TIREMAAX®EC HAND-HELD PROGRAMMING DEVICE OPERATION

3

L867A

HAND-HELD PROGRAMMING

DEVICE OPERATION

INTRODUCTION

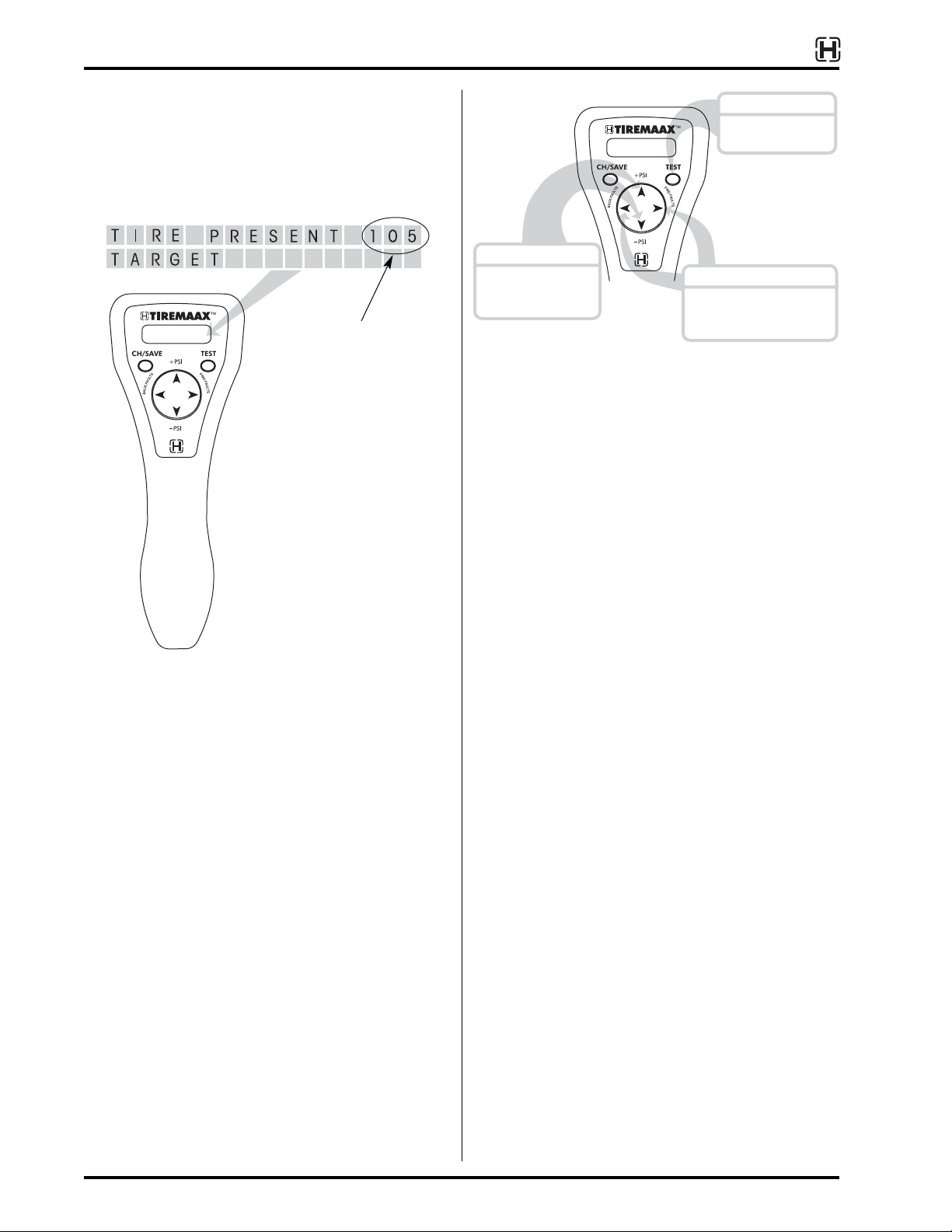

The optional hand-held programming device is used to:

• Program a target pressure setting other than the

factory preset value

• Run diagnostics

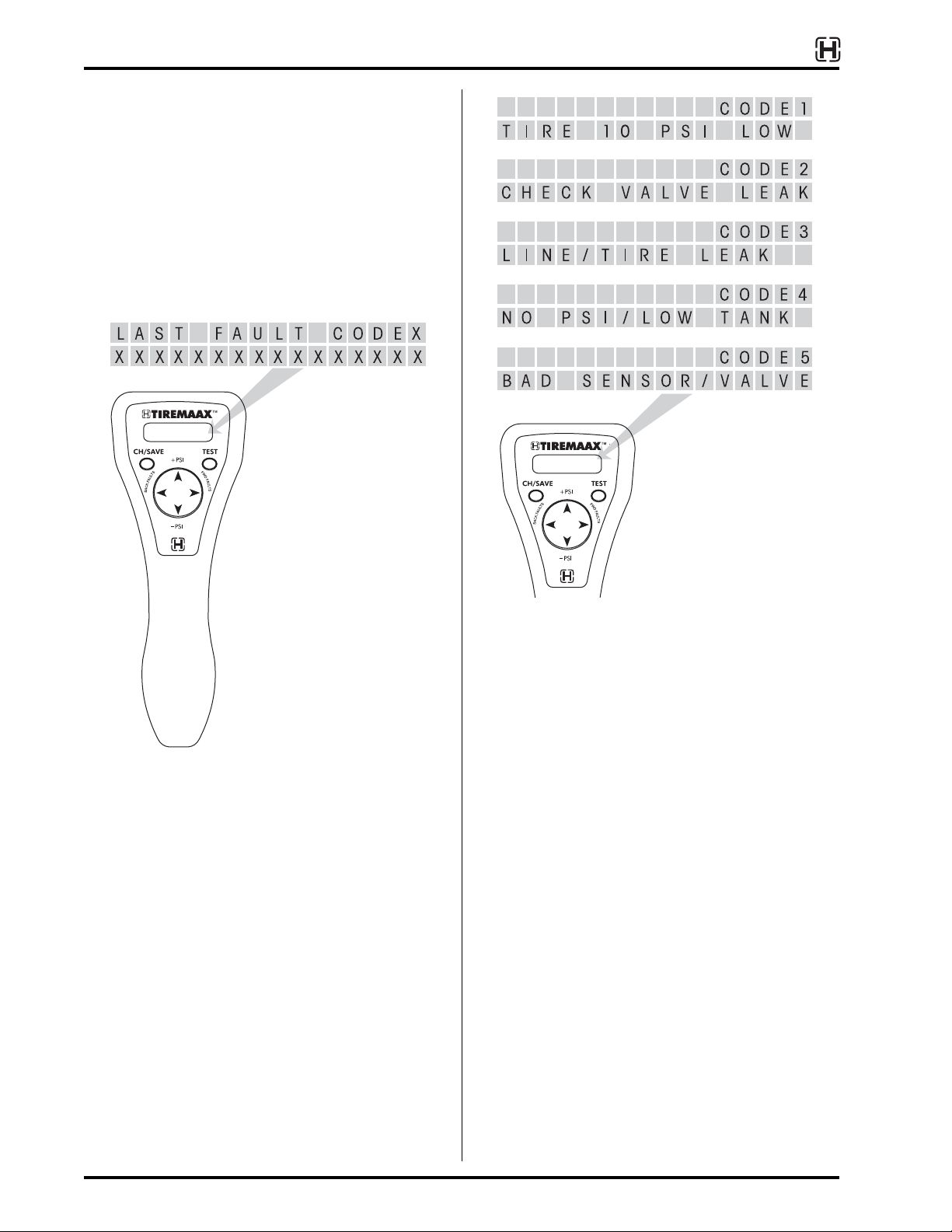

• Display fault code history

NOTE: The hand-held programming device is not

required to identify the fault that caused the

trailer mounted warning lamp to illuminate.

Before power is removed from the trailer, the

LED on the controller assembly will blink a

code associated with the fault that caused the

warning lamp to illuminate (refer to the blink

code descriptions in Hendrickson publication

L818,

TIREMAAX

®

Installation, Service and

Troubleshooting Procedures

for more details).

However if the blink code was not observed

before power was removed from the trailer, the

hand-held programming device will be needed

to reveal the last fault code stored before

power was removed.

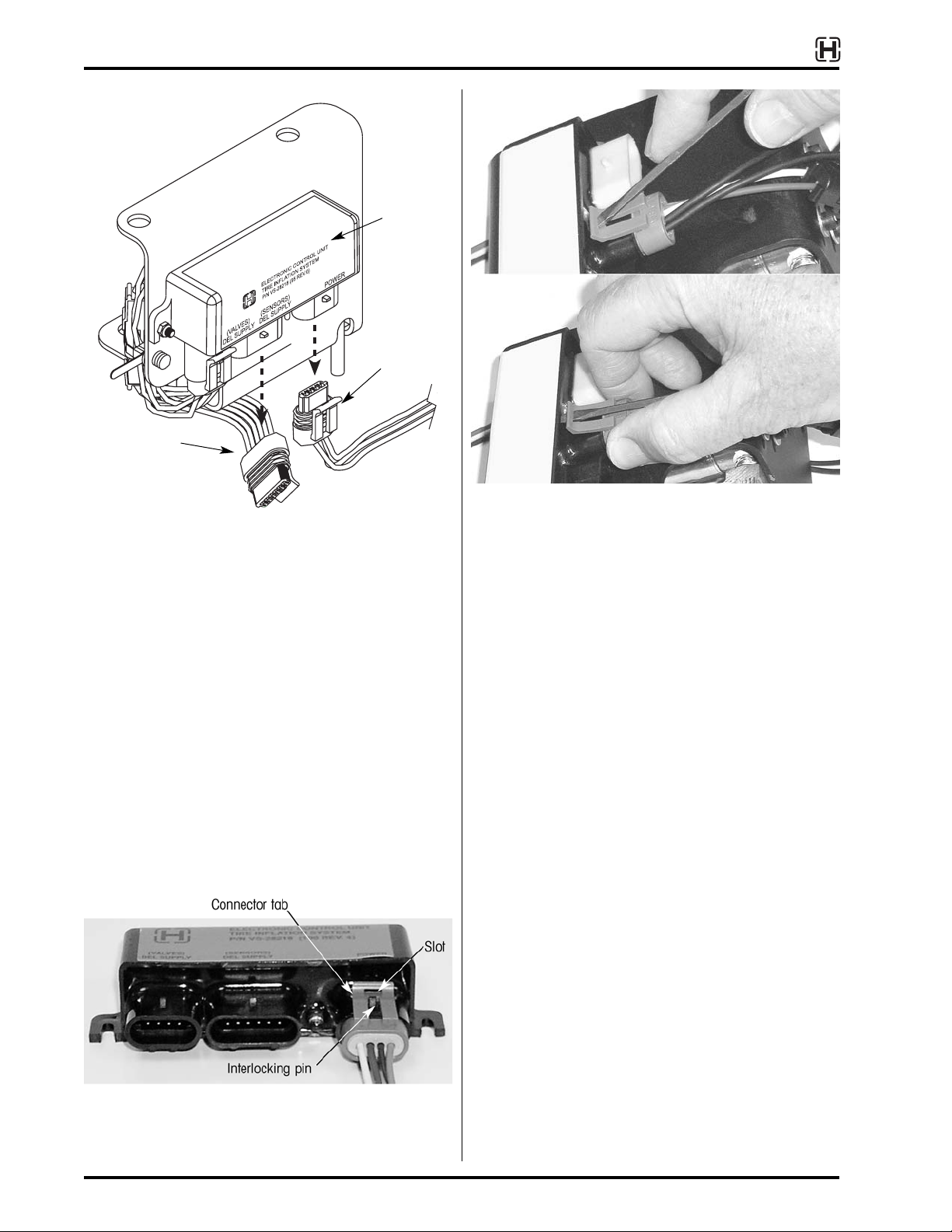

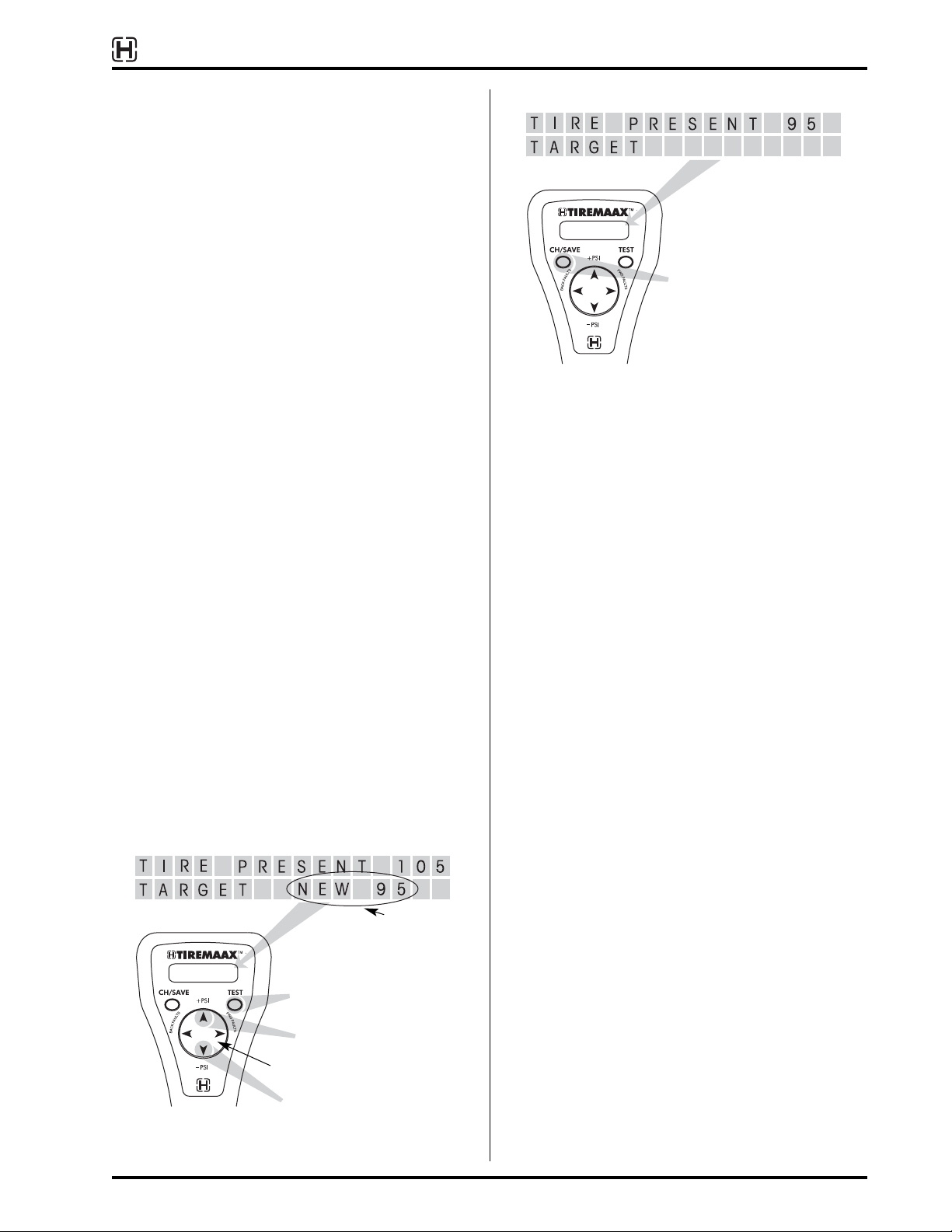

To use the hand-held programming device for any of

these tasks, it must first be connected to the

TIREMAAX®EC controller assembly, between the

pressure sensors and the ECU. When connected, the

hand-held programming device will be powered from

the trailer power circuit and is ready for use. No

additional power supplies or on / off switches are

required to use the hand-held programming device.

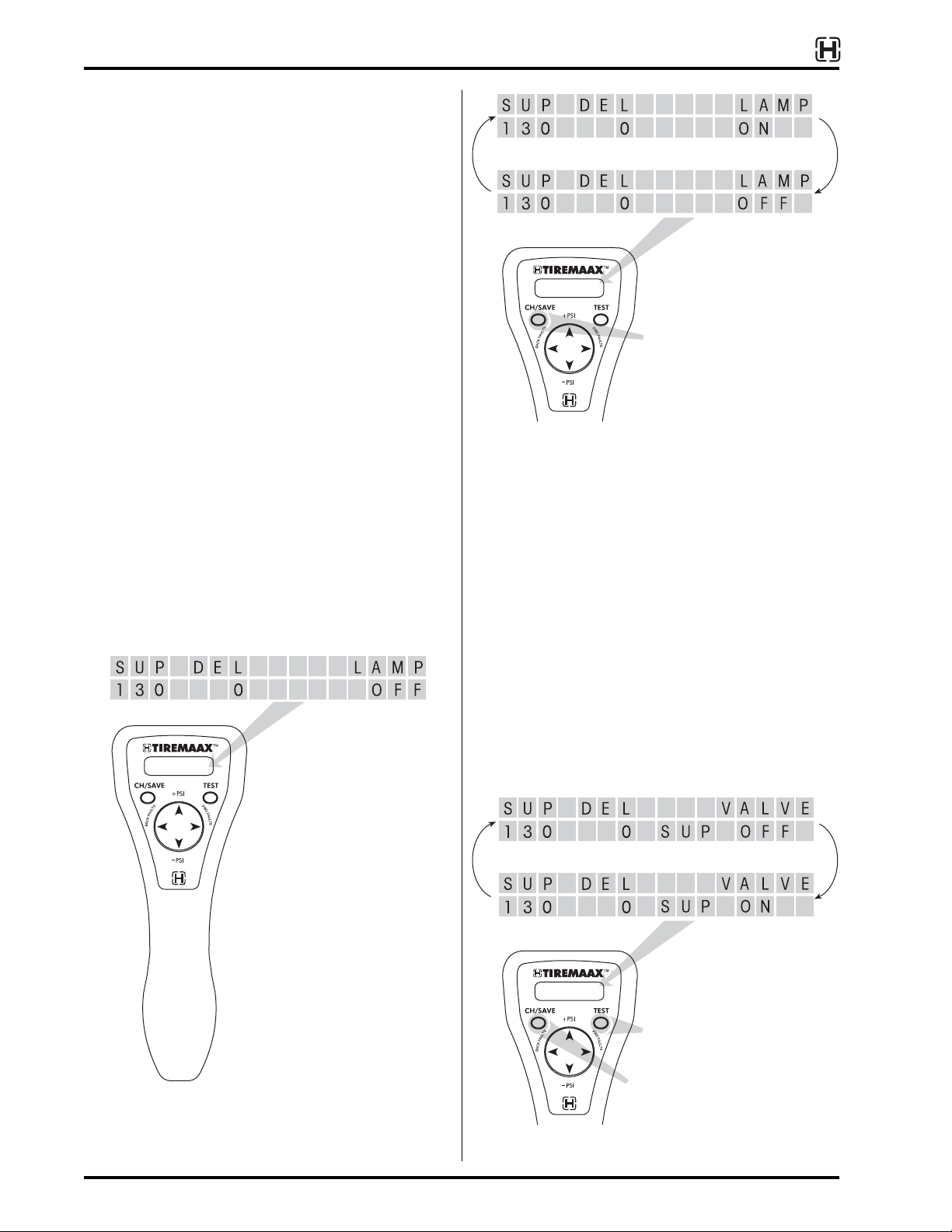

Use the following procedure to connect the hand-held

programming device to the controller assembly.

IMPORTANT: Do not vary the connection order from

what is presented in the following steps.

The last connection made must be the

four-pin trailer power cable into the

hand-held programming device.

HAND-HELD PROGRAMMING DEVICE

CONNECT PROCEDURE

1. Power the trailer.

The hand-held programming device derives

power from the trailer, so the trailer must be

powered for the hand-held programming device

to function.

NOTE: Do not plug the four-pin trailer power cable

into the hand held programming device at this

time. This connection must be the last one

made in order for the hand-held programming

device to properly enter the target pressure

setting mode.

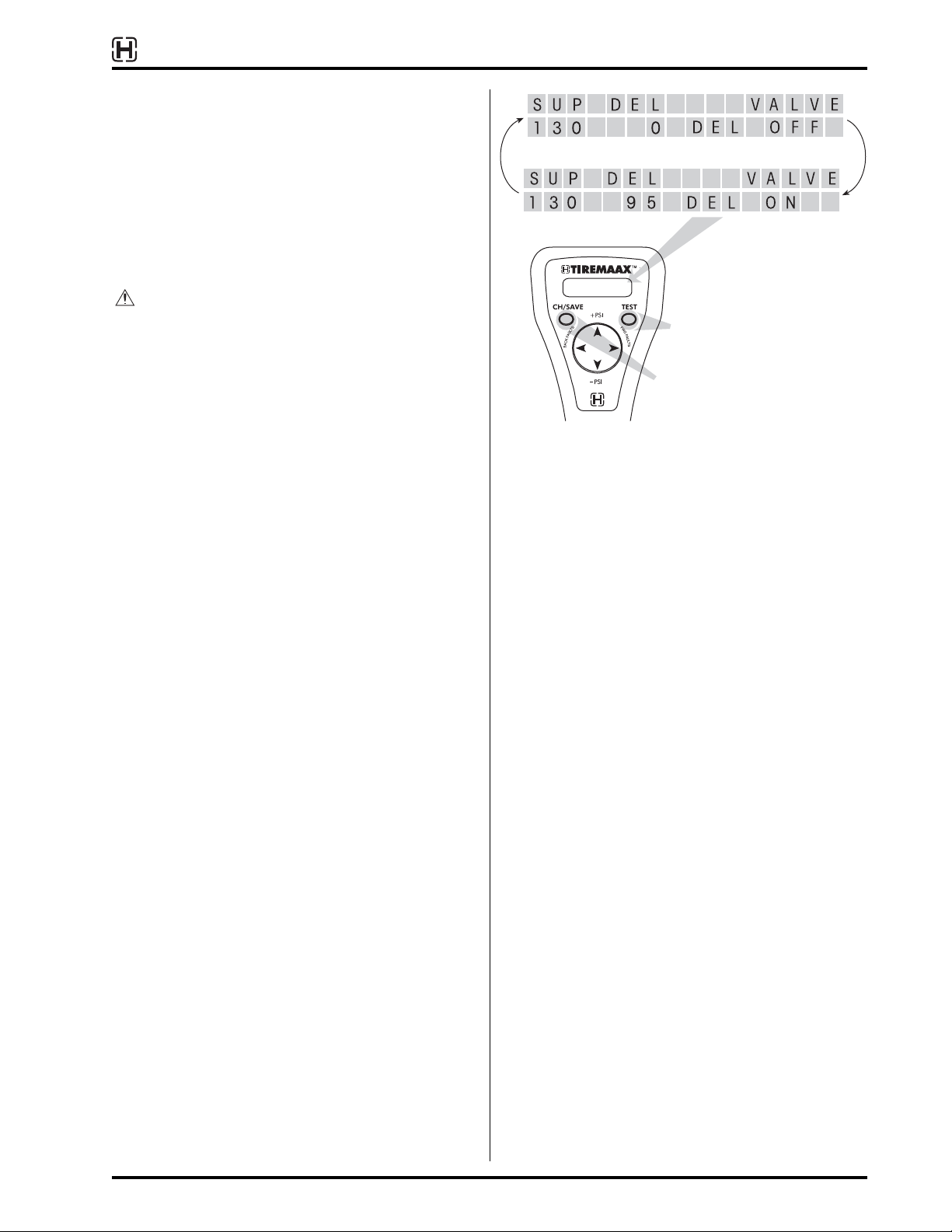

2. Pressurize the trailer air tank (optional).

If you wish to run the diagnostics to functionally

check the solenoid valves and pressure sensors,

the trailer must have enough air pressure (90

psi) to open the pressure protection valve on the

trailer air tank. If you do not wish to run the

diagnostics, this step can be skipped.

CAUTION: Potential overinflation hazard. When

performing diagnostics, the trailer air

tank pressure MUST NOT be higher

than the target pressure setting.

If the trailer air tank pressure is

higher, the tires will overinflate when

both supply and delivery solenoid

valves are opened at the same time.

No method exists to exhaust the

overinflated tires, other than

disconnecting the tire hoses and

manually depressing the valve stem

core at each tire.