabilise the parallelism of the system, mount at least

one distance tube before aligning the system at the post.

• Insertthewasherandturnthedistancetubeholderinto

the end cap of the distance tube until it is fully in.

• Alignthetighteningsurfacesofbothholders.

• Securetheholdersintheguiderailswithscrewsand

hammerhead threaded plates.

The writing on the hammerhead threaded plates must

point towards the surface of the holder.

• Thepositiondependsontheextendedlengthofthe

system.Uptoanextendedlengthof3500mmnearthe

posts, from 3501mm extended length distributed evenly

over the length of the guide rails.

Thepositionofthedistancetubescanalsobeadjusted

to the cross seams of the fabric.

• Distributeadditionaldistancetubesoverthelength

of the guide rails.

To fasten the distance tube holders, push the screws with

the hammerhead threaded plates up and twist (as described

in 2.8.). Ensure that the hammerhead threaded plates have

twisted correctly in the installation channel.

• Aftertightening,thelongerdiagonalmustbecrosswise

to the clamping channel of the guide rail (see drawing

next to the text).

• Lockthenutsagainsttheendcapsofthedistancetube.

parallelism rear

parallelism front

diagonal

diagonal

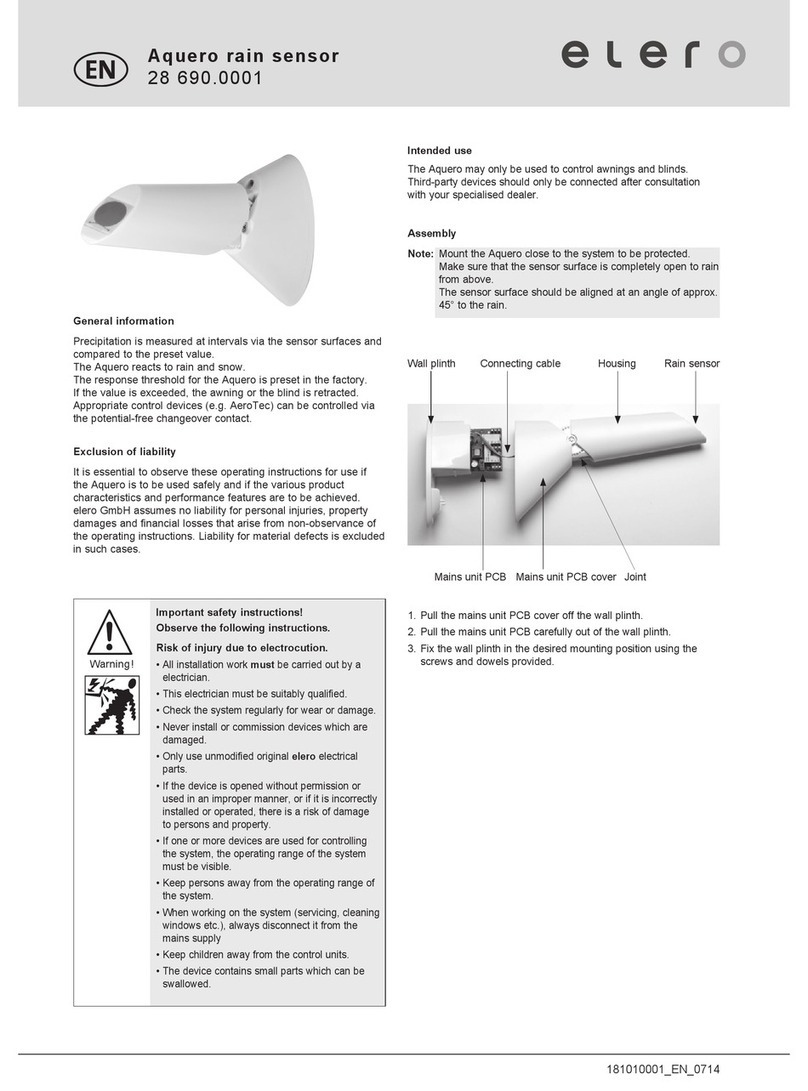

2.8.MOUNTINGTHEDISTANCETUBE(S):

i •Tostabilisetheparallelismofthesystem,mountat

least one distance tube before aligning the system at

the post.

•Insertthewasherandturnthedistancetubeholder

into the end cap of the distance tube until it is fully in.

•Alignthetighteningsurfacesofbothholders.

•Securetheholdersintheguiderailswithscrewsand

hammerhead threaded plates.

i •Thewritingonthehammerheadthreadedplates

must point towards the surface of the holder.

•Thepositiondependsontheextendedlengthofthe

system.Uptoanextendedlengthof3500mmnear

theposts,from3501mmextendedlengthdistributed

evenly over the length of the guide rails. The position

ofthedistancetubescanalsobeadjustedtothe

cross seams of the fabric.

•Distributeadditionaldistancetubesoverthelengthof

the guide rails.

i •Tofastenthedistancetubeholders,pushthescrews

with the hammerhead threaded plates up and twist

(asdescribedin2.8.).Ensurethatthehammerhead

threaded plates have twisted correctly in the

installation channel.

•Aftertightening,thelongerdiagonalmustbe

crosswise to the clamping channel of the guide rail

(seedrawingnexttothetext).

•Lockthenutsagainsttheendcapsofthedistance

tube.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 11

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 10

InstallatIon InstructIons

Pergoline

2.9. mounting the DiStanCe tube(S):

2.10. a lignment oF the SyStem

• Alignthesystembymovingthecasinginthebracketsor

sideways movement of the two posts in the diagonal.

Deviations of the diagonal measurements by more than

5 mm may result in malfunctions.

• Verticallyaligntheposts

To stabilise the parallelism of the system, mount at least

one distance tube before aligning the system at the post.

• Insertthewasherandturnthedistancetubeholderinto

the end cap of the distance tube until it is fully in.

• Alignthetighteningsurfacesofbothholders.

• Securetheholdersintheguiderailswithscrewsand

hammerhead threaded plates.

The writing on the hammerhead threaded plates must

point towards the surface of the holder.

• Thepositiondependsontheextendedlengthofthe

system.Uptoanextendedlengthof3500mmnearthe

posts, from 3501mm extended length distributed evenly

over the length of the guide rails.

Thepositionofthedistancetubescanalsobeadjusted

to the cross seams of the fabric.

• Distributeadditionaldistancetubesoverthelength

of the guide rails.

To fasten the distance tube holders, push the screws with

the hammerhead threaded plates up and twist (as described

in 2.8.). Ensure that the hammerhead threaded plates have

twisted correctly in the installation channel.

• Aftertightening,thelongerdiagonalmustbecrosswise

to the clamping channel of the guide rail (see drawing

next to the text).

• Lockthenutsagainsttheendcapsofthedistancetube.

parallelism rear

parallelism front

diagonal

diagonal

2.9. ALIGNMENT OF THE SYSTEM

•Alignthesystembymovingthecasinginthe

brackets or sideways movement of the two posts in

the diagonal.

i •Deviationsofthediagonalmeasurementsbymore

than5mmmayresultinmalfunctions.

•Verticallyaligntheposts

•Fixthepostproleonthepost’sbaseplate.

•Forthispurpose,turnthethreadedpinsinthegroove

nuts through the drillings onto the peg of the post’s

base plate and tighten firmly.

•Fixthepost’sbaseplatewiththeappropriatexing

materials on the base.

•Connectatestcabletothesystemandextend

approximately20cm.

•Connecttheguiderailswiththepegsofthecasing

using the countersunk screws.

Valid from February 2010 Literal mistakes and technical changes excepted © bei WO&WO Art.-Nr.: 930059 Page 11

InstallatIon InstructIons

Pergoline

• Fixthepostproleonthepost’sbaseplate.

• Forthispurpose,turnthethreadedpinsinthegroovenuts

through the drillings onto the peg of the post’s base plate

and tighten firmly.

• Fixthepost’sbaseplatewiththeappropriatexing

materials on the base.

• Connectatestcabletothesystemand

extend approximately 20cm.

• Connecttheguiderailswiththepegsofthe

casing using the countersunk screws.

3. line SyStemS

To install line systems, at first mount all boxes and

only then proceed with the guide rails and posts as

described for the individual systems.

Before inserting the end cap of the centre guide rail as

described in 2.8, it is necessary to fit the second pulling

strap with the pulley.

• Fortheinstallation,pullthefallbarofbothsystemson

the side of the centre guide rail approximately 100mm

in extended direction with the pulling strap, and then

insert a screwdriver between the fall bar and the casing

to prevent the fall bar from retracting.

• Attheendcapofthecentreguiderail,loosen

countersunk screw (1) with an SW 6 Allen key and

remove including the interior sleeve (2). Take out the

deflection pulley (3) and place pulling strap over it.

• Placethepulleywiththepullingstrapintheendcap

(ensuring that the pulling strap is not twisted!). Insert the

sleeve with the chamfer of the bore pointing towards the

screw head. Firmly tighten the countersunk screw.

• Nowremovethestrapsecuringclips(4)andproceed

according to 2.8.

Chamfer

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 12

Valid from February 2010 Literal mistakes and technical changes excepted © bei WO&WO Art.-Nr.: 930059 Page 11

InstallatIon InstructIons

Pergoline

• Fixthepostproleonthepost’sbaseplate.

• Forthispurpose,turnthethreadedpinsinthegroovenuts

through the drillings onto the peg of the post’s base plate

and tighten firmly.

• Fixthepost’sbaseplatewiththeappropriatexing

materials on the base.

• Connectatestcabletothesystemand

extend approximately 20cm.

• Connecttheguiderailswiththepegsofthe

casing using the countersunk screws.

3. line SyStemS

To install line systems, at first mount all boxes and

only then proceed with the guide rails and posts as

described for the individual systems.

Before inserting the end cap of the centre guide rail as

described in 2.8, it is necessary to fit the second pulling

strap with the pulley.

• Fortheinstallation,pullthefallbarofbothsystemson

the side of the centre guide rail approximately 100mm

in extended direction with the pulling strap, and then

insert a screwdriver between the fall bar and the casing

to prevent the fall bar from retracting.

• Attheendcapofthecentreguiderail,loosen

countersunk screw (1) with an SW 6 Allen key and

remove including the interior sleeve (2). Take out the

deflection pulley (3) and place pulling strap over it.

• Placethepulleywiththepullingstrapintheendcap

(ensuring that the pulling strap is not twisted!). Insert the

sleeve with the chamfer of the bore pointing towards the

screw head. Firmly tighten the countersunk screw.

• Nowremovethestrapsecuringclips(4)andproceed

according to 2.8.

Chamfer

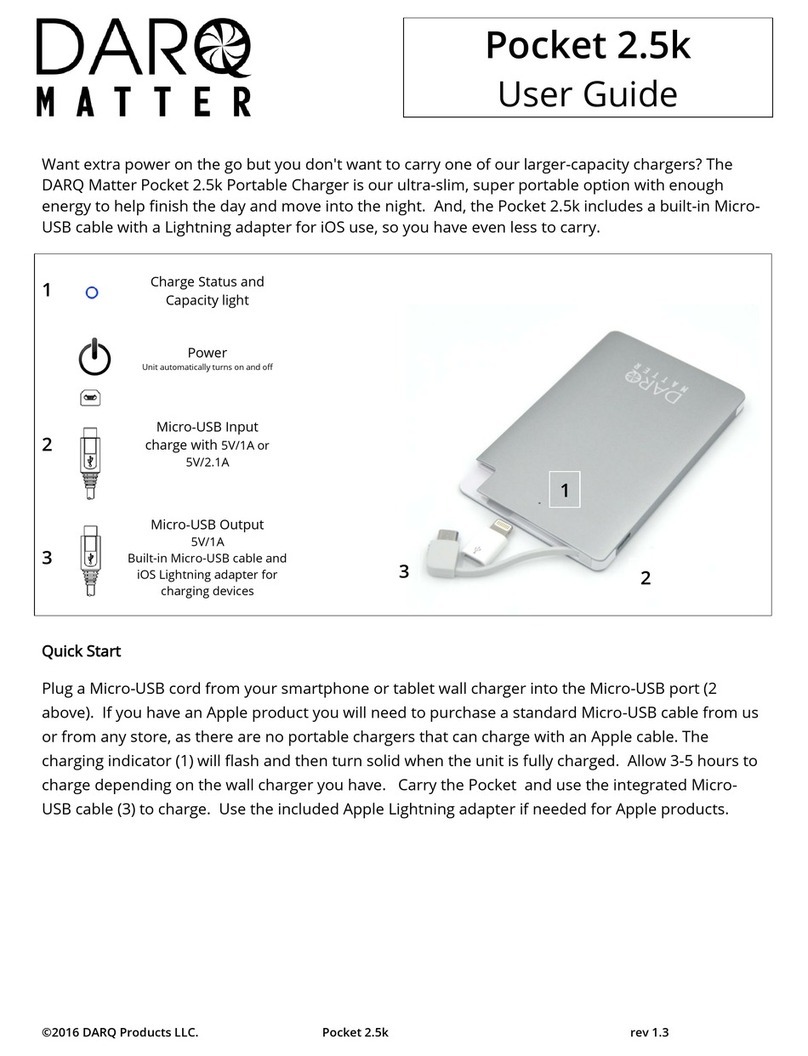

3.LINESYSTEMS

•Toinstalllinesystems,atrstmountallboxesand

only then proceed with the guide rails and posts as

described for the individual systems.

! •Beforeinsertingtheendcapofthecentreguiderail

asdescribedin2.8,itisnecessarytotthesecond

pulling strap with the pulley.

•Fortheinstallation,pullthefallbarofbothsystemson

thesideofthecentreguiderailapproximately100mm

in extended direction with the pulling strap, and then

insert a screwdriver between the fall bar and the

casing to prevent the fall bar from retracting.

•Attheendcapofthecentreguiderail,loosen

countersunkscrew (1)withanSW6Allenkey

andremoveincludingtheinteriorsleeve(2).Takeout

thedeectionpulley(3)andplacepullingstrapoverit.

•Placethepulleywiththepullingstrapintheend

cap(ensuringthatthepullingstrapisnottwisted!).

Insert the sleeve with the chamfer of the bore

pointing towards the screw head. Firmly tighten the

countersunk screw.

•Nowremovethestrapsecuringclips(4)andproceed

accordingto2.8.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 13

4.INITIALOPERATION

! Beforetheinitialoperationoftheawning,removeallobjects(e.g.ladders,toolsetc.)fromthefulltravelrang(in/out)of

the awning and from underneath the awning. During the trial operation, ensure that nobody is in this area – there is a

riskofinjuryincaseofamalfunction.

! Fortrialoperation,alwaysusethetestcable(noautomaticcontrolunitsetc.).Inaddition,theoperatormustbeableto

see the awning. If the test cable has not yet been connected, connect to the cable of the driving gear.

Fully extend awning and check switch-off point.

!Electrical installation work and connections to the mains must be carried out exclusively by a licensed electrical

company.

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 14

5.DISMOUNTINGTHEAWNING

! •Ensurethattheareaaroundtheawningisfreeofunauthorisedpersonnel.

•Dismounttheawningexclusivelyinretractedcondition.

•Dismountingoftheawningisthereverseofthemountingprocedure.

6.TROUBLESHOOTING

TYPE OF DEFECT CAUSE REMEDY

Driving gear does not work

No power Checkconnection(specialisedcompany)

Driving gear not correctly connected Checkconnection(specialisedcompany)

Thermal protection of the driving gear activated Waitfor15-20mins,thenoperateagain

Remote control batteries empty Check light signal on sending unit, replace

batteries

Higher-level control unit prevents manual

operation

Waituntilhigher-levelsignalisnotactivated

any more.

Driving gear does not work End positions of the driving gear changed, or

incorrect end position setting

Resetorre-programendpositions(seeDriving

GearInstructionManual)

System does not close on one side Thickness of the tapes differs

In retracted condition, apply textile tape

backing to the pulley on the side on which the

system does not retract sufficiently. Extend

system and achieve parallel fall bar alignment.

Awning fabric sags unevenly

Not the same number of windings on the pulley Check number of strap windings on the pulley

and equalise.

Fall bar parallelism changed or incorrectly

adjusted. Resetfallbarparallelism(seeAnnex)

Whenoperated,systemmovesbyjerks

andjoltsorgeneratesindenablenoises

Rail parallelism or rectangularity changed Reset rail parallelism or rectangularity

(seeitem2.9.)

Foreign bodies or lots of dirt in the channels of

the guiding rails

Clean guiding rails and spray lubricant on

the rollers of the fall bar

VARIO-PERGOLA

INSTALLATION INSTRUCTIONS

Helioscreen Australia Pty Ltd

Page 15

Art.-Nr.: 930059 © by WO&WO Literal mistakes and technical changes excepted Valid from February 2010

Page 14

InstallatIon InstructIons

Pergoline

7. annex

Foradjustmentsofthedrivinggear,pleaserefertothe“Drivinggearadjustment”sheet.

The XLINEshadingsystemrequirestheadjustmentofbothdrivinggearendpositions.Afailuretosetthedriving

gear end positions can lead to an impaired function of or damages to the system. (the use of a driving gear with

electronic torque-activated cut-off mechanism is not permissible).

a. aDjuStment oF the Driving gear enD PoSition

b. alignment oF the Fall bar

Measure the distance between the fall bar and the rail end

on both sides.

The correction is made on the side that extends further.

Remove countersunk screw (1) with SW 4mm Allen key and

take off plastic cover (2). Get hold of the end of the strap (5)

with your hand or a tool and do not let go.

Loosen counternut (3) with SW13mm ring spanner.

Loosen the threaded pin (4) with SW 4mm Allen key.

Now give pulling strap enough rope so that the fall bar

moves to the correct position.

Then slightly tighten threaded pin (4) and lock with nut (3).

Wind up protruding tape and stow away in the cover. Fit

cover and fasten with countersunk screw.

If the fall bar is parallel, the fabric tension should be roughly

the same on either side.

35 4

21

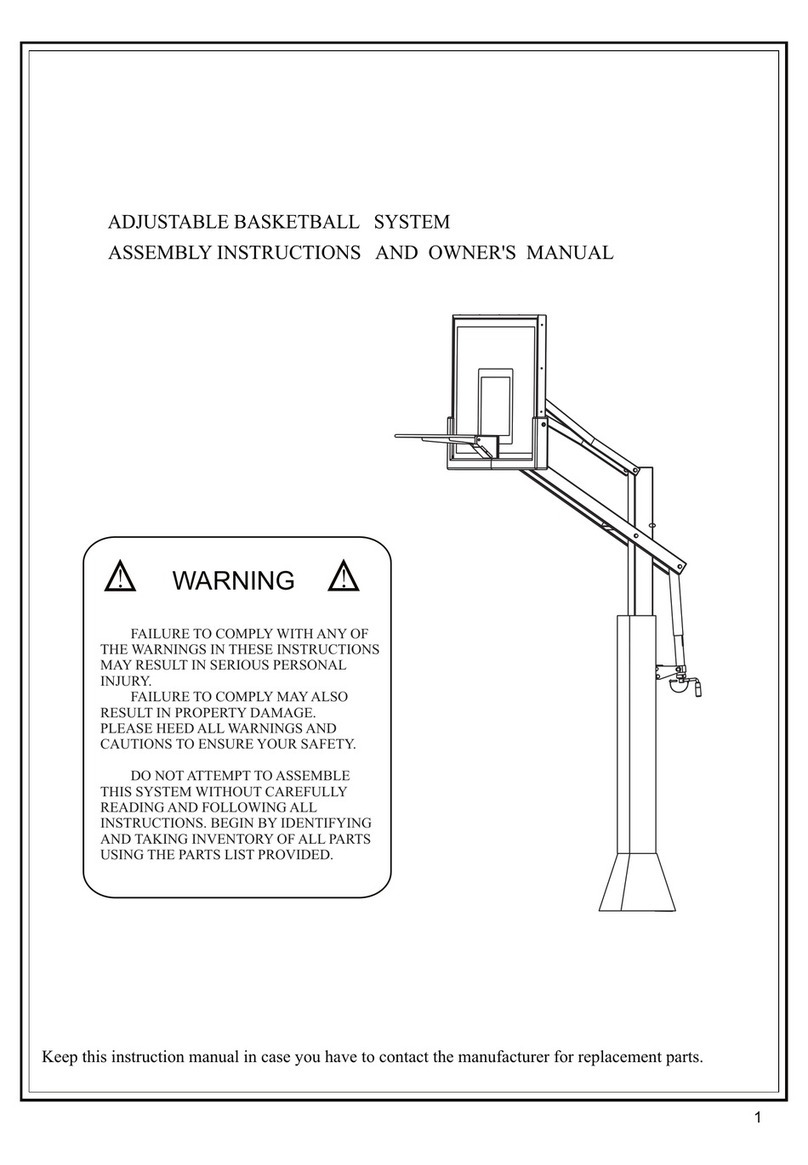

7.ANNEX

7.1.ALIGNMENTOFTHEFALLBAR

Measure the distance between the fall bar and the rail end

on both sides.

The correction is made on the side that extends further.

Removecountersunkscrew(1)withSW4mmAllenkey

andtakeoffplasticcover(2).Getholdoftheendofthe

strap(5)withyourhandoratoolanddonotletgo.Loosen

counternut(3)withSW13mmringspanner.Loosenthe

threadedpin(4)withSW4mmAllenkey.Nowgivepulling

strap enough rope so that the fall bar moves to the correct

position.Thenslightlytightenthreadedpin(4)andlock

withnut(3).

Windupprotrudingtapeandstowawayinthecover.Fit

cover and fasten with countersunk screw.

If the fall bar is parallel, the fabric tension should be roughly

the same on either side.

Table of contents

Other Helioscreen Accessories manuals

Popular Accessories manuals by other brands

elero

elero Aquero manual

Barbarian Basketball Systems

Barbarian Basketball Systems Titanium Series Assembly instructions and owner's manual

Satel

Satel AGD-200 quick start guide

Festo

Festo Sorting Station Inline operating instructions

Thule

Thule Omnistor 8000 installation manual

Honeywell

Honeywell RPW319 Instruction leaflet