HEMWAY YUNBA H99X1 User manual

YUNBA H99X1 SMART IRONING STEAM GENERATOR

INSTRUCTIONS

SHENZHEN HANMINGWEI SMART EQUIPMENT CO., LTD

Add:

Building 3B, 8 Cichang Road, Henggang, Longgang District, Shenzhen

Tell:0755-8467 9158 Fax:0755-2377 3276

hemway@hemway.com.cn

STATEMENT

SHENZHEN HEMWAY SMART DEVICE CO.,LTD

All right reserved.

Without the express written permission of SHENZHEN HEMWAY SMART DEVICE

CO.,LTD, no unit or individual may act arbitrarily to reproduce, reproduce or trans-

late partor all of the contents of this instruction shall not be used in any form or by

any means (electronic, mechanical, photocopying,recording or otherwise) for the

dissemination of commodities or for any commercial or profit-making purposes.

If there are any changes in the product structure and appearance, please refer to

the real product.The product specifications and information mentioned in this

instruction arefor reference only and are subject to change without notice.Check

out our website at anytime:

http://www.hemway.com.cn

The product works under high temperature and high pressure environment.

Non-professional maintenance personnel are not allowed to disassemble the

product without permission. Please refer to our warranty card for warranty.

Outside the warranty period, we also provide services. If you need to replace the

parts, we will charge a certain amount for the parts.

Unless otherwise agreement, this instruction is used only as a guidence and all

statements, information, etc. in this book do not constitute any form of warranty.

INDEX

Product Installation Standards

Packing list

四 、

五 、

六 、

Technical Parameters

Product External Structure

06

07-10

01

01

05

12

11

13-14

15

02-04

Product Introduction

Product Introduction

Installation Guidance

Operating Guidance

Maintaince

Fault Analysis and Troubleshooting

After Service

三 、

Equipment Installation

2

1

Rated evaporation

water source pressure

Size of Host

H99X1

12kW

AC380V(Details pls. review the nameplate)

547*257*770mm

13.5L/H

1~3Kg/cm²

1.5~4.2Kg/cm² (Adjustable)

一、 PRODUCT INTRODUCTION

Product Introduction

Technical Parameters

YUNBA H99X1 Smart ironing steam generator

Name

Product Model

Heater Rated Power

Rated Voltage

Working Pressure

YUNBA H99X1 smart ironing steam generator is a garment ironing product

independently developed by our company and obtained a number of national

patents. The product has the functions of automatic water adding, frequency

conversion heating, automatic drainage,discharging and intelligent scale

removal. At the same time, it has the characteristics of adjustable pressure,

intelligent dormancy and fault code reminder. The steam capacity of the

product is sufficient to meet the requirements of small ironing,medium

ironing , big steam ironing and other industries .

This product is suitable for all kinds of clothing factories, clothing finishing

centers,home textile stores, curtain stores, laundry rooms, etc. It can remove

wrinkles and finalizethe design of various fabrics, achieve ideal ironing effect,

and meet the steam supply of other equipment.

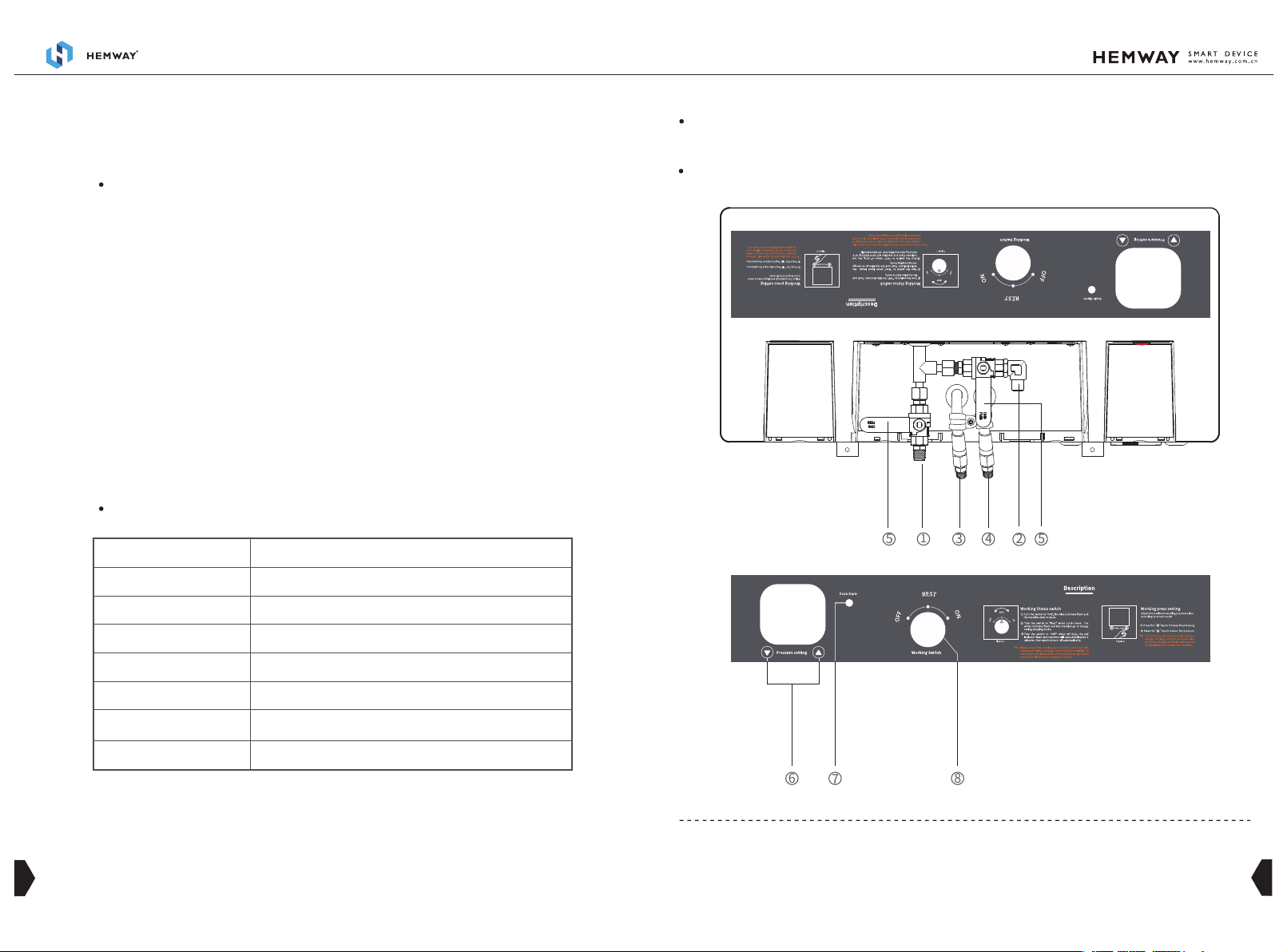

8

7

6

2

3

4

5

5

1

2、 Steam pipe interfaceⅡ

5、 Steam control switch

3、 Water return pipe interfaceⅠ

4、 Water return pipe interfaceⅡ

1、 Steam pipe interfaceⅠ

6、 Pressure setting button

7、 Drainage warning indicator 8、 Working Status Switch

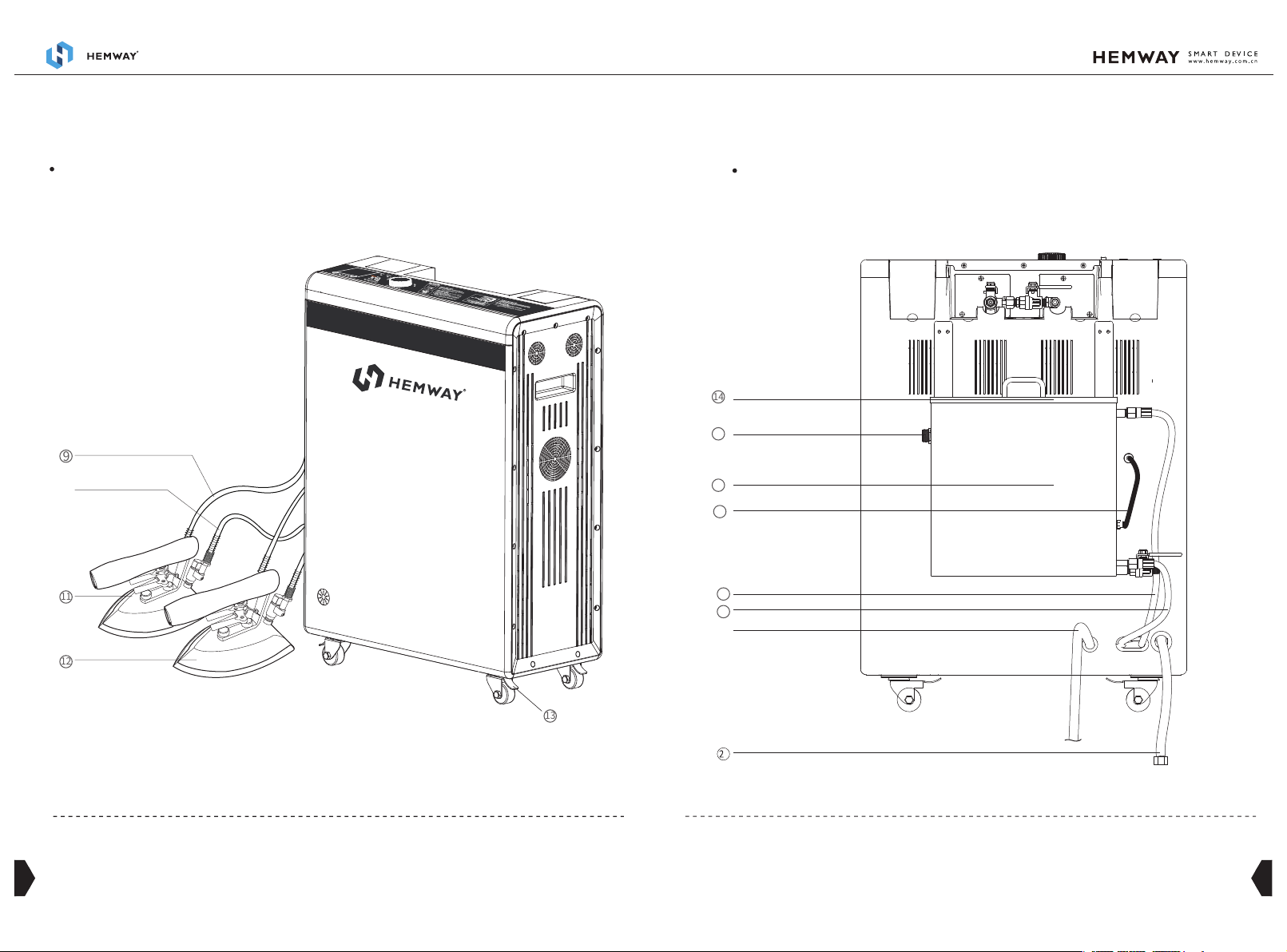

Product External Structure

Host--TOP

4

3

9

11

12

13

⑩

Host--FRONT

9、 Steam pipe 10、 Water return pipe 11、 IronⅠ12、 IronⅡ13、 Wheel brake

18

19

17

16

16、Water tank

17、Water level detector signal line 18、Condensate pipe 19、pump inlet pipe

15、Water source inlet

15

14、Water tank top cover

21、drainage pipe20、 power cable

14

⑳

1

Host--BACK

6

5

Water inlet pipex1

Water Tankx1

M4x8 Screwx4 M4x16 Screwx4

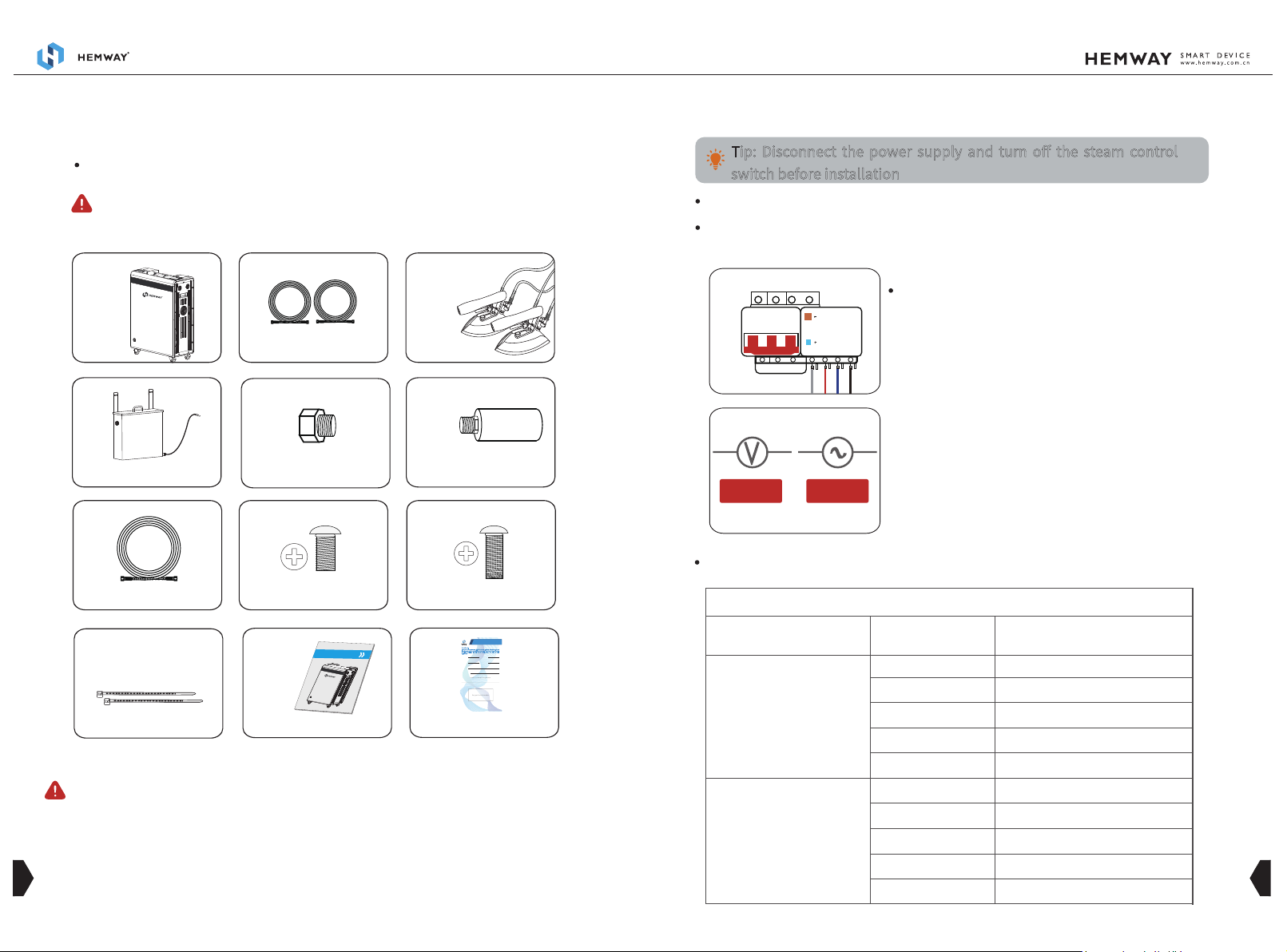

Packing List

Ribbon x 2

Drainage head x 1

Steam pipe x2

Water return pipe x2

Host x1Iron x 2

User's manual x 1 Warranty card x 1

Drainage adapter X1 (Optional)

when opening the outer packing, please read the instructions

carefully and keep the relevant certificates properly.

if there is a shortage or damage of parts, please contact the local

distributor .

NOTE

NOTE

二、 INSTALLATION GUIDANCE

380V 20A

Connect 380V Power short-Circuit

Protection

Note: Disconnect the power supply before connect

the Power short-Circuit Protection switch

380V/20A

漏电指示

每月按一次

T

When the rated voltage on rating label is

380V,the current of the supply line must no less

than 20A ,connect 380V Power short-Circuit

Protection and GROUND; use the corresponding

power supply line to avoid overload of the

circuit caused by the equipment being

energized.

Circuit Installation

Product Installation Standards

Power short-Circuit Protection Installation Instructions .

Tip: Disconnect the power supply and turn off the steam control

switch before installation

Power cable Load Standard

AC380V three-phase electric power supply line reference

one set

two sets

three sets

four sets

five sets

one set

two sets

three sets

four sets

five sets

within 10 meters

more then 10 meters

RVV5*4.0mm²

RVV5*6.0mm²

RVV5*10.0mm²

RVV5*16.0mm²

RVV5*16.0mm²

RVV5*2.5mm²

RVV5*6.0mm²

RVV5*10.0mm²

RVV5*10.0mm²

RVV5*16.0mm²

Device quantity

The Distance between

Power switch and devices power cable Specification

Dearcustomers:

Key part serial number

CustomerName PhoneNumber

DealerContactNumber

Dealer's stamp or Signature

Product Model PurchaseDate

MailingAddress

Warranty Card

Thankyou for your patronage of HEMWAY products! In order to protect your rights and

interests,please read the warranty terms and conditions on the back of this card carefully

and fill in the following information for safe keeping. Please show this card during

maintenance!

YUNBA H99X1 SMART IRONING STEAM GENERATOR

INSTRUCTIONS

78

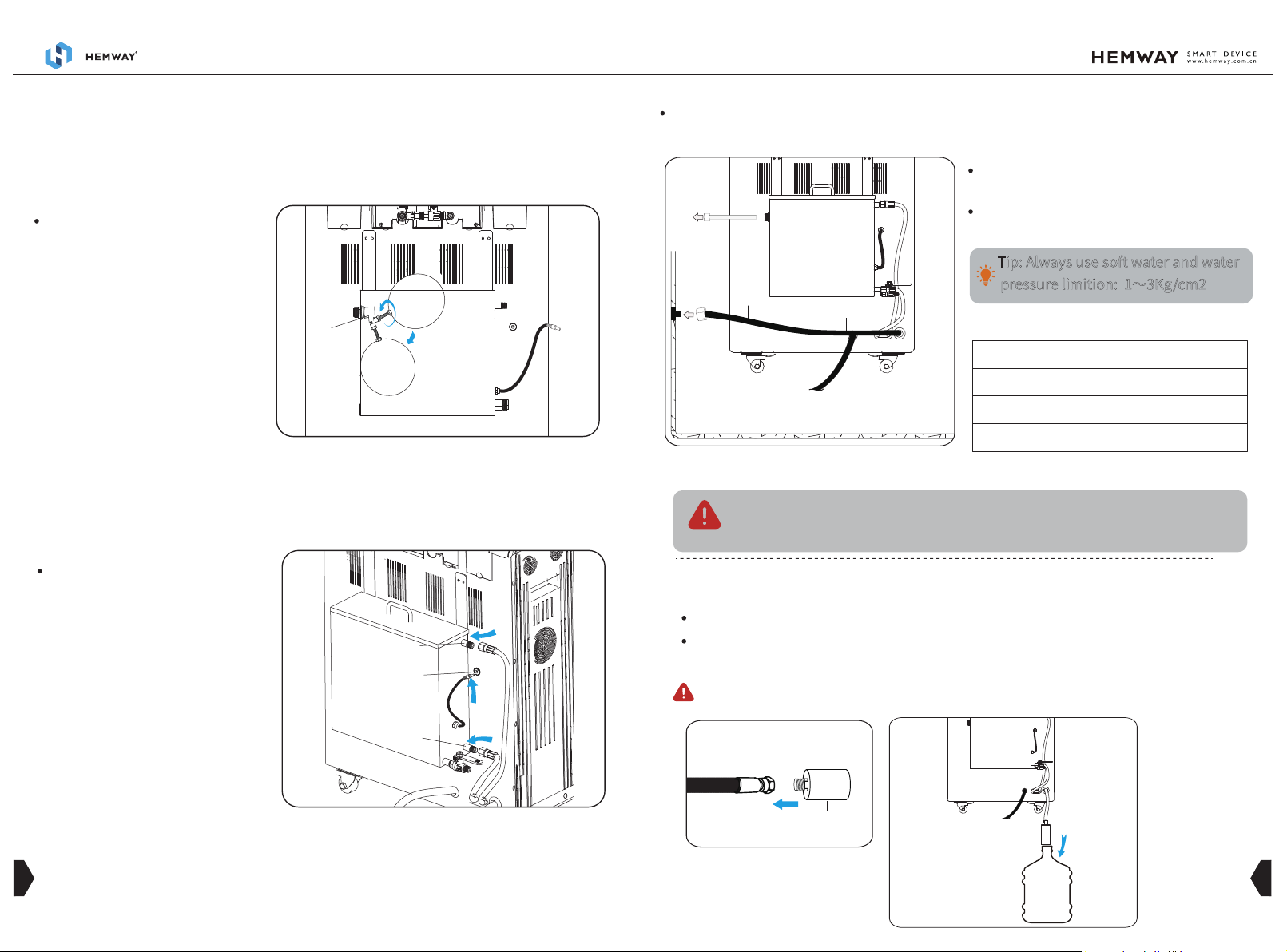

Figure 2

Figure 1

Iron Installation

Equipment Installation

Water return pipe

Water return pipe joint

Steam pipe

Steam pipe joint

Steam pipeⅡ

Steam pipeⅠ

Water return pipeⅠ Water return pipeⅡ

Refers to figure 1,install the

steam pipe and water return pipe

of the iron on the corresponding

wiring port(Steam pipe joint and

Water return pipe joint ) and lock

them tightly.

Refers to figure 2,install the

steam pipe and water return pipe

of the iron on the corresponding

wiring port(Steam pipe joint and

Water return pipe joint ) and lock

them tightly.

(Disclaimer: Hemway will not be responsible for any consequences arising from the

failure to operate as required.)

Figure 4

Water tank installation

As shown in Figure 3, use 4 M 4 x 8

screws to fix the fixing bar on the

upper back of the water tank,

paying attention to the installation

direction of the fixing bar.

As shown in Figure 4, use 4 M 4 x 16

screws to fix the water tank on the

equipment, and tighten the screws

to prevent loosening.

water level detector

signal line

Figure 3

10

9

Float switch

water level detector

steam return inlet

water inlet

Figure 6

Figure 5

As shown in Figure 5, install the

floating ball on the float switch and

tighten it, and keep the floating ball

facing down vertically.

As shown in Figure 6, after fixing the

water tank, install the water pipes

as shown in the figure, paying

attention to the exhaust gas return

pipe, the water pump inlet pipe,

and the water tank water level

detector signal line.

After the initial installation or disassembly for maintenance, you must keep the

water! in the state for 10 minutes before turning on the machine to prevent the

pump from being damaged by dry pumping!

Device pipeline installation

Connect the water inlet connector

to the water inlet main pipe.

Connect the drainage pipe to the

drainage main pipe.

Recommend Installation Method

Drainage Pipeline Standard

Device Quantity

three sets

five sets

ten sets

3/4”

1”

1.5”

Pipe

Recommend Material: 304 stainless steel pipe,Op-

tional Material: galvanized pipe, PPR pipe

Tip: Always use soft water and water

pressure limition: 1~3Kg/cm2

Put the water inlet tube into the inlet bucket.

Optional Installation Methods (Not Recommend)

When the workshop does not install the water pipe

Tighten the connection between the drainage pipe and drainage head of the equipment and put

it into the drainage container.

(Disclaimer: Hemway will not be responsible for any consequences arising from the

failure to operate as required.)

Drainage

container

Sewage pipe Blowdown head

line

draniage main pipe

Drainage pipe

inlet pipe

12

11

下

班

O

F

F

(

排

污

)

Control Pane

下

班

O

F

F

(

排

污

)

Control Pane

To Start Working

To Take A Rest

三、 OPERATATION GUIDE

please carefully check whether all parts had been installed in

place,make sure every joint is tightly locked .

To adjust the steam pressure, please press

“ ” or “ ”in the pressure setting area of

the control panel.

Turn the status switch to the ON position, the

corresponding indicator on the control panel

light up,and the system enter the working

state.

During the lunch break, turn the status

switch to the REST position, the correspond-

ing indicator on the control panel light

up,and the system enter the standby state.

NOTE

When Off Work

Mode A:

Mode B:

Switch to the OFF position two minutes in

advance to off work, and thesystem enters

the drainage status. Please ensure that the

drainage pipe is connected in the following

way before draining:

Mode A: please ensure that the drainage pipe

is firmly connected to the main drainage

pipe;

Mode B: please ensure that the drainage pipe

is firmly connected to the drainage head and

put the drainage pipe with drainage head

into the drainage container.

the drainage process takes about two minutes,during which time do

not switch off the power.

(When draining, will cause heavy airflow roar voice, it is normal

phenomenon)

NOTE

Main drainage pipe

Connect the main

drainage pipe.

Main drainage

pipe

Connect the drainage

head and put into the

drainage container.

四、 MAINTENANCE

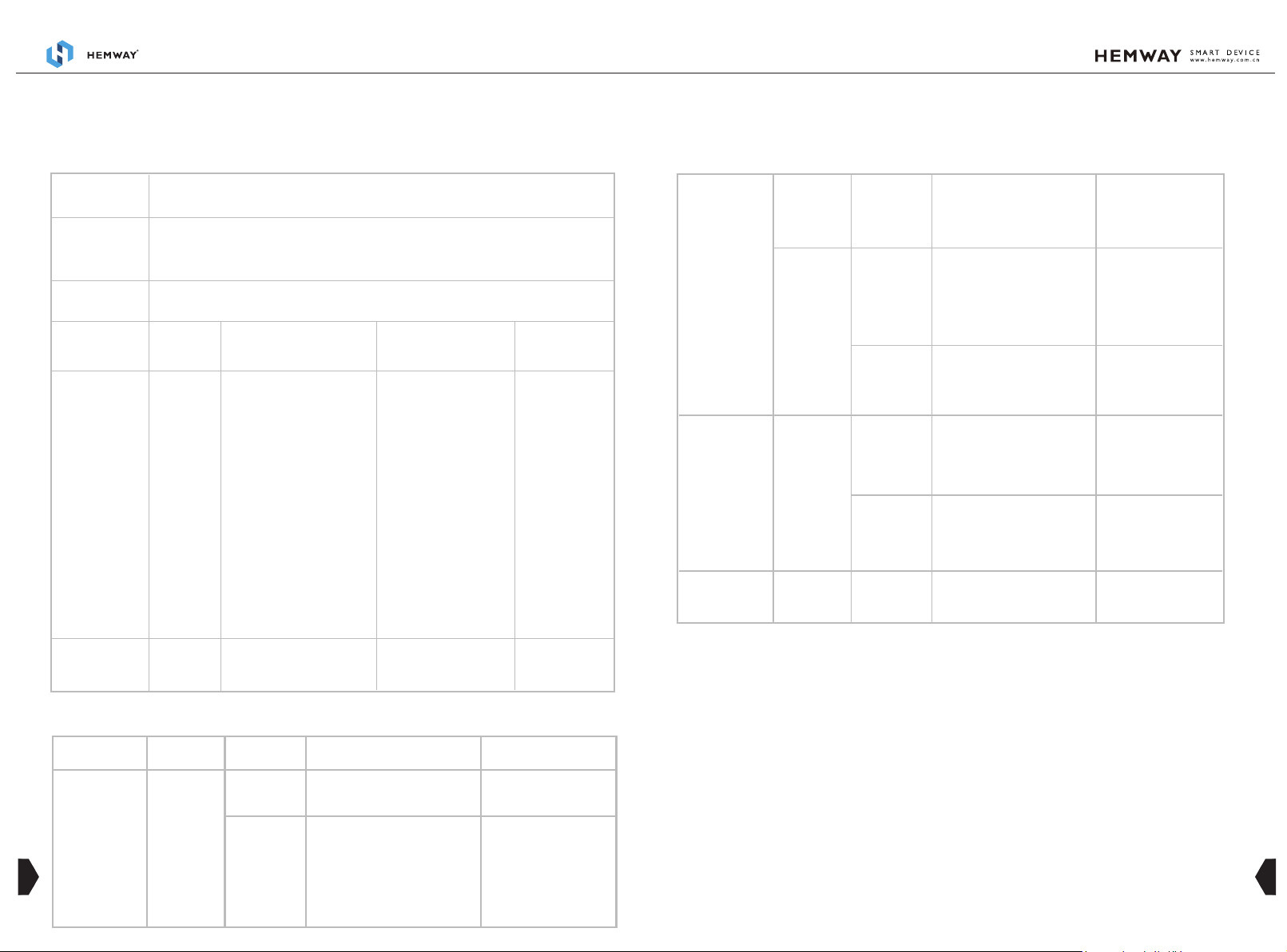

ITEM CONTENT FREQUENCY

draining after off work Daily

Monthly

Monthly

Monthly

Weekly

Every Six

month

Drainage

Drainage pipe

Deeply Descaling

Heat emission

Holes

Circuit

Water tank clean

check the drainage pipe joints, and tighten it with

wrench if there is any loose;check the drainage pipe

for blocking, clean the pipe in time to avoid affect-

ing the drainage.

Clean the residual scale in the boiler innerface, and

remove the water level detector and use sandpaper

to clean the scale on the surface;Clean the heater

and boiler innerface regularly (many scale accumu-

lates on the innerface of the heater used for a long

time, which will reduce energy efficiency and

increase power consumption. It is recommended to

replace it)

Check whether the short-cut protection circuit

function is normal, whether the short-cut protec-

tion circuit switch is loose, fire traces, use screw-

driver to tighten or replace it.

① Open the water tank cover to clean the water

tank.

② Please use soft water to reduce scale formation.

① Check the air outlet of the cooling fan regularly

for foreign matter and shielding (timely cleaning).

② Check regularly whether the cooling fan is

rotating normally (with or without wind power), and

maintain in time if any abnormality is found.

③ Clean the cooling fan filter regularly

14

13

1.Fault Code Analyses:

Fault code

Fault

phenomenon

Fault

character

Fault point

Handling

method

F02

五、 FAULT ANALYSIS AND TROUBLESHOOTING

Check and

confirm methods

Abnormal time for adding water and replenishing water (when the water is

added for more than 6 minutes and none stop, or when the water is replenished

for more than 4 minutes and is not replenished)

water adding system error

Water source

Check if water

is blocked

Water pump Two position three

way solenoid valve

Water tank

(equipment with

water tank)

①Check if the pump is

working normally (there is

slight vibration and sound

when working normally)Wa-

ter will come out of the

drainage pipe within 5

seconds after starting the

machine.

②When there is no

vibration, check whether the

pump power supply end

voltage is normal (DC24V),

normal means the water

pump is broken.

③No drain when vibration,

check whether the voltage

at the power supply end of

the pump is normal (DC24V),

otherwise the pump is

broken.

①Check if the voltage at

the power supply end of

two position three-way

solenoid valves is normal

(DC24V), which is

combined with crisp

sound under normal

circumstances.No sound

absorption means that

the water return valve is

broken.

②Under normal circum-

stances, suction but no

water, it means that the

pipeline or one-way

valve blocked.

Check if there is

water in the

water inlet tank

check water

source

Replace water pump

Clean the

blockage

Replace water retrun valve or

clean the

2.Other Fault Analysis:

Fault Phenomenon Fault Character Fault Point Check And Confirm Methods Handling Method

Iron serious spraying

water

Abnormal water

level control

Water level sensor

scale

After drain, disassemble the equipment

to check if the water level probe is

scaling

Clean water level probe

Main control board

damaged

After drain, check if the voltage between

the water level probe and the hardware

plate where the probe is located is

AC12±1v;After the equipment is filled

with water, check if the voltage between

the water level probe and the hardware

plate where the probe is located is

AC0±1V.

① Replace main control board

② Check the water level line

and water level grounding port

六、 AFTER SERVICE

If you have any quality problems or other problems after purchase Hemway products, please

contact the local distribut or hemway@hemway.com.cn for consultation.

To apply for a warranty must be in accordance with the below conditions:

1. Please operate the machine strictly according to the manual when it is first started up and

used.

2. Please use parts only from HEMWAY original.

3. Please refer to the warranty card for other terms.

The screen does not

display and the power

indicator does not light

Pressure setting failure

The equipment cannot

enter the descaling

state

Abnormal power

supply

failed to connect

control board or

display board

failure

Pressure setting

system abnormal

Descaling abnorma Abnormal power

supply plug of the

cleaner

Electric leakage

protection switch

Check whether the electric leakage

protection input voltage is normal; if the

voltage is normal, check the output

voltage; if there is no voltage at the

output end, then the electric leakage

protection switch is damaged.

Replace electric leakage switch

LED Display

obnormal

connection wire

Pressure setting key

Main control board

Firstly check the power LED indicator on

the back of LED display, if it is on, If it is

on, use a multimeter to observe the

voltage between the second and third

pins of the main control board and the

ground wire. Normally, the DC voltage

should be about 2V, and the AC voltage It

should also be around 2V.

Inspection method: Use a multimeter to

measure the voltage between the two

ends of the wiring to the ground. If the

voltage at both ends is not the same to

the ground, it should be problem.

Disconnect the power supply, open the

side cover of the device, press the

pressure setting key, and test the two

ends of the key with the multimeter.

Failure to connect means the key is

broken.

Disconnect the power supply, open the

side cover of the equipment, press the

pressure setting key, and test with

multimeter. If it is connected, the main

control board is broken.

Check if the power supply plug of the

cleaner is loose or not.

If the power LED indicator is off

or the voltage is abnormal,

replace the display board

replace connection wire

Replace the keys

Replace main control board

Tighten the plug

Table of contents

Other HEMWAY Iron manuals