Helm HM1525 User manual

Model HM1525

10/05/2018

Instruction Manual

October, 2018

1769 Weigh Scale

Module

Helm Instrument Company, Inc.

361 West Dussel Drive

Maumee, Ohio 43537 USA

419/ 893-4356

Fax: 419/ 893-1371

www.helminstrument.com

HM1525 Weigh Scale Module

Page 2

Solid state equipment has operational characteristics differing from those

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Allen-Bradley

Publication SGI-1.1) describes some important differences between solid

state equipment and hard-wired electromechanical devices. Because of

this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment

is acceptable.

In no event will the Allen-Bradley Company or Helm Instrument

Company be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company or

Helm Instrument Company cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company or Helm

Instrument Company with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company and Helm Instrument

Company is prohibited.

Throughout this manual we use note to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to property damage.

Identifies information that is especially important for

successful application and understanding of the product.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

ATTENTION: Please check power supply ratings

before proceeding! Each tonnage module

consumes (+24, 50mA +5, 66mA). Be sure to not

overload the power supply.

Important User

Information

HM1525 Weigh Scale Module

Page 3

Read this preface to familiarize yourself with the rest of this manual. This

preface covers the following topics:

who should use this manual

the purpose of this manual

terms and abbreviations

conventions used in this manual

Allen-Bradley support

Use this manual if you are responsible for the design, installation, programming,

or maintenance of an automation control system that used Allen-Bradley small

logic controllers.

You should understand electronic process control and be able to interpret the

ladder logic instructions required to generate the electronic signals that control

your application. If you do not, contact your local Allen-Bradley representative for

the proper training before using this product.

This manual is a learning and reference guide for the Helm Weigh Scale Module.

It contains the information you need to install, wire, and use the module.

Purpose of

This Manual

Who Should

Use this

Manual

Preface

HM1525 Weigh Scale Module

Page 4

HM1525 Weigh Scale Module

Page 5

HM1525 Weigh Scale Module

Page 6

HM1525 Weigh Scale Module

Page 7

HM1525 Weigh Scale Module

Page 8

HM1525 Weigh Scale Module

Page 9

OUTPUT TAG DESCRIPTIONS

CALMODE

Used for initial installation. All math is disabled, weigh value is not scaled, leaving raw A/D value.

WEIGH MODE

Factory cal setting 100,000 counts = 2MV/V

CLEAR TARE CH1/CH2 Bit

Clears internal tare value for “zero state”.

Useful when troubleshooting load cell wiring or other failures.

TARE CH1/CH2

Sets A/D value to zero.

READ ADTRIM BIT

(HELM Factory setting only).

CH1/CH2 AUTO TUNE BITS

Set to “1” when in auto cal mode

Reference/cal weight on before setting bit

READ SCALE SET BIT

Set to “1” to verify CH1/CH2 scale sets

ENABLE FILTER BITS

Set to “1” to enable 60/50 h2 filter

CH1/CH2 FILTER ON BIT

Set to “1” to enable filter

Set to “0” to disable filter

HM1525 Weigh Scale Module

Page 10

OUTPUT TAG DESCRIPTIONS

MSF BITS –(Motion Stabilization Filter)

Used for applications with constant or static type loads to keep display value stable.

MSF1_2 (1 count up –2 counts down).

MSF2_4

MSF4_8

MSF5_10

Set one bit only.

ZERO-DEAD-BAND BITS

Useful for Auto-Tare functions with production runs.

Set only one bit.

ZEROBAND_025 = .025% full scale

ZEROBAND_05 = .05% full scale

ZEROBAND_075 = .075% full scale

Auto tare occurs when load cell weight is at bit level or lower.

READ MV/V BIT

Check verify mV/V settings

READ CAL FACTOR BIT

Check auto cal values

SAVE TO EEPROM

Stores CH1/CH2 scale settings

AUTO CAL MODE

Set to “1” for auto cal mode

SET CH1 SCALE BIT

Set to “1” to set CH1 scale

SET CH2 SCALE BIT

Set to “1” to set CH2 scale

HM1525 Weigh Scale Module

Page 11

REQUIRED CONTROLLER TAGS

CH1/CH2 SCALE SET AND AUTOCAL REFERANCE

CH1_SCALE_MOD1

Full scale setting for CH1, CH2

Value is determined by capacity of load cell and by resolution required.

Example: 10KG = 10,000

GET WEIGH VALUE CH1

CH1_WEIGHT_MOD1

CH2_WEIGHT_MOD1

Reports measured weigh value in RUN mode.

Reports raw A/D count value in CAL mode.

SET AVERAGE SAMPLE COUNT

SMAPLE_SET_MOD1

Set number of samples to take for average type filter.

SET mV/V CH1, CH2

CH1_MV_V MOD1

CH2_MV_V MOD1

CH1/CH2 MV_V Settings

Enter 2000 for 2.0 mV/V

Actual value is from load cell specification.

FILTER TIME _MOD1

FILTER_TIME_MOD1

Each count = 1 msec

50 h2: 20 msec = 20

60 h2: 16 msec = 16

HM1525 Weigh Scale Module

Page 12

Specifications - HM1734-WM Strain Gage Input Module

Module Location 1734-TOP (screw terminal) or 1734-TOPS (spring loaded terminal)

Type of input Strain Gage (350 ohm, 700 ohm)

Gage Excitation Voltage 5 Volt

Input Impedance 5.11 meg. ohm

Display Resolution Up to .0025% of full scale

Module Accuracy Dependent on Load Cell Specification

Module Update Time Software selectable from 2ms to 100ms

Number of Channels 2 (isolated)

A/D Conversion Method Successive Approximation - 24 bit

Normal Mode Rejection:

(between +/- input) 116DB CMRR

Amplifier Bandwidth 200 kHz

Calibration Software Selectable

Isolation: 500 VDC continuous between inputs

and chassis ground, and between input

and backplane

LED indicators 2 LED's for Power and Alarm

Recommended Cable Strain Gage Cable (Helm part number 6117)

Operating Temperatures 0°C to 60°C (32°F to 140°F)

Emissions CISPR 11

Group 1, Class A

Pointbus Current 5V @ 72ma

External Power 24V @ 19.5ma

Dimensions 2.21H x 0.47W x 2.97L (Millimeters 56H x 12W x 75.5L)

HM1525 Weigh Scale Module

Page 13

AUTO-CAL PROCEDURE

1) Set known weight for channel at scale parameter.

2) Tare-0 (with no weight on cell/scale).

3) Apply known load (test weight) to load cells/ scale.

4) Set AUTOCAL bit on for CH1 (CH2 if applicable).

5) Turn bit off before removing known weight.

6) To ensure accuracy, repeat the steps above.

7) Toggle “save to eeprom” bit

HM1525 Weigh Scale Module

Page 14

SETTING UP HM1525WM MODULE

Step #1

Add module to project as following:

HM1525WM MODULE PROPERTIES

General Tab Settings

Connection Tab Settings

HM1525 Weigh Scale Module

Page 15

Step #2

Open “Template” file

Copy all controller tags

Open project file

Paste controller tags

Duplicates may be created, delete them now

Step #3

Open “Template” file

Copy add-on instruction “HM1525WM”

Open project file

Paste add-on instruction in add-on’s section

HM1525 Weigh Scale Module

Page 16

Step #4

Open “Template” file

Copy weightmodule1

Open project

Paste weighmodule1

Check program tag here should be as

Example

HM1525 Weigh Scale Module

Page 17

Step #5

Check routine for entries

HM1525 Weigh Scale Module

Page 18

Data Map for HM1734-WM on Ethernet/IP

OUTPUT TAGS

Description

Output_bits_mod1.0

bit

Set Cal Mode Bit

Output_bits_mod1.1

bit

Set Run Mode Bit

Output_bits_mod1.2

bit

Ch1 Clear Tare Bit (momentary)

Output_bits_mod1.3

bit

Ch1 Tare Bit (momentary)

Output_bits_mod1.4

bit

Ch2 Clear Tare

Output_bits_mod1.5

bit

Ch2 Tare

Output_bits_mod1.6

bit

Read mV/V sets

Output_bits_mod1.7

bit

Read cal factor

Output_bits_mod1.8

bit

Save to eeprom

Output_bits_mod1.9

bit

Read adtrim

Output_bits_mod1.10

bit

Auto cal mode

Output_bits_mod1.11

bit

Set Ch1 scale

Output_bits_mod1.12

bit

Set Ch2 scale

Output_bits_mod1.13

bit

Ch1 auto-tune

Output_bits_mod1.14

bit

Ch2 auto-tune

Output_bits_mod1.15

bit

Read scale sets

Parameter_bits_mod1.0

BOOL

Msf 1-2

Parameter _bits_mod1.1

BOOL

Msf 2-4

Parameter _bits_mod1.2

BOOL

Msf 4-8

Parameter _bits_mod1.3

BOOL

Msf 5-10

Parameter _bits_mod1.4

BOOL

Msf 6-12

Parameter _bits_mod1.5

BOOL

Msf 7-13

Parameter _bits_mod1.6

BOOL

Msf 8-14

Parameter _bits_mod1.7

BOOL

Reserved

Parameter _bits_mod1.8

BOOL

Zero band 25

Parameter _bits_mod1.9

BOOL

Zero band 50

Parameter _bits_mod1.10

BOOL

Zero band 75

Parameter _bits_mod1.11

BOOL

Enable filter

Parameter _bits_mod1.12

BOOL

Ch1 filter on

Parameter _bits_mod1.13

BOOL

Reserved

Parameter _bits_mod1.14

BOOL

Reserved

Parameter _bits_mod1.15

BOOL

Ch2 filter on

Data Map for HM1734-WM on Ethernet/IP

HM1525 Weigh Scale Module

Page 19

Required Controller Tags

Data Tags Name

Data Type

Ch1_mv_v_mod1

INT

Ch1_scale_mod1

DINT

Ch1_weigh_mod1

DINT

Ch2_mv_v_mod1

INT

Ch2_scale_mod1

DINT

Ch2_weight_mod1

DINT

Filter_time_mod1

INT

Mode_set_bits_mod1

INT

Parameter_bits_mod1

INT

Sample_set_mod1

INT

HM1525 Weigh Scale Module

Page 20

The following documents contain information that may be helpful to you as you use Allen-Bradley SLC

products. To obtain a copy of any of the Allen-Bradley documents listed, contact your local Allen-Bradley

office or distributor.

For

Read this Document

Document

Number

CompactLogix 5370 L1 Programmable

Automation Controllers

CompactLogix 5370 L1 Programmable

Automation Controllers

1769-PP012

An overview for the MicroLogixTM

Programmable Controllers

MicroLogix 1500 Programmable Controllers

1764-UM001A-US-P

A description on how to install and use your

MicroLogix Programmable Controller

MicroLogix 1500 Programmable Controller

Base Units Installation Instructions and

Wiring Diagrams

1764-IN001A-ML-P

A description on how to install the processor

into the MicroLogix 1500 Base unit.

MicroLogix 1500 Processor Installation

Instructions

1764-IN002A-ML-P

Selecting Discrete Input/Output Modules

Compact Discrete Input/Output Modules

Technical Data

1769-2.1

View power usage of expansion modules to

determine power supply requirements

Expansion Modules System Qualifier

RA Website Download

End Cap Installation

Compact I/O End Caps/Terminators

Installation Instructions

1769-5.16

A complete listing of current Automation

Group documentation, including ordering

instructions. Also indicates whether the

documents are available on CD-ROM or in

multi-languages

Automation Group Publication Index

SD499

A glossary of industrial automation terms

and abbreviations

Allen-Bradley Industrial Automation

Glossary

ICCG-7.1

An article on wire sizes and types for

grounding electrical equipment

National Electrical Code

Published by the

National Fire

Protection

Association of

Boston, MA.

Related

Documentation

Other manuals for HM1525

1

Table of contents

Other Helm Control Unit manuals

Popular Control Unit manuals by other brands

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

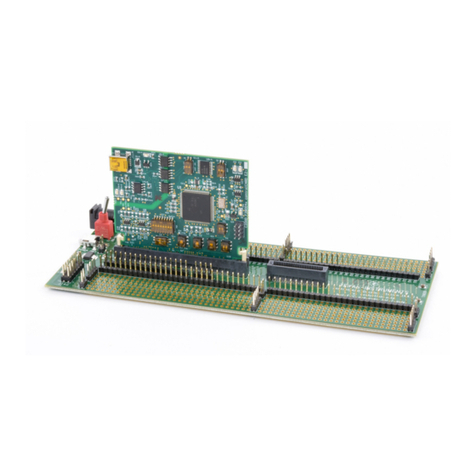

Tews Technologies

Tews Technologies TPMC866-TM-20 user manual

Atkinson Electronics

Atkinson Electronics GSCM-MINI-50 manual

Trox Technik

Trox Technik XS installation manual

Lenz

Lenz Digital Plus BM3 Information

Sierra Wireless

Sierra Wireless AirPrime WP7504 Hardware integration guide

Beta LaserMike

Beta LaserMike LASERSPEED 8000 Instruction handbook

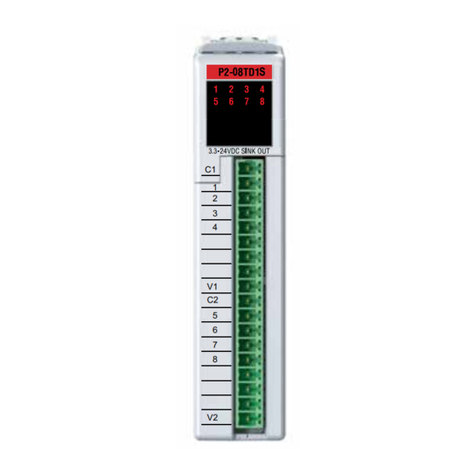

Automationdirect.com

Automationdirect.com Productivity 2000 P2-08TD1S manual

Novanta

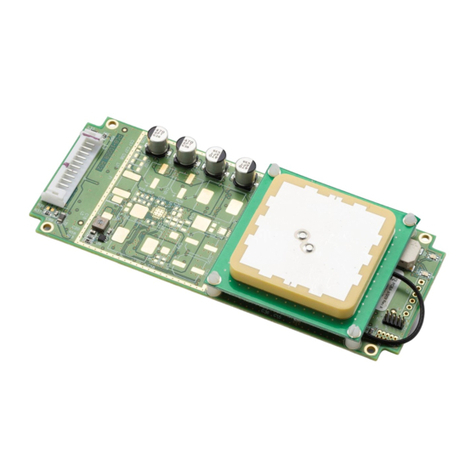

Novanta JADAK THINGMAGIC EL6E Getting started

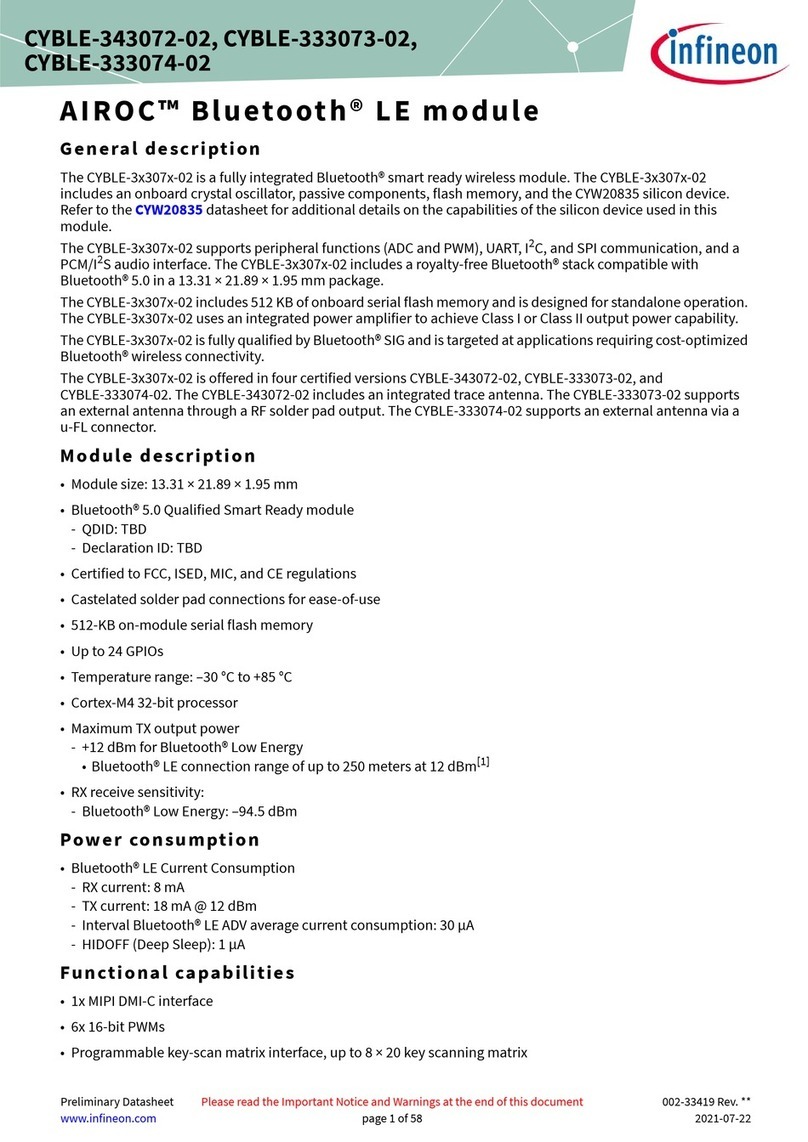

Infineon

Infineon AIROC CYBLE-343072-02 manual

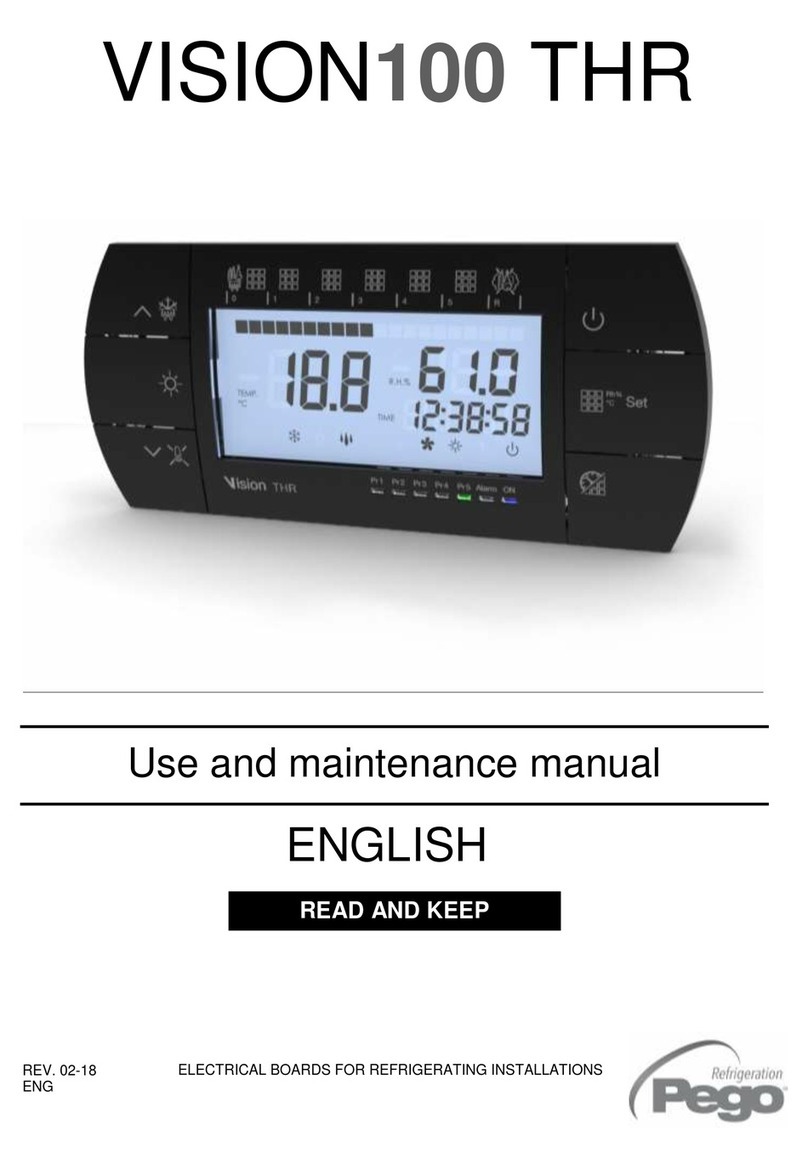

Pego

Pego VISION100 THR Use and maintenance manual

Sony

Sony MB0402C2 user manual