Helm HM-1734-WM User manual

Point I/O Strain Gage Input Module

Model HM-1734-WM

Instruction Manual

Rev. 4.18

June, 2021

Helm Instrument Company, Inc.

361 West Dussel Drive

Maumee, Ohio 43537 USA

419/ 893-4356

Fax: 419/ 893-1371

www.helminstrument.com

Force Measurement and Control Solutions

1 HM1734-WM STRAIN GAGE INPUT MODULE

This Series C product can be used with DeviceNet and PROFIB

US

adapters. It can be used with Ethernet/IP and Ethernet adapter

s using

RSLogix 5000, version 11 (or higher) software.

Important User Information

Because of the va

riety of uses for the products described in this publication,

those responsible for the application and use of these products must satisfy

themselves that all necessary ste

ps have been taken to assure that each

application and use meet all performance and safety requirements

, including

any applicable laws, regulations, codes and standards. In no ev

ent will

Allen

-Bradley be responsible or liable for indirect or consequential damag

e

resulting from the use or application of these products.

Any illustra

tions, charts, sample programs

, and layout examples shown in this

publication is intended solely for purposes of example.

Since there are many

v

ariables and requirements associated with any par

ticular installation,

Allen

-Bradley does not assume responsibility or liability (to include

intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen

-Bradley publication SGI-1.1, Safety

Guidelines for the Application,

Installation and Maintenance of Solid-State Control

(available from your local

Allen

-Bradley office), describes some impor

tant differences between

solid-state equipment and electromechanical devices that should be taken

into

consideration when applying products such as those described in this

publication.

R

eproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this publ

ication, notes may be used to make you aware of safety

considerations. The following annotations and their accompanying

statements

help you to identify a potential hazard, avoid a potential hazard, and

recognize

the consequences of a potential hazard.

Identifies infor

mation about practices or

W

A

R

N

I

N

G

circumstances that can cause an

explosion in a

hazardous environment, which may lead to

!

personal injury or death, property damag

e, or

economic loss.

2 HM1734-WM STRAIN GAGE INPUT MODULE

Identifies information about pra

ctices or

ATTENTION

circumstances that can lead to personal injur

y or

death, property damage, or economic loss.

!

Identifies infor

mation that is critical for

IMPORTANT successful

application and understanding of the

product.

-

3 HM1734-WM STRAIN GAGE INPUT MODULE

Environment and Enclosure

ATTENTION

!

This equipment is intended for use in a Pollution Deg

ree 2

industrial environment, in overvoltage Category

II applications

(as defined in IEC publication 60664-1), at altitudes up to 200

0

meters without derating.

This equi

pment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there

may be potential difficulties

ensuring electromagnetic compatibility in other en

vironments

due to conducted as well as radiated disturbance.

This equipment is supplied as "open type" equipment. It must

be mounted within an enclosure that is suitably des

igned for

those specific environmental conditions that will be present and

appropriately designed to prevent personal injur

y resulting from

accessibility to live parts

. The interior of the enclosure must be

accessible only by the use of a tool. Subsequ

ent sections of this

publication may contain additional infor

mation regarding

specific enclosure type ratings that a

re required to comply with

certain product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as appli

cable, for explanations of the degrees of

protection provided by different types of enclosure. Also, see

the

appropr

iate sections in this publication, as well as the

Allen

-Bradley publication 1770-

4.1 ("Industrial Automation

Wiring and Groun

ding Guidel

ines"), for additional installation

requirements pertaining to this equipment.

POINT I/O is grounded through the DIN

rail to

ATTENTION

chassis g

round. Use zinc plated, yellow chromated

!

steel DIN rail to assure proper grounding

. Using

other DIN rail materials (e.g. aluminum, plastic

,

etc.) which can cor

rode, oxidize or are poor

conductors can result in improper or inter

mittent

platform grounding.

4 HM1734-WM STRAIN GAGE INPUT MODULE

EXPLOSION HAZARD

WARNING

Do not disconnect equipment unless power has been

!

removed or the area is known to be nonhazardous

.

Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connecti

ons that mate

to this equipment by using screws, sliding latches

, threaded

connectors, or other means provided with this product.

Substitution of components may impair suitability for

Class

I, Division 2.

If this product contains batteries, they mus

t only be

changed in an area known to be nonhazardous.

Preventing Electrostatic Discharge

ATTENTION

This equipment is sensitive to electrostatic

!

discharge, which can cause internal damag

e and

affect normal operation. F

ollow these guidelines

when you

handle this equipment:

Touch a grounded object to discharg

e potential

static.

Wear an approved grounding wrist strap.

Do not touch connectors or pins on component

boards.

Do not touch circuit components inside the

equipment.

If available, use a static-safe workstation.

When not in use

, store the equipment in

appropriate static-safe packaging.

ATTENTION

Check label on the module for the Firmware

Revision (4.17 or 4.18)

5 HM1734-WM STRAIN GAGE INPUT MODULE

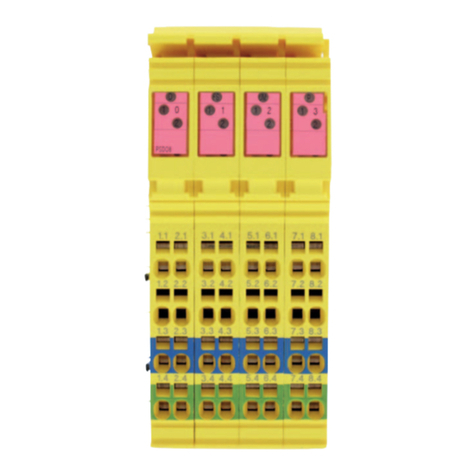

Installing the Mounting Base

To install the mounting base on the DIN rail, proceed as follows.

1. Position the mounting base ver

tically above the installed units

adapter, power supply or existing module.

2.

Slide the mounting base down allowing the interlocking side pieces to

engage the adjacent module or adapter.

3. Press firmly to seat the mounting base on the DIN rail. The

mounting

base will snap into place.

4. To remove the mounting base from the DIN rail, remove the module,

and use a small bladed screwdriver to rotate the base locking screw to

a vertical position. This releases the locking mechanism. Then lift

straight up to remove.

1. Using a bladed screwdriver, rotate the key switch (2) on the mounting base

clockwise until the number required for the type of module being installed

aligns with the notch in the base.

2. Make certain the DIN rail locking screw is in the horizontal position.

(You cannot insert the module if the locking mechanism is unlocked.)

3. Local: 2.0. Data [2].0 (Rev 418 Enable Bit)

A) This module with Rev 418 has dual function, it can run as Rev 417 or

Rev 418

B) For existing customers with SP417 ladder logic make sure Bit is

cleared for existing ladder logic in project.

C) For new installations set this Bit and run with Rev 418 ladder logic,

or, clear Bit to run with existing ladder logic projects (SP417).

D) This function has been maintained for systems using SP417 ladder

so that modules can be replaced without changing ladder logic.

Installing the I/O Module

The module can be installed before, or after base installation. Make sure

that the mounting base is correctly keyed before installing the module

into the mounting base. In addition, make sure the mounting base locking

screw is positioned horizontal referenced to the base.

The module can power (2) load cells @ 350Ω

LCP module is needed for more than (2) load cells

(1) LCP module can support up to (4) load cells at 350Ω

for summing applications, the mV/V to enter is the average of

the mV/V for each load cell

the scale set on summing applications is equal to the capacity of

the cells multiplied by the total number of cells

6 HM1734-WM STRAIN GAGE INPUT MODULE

When you connect or disconnect the Removable

WARNING Terminal Block (R

TB) with field side power

applied, an electrical arc can occur

. This could

!

cause an explosion in hazardous

location

installations

.

Be sure that power is remov

ed or the area is

nonhazardous before proceeding.

Some non-Helm load cell summing devices may

be incompatible due to signal trimming. Please

contact Helm support for verification at

704-942-4710.

4. Insert the module straight down into the mounting base and press to secure.

The module will lock into place.

Installing the Removable Terminal Block (RTB)

A removable terminal block is supplied with your wiring base assembly. To

remove, pull up on the RTB handle. This allows the mounting base to be

removed and replaced as necessary without removing any of the wiring. To

reinsert the removable terminal block, proceed as follows.

1. Insert the end opposite the handle into the base unit. This end has a

curved section that engages with the wiring base.

2. Rotate the terminal block into the wiring base until it locks itself in place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

7 HM1734-WM STRAIN GAGE INPUT MODULE

Re

m

o

v

ing a

M

ounting Bas

e

To remove a mounting base, you must remo

ve any installed module, and the

module installed in the base to the right. Remove the removable ter

minal

block (if wired).

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the removable terminal block.

When you connect or disconnect the Removable

WARNING Terminal Block (RTB) with field si

de power

applied, an electrical arc can occur

. This could

!

cause an explosion in hazardous location

installations

.

Be sure that power is remov

ed or the area is

nonhazardous before proceeding.

3. Press on the module lock on the top of the module.

4. Pull on the I/O module to remove from the base.

When you inse

r

t or remove the module while

WARNING

backplane power is on, an electrical arc can

occur

. This could cause an explosion in

!

hazardous location installations

. Be sure that

power is removed or the area is nonhazar

dous

before proceeding.

5. Repeat steps 1, 2, 3 and 4 for the module to the right.

6. Use a small bladed screwdriver to rotate the orange base

locking

screw to a vertical position. T

his releases the locking mechanism.

7. Then lift straight up to remove.

8 HM1734-WM STRAIN GAGE INPUT MODULE

OUTPUT TAG DESCRIPTIONS

CALMODE

Used for initial installation. All math is disabled, weigh value is not scaled, leaving raw A/D value.

Value = 2,090,000 to 2,100,000 at normal zero (at rest state).

RUNMODE

Factory Cal setting 100,000 counts = 2MV/V

CLEAR TARE CH1/CH2 Bit

Clears internal tare value for “zero state”.

Useful when troubleshooting load cell wiring or other failures.

TARE CH1/CH2

Sets A/D value to zero.

READ ADTRIM BIT

(HELM Factory setting only).

SET-TO-CH1 Bit

Used for one channel operation where a faster sample speed is required.

1 = 2msec (max speed)

0 = 4msec (max speed-default)

FREQUENCY BITS

Used to set sample rate and filter options.

With no bits set: Sample = 100msec.

Set one bit only.

Note: For one channel operation, sample rate is at bit selected.

For two channel operation, sample rate is 2 times bit time selected.

ZERO-DEAD-BAND Bits

Useful for Auto-Tare functions with production runs.

Set only one bit.

ZEROBAND_025 = .025% full scale

ZEROBAND_05 = .05% full scale

ZEROBAND_075 = .075% full scale

Auto tare occurs when load cell weight is at bit level or lower.

9 HM1734-WM STRAIN GAGE INPUT MODULE

REQUIRED CONTROLLER TAGS

CH1/CH2 SCALE SET / REFERENCE WEIGH VALUE

LOCAL : 2 : C, DATA[0]

LOCAL : 2 : C, DATA[3]

Full scale setting for CH1, CH2

Value is determined by capacity of load cell and by resolution required.

Example: 10KG = 10,000

GET WEIGH VALUE CH1, CH2

GET_WEIGH_CH1

GET_WEIGH_CH2

Reports measured weigh value in RUN mode.

Reports raw A/D count value in CAL mode.

SET AUTOCAL CH1, CH2 Enable Bit

CH1 AUTO TUNE

CH2 AUTO TUNE

With ladder logic provided, an auto-cal method for calibrating is available.

Set to (1) to initiate Auto-Cal for the channel.

SET AVERAGE SAMPLE COUNT

(SAMPLE BITS) Only set to 1 Bit

Set number of samples to take for average type filter.

(Sample=10) set to 1

(Sample =20) set to 1

(Sample=50) set to 1

All Bits clear Sample=1

SET mV/V CH1, CH2

LOCAL : 2 : C, DATA[2]

LOCAL : 2 : C, DATA[5]

CH1/CH2 MV_V Settings

Enter (2000) for 2.0MV/V for nominal load cell.

Actual value is from load cell specification.

10 HM1734-WM STRAIN GAGE INPUT MODULE

Troubleshooting with the Indicators

Module Status:

Off

No power applied to device

.

Green

D

e

vice operati

ng nor

mally

.

Flashing Green

Device needs commissioning due to

configuration missing, incomplete or incorrect.

Flashing Red

Recoverable fault

.

Red

Unrecoverable fault.

May requ

ire d

evice

replacement.

Flashing Red/Green Device is in self-test.

Network Status:

Off

Device is not on-line. Device has not completed

dup_MAC_id test. Device not powered. Check

module status indicator.

Green Device on-line and has connections to the

established state.

Flashing Green

Device

is on

-

li

n

e

but has no c

onnect

ions in the

established state.

Flashing Red

One or more I/O connections is in timed

-

out

state.

Red Critical link failure – failed communications

device.

Flashing Red/Green

Network access error and is in communication

faulted state. Device has received and accepted

an Identity Communication Faulted Request –

long protocol message.

11 HM1734-WM STRAIN GAGE INPUT MODULE

A complete listing of a sample ladder logic program is included

at the back of this manual.

Examples shown here are for reference.

All values are 0 (default) on initial start-up.

This means that all alarms are disabled.

You must make the following adjustments for proper operation:

Balance sensor input(s)

Set Calibration numbers

PLEASE NOTE:

The module excitation voltage is 5VDC.

Most load cells are rated for 10VDC to 15VDC.

Even though the module voltage is lower than the load cell rated voltages it

will perform with 5VDC for all load cells.

Follow Steps 1 and 2 for each channel.

Step 1. Balance Sensor Input Check

1. Set to CAL mode.

2. Set Clear Tare bit momentarily.

3. Check Raw A/D value. (Range 2,090,000 to 2,100,000)

CH1 = Controller Tag GET_WEIGH_CH1

CH2 = Controller Tag GET_WEIGH_CH2

4. Set Zero Tare bit momentarily.

Step 2. Set Calibration Numbers

1. Set Scale to capacity of load cell.

2. Set mV/V to load cell specification.

Example:

100 ton load cell, 2.025 mV/V

For scale set, enter 100

For mV/V set, enter 2025

3. Set to RUN mode.

Setup Procedure

12 HM1734-WM STRAIN GAGE INPUT MODULE

Module Location 1734-TOP (screw terminal) or 1734-TOPS (spring loaded terminal)

Type of input Strain Gage (350 ohm, 700 ohm)

Gage Excitation Voltage 5 Volt

Input Impedance 5.11 meg. ohm

Display Resolution Up to .0025% of full scale

Module Accuracy Dependent on Load Cell Specification

Module Update Time Software selectable from 2ms to 100ms

Number of Channels 2 (isolated)

A/D Conversion Method Successive Approximation - 24 bit

Normal Mode Rejection:

(between +/- input) 116DB CMRR

Amplifier Bandwidth 200 kHz

Calibration Software Selectable

Isolation: 500 VDC continuous between inputs

and chassis ground, and between input

and backplane

LED indicators 2 LEDs for Power and Alarm

Recommended Cable Strain Gage Cable (Helm part number 6117)

Operating Temperatures 0°C to 60°C (32°F to 140°F)

Emissions CISPR 11

Group 1, Class A

Pointbus Current 5V @ 72ma

External Power 24V @ 19.5ma

Dimensions 2.21H x 0.47W x 2.97L (Millimeters 56H x 12W x 75.5L)

Specifications - HM1734-WM Strain Gage Input Module

Note: Excitation above 5V is acceptable.

13 HM1734-WM STRAIN GAGE INPUT MODULE

SETTING UP HM1734WM MODULE USING 1734-AENT/A on Ethernet/IP

Step #1

Add module to project as following:

HM1734WM MODULE PROPERTIES

General Tab Settings

Connection Tab Settings

*RPI rate cannot be faster than 4ms.

14 HM1734-WM STRAIN GAGE INPUT MODULE

Step #2

Open “HM1734_WM_AOP_REV418. ACD”

Copy HM1734WM_main routine

Open project

Paste HM1734WM_main routine

Check program tag here should be as

Example

15 HM1734-WM STRAIN GAGE INPUT MODULE

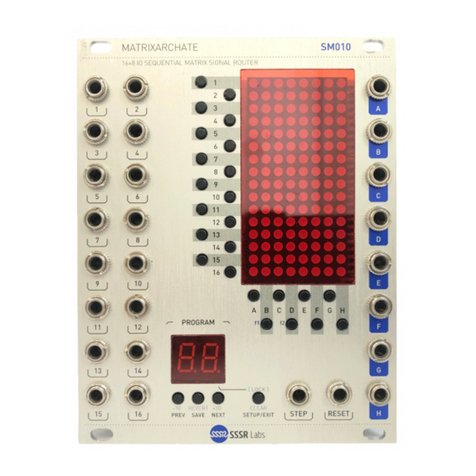

Data Map for HM1734-WM on Ethernet/IP

OUTPUT BITS

Local:2:O.Data[0].0 1 cal mode

Local:2:O.Data[0].1 0 run mode

Local:2:O.Data[0].2 0 ch1 clear tare

Local:2:O.Data[0].3 0 ch1 tare

Local:2:O.Data[0].4 0 ch1 set adtrim

Local:2:O.Data[0].5 0 read adtrim

Local:2:O.Data[0].6 0 ch2 clear tare

Local:2:O.Data[0].7 0 ch2 tare

Local:2:O.Data[1]

Local:2:O.Data[1].0 0 ch2 set adtrim

Local:2:O.Data[1].1 0 ch1 only

Local:2:O.Data[1].2 0 4msec

Local:2:O.Data[1].3 0 8msec

Local:2:O.Data[1].4 0 16msec

Local:2:O.Data[1].5 0 32msec

Local:2:O.Data[1].6 0 40msec

Local:2:O.Data[1].7 0 48msec

Local:2:O.Data[2] 5

Local:2:O.Data[2].0 1 rev418 enable

Local:2:O.Data[2].1 0 10x scale

Local:2:O.Data[2].2 0 samples = 10

Local:2:O.Data[2].3 0 samples = 20

Local:2:O.Data[2].4 0 samples = 50

Local:2:O.Data[2].5 0 zero band .025

Local:2:O.Data[2].6 0 zero band .050

Local:2:O.Data[2].7 0 zero band .075

Local:2:O.Data[3]

Local:2:O.Data[3].0 0 read scale sets

Local:2:O.Data[3].1 0 auto cal mode

Local:2:O.Data[3].2 0 ch1 auto tune

Local:2:O.Data[3].3 0 ch2 auto tune

Local:2:O.Data[3].4 0 read autocal values

Local:2:O.Data[3].5 0 read sample set

Local:2:O.Data[3].6 0 read mv_v sets

Local:2:O.Data[3].7 0 extra test

16 HM1734-WM STRAIN GAGE INPUT MODULE

Data Map for HM1734-WM on Ethernet/IP

CONTROLLER TAGS

get_weight_ch1 2792725 Decimal DINT

get_weight_ch2 2794308 Decimal DINT

Local:2:C.Data[0] 5000 Decimal INT ch1 scale

Local:2:C.Data[1] 2000 Decimal INT ch1mv_v

Local:2:C.Data[2] 5000 Decimal INT ch2 scale

Local:2:C.Data[3] 2000 Decimal INT ch2 mv_v

Set or Change Configuration Data:

Must be “On-Line”

Must be in “Program Mode”

Enter new configuration data

Power Down/ then Power Up

(MODULE LOADS IN CONFIG DATA ON POWER UP)

Scale Settings:

FOR SCALE = 10,000

Enter 10,000 at SCALE SET

Set 10X scale = 0

FOR SCALE = 100,000

Enter 10,000 at SCALE SET

Set 10X scale = 1

USE “READ BITS” TO CHECK FOR MODULE CURRENT CONFIG DATA

17 HM1734-WM STRAIN GAGE INPUT MODULE

HM1734-WM AOP rev418. ACD

CALIBRATING WITH KNOWN LOAD (AUTO-CAL) Ver. 4.18

1) Set known weight for channel at scale parameter.

2) Tare-0 (with no weight on cell/scale).

3) Set module to AUTOCAL mode (BIT).

4) Apply known load (test weight) to load cells/ scale.

5) Set AUTO TUNE BIT on for CH1 (CH2 if applicable).

6) To ensure accuracy repeat the steps above.

7) MAKE SURE AUTOCAL MODE BIT STAYS ON.

18 HM1734-WM STRAIN GAGE INPUT MODULE

HM1734-WM ADDON rev3. ACD

19 HM1734-WM STRAIN GAGE INPUT MODULE

HM1734-WM ADDON rev3. ACD

HM1734WM:1:O.Data[0].0

0 BOOL cal mode

HM1734WM:1:O.Data[0].1

0 BOOL run mode

HM1734WM:1:O.Data[0].2

0 BOOL ch1 clear tare

HM1734WM:1:O.Data[0].3

0 BOOL ch1 tare

HM1734WM:1:O.Data[0].4

0 BOOL ch1 adtrim

HM1734WM:1:O.Data[0].5

0 BOOL read adtrim

HM1734WM:1:O.Data[0].6

0 BOOL ch2 clear tare

HM1734WM:1:O.Data[0].7

0 BOOL ch2 tare

HM1734WM:1:O.Data[1].0

0 BOOL ch2 adtrim

HM1734WM:1:O.Data[1].1

0 BOOL ch1 only

HM1734WM:1:O.Data[1].2

0 BOOL 4msec

HM1734WM:1:O.Data[1].3

0 BOOL 8msec

HM1734WM:1:O.Data[1].4

0 BOOL 16msec

HM1734WM:1:O.Data[1].5

0 BOOL 32msec

HM1734WM:1:O.Data[1].6

0 BOOL 40msec

HM1734WM:1:O.Data[1].7

0 BOOL 48msec

HM1734WM:1:O.Data[2].0

0 BOOL set to zero

HM1734WM:1:O.Data[2].1

0 BOOL msf .002 to .001

HM1734WM:1:O.Data[2].2

0 BOOL msf .004 to .002

HM1734WM:1:O.Data[2].3

0 BOOL msf .008 to .004

HM1734WM:1:O.Data[2].4

0 BOOL msf .01 to .005

HM1734WM:1:O.Data[2].5

0 BOOL zero band .025

HM1734WM:1:O.Data[2].6

0 BOOL zeroband .05

HM1734WM:1:O.Data[2].7

0 BOOL zeroband .075

HM1734WM:1:O.Data[3] 0 SINT sample bits

Table of contents

Other Helm Control Unit manuals

Popular Control Unit manuals by other brands

Bosch

Bosch Rexroth R-IB IL 24 PSDO 8-PAC manual

ClimateMaster

ClimateMaster AHWG Series Installation, operation & maintenance instructions

Fisher

Fisher D Series instruction manual

ICP DAS USA

ICP DAS USA I-8124W user manual

ZyXEL Communications

ZyXEL Communications N-611 user manual

Varifan

Varifan VSD-1C Installation and user guide