HELVAR LC45iC-DA-100-900 User manual

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

Functional Description

• DALI Type 8 compatible. One DALI address for controlling colour temperature by two output channels

• DALI colour type: Colour temperature Tc

• Adjustable constant current output: 100 mA to 900 mA (350 mA default current)

• Current setting programmable via NFC or DALI

• Suitable for flicker-free camera recording applications

• Patented Switch-Control 2 functionality for easy-to-use intensity and colour temperature control with single push button

• Full load recognition with automatic recovery, open and short circuit protection

• Constant Light Output (CLO), adjustable up to 100 000 h (default disabled)

• Energy consumption monitor (real time), running hour monitor (accumulative), energy management (accumulative)

• Memory bank for OEM customer data

Mains Characteristics

Nominal rated voltage range 220 V – 240 V, 0 / 50 – 60 Hz

AC voltage range 198 VAC – 264 VAC

Withstands max. 320 VAC (max. 1 hour)

Withstands min. 176 VAC (max. 1 hour)

DC voltage range 176 VDC –280 VDC

DC starting voltage > 190 VDC

Mains current at full load < 0.24 A

Frequency 0 / 50 Hz –60 Hz

Stand-by power consumption < 0.5 W

THD at full power < 15 %

Tested surge protection 1 kV L-N, 2 kV L-GND (IEC 61000-4-5)

Tested fast transient protection 2 kV (IEC 61000-4-4)

Insulation between circuits & driver case

Mains circuit - SELV circuit Double/reinforced insulation

DALI circuit - SELV circuit Double/reinforced insulation

Mains circuit - DALI circuit Basic insulation

Mains, DALI and output - Driver case Double/reinforced insulation

Mains input - Ground input Basic insulation

Load Output (SELV <60 V)

Output current (Iout) 100 mA –900 mA

Accuracy ± 5 %*

Ripple < 1 %** at ≤ 120 Hz *) At maximum current **) Low frequency, LED load: Cree XP-G LEDs

PstLM < 0.15*

SVM < 0.01* *) At full power, measured with Cree XP-G LED modules.

Uout (max) (abnormal) 60 V

ILED* 100 mA 350 mA (default) 900 mA

PRated* 5 W 17.5 W 45 W

ULED* 12 – 50 V 12 – 50 V 12 –50 V

PF (λ) at full load 0.67 0.89 0.97

Efficiency (η) at full load 66 % 83 % 88 %

45 W Dimmable two channel intelligent Colour LED driver

• 2-channel tunable white for human centric lighting

• Wide dynamic range of colour temperatures on all dimming levels *

• Amplitude dimming for the highest quality light output, complying

with IEEE 1789 recommendation

• NFC technology for wireless programming

• Suitable for use in emergency lighting applications

• Suitable for Class I and Class II luminaires

• Optional strain relief for independent use outside of luminaire (LC-

SRB and LC-SRB-LOOP) and driving Class III luminaires

• Helvar Driver Configurator support

*) See pages 2-3 for details

45 W 220 – 240 V 0/ 50 – 60 Hz

Product code: 5765

*Current and power are divided into two channels according to the chosen CCT and module specifications. Total maximum power of the

two channels can’t exceed given PRated .

TUNABLE WHITE

23.06.2022 1/7T22 187 1A

LC45iC-DA-100-900

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

Operating window

Driver performance

Operating Conditions and Characteristics

Absolute highest allowed tcpoint temperature 75 °C

Tc life (50 000 h) temperature 75 °C

Ambient temperature range* –25 °C ... +50 °C*

in independent use –25 °C ... +45 °C

Storage temperature range –40 °C ... +80 °C

Maximum relative humidity No condensation

Life time(90 % survival rate) 100 000 h, at tc = 65 °C

70 000 h, at tc = 70 °C

50 000 h, at tc = 75 °C

*) For other than independent use, higher taof the controlgear possible as long as highest allowed tcpoint temperature is not exceeded

*From 500 mA to 900 mA, full dimming range ( 2 % - 100 %) and wide CCT dynamic range available in the whole area.

From 100 mA to 500 mA, the absolute minimum dimming level is limited to 10 mA of total current. Dimming / CCT

control possible all the way down to that current, but the dynamic range may be limited. Each single channel can dim

down to 0.5 mA level.

0

10

20

30

40

50

60

0,00 0,10 0,20 0,30 0,40 0,50 0,60 0,70 0,80 0,90 1,00

Output voltage [V]

Output current [A]

ULED (max), V

ULED (min), V

50,0

56,0

62,0

68,0

74,0

80,0

86,0

92,0

0 5 10 15 20 25 30 35 40 45 50

Efficiency (%)

Total output power (W)

Typical efficiency

900 mA

350 mA

0,65

0,70

0,75

0,80

0,85

0,90

0,95

1,00

0 5 10 15 20 25 30 35 40 45 50

λ

Total output power (W)

Typical power factor

900 mA

350 mA

23.06.2022 2/7

LC45iC-DA-100-900

T22 187 1A

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

Amplitude dimming technology

LC45iC-DA-100-900 LED driver implements amplitude dimming technology across whole dimming range. Amplitude dimming offers

the best available technology for dimming the light output in an accurate and flicker-free way to ensure high quality lighting in even

the most demanding situations such as camera recording applications. Amplitude dimming technology complies with IEEE 1789-2015

recommendations of current modulation to mitigate health risks to viewers.

0.1 % 100 %

0.1 %

100 %

LED current

Brightness

Amplitude

dimming

Dimming range per

single channel

Dimming range in

tunable white use Dimming technology

0.1 % –100 % 2 % - 100 % Amplitude (DC)

100% - 2 %

Constant dimming range across

the operating window

Cool white

Dynamic range

Warm white

1200 mA 500 mA

Dynamic range in colour temperature control

LC45iC-DA-100-900 LED driver is ready to be used out of the box.

Highest precision and color consistency in controlling combinations of different luminaire types is achieved by setting colour temperatures

and lumen outputs before use with Helvar driver configurator. The configured colour temperatures of the channels should match the ones

of the LED modules used. The factory default settings of cool and warm channels are 6500 K and 2700 K accordingly.

After setting up the colour temperatures, the lumen output values of full dimming level (100 %) should be configured for both channels. By

default, output currents are set to be equal in both channels.

10 mA

500 mA Total available dimming range

100 % - 10 %100 % - 2 %

Dimming range depends on the

set output current

100 mA

500 mA

Cool white

Warm white

Dynamic range

Dimming

outside the

operating

window

900 - 500 mA 500 - 100 mA

23.06.2022 3/7

LC45iC-DA-100-900

T22 187 1A

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

Switch-Control 2 with tunable white

Helvar iC drivers provide the simplest form of control in tunable

white with Helvar patented single switch Switch-Control 2

functionality. With single push button the user is able to control

both the light intensity and colour temperature to the desired level.

The system synchronises the light levels and CCTs every time the

colour temperature is adjusted to ensure pleasant user experience

and uncompromised lighting comfort. More information about the

functionality can be found in Switch-Control user guide at www.

helvar.com.

Wireless configuration

LC45iC-DA-100-900 LED driver is equipped with NFC wireless

technology for effortless configuration of the driver via Helvar

Driver Configurator Support. Helvar Driver Configurator enables

easy-to-use automatic configuration of the driver parameters via

NFC, without mains or DALI connection to the driver. The most

popular MD-SIG qualified NFC readers are supported giving flex-

ibility for the operator. For further information about the usage

with Helvar Driver Configurator, please see the user guide at

www.helvar.com

Feig NFC reader

Quantity of drivers per miniature circuit breaker 16 A Type C

CONVERSION TABLE FOR OTHER TYPES OF

MINIATURE CIRCUIT BREAKER

MCB

type

Relative quantity of

LED drivers

B 10 A 37 %

B 16 A 60 %

B 20 A 75 %

C 10 A 62 %

C 16 A 100 % (see table above)

C 20 A 125 %

CONTINOUS CURRENT

Total continous current of the drivers and installation environment must always be considered and taken into calculations when installing drivers behind

miniature circuit breaker. Example calculation of total drivers amount limited by continous current: n(Icont)= (16 A (Inom,Ta) / “nominal mains current with full

load”) x 0.76). This calculation is an example according to recommended precautions due to multiple adjacent circuit breakers (> 9 MCBs) and installa-

tion environment (Ta30 degrees); variables may vary according to the use case. Both inrush current and continous current calculations are based on

ABB S200 series circuit breakers. More specific information in ABB series S200 circuit breaker documentation.

NOTE! Type C MCB’s are strongly recommended to use with LED lighting. Please see more details in “MCB information” document in each driver product

page in “downloads & links” section.

I (A)

T (ms)

Ipeak

Δt

½ Ipeak

PE

0

I

Color temperature

and intensity control

Retractive Switch

(push to make)

Based on Icont Based on inrush current Ipeak Typ. peak inrush current Ipeak 1/2 value time, Δt Calculated energy, Ipeak

2Δt

51 pcs 58 pcs 29 A 153 µs 0.093 A2s

23.06.2022 4/7

LC45iC-DA-100-900

T22 187 1A

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

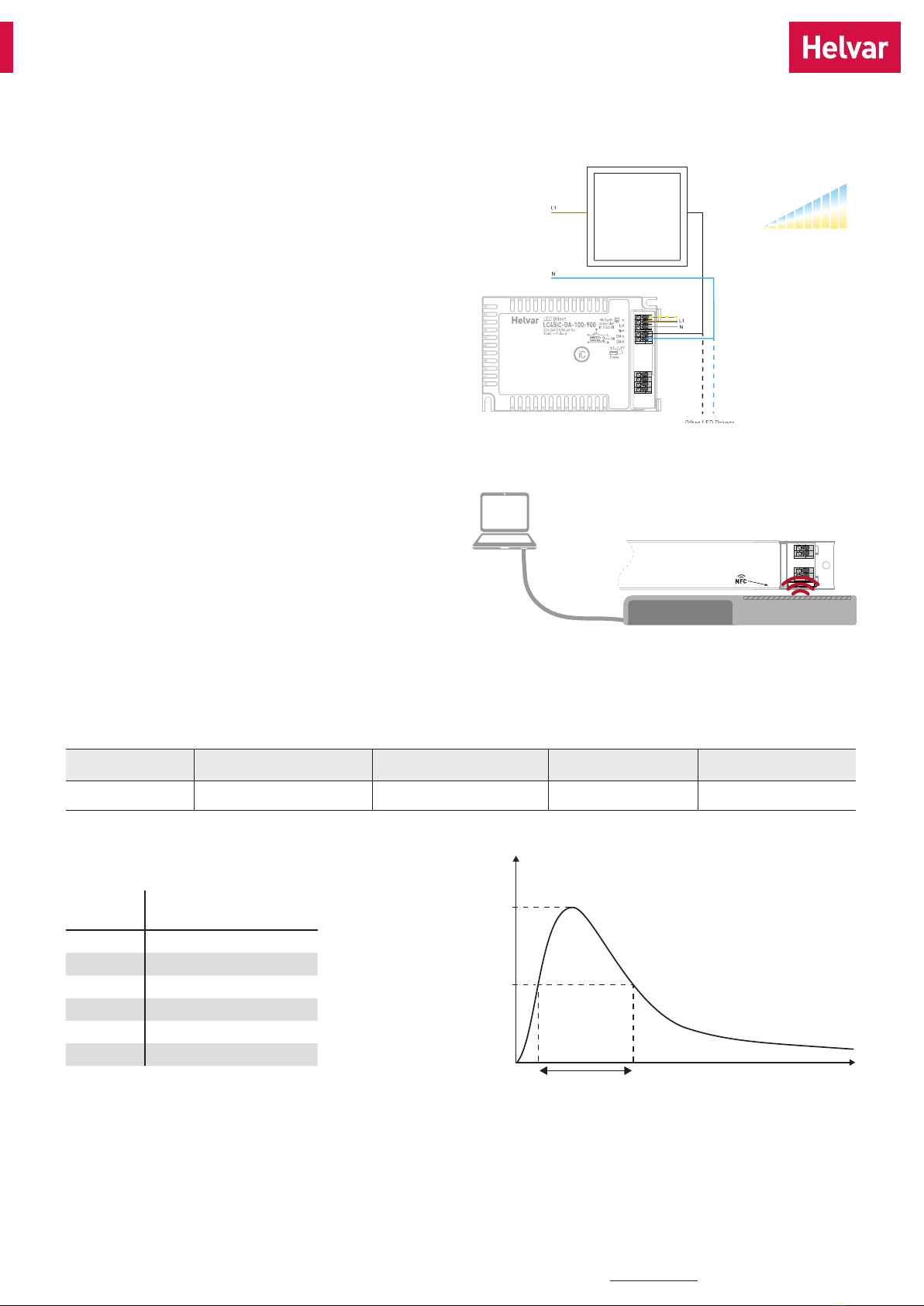

Connections

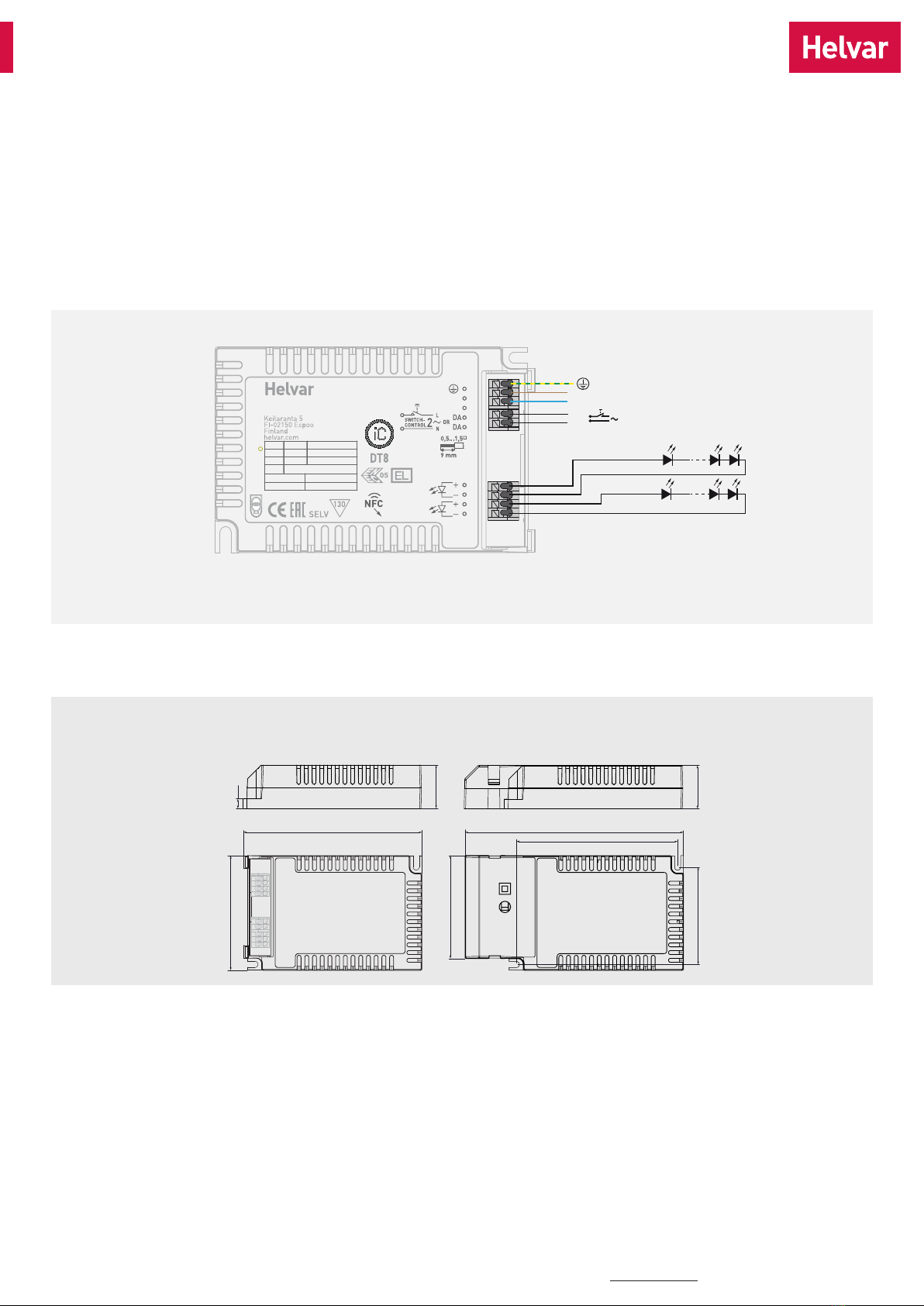

Dimensions (mm)

Connections and Mechanical Data

Wire size 0.5 mm2 –1.5 mm2

Wire type Solid core and fine-stranded

Wire insulation According to EN 60598

Maximum driver to LED wire length 1.5 m

Weight 193 g

IP rating IP20

CH1

(Cool white)

CH2

(Warm white)

L

N

DA

Switch-Control

tc

I-LED

350 mA 100 - 900 mA

5 - 45 W*

U-LED

dc

12...50 V

t

a

-25...+50 °C

U-OUT 60 V

t

c

+75 °C

λ

P

RATED

17.5 W

LED Driver

LC45iC-DA-100-900

220-240 V 50-60 Hz AC/DC

Made in Finland

Ch1

(Cool White)

Ch2

(Warm White)

L

N

5765000*WKYXXXXX

No Earth

connection

in Class II

NFC / DA

Default

0.97 at full power

* Depending on output power

30

With strain relief (LC1x70-SR)

122.9

79

150,5

71

111

67

30

6.5

Note:

• Earth connection to PE terminal is optional and not needed for the functionality of the driver. See page 4 for details.

• Not suitable for load side switching operation

• Label may differ if the unit is preset to fixed current

23.06.2022 5/7

LC45iC-DA-100-900

T22 187 1A

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

LC45iC-DA-100-900 LED driver is suited for built-in usage in luminaires. With LC1x70-SR/LC-SRB/LC-SRB-LOOP strain relief, independent

use is possible too. In order to have safe and reliable LED driver operation, the LED luminaires will need to comply with the relevant

standards and regulations (e.g. IEC/EN 60598-1). The LED luminaire shall be designed to adequately protect the LED driver from dust,

moisture and pollution. The luminaire manufacturer is responsible for the correct choice and installation of the LED drivers according to

the application and product datasheets. Operating conditions of the LED drivers may never exceed the specifications as per the product

datasheet.

Installation & operation

Maximum ambient and tctemperature:

• For built-in components inside luminaires, the taambient

temperature range is a guideline given for the optimum

operating environment. However, integrator must always

ensure proper thermal management (i.e. mounting base of the

driver, air flow etc.) so that the tcpoint temperature does not

exceed the tcmaximum limit in any circumstance.

• Reliable operation and lifetime is only guaranteed if the

maximum tcpoint temperature is not exceeded under the

conditions of use.

LED driver earthing

• LC45iC-DA-100-900 is Class I LED driver suitable for Class I and

II luminaires, as well as driving Class III (SELV) luminaire parts

in independent installation with external strain relief.

• If used inside Class I luminaires, the earth cable is recommended

to be connected to improve the EMC performance of the driver,

but it is not mandatory. It is the responsibility of the integrator

to ensure that the assembled luminaire EMC performance

complies with the latest standards. Driver RFI measurement

data will be provided by request.

• If used inside Class II luminaires, the safety of the luminaire shall

be ensured through double/reinforced insulation of live parts.

LC45iC-DA-100-900 has double/reinforced insulation between

accessible and live parts, and is suitable for use in all Class II

luminaires. In this case the earth terminal of the driver must

be left unconnected and the luminaire terminal block shall not

have any protective earthing terminal.

• If used in independent installation with Class I/II/III luminaires,

the earth cable connection is optional. Please follow the

instructions provided in the strain relief datasheets.

Miniature Circuit Breakers (MCB)

• Type-C MCB’s with trip characteristics in according to EN 60898

are recommended.

• Please see more details in “MCB information” document in each

driver product page in “downloads & links” section.

Installation site

• The general preferred installation position of LED drivers for

independent use is to have the top cover facing upwards.

• Minimum recommended distances below:

• Suitable for installation upside down and in the corner, in this

case separate spacers must be used. For more information,

please consult Helvar.

Helvar Driver Configurator -support

LC45iC-DA-100-900 LED driver is supported by Helvar Driver

configurator software. The LC45iC-DA-100-900 driver supports

output current setting with software, the output current of the

driver can be programmed using Helvar Driver Configurator, as

well as OEM customer data and parameters for functions such as

CLO and Tunable White behavior. Programming the driver with

Helvar Driver Configurator can be done either wirelessly via NFC

or then via DALI bus.

23.06.2022 6/7

Information and conformity

T22 187 1A

Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

Conformity & standards

General and safety requirements EN 61347-1

Particular safety requirements for DC

or AC supplied electronic control gear

for LED modules

EN 61347-2-13

Additional safety requirements for AC or

DC supplied electronic controlgear for

emergency lighting

EN 61347-2-13,

Annex J

Thermal protection class EN 61347, C5e

Mains current harmonics EN 61000-3-2

Limits for voltage fluctuations and flicker EN 61000-3-3

Radio frequency interference EN 55015

Immunity standard EN 61547

Performance requirements EN 62384

Digital addressing lighting interface:

General requirements for DALI system

Requirements for DALI control gear

Requirements for control gear of LED

modules

Particular requirements for control gear

- Colour control (Dali Device Type 8)

EN 62386-101

EN 62386-102

EN 62386-207

EN 62386-209

Recommended Practices for Modulating

Current in High-Brightness LEDs for

Mitigating Health Risks to Viewers

IEEE 1789-2015

Compliant with relevant EU directives

RoHS/REACH compliant

ENEC and CE / UKCA marked

Label symbols

Safety isolating control gear with short circuit protection

(SELV control gear).

Thermally controlled control gear, incorporating means

of protection against overheating to prevent the case

temperature under any conditions of use from exceeding

120 °C.

Driver equipped with NFC wireless technology for

effortless configuration.

Helvar Intelligent Colour drivers providing DALI colour

control (tunable white) functionality.

Lamp failure functionality

No load

When open load is detected, driver will go to standby power

consumption and remains in automatic recovery mode. In automatic

recovery mode, the driver waits till load is returned and once that

happens, it returns to normal operation.

Short circuit

When short circuit is detected, driver goes to automatic recovery

mode and follows the same logic as described in the no load

condition.

Overload

When overload is detected, driver goes to standby mode and returns

through mains reset.

Underload

When undervoltage is detected, driver goes to standby mode and

returns through mains reset.

Switch-Control 2

Use of Switch-Control functionality

• Maximum numbers of LED drivers to be connected to one switch

is 60. Wire length is not restricted by the driver technology.

• Ensure that all components connected to Switch-Control

circuitry are mains rated.

• More information in Switch-Control User Guide at www.helvar.

com.

23.06.2022 7/7

Information and conformity

T22 187 1A

This manual suits for next models

1

Table of contents

Other HELVAR DC Drive manuals

Popular DC Drive manuals by other brands

Linear Technology

Linear Technology DC1187A quick start guide

Danfoss

Danfoss VLT FC 300 instruction manual

Siruba

Siruba 700LD manual

Overland Storage

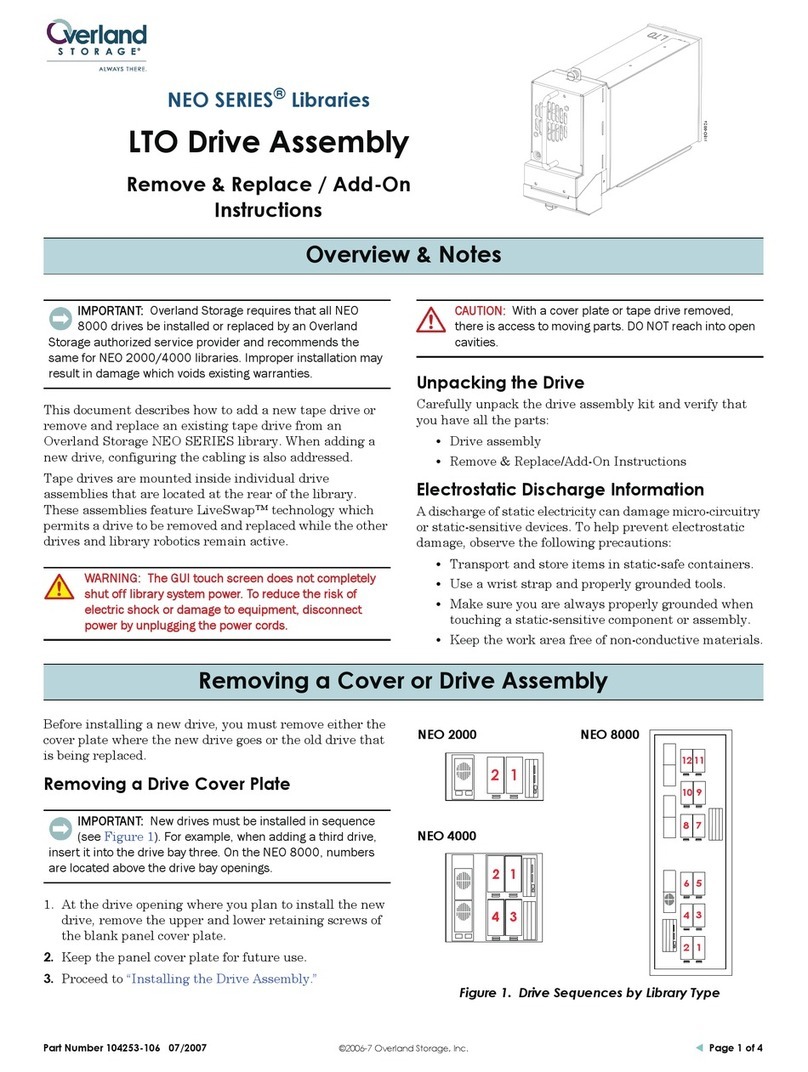

Overland Storage NEO Series Remove & Replace / Add-On Instructions

Fagor

Fagor BCSD installation manual

Lenze

Lenze L-force EZAMBHXM00 Series Mounting instructions