04.04.2022 5/6Helvar |Helvar Oy Ab, Keilaranta 5 FI-02150 Espoo, Finland. Data is subject to change without notice. www.helvar.com

LL1x150-CR-DA LED driver is suited for built-in usage in luminaires. With LL1x2130-SR strain reliefs, independent use is possible too (see

the LL1x2130-SR datasheet for details). In order to have safe and reliable LED driver operation, the LED luminaires will need to comply

with the relevant standards and regulations (e.g. IEC/EN 60598-1). The LED luminaire shall be designed to adequately protect the LED

driver from dust, moisture and pollution. The luminaire manufacturer is responsible for the correct choice and installation of the LED

drivers according to the application and product datasheets. Operating conditions of the LED drivers may never exceed the specifications

as per the product datasheet.

Installation & operation

Maximum ambient and tctemperature

• For built-in components inside luminaires, the taambient

temperature range is a guideline given for the optimum

operating environment. However, integrator must always

ensure proper thermal management (i.e. mounting base of the

driver, air flow etc.) so that the tcpoint temperature does not

exceed the tcmaximum limit in any circumstance.

• Reliable operation and lifetime is only guaranteed if the

maximum tcpoint temperature is not exceeded under the

conditions of use.

Current setting resistor

LL1x150-CR-DA LED driver features a constant current output

adjustable via current setting resistor or software.

• An external resistor can be inserted in to the current setting

terminal, allowing the user to adjust the LED driver output current

• When no external resistor is connected, then the LED drivers will

operate at their default lowest current level

• A standard through-hole resistor can be used for the current

setting. To achieve the most accurate output current it is

recommended to select a quality low tolerance resistor. Minimum

diameter for resistor leg is 0.51mm.

• Always connect the current setting resistor only into the terminals

marked with Iset on the LED driver label.

• Specific Iset resistor/current values are presented in the table on

page 3.

Miniature Circuit Breakers (MCB)

• Type-C MCB’s with trip characteristics in according to EN 60898

are recommended.

• Please see more details in “MCB information” document in each

driver product page in “downloads & links” section.

Switch-Control 2

Before installation and for troubleshoot and guidance, refer to

Switch-Control User Guide at www.helvar.com.

Use of Switch-Control functionality

• Maximum numbers of LED drivers to be connected to one switch

is 60. Wire length is not restricted by the driver technology.

• Ensure that all components connected to Switch-Control

circuitry are mains rated.

• The X2 rated (1 μF) capacitor has to be installed between control

lines in case of unwanted behavior of lights. See details and

guidance from the user guide.

Helvar Driver Configurator -support

LL1x150-CR-DA LED driver is supported by Helvar Driver configurator

software. The LL1x150-CR-DA driver supports output current setting

with software, the output current of the driver can be programmed

using Helvar Driver Configurator, as well as parameters for functions

such as CLO. Also the operation of the multifunction Iset terminal

usage can be changed from current setting resistor (default) to NTC

overtemperature protection operation.

Lamp failure functionality

No load

When open load is detected, driver will go to standby. Automatic

recovery is on during the first 10 minutes. If open load is still detected

after the first 10 minutes, driver goes to standby mode and recovers

through mains reset.

Short circuit

When short circuit is detected, driver goes to standby mode and

returns through mains reset or DALI command.

Overload

When high overload is detected, driver goes to standby mode and

follows the same logic as described in the short circuit condition.

When low overload is detected, output current will be reduced to have

maximum rated output power.

Underload

When undervoltage is detected, driver goes to standby mode and

returns through mains reset.

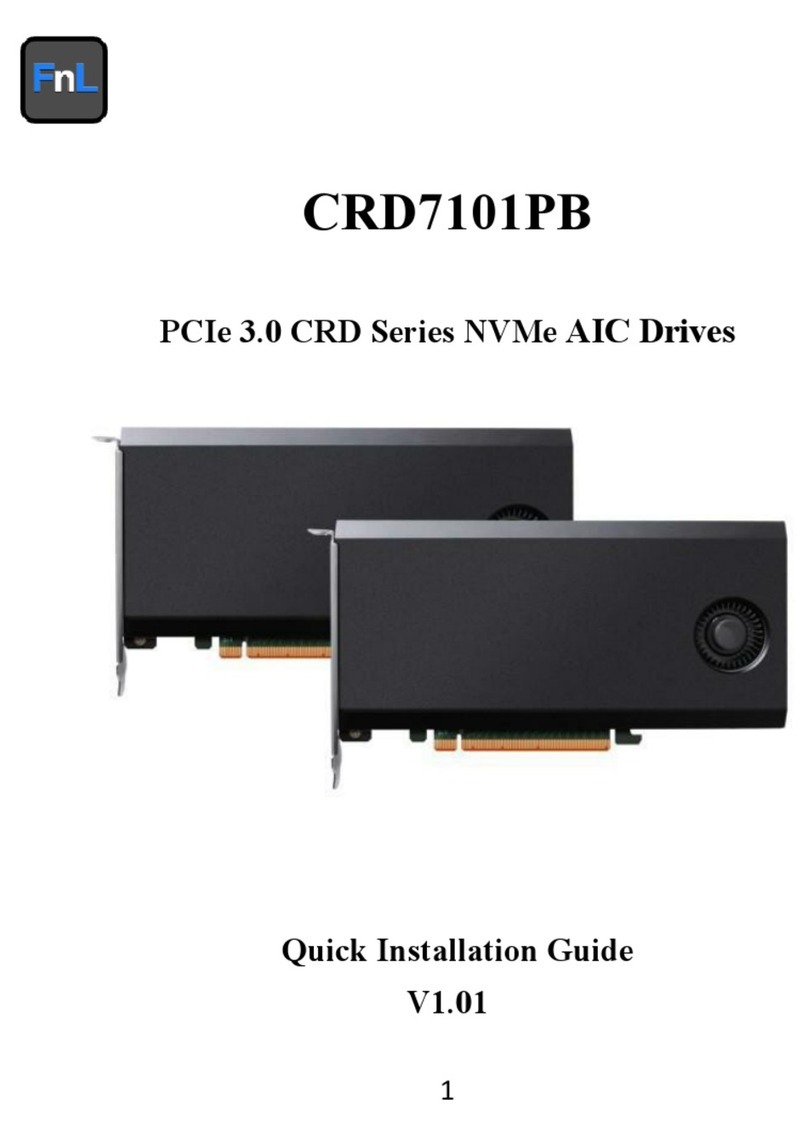

NTC trigger

When NTC is enabled via Helvar Driver Configurator, driver follows

NTC feature behaviour. Default NTC trigger point is 8,2 kΩ, after

which the driver starts to decrease the output level.

Information and conformity

T22 121 1E