CONTENTS

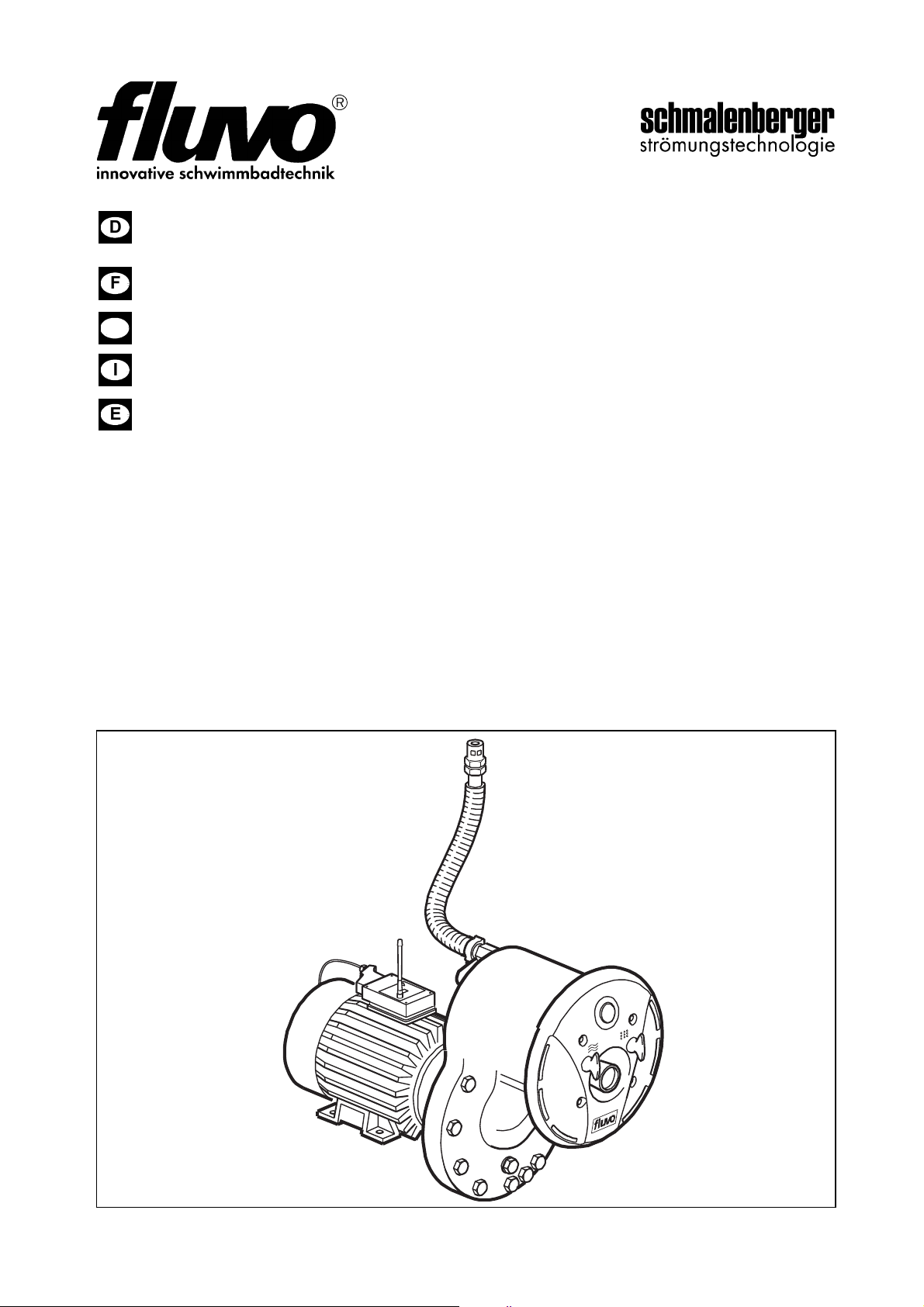

2NT2 rondo

Version:27211 - F

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

Contents

1General.................................................................................................3

2Safety Instructions..............................................................................3

3Unit Description / General Technical Data........................................5

4Installation Site Specifications / Installation....................................8

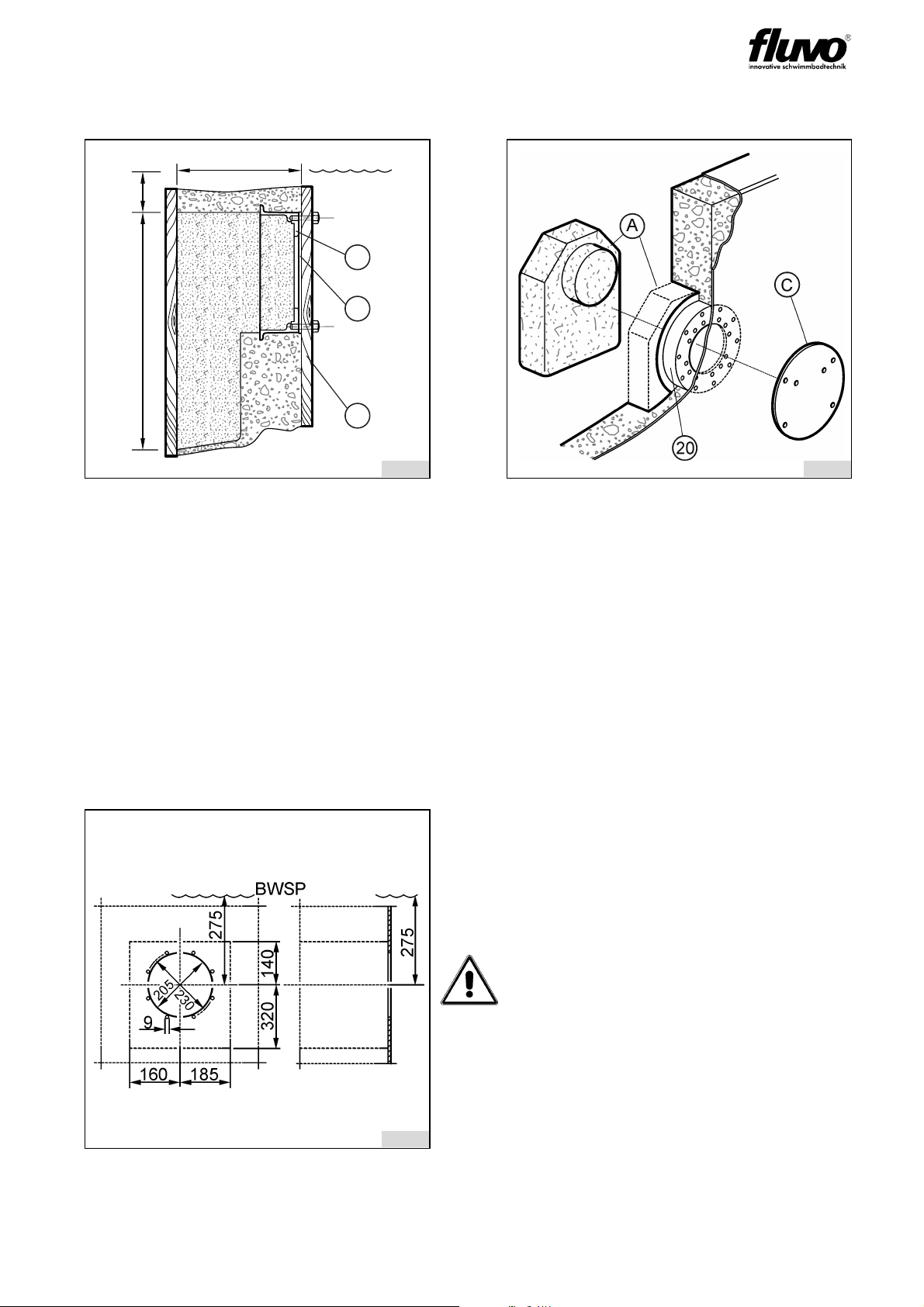

4.1 Planning the pump pit .......................................................................................................8

4.2 Installation Preparations / Concrete pool ..........................................................................9

4.3 Installation Preparations / Pre-fabricated pool ..................................................................9

4.4 Installation Preparations / Wood-liner pool .......................................................................10

4.5 Pump kit Installation / Concrete-tile pool ..........................................................................10

4.6 Pump kit Installation / Concrete-liner pool ........................................................................11

4.7 Installation kit and Pump kit Installation / Pre-fabricated pool ..........................................11

4.8 Installation kit and Pump kit Installation / Wood-liner pool ................................................12

4.9 Non-return air valve Installation .......................................................................................13

4.10 Installation of the face plate assembly - general ...............................................................13

5Electrical Connections .......................................................................16

5.1 Electrical Connections - general........................................................................................16

5.2 Electrical connections three-phase current........................................................................17

5.3 Electrical connections AC..................................................................................................17

6Start-up / Operating ............................................................................18

7Shutdown / Overwintering..................................................................20

7.1 Empty the pool .................................................................................................................20

7.2 Face plate assembly overwintering ...................................................................................20

7.3 Emptying the pump ........................................................................................................20

8Maintenance / Repairs........................................................................21

8.1 General Instructions...........................................................................................................21

8.2 Maintenance / Service .......................................................................................................21

8.3 Repairs ..............................................................................................................................21

9Spare parts ..........................................................................................21

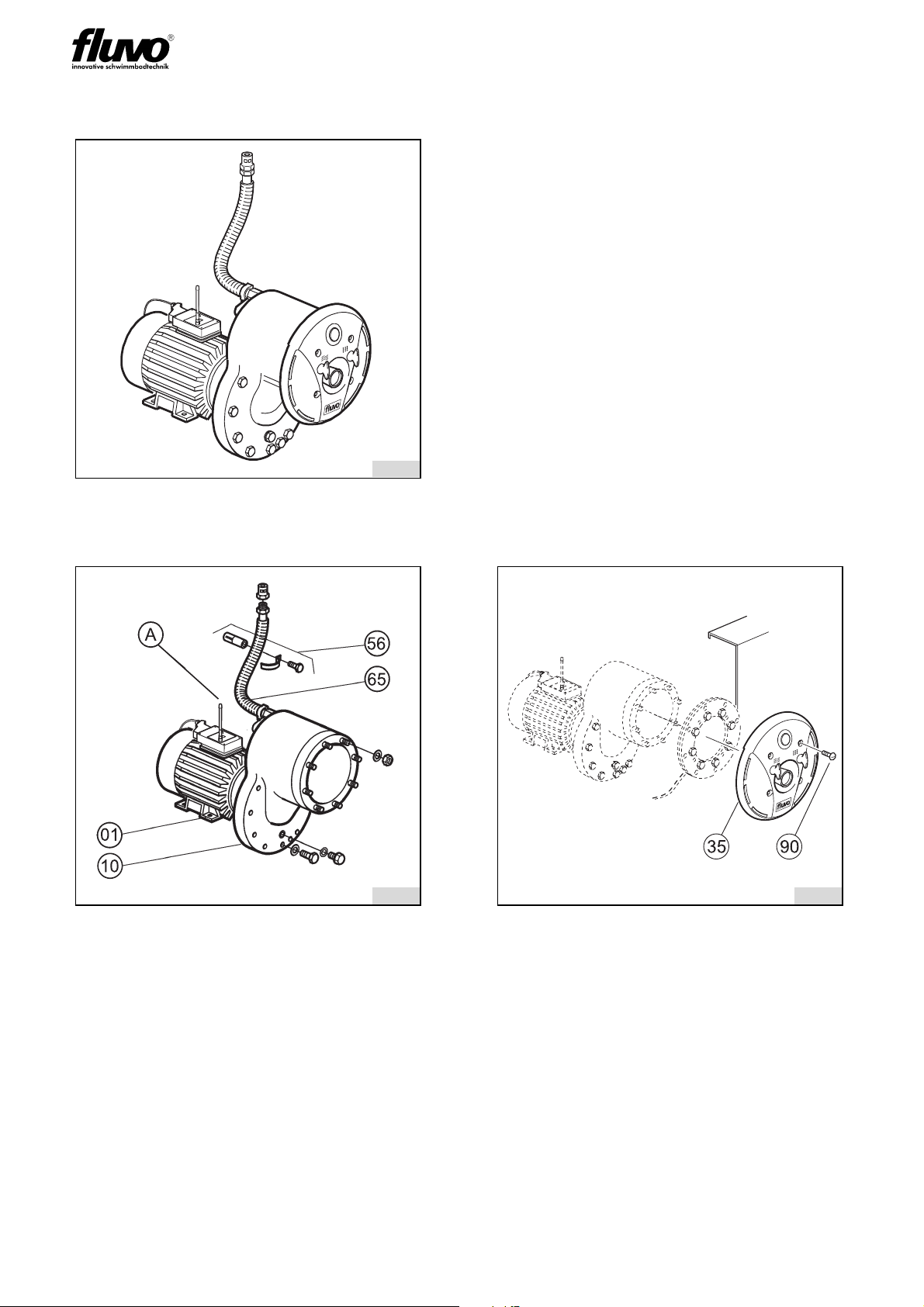

10 Spare parts list an drawing..............................................................22

10.1 Spare parts list.................................................................................................................22

10.2 Drawing............................................................................................................................26