Hengesbach LEVELTEC S Series User manual

Hengesbach GmbH & Co. KG · Schimmelbuschstr. 17 · 40699 Erkrath, Germany · Phone +49 (0) 21 04/30 32 0 · Fax +49 (0) 21 04/30 32 0 www.hengesbach.com

N-TI200-D-19 Page 1 / 4

Capacitive LEVELTEC Level Probe

Operation and Conguration

Capacitive LEVELTEC Level Probe

Operating Instructions

English

N - TI200

Version 1.0

Series LEVELTEC S

LEVELTEC L

LEVELTEC LR

Hengesbach GmbH & Co. KG · Schimmelbuschstr. 17 · 40699 Erkrath, Germany · Phone +49 (0) 21 04/30 32 0 · Fax +49 (0) 21 04/30 32 0 www.hengesbach.com

N-TI200-D-19 Page 2 / 4

Capacitive LEVELTEC Level Probe

Operation and Conguration

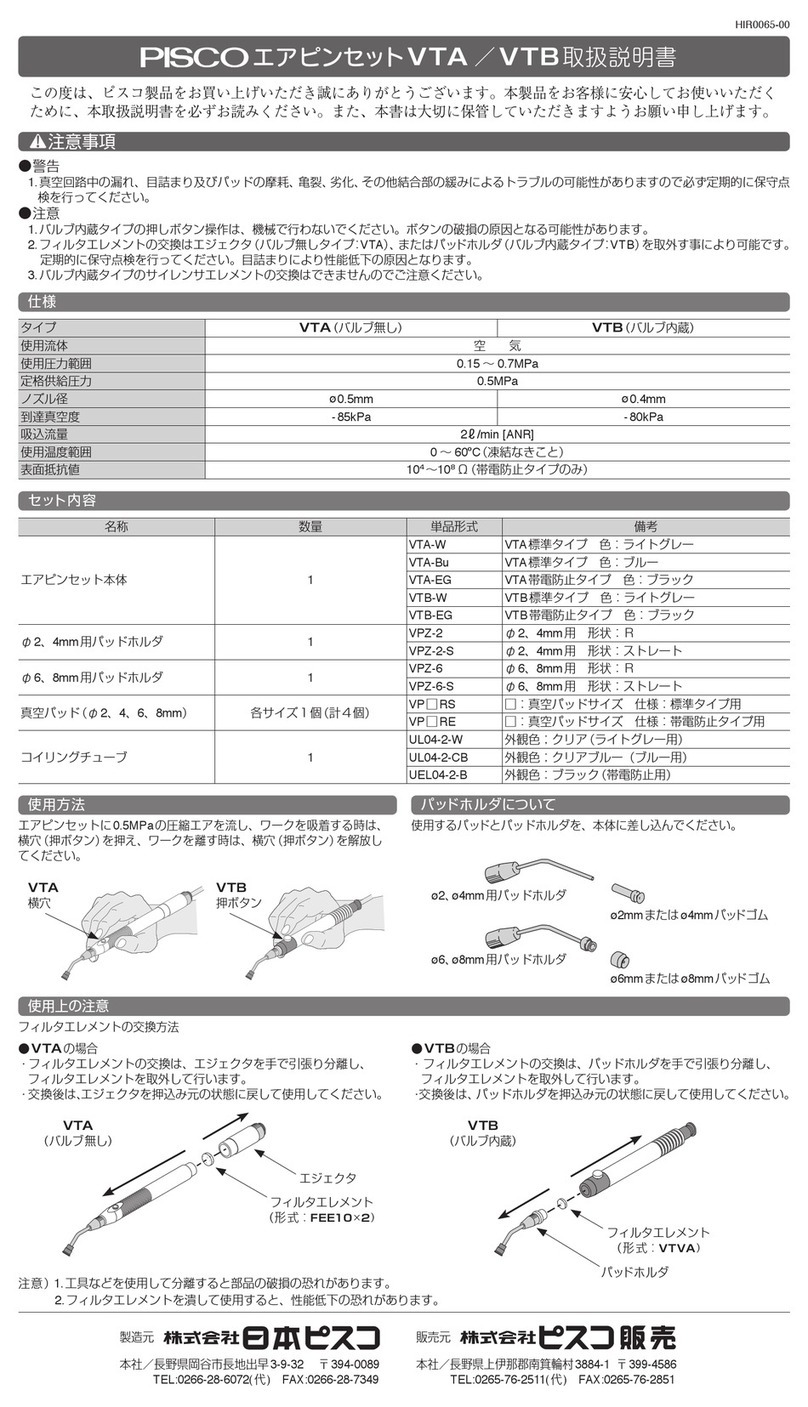

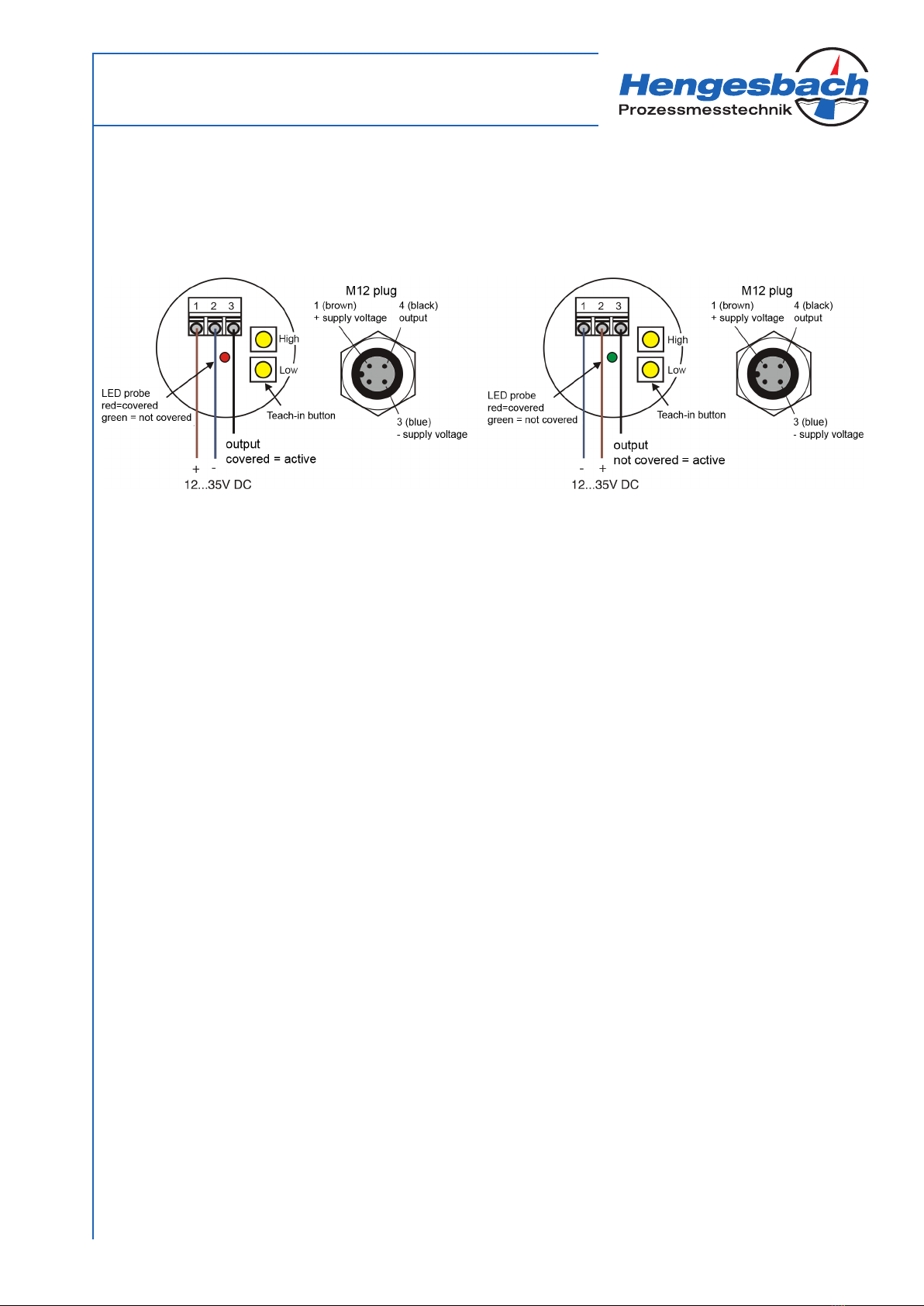

1 Connection

2 Sensitivity Matching for Models LEVELTEC

Using Teach-in Key

The factory setting of the capacitive Leveltec level probe is a DC value of about ɛ 25 to

reliably detect uids with a water content of 20% or more.

For the following media / applications we recommend, however, to adjust the sensitivity

level:

• media with a very low DC value (e.g., fruit juice concentrates, sugar solutions,

edible oils, or other uids with little or no water content);

• viscous or adhesive media; or

• if the factory setting fails to achieve reliable switching behaviour.

.

Press the teach-in buttons to optimally adjust the sensitivity of the Leveltec level

probe to your application!

ELECTRIC CONNECTION

Full level indication Empty level indication

Hengesbach GmbH & Co. KG · Schimmelbuschstr. 17 · 40699 Erkrath, Germany · Phone +49 (0) 21 04/30 32 0 · Fax +49 (0) 21 04/30 32 0 www.hengesbach.com

N-TI200-D-19 Page 3 / 4

Capacitive LEVELTEC Level Probe

Operation and Conguration

3 Sensitivity Adjustment Using Teach-in Key

Please follow these instruction for successful teach-in:

3.1 Teach-in with installed level probe

1. Make sure that the coupling part (PEEK) of the installed level probe is fully covered

by the medium to be detected.

2. The level probe’s supply voltage is connected.

3. Press the teach-in button "High" and keep it pressed for about 3 seconds.

4. Teach-in is completed and the LED probe should now light up red (i.e., the sensor

is covered).

5. The sensitivity setting is retained even after the supply voltage is switched o and

can be repeated at any time as described above.

3.2 Teach-in with uninstalled level probe

1. Get a container lled with the medium to be detected (100ml or more).

2. Turn a hygienic weld-in lug (e.g., TEM1FTP16) towards the level probe.

3. Connect the level probe to the supply voltage (12–35VDC).

4. Dip the tip of the level probe into the medium until the front of the weld-in lug is

completely covered by the medium.

5. Press the teach-in button "High" (when submerged) and keep it pressed for about

3 seconds.

6. Teach-in is completed and the LED probe should light up in red when submerged

and in green when not submerged.

7. The sensitivity setting is retained even after the supply voltage is switched o and

can be

repeated at any time as described above.

3.3 Teach-in the switch-o status

The switch-o status can be set with the additional Teach-in "Low" button.

1. Make sure that the probe tip comes into full contact with the medium. If the LED

does not light up red, then rst follow the instructions of chapter 3.1. resp. 3.2.

2. Afterwards, make sure that the probe tip is not covered by the medium to be de

tected. Now there should only be a few buildups on the probe tip.

3. If the LED is green, no further setting is required.

4. If the LED lights up red, press the Teach-in button "Low" and hold it down for ap

prox. 3 seconds

5. The Teach-in "Low" has been carried out. The LED should light up green.

6. The sensitivity setting is retained even after the supply voltage is switched o and

can be repeated at any time according to this scheme.

The device must not be used in hazardous areas.

Hengesbach GmbH & Co. KG · Schimmelbuschstr. 17 · 40699 Erkrath, Germany · Phone +49 (0) 21 04/30 32 0 · Fax +49 (0) 21 04/30 32 0 www.hengesbach.com

N-TI200-D-19 Page 4 / 4

Capacitive LEVELTEC Level Probe

Operation and Conguration

TECHNICAL DATA

General details

Device type/measuring principle LEVELTEC / capacitive for detection of liquid media

Output

Output signal active, 50mA max. (PNP), short-circuit-proof

Switching function Full/empty level indication specied by polarity of the auxiliary voltage, constant indication by 2-colour

LED

Time delay 0.1 s non-adjustable

Electronics

Version Standard version, set to a dielectric constant (DC value), factory setting ε=25

Parametrised by pressing on teach-in key „HIGH“ (3...4 seconds) in the device, probe must be

covered

Auxiliary energy resources

Supply voltage 12...36 V DC, max. 45 mA (bei 24 V DC) without switching load

Immunity to interference CE-conformity is fullled

Conditions of use

Installation position see installation instructions

Setting Press and hold teach-in „HIGH“ key for approx. 3 seconds; probe must be covered when settings are

created

Press teach-in key “LOW” for approx. 3 seconds. Probe should be covered by adhesives.

Medium temperature -20...+100°C, short duration 140°C for max. 30 min

Ambient storage temperature -20...+65°C

Max. operating pressure 10bar (with TEM1FTP16 weld-in socket)

Protection class acc. to EN60529 IP 67 and IP 69K with M12-plug and mating plug

Construction

Electrical connection M16x1.5 cable screw connection – nickel-plated brass, or

M12x1 plug-in connector, nickel-plated brass (stainless steel available on request)

Tightening torque max. 5-10Nm (during initial assembly)

Process connection - G1/2“ with elastomer-free sealing cone (TP16)

Materials - Field housing / lid: CrNiSt 1.4301 (304)

- Housing seal: FKM

- Process connection/extension tube: CrNiSt 1.4305

- Messspitze: PEEK

Accessories

Process connection adapter see ordering information

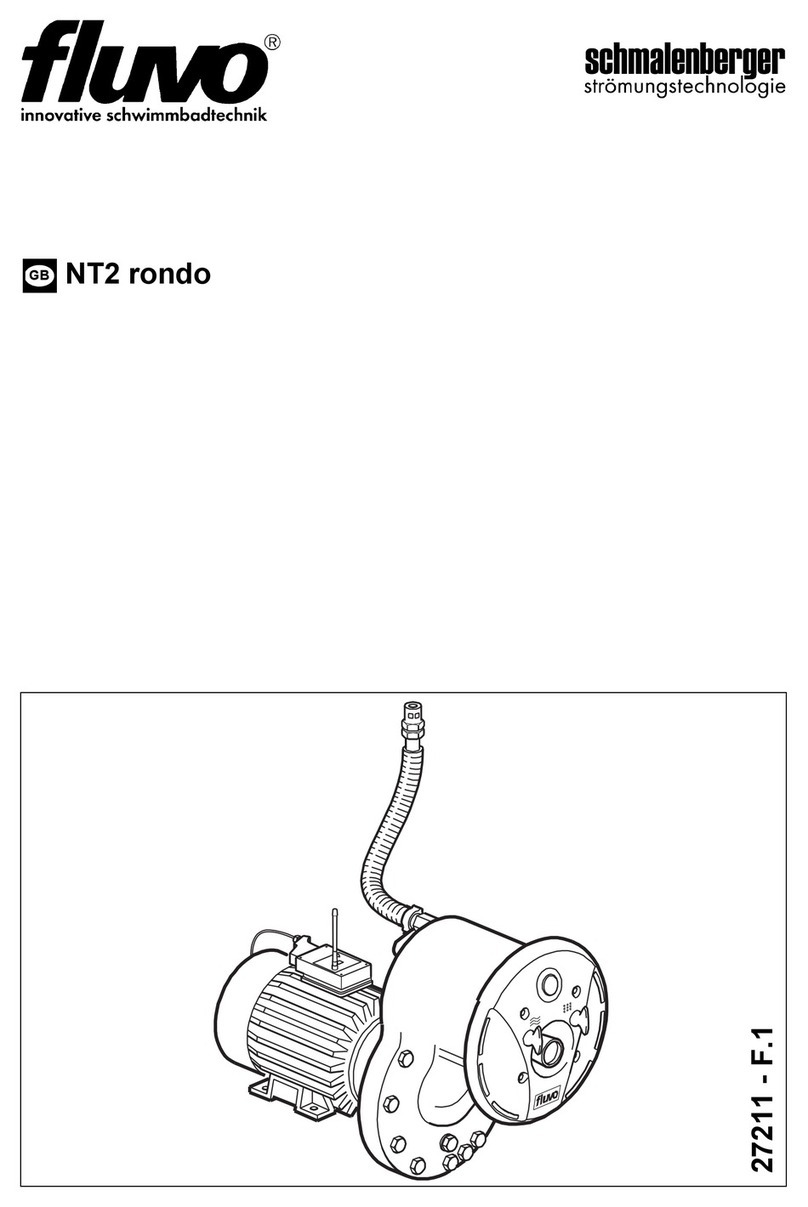

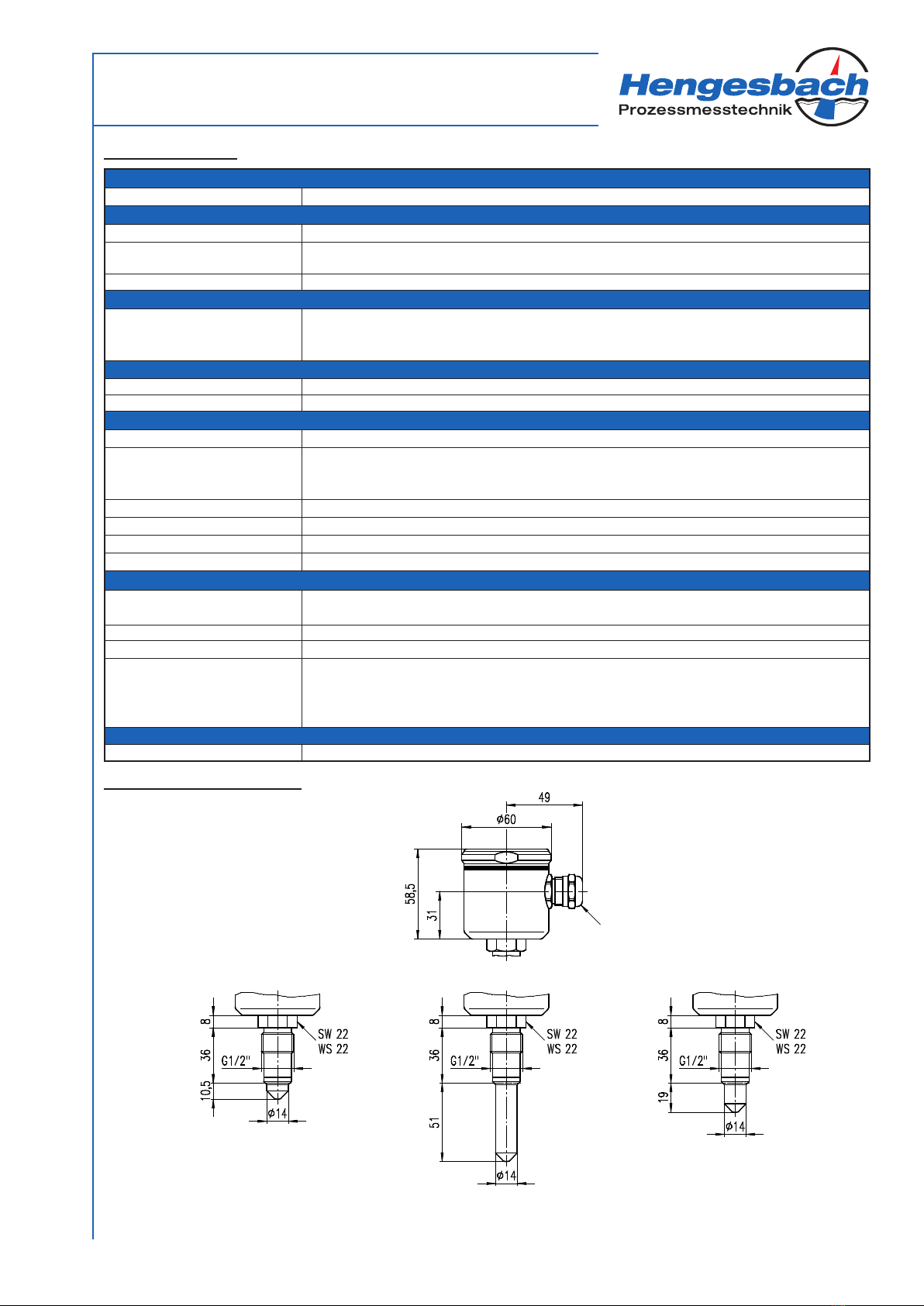

DIMENSIONAL DRAWINGS (dimensions in mm)

Z-TEM4FTP16

Einschweißmuffe

für Rohr

welding socket

for pipe

M16x1,5

(M12-Stecker /

M12 circular connector)

LEVELTEC LLEVELTEC S

Z-NAM1FTP16

Adaptermuffe L

adapter socket L

Z-TMN...FTP16

Kegelstutzen DIN 11851

conical nozzle DIN 11851

DN25, DN40, DN50

Z-TVA6LTP16

VARIVENT-Flansch Ø68

mit Leckagebohrungen

VARIVENT-flange Ø68

with leakage holes

Z-TVA6FTP16

VARIVENT-Flansch Ø68

VARIVENT-flange Ø68

Z-TEM1LTP16

Einschweißmuffe

mit Leckagebohrungen

welding socket

with leakage holes

Z-TEM1FTP16

Einschweißmuffe

für Tank

welding socket

for tank

REFERENZZEICHNUNGEN / REFERENCE DRAWINGS

(Maße in Millimeter /dimensions in millimetres)

LEVELTEC LR

Z-TCL4FTP16

Clamp DIN 32676

DN25-40

Prozessanschlussadapter:

(weitere Ausführungen auf Anfrage)

adapters for process connections:

(other constructions on request)

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIMATIC NET SCALANCE M874 operating instructions

probst

probst VZ-I operating instructions

Würth

Würth 0713 922 100 operating instructions

ABB

ABB HT843233 Operation manual

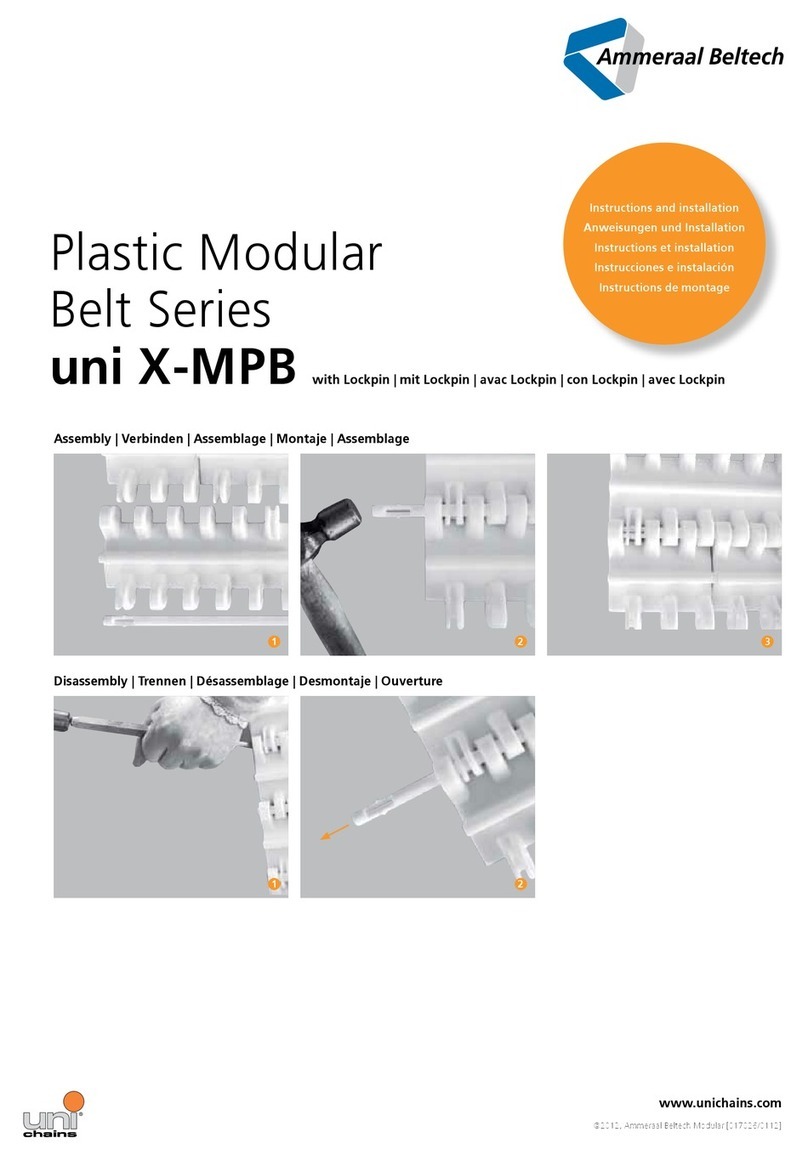

Ammeraal Beltech

Ammeraal Beltech uni chains uni X-MPB Series Instructions and installation

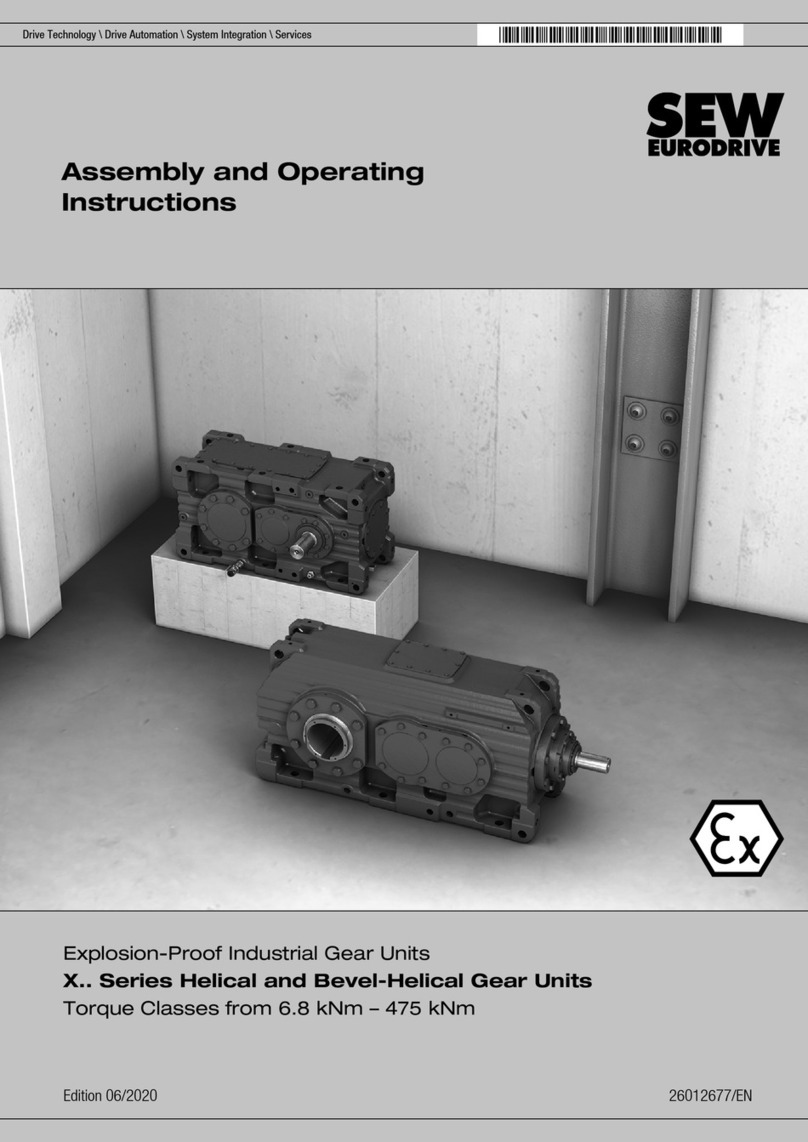

SEW-Eurodrive

SEW-Eurodrive X Series Assembly and operating instructions