Thompson YBX3 Series User manual

www.thompsonelectricindustries.com

CATÁLOGO

MANUAL INSTRUCTION

YBX3 SERIES

THREE PHASE EXPLOSION - PROOF

INDUCTION MOTOR

1.- OUTLINES .............. ..............................................................................................................

2.- INSTRUCTION OF PRODUCT TYPE AND NAME .........................................................

3.- APPLICABLE SCOPE AND CONDITIONS ..........................................................................

4.- THE ELECTRIC MOTOR MAIN SPECIFICATION AND INSTALLMENT

STRUCTURAL STYLE........................................................................................................................

5.- THE MAIN STRUCTURE SUMMARIZES ............................................................................

6.- EXPLOSION - PROOF MAIN POINT ...................................................................................

7.- INSTALL AND USE .....................................................................................................................

8.- MAINTAINS ...................................................................................................................................

www.thompsonelectricindustries.com

CONTENTS

3

3

4

4

6

7

8

10

1. Outlines

YBX3 series 3-phase explosion-proof induction motor are made according to

electrical apparatus for explosive gas atmospheres-part 1: General

requirements>and<Electrical apparatus for explosive gas atmospheres-part2:

Flameproof enclosure “d”>.Explosion-proof mark includes dⅠ,dⅡAT4, dⅡBT4, dⅡ

CT4. Motors can be used with the electrical apparatus for atmosphere including CH4

or dust or the explosive gas atmosphere(dⅠ)under the coal mine or be used as

general power equipment for the atmosphere including ignitable gas Class A and B,

kind of T1 to T4, or the mixture with stream and air. Administer criterion is

JB/T7565.1-2004 and MT451-1995.

Remarks: The series product efficiency level attain GB 18613-2006 《Minimum

allowable values of energy efficiency and the energy efficiency grades for small and

medium three-phase asynchronous motors》of minimum allowable values of energy

efficiency, belong to grade 3.

2. Instruction of product type and name

Y B X3 160 L - 4 - W

Environment code

F1- indoor medium corrosion type

F2- indoor high corrosion type

WF1- outdoor medium corrosion type

WF2- outdoor high corrosion type

TH- humid tropical

TA- dry tropical

G- Plateau

Pole

Length (S-short, M-medium, L-long)

Frame (Centre Height

High Efficiency(3-the 3rd design)

Explosion-proof

Induction motor

3

3. Applicable scope and conditions

3.1 Applicable common ignitable gas, steam rank, temperature, see table 1.

Table 1

Class T1 T2 T3 T4

I

Methane,

Ammonia, Acetic

acid

Butanol,

Acetic anhydride Cyclohexane /

IIA

Ethane, Propane,

Acetone, Styrene,

Benzene,

Toluene, Carbon

monoxide

Ethane, Ethanol,

Propylene, Butyl

acetate, Amyl

acetate, Chlorine b

Tong, Ethyl

acetate, Methanol

Pentane, Ethane,

Kwai alkanes,

Octane, Kwai

alkanes, Gasoline

Ethyl ether, Acetic

acid

IIB City gas, Coke

oven gas

Epoxy ethane, 1.3

a butadiene,

Ethylene

Dimethyl ether,

Hydrogen sulfide

Ethyl methyl, Diethyl

ether,

Tetrachloroethylene

IIC Chlorine water

gas, Chlorine Acetylene / /

Remark: application conditions are under the mine and the main gas is CH4 with the “d I”

mark.

3.2 Working conditions

Environment air temperature changes along with season, but does not exceed 35℃(under

mine)or 50℃(for factory).The lowest temperature is -15℃

3.2.2 The altitude above sea level is below 1000m.

3.2.3 The maximum relative air humidity does not surpass 95% when the temperature is 25℃

under the mine or the temperature does not surpass 25℃in the wettest month for factory

when the maximum relative air humidity does not surpass 90% in the same month.

3.2.4 The rated voltage is 380V, 660V, 380/660V. Other voltage is available.

3.2.5 The rate frequency is 50Hz. 60Hz is available.

3.2.6 The electric motor can work continuously and be started with rated voltage.

3.2.7 The insulation of the electric motor is class and the temperature rising cannot surpass

80K.The value gap is 1.

4

4. The electric motor main specification and installment structural style.

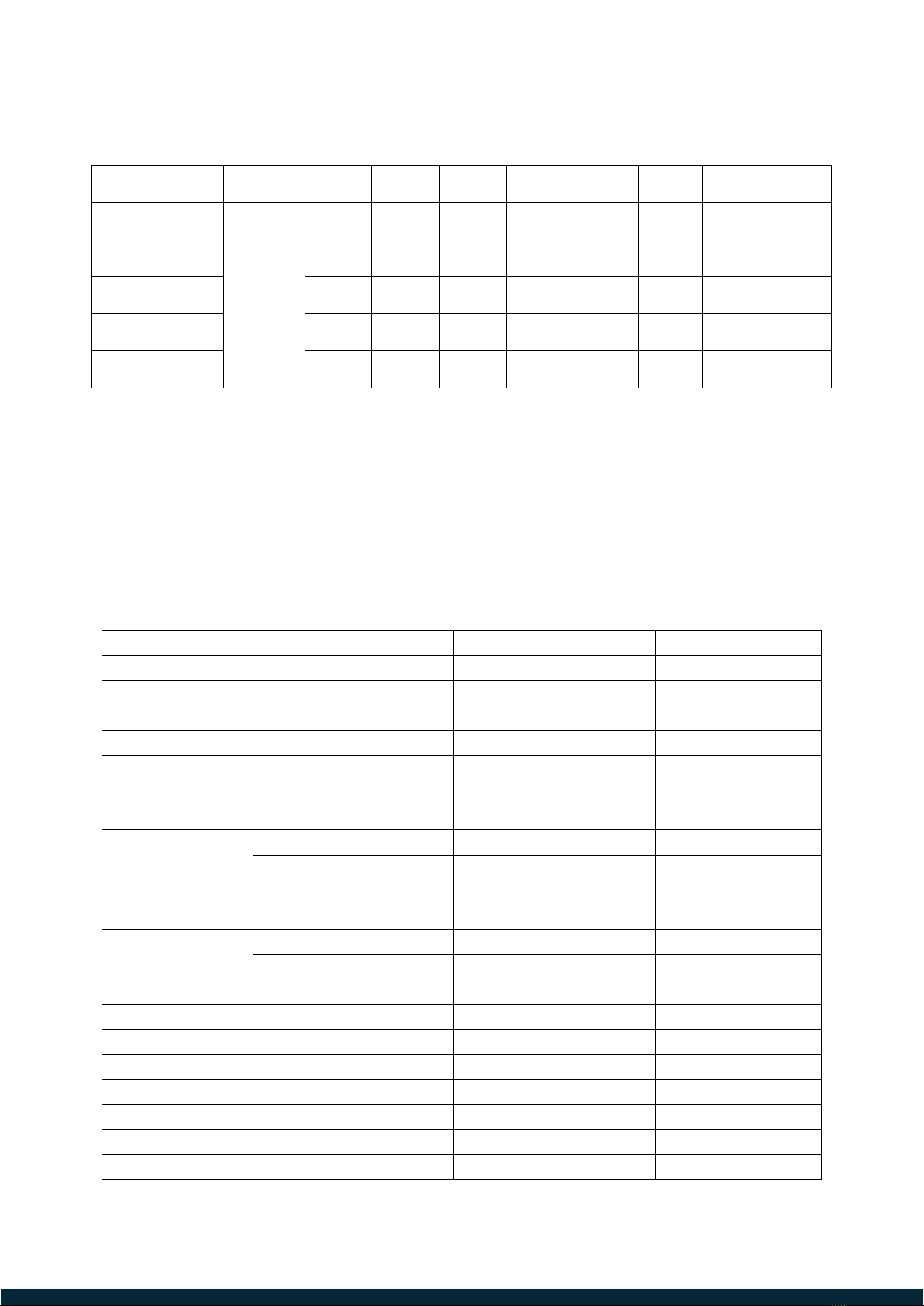

4.1 This series electric motor main specification, please look at Table 2

Table 2

Frame No

Asynchronous speed r/min

3600 1800 1200 900 720

Power

80M1

0.75

0.55

0.37

0.18

-

80MM2

1.1

0.75

0.55

0.25

-

90S

1.5

1.1

0.75

0.37

-

90L

2.2

1.5

1.1

0.55

-

100L1

3

2.2

1.5

0.75

-

100L2

3

1.1

-

112M

4

4

2.2

1.5

-

132S1

5.5

5.5 3 2.2

-

132S2

7.5

-

132M1

-

7.5

4

3

-

132M2

-

5.5

-

160M1

11

11 7.5

4

-

160M2

15

5.5

-

160L

18.5

15

11

7.5

-

180M

22

18.5

-

-

-

180L

-

22

15

11

-

200L1

30

30

18.5

15

-

200L2

37

22

-

225S

-

37

-

18.5

-

225M

45

45

30

22

-

250M

55

55

37

30

-

280S

75

75

45

37

-

280M

90

90

55

45

-

315S

110

110

75

55

-

315M

132

132

90

75

55

315L1

160

160

110

90

75

315L2

200

200

132

110

90

355S1

(185)

(185)

160 132 (90)

355S2

(200)

(200)

355M1

(220)

(220)

(185)

160

110

355M2

250

250

185

132

355L1

(280)

(280)

220

185

160

355L2

315

315

250

200

(185)

Remark: 1 and 2 after S M and L means the different power in the same frame No. The power

in the parenthesis is not commendatory.

5

4.2 This series electric motor main specification please looks at Table 3

Table 3

Frame No Structure and installment code number (IM)

80-112 B3、B5、B6、B7、B8、B14、B34、B35、V1、V3、V5、V6、V15、

V18、V36

132-160 B3、B5、B6、B7、B8、B35、V1、V3、V5、V6、V15、V36

180-280 B3、B5、B35、V1

315-355 B3、B35、V1

5. The main structure summarizes

5.1 The terminal box is on the top of this series motor, which can be rotated in four directions.

It is suitable to the rubber cable or the steel pipe wiring. The terminal box can have 3 or 6

power lines and one earth line, and the cable gland size can be M10 or two M16.

5.2 The motor frame no above 250 can be greased continually and for the motor frame 180 to

250, can be same when the customer wants.

5.3 The series electric motor main body structure, please look at drawing No 1. The

connecting box structure, please look at drawing No 2.

Drawing No 1.

1-Sealing ring 2-End cover 3-Bearing 4-Junction box 5-Stator 6-Rotor 7-Grounding card

8-Wave spring 9-Fan cover 10-Fan

6

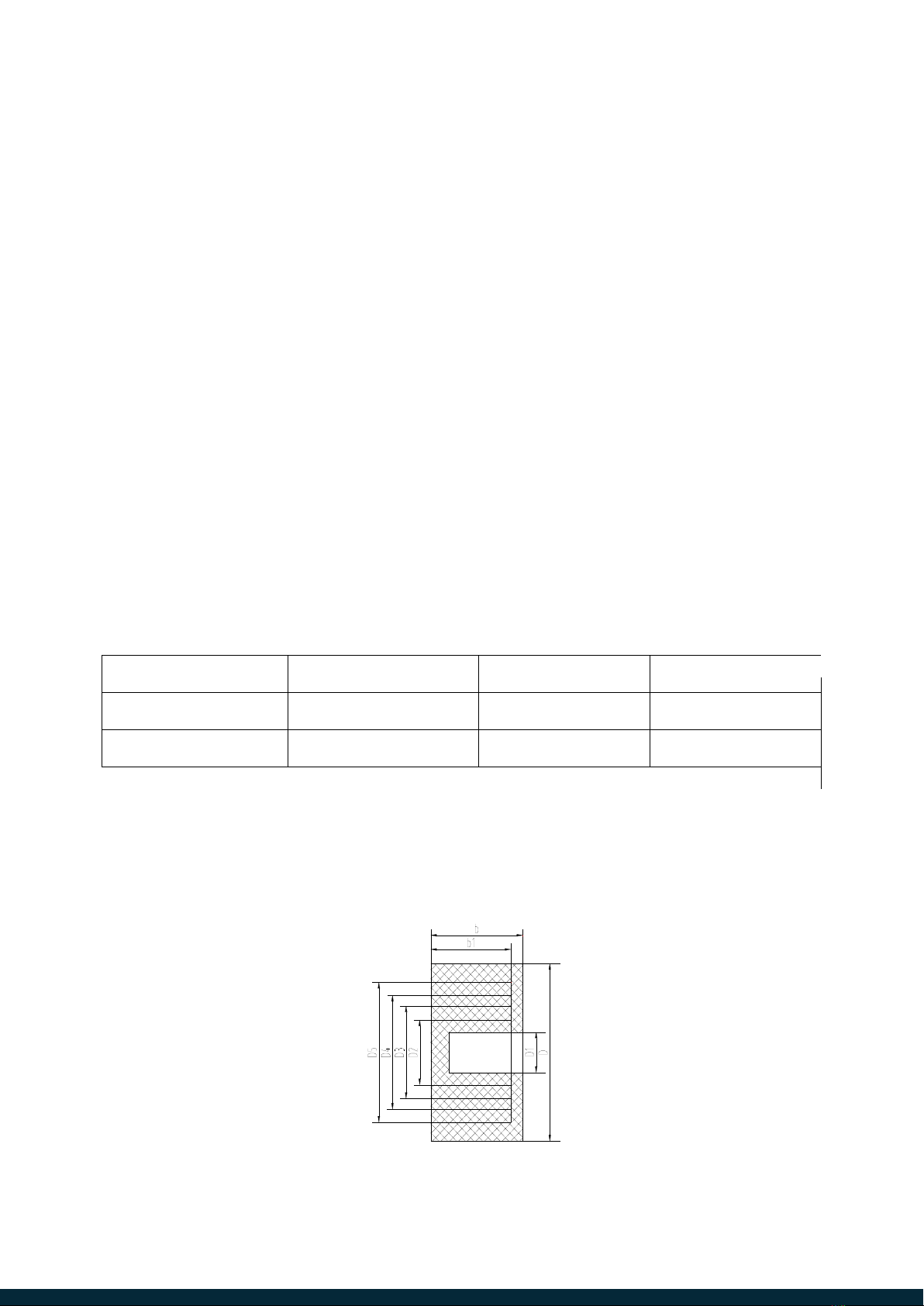

Drawing No 2.

Frame No.

A

B

C

1

2

3

4

YBX3 80

~

112

169

169

116

M8×25

M5

M8×25

M5

YBX3 132

~

180

202

202

116

M10×30

M6

M10×30

M6

YBX3 200

~

225

235

235

148

M12×30

M8

M12×45

M8

YBX3 250

~

280

310

310

168

M12×40

M10

M12×50

M10

YBX3 315

~

355

360

360

200

M12×40

M16

M16×60

M16

5.4 The connection of the motor which power is equal to or less than 3KW is star for the rated

is 380V and the others are delta.

Conn. Y Conn. ΔConn. Y/Δ

6. Explosion—proof main point

6.1 The series electric motor is explosion-proof motor , the outer covering of the motor should

not damage or distorted causing tothe failing to explosion-proof , and the other explosive gas

should not explode by the fire through the junction plane for the explosion-proof after the inner

gas explode . For:

a. The parts of the motor covering, example the end cover, bearing inside cap, terminal

7

box lid, terminal box base, should pass the hydraulic pressure lest, with the pressure is

1.0MPa and lasted 1 minute.

b. The length of the junction plane for explosion-proof, the gap, the surface roughness, the

electric gas between the exposed conductors, between the exposed conductor and the

metal covering ,and the creeping distance ,please look at the drawing No.1、2.

c. There are spring washers under the bolts connect the outer covering parts, which can

prevent the bolts loosing.

d. The stator housing, end cover, the inner bearing cap, the terminal box, the terminal

block, the shaft, and the oil seal is the parts for the explosion–proof.

6.2 Under the worst status, the temperature of the surface of the motor should not surpass

+135℃. The factory should use the motor according to table 4.

Table 4

Type of explosive admixture T1 T2 T3 T4

Allowed temp rising of the surface (℃) 450 300 200 135

7. Install and use

7.1 Preparative before to install

7.1.1. The wrapping is good or not should be checked up before it open.

7.1.2. The dust and the anticorrosive things should be eliminated the motor are installed.

7.1.3. The steps should be done before install the motor.

a. There are a mark and a card number of explosion-proof with the motor. Please check

if it fulfillsthe demand of the using environment.

b. The bolts connecting the outer covering parts should not loose.

c. The parts of outer covering should have not crackled or disfigurements.

d. The grease must be enough, and the tools for grease are good.

e. The insulation resistance should not be lower than 0.38 MΩwhen the rated voltage is

380V and should not be lower than 0.66MΩwhen the rated voltage is 660V.

7.2 The electric motor uses the elastic shaft coupling transmission; the center of the motor

8

shaft and center of the drive machine must maintain consistently otherwise can cause the

bearing damage.

7.3 The connection between the motor and power.

7.3.1. The outer diameter of the power cable must tally with seal, which material is rubber

XH-21. The difference between both outer diameters should not be bigger than 1mm, when

the cable gland is fixed, there should be no clearance between the cables and between the

seal and terminal box otherwise will lose the explosion-proof performance.

7.3.2. The cable should be fixed between two bows gaskets, the attention core burr is

prominent, and should be fixed closely by blocks and the gaskets.

7.3.3. The motor with six terminal bolts can be used with two voltages by 2 different

connections. When just 1 cable gland is used, another metal washer, which thickness is 2mm,

should not be removed. Otherwise the explosion-proof performance will be losing.

7.3.4. The order of the 3 phase of the power should be same as the motor cable. The

rotation should be clockwise.

Table 5

Phase sequence A B C

Head U1 V1 W1

Tail U2 V2 W2

7.3.5. Other earth bolt should connect with the ground.

7.3.6. After connected correctly, the motor should run with no load, if there is no problem, it

can run with load.

7.3.7. Terminal-box Seal Dimensions (MM)

9

8. Maintains

8.1. The motor should be clear and check termly. There should no dust in the surface,

spraying to the motor with the water cock is not allowed.

8.2. The temperature of the bearing should not surpass +95℃, the bearings must be

degreased in 2500 hours at least, change the lubrication if it is not good. Before changing it,

the bearing cap, the lubrication cup and wasted lubrication must be cleaned with gasoline, the

quantity should reach the 1/2 of the bearing house for 2 poles, 2/3 for 4 poles.

Table 6

Frame No.

Number of poles

Drive end

Non driving end

80

all

180204

180204

90

all

180205

180205

100

all

180206

180206

112

all

180206

180206

132

all

180208

180208

160

2P

180209

180209

4

~

8P

180309

180209

180

2P

211ZV

211ZV

4

~

8P

311ZV

211ZV

200

2P

212ZV

212ZV

4

~

8P

312ZV

212ZV

225

2P

312ZV

312ZV

4

~

8P

313ZV

312ZV

250

2P

313ZV

313ZV

4

~

8P

314ZV

313ZV

280

2P

314ZV

314ZV

4

~

8P

317ZV

314ZV

315

2P

M-316Z1

M316Z1

4

~

10P

M-2319Z1

M-319Z1

355

2P

319-ZV2

319-ZV2

4

~

10P

2322

322-ZV2

Frame Inlet D D1 D2 D3 D4 D5 b b1

80~112

Rubber

cable

φ420

-0.062

φ14 φ20

φ25 — — 25

24

132~180 φ580

-0.74

φ26 φ31 φ35 26

200~225 φ720

-0.74 φ20 φ26 φ32 φ38 φ42 32 30

250~280 φ900

-0.87

φ25 φ31 φ36 φ45 φ50 38 36

315~355 φ1050

-0.5 φ40 φ46 φ51 φ57 φ64 45 42

10

8.3. The explosion-proof surface should be paid attention when the motor Disassembles and

assembled, there is no outer bearing cap in the motor frame No. from 80 to 160. the bearings

was fixed by the bearing ring. Disassembling the electric motor, we should disassemble the V

bearing ring, then the front end-shield, the fan cover, the bolt of the hinder end-shield, remove

the hinder end-shield from the rotor, assembling the motor, we should do in reverse.

8.4. Motor affected with damp, must undertake the drying process, the drying furnace or the

short circuit current method. In the process of drying, winding temperature rise should be

increased gradually, and not more than 155 ℃. Short circuit current method when dry, the

motor is under the short circuit state, the input current tothe 0.6~0.8 times of the rated

current for appropriate, serious damp motor is not easy to use DC electric drying, so as to

avoid electrolysis.

8.5. Replacing the winding, the technical data should be got from the company, if not, the

motor always work not so well, even burn out.

11

Thompson Electric Industries

343 Sn 183 Terrale

Pembroke Pines,

Miami Fl 33029

Email: sales@thompsonelectricindustries.com

www.thompsonelectricindustries.com

Table of contents