henke sass wolf EPIG User manual

1

User Manual: EPIG®

Contents

1. About this User Manual................................................................................................................... 4

2. Transport and storage ..................................................................................................................... 4

3. General safety advice for operating and cleaning........................................................................... 4

4. General description and information.............................................................................................. 5

4.1. Description .............................................................................................................................. 5

4.2. Packaging contents.................................................................................................................. 5

4.3. Operating requirements.......................................................................................................... 5

4.4. Target species.......................................................................................................................... 5

4.5. Mode of action ........................................................................................................................ 5

5. Bottle connection / disconnection .................................................................................................. 7

6. Device Start ..................................................................................................................................... 8

7. User Menu....................................................................................................................................... 9

8. Sensors .......................................................................................................................................... 11

8.1. Position Sensor...................................................................................................................... 11

8.2. Air Detection Sensor.............................................................................................................. 11

8.3. Nozzle Sensor ........................................................................................................................ 11

EN - EPIG User manual 2

2

9. Vaccination Process....................................................................................................................... 11

10 Device Cleaning ......................................................................................................................... 13

10.1 Rinsing ................................................................................................................................... 13

10.2 Cleaning of the device ........................................................................................................... 14

11. Maintenance and Repair ........................................................................................................... 14

11.1. Cylinder Service ................................................................................................................. 14

11.2. Maintenance and repair service........................................................................................ 16

12. Dismantling................................................................................................................................ 18

13. The battery and the charger...................................................................................................... 19

14. Troubleshooting ........................................................................................................................ 21

15. Technical Specifications............................................................................................................. 22

16. Disposal ..................................................................................................................................... 22

17. EC declaration............................................................................................................................ 23

EN - EPIG User manual 3

3

EPIG® User Manual

This user manual is part of the EPIG® injector and an important part of the safe usage concept.

- Read the user manual carefully and follow the instructions -

© copyright · Henke-Sass, Wolf GmbH · 8300052134 – 10/20 · Subject to amendments in technology and design ·Printed in Germany

The EPIG® injector is manufactured by:

Henke-Sass, Wolf GmbH

Keltenstrasse 1

78532 Tuttlingen

Germany

Tel. +49 74 62 94 66 207

Fax +49 74 62 94 66 52 08

www.henkesasswolf.de

E-mail: [email protected]

EN - EPIG User manual 4

4

1. About this User Manual

While reading the user manual you will see that it includes warning signs, to alert you

to risks arising from incorrect usage of the product that could result in death, injuries

or material damage. Always take careful note of these warnings! The warning signs are

highlighted as shown on the right.

2. Transport and storage

Protect the product against external forces (e.g. impacts, shocks and knocks) during transport

Check the EPIG® injector for any transport damage before use.

Transport and/or store the EPIG® injector in its original packing.

Store the EPIG® injector so that it is protected from sunlight.

Do not store the batteries at temperatures lower than 5°C.

Never store the EPIG® injector in a wet or damp condition (e.g. directly after cleaning).

3. General safety advice for operating and cleaning

Direct contact between the vaccine and/or rinsing fluid and the eyes and/or respiratory tract of

the operator can be harmful. In these cases, seek immediate medical advice and show the vaccine

information sheet.

Use the EPIG® device for vaccinating pigs around weaning until the end of nursery only (max. 10

weeks of age) with aqueous vaccines.

Keep children out of the operating area.

Do not point the EPIG® device towards any part of your body or towards other people! In case of

accidental injection of vaccine and/or rinsing fluid, seek immediate medical advice and show the

vaccine information sheet.

Beware of the spike in the bottle holder. It may contain residues of the vaccine and/or rinsing

fluid. In case of a spike wound, seek immediate medical advice and show the vaccine information

sheet.

Do not operate the safety cylinder around the injection heads with your hand when starting,

vaccinating or cleaning.

If the safety cylinders are pressed when fingers or any other part of the body are in front of the

injection heads, there is a danger of accidental self-injection with vaccine or rinsing fluid. Seek

immediate medical advice and show the vaccine information sheet.

Wear safety goggles and a mask when using the EPIG® device. Ensure goggles are clean for optimal

vision.

Wear rubber gloves when cleaning the EPIG® device.

Do not throw the battery into water. Protect the battery from water and humidity, which could

cause it to leak and release hazardous substances.

Do not throw the battery into fire, nor heat the battery. It may explode and/or release hazardous

substances.

Do not expose the battery to temperatures higher than 60°C. It may explode and/or release

hazardous substances.

Only veterinary practitioners or operators instructed by a veterinary practitioner are permitted to

work with the EPIG® device and vaccines.

Dropping the device while it is loaded with liquid may cause an unintended release.

EN - EPIG User manual 5

5

To prevent leakage, reduce the pressure inside the bottles by piercing them with a sterile needle

prior to mounting a bottle on the device. Hold the EPIG® device upside down when mounting a

new bottle.

Releasing the trigger of the EPIG® device will immediately switch off all controls, making it

impossible to give an injection.

When expelling residual vaccine or rinsing fluid from the device, always position the injection

nozzles on a cloth in a receptacle placed on a firm base. Never inject into the air.

If the safety cylinders remain jammed around the injection nozzles after firing, immediately

release the trigger of the EPIG® device and contact your supplier.

Operating the EPIG® device for a longer period of time may induce cramps in the operator’s hands.

Regular breaks are recommended.

4. General description and information

4.1. Description

EPIG® is intended for the needle-free intra-muscular vaccination of piglets with either 1ml or 2ml

volume.

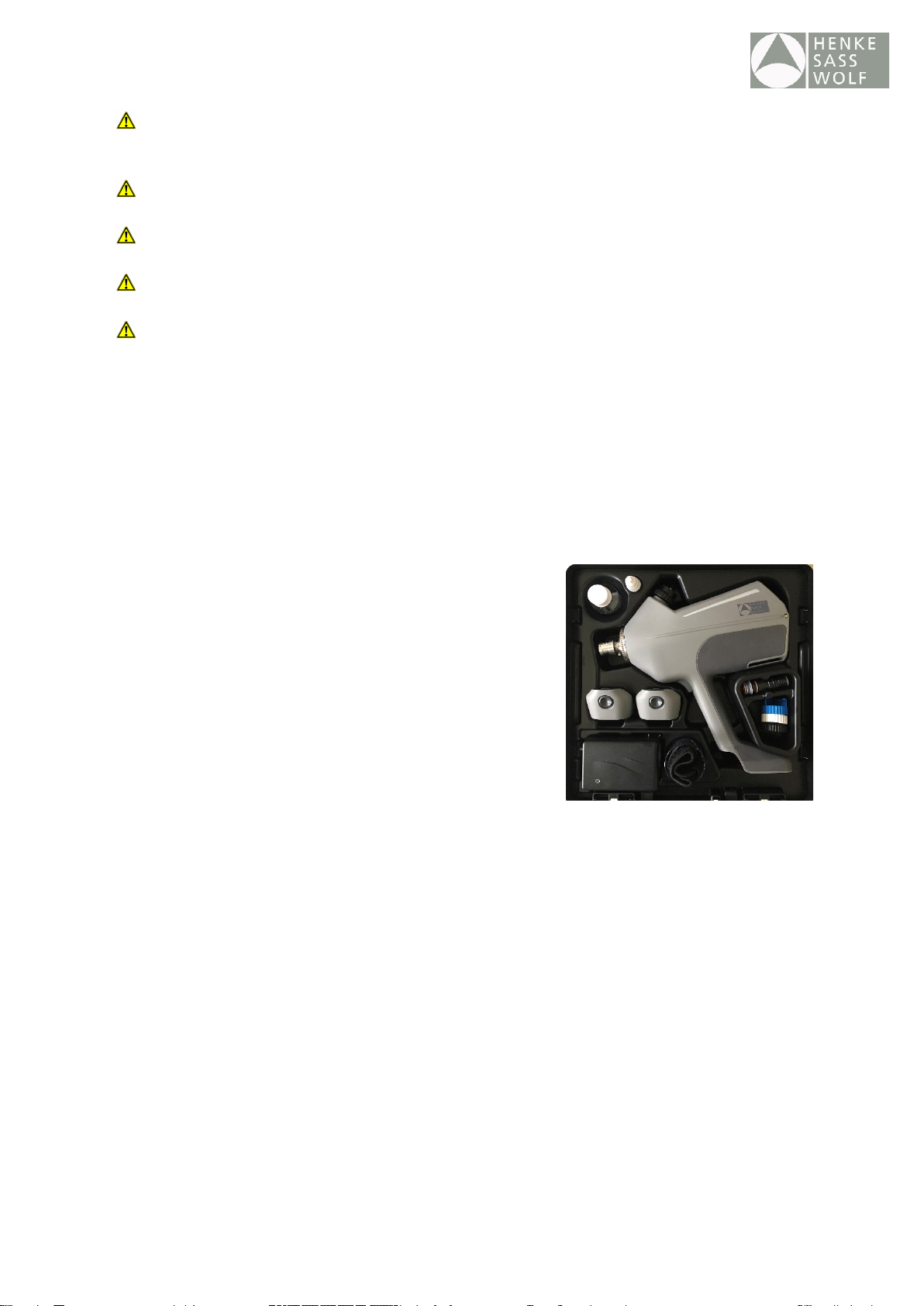

4.2. Packaging contents

-EPIG® device (1)

-Spare cylinder (2)

-Two batteries (3)

-Battery charger (incl. international socket adapters) (4)

-PET bottle for use with defined cleaning liquids (5)

-Threaded bottle collar for use with PET bottle (6)

-Tubing adapter + Tubing (under the device) (7)

-Universal bottle collars (Ø20mm & Ø30mm) (8)

-Lubricant for cylinder service (10ml, white oil) (9)

-Wrist strap (10)

Note: Before using EPIG® for the first time, charge the batteries in the battery charger. Please read

chapter 13 on how to optimize the lifetime and durability of the batteries.

4.3. Operating requirements

Please read the user manual carefully before first use.

4.4. Target species

EPIG® should only be used for vaccinating piglets not older than 10 weeks of age. It must not be used

on older pigs, breeding animals (sows, boars) or in other species. The functionality of the EPIG® device

should only be tested on an appropriate surface, such as a sponge or a thick cloth in a receptacle.

4.5. Mode of action

EPIG® has a bottle holder equipped with a draw-off spike (see ‘A’ in diagram on next page), on which

bottles can be mounted. Vaccination takes place through the injection head (E). The injection head is

fitted with a mechanical safety cylinder.

A pen counter, day counter, bottle counter and a service counter are integrated in the EPIG® device.

The two buttons underneath the screen (B) operate its display. The LED bars (H) on each side of the

1

2

3

4

5

6

7

8

9

10

EN - EPIG User manual 6

6

device are an optical indicator for every action that is carried out during the vaccination process (see

chapter 9).

The EPIG® device comes with two batteries and a battery charger. Before use, insert a charged battery

into the base of the EPIG® device (D).

Operation of the EPIG® begins with inserting a bottle of vaccine into the bottle holder (A) and pressing

the trigger (F) to activate the injector. This will start the pump and vaccine is automatically drawn out

of the bottle. The rinsing fluid, which is present inside the tube during storage, is pumped out of the

tubes via the injection head.

The device comes with an eyelet to mount a shoulder strap (C) as well as a slot (G) for the wrist strap

supplied.

D

A

B

E

F

G

H

C

EN - EPIG User manual 7

7

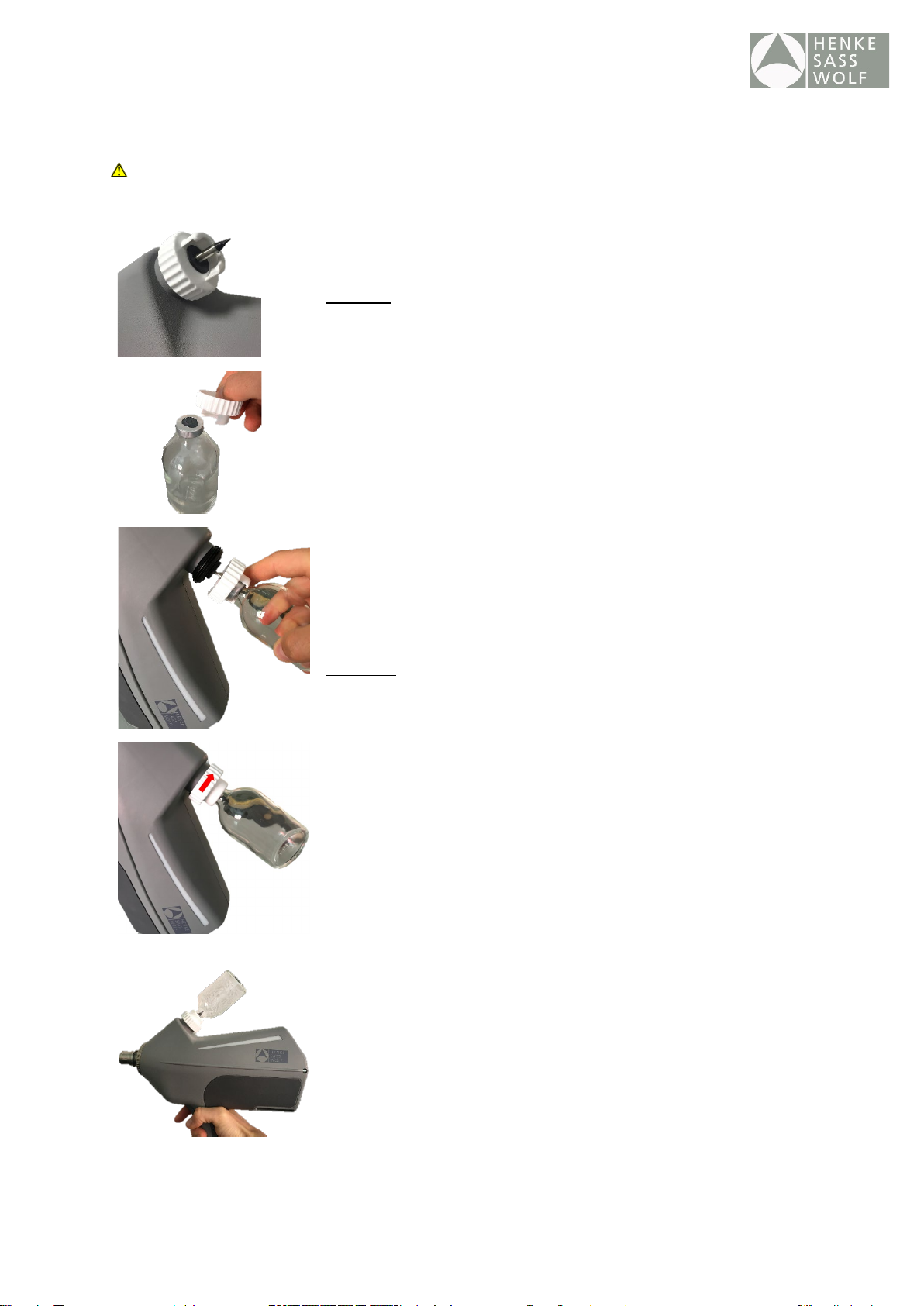

5. Bottle connection / disconnection

Connect a bottle (vial) of vaccine or rinsing fluid (see chapter 9 “Device Cleaning”) to the device by

following these steps:

a. Unscrew the bottle collar (white adaptor on the picture) from the

bottle mount spike.

CAUTION: The spike is very sharp as it has to puncture the stopper of

a vaccine bottle. Please avoid unintended contact with the tip of the

spike.

b. Attach the bottle collar to the bottle as shown on the picture.

c. Pre-puncture the stopper of the vaccine bottle centrally with a

sterile needle to avoid rubber particles being drawn into the spike of

the vaccination device. Place the injector on a solid surface (as shown

on the picture) and push the bottle onto the spike using the pre-

punctured hole.

CAUTION: Without pre-puncturing of the bottle stopper

, rubber

particles may be drawn into the device,

leading to potential

dysfunction by blocked valves and / or nozzle.

d. Connect bottle to device by screwing the collar onto the thread

(clockwise) until it is tight. Please make sure to screw only the white

collar, not the bottle itself. After completion of this step, check if the

bottle sits tightly.

e. Turn the injector back into an upright position. Insert the battery at

the bottom of the handle. This step will activate the device.

EN - EPIG User manual 8

8

To disconnect a bottle from the device, proceed in the reverse order. Always make sure to have the

draw-off spike of the device pointing downwards when connecting or disconnecting a bottle.

Otherwise, vaccine will be spilled over the device while a bottle is being connected to or disconnected

from the bottle mount.

If using the tubing collar to connect a larger bottle via tubing, prefill the tubing (!) prior to attaching it

to the tubing collar. When the tube starts to fill, kink the tube just before the end to prevent loss of

vaccine. Then quickly connect the tubing to the adapter.

6. Device Start

Once the vaccine bottle is connected, insert the battery and the device will turn on, showing both the

Henke-Sass Wolf logo and the EPIG® logo on the display. Both logos are shown for 1 second.

If the battery is sufficiently charged:The display will switch initially to the User Menu, unless the

device is in a loaded condition (cylinder filled with vaccine / rinsing fluid) – in which case the display

will show “! Loaded Device ! Press any button” and the LED bars turn red.

By pressing one of the display buttons, the device will rinse once, to unload the device. The liquid will

be sprayed out through the injection head.

Afterwards, the device will switch to the initial display of the User Menu (see chapter 7).

Before pushing the trigger for the first time, make your settings in the User Menu.

EN - EPIG User manual 9

9

If the battery is too low: The display will show “Low Battery Please Charge”.

7. User Menu

The initial display of the User Menu will show the most relevant

information, including battery level, da

y counter, currently set

volume, time, activated sensors (see chapter 8) and Bluetooth. The

dots at the bottom of the screen are to indicate the current menu

page.

On the second page, the Pen Counter is shown. To reset this pen

counter, press and hold the left display button for two (2) seconds.

On the third page, the Day Counter is shown. T

o reset the day

counter, press and hold the left display button for two (2) seconds.

On the fourth page, the volume can be adjusted. The currently set

volume is shown in the middle, the optional volume is shown on the

lower left side. Press the left display button to choose the optional

volume. The dose will be changed only upon usage of the device (after

the rinsing cycles and before the first injection).

The fifth page shows the Service Counter, which is counting from

12,000 to 0. If the value falls below 0, the counter continues counting

negatively. Press and hold the left display button for two (2) seconds

to reset the service counter.

A ‘Service due’ message appears after there have been 12,000 or

more injections, showing that a cylinder service need

s to be

performed (see chapter 11.1)

The sixth page shows the Total Counter. This counter cannot be reset.

The last page shows the submenu “Settings”. Enter the submenu with

the left display button. Pushing the right display button returns the

screen to the initial display (see above).

EN - EPIG User manual 10

10

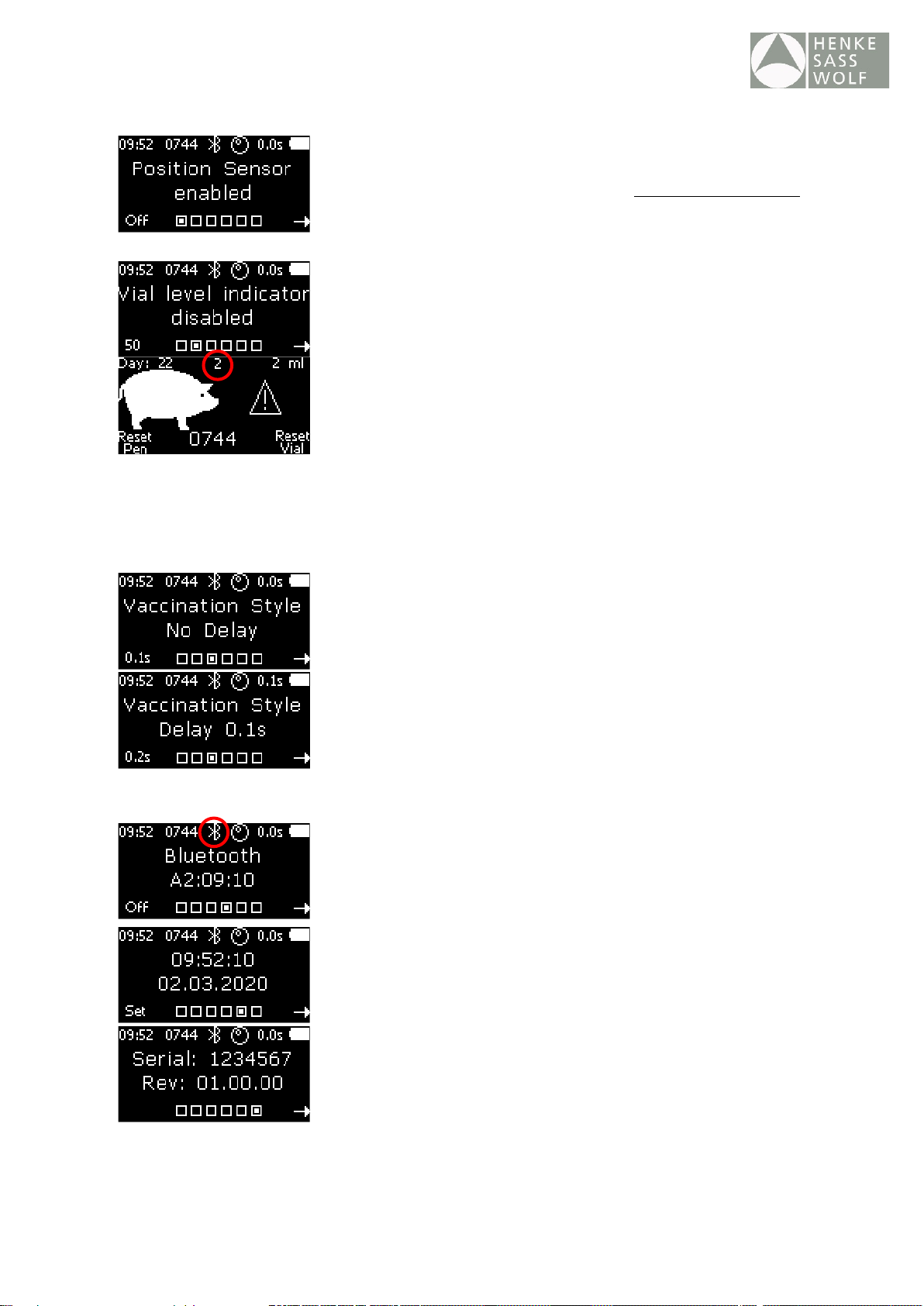

Submenu “Settings”:

On the first page of the submenu, the Position Sensor can be

controlled. Press the left display button to disable or

enable the

position sensor. Recommended setting is an enabled Position Sensor.

(Disabling is only recommended when using the tubing adapter

supplied with the device and having vaccine delivered via tubing.) For

further details, see chapter 8 “Sensors”.

On the second page, the Vial level indicator can be controlled. This

indicator will give an optical warning (via yellow LED bars and warning

sign between piglets on the display) once you have used 90% of the

vaccine inside the connected bottle. When this warning appears, you

have 10% left inside the bottle that is mounted to the EPIG® device.

This allows for a better overview on when to change a bottle during

the vaccination session. To activate the vial level indicator, choose the

size of the bottle / canister you want to mount by pushing the left

display button (50ml, 100ml, 200ml, 500ml, 1000ml, 2000ml, 5000ml,

all above 200ml ideally being connected via tubing.)

CAUTION: The vial level indicator is a simple counter that needs to be

set up according to the bottle size mounted to the device. It counts

backwards from the set volume to zero, the current counter reading

is shown in the top center of the display.

On the third page, the Vaccination Style can be selected. Default

vaccination style is “No Delay”, which is for lifting / presenting the

piglets to a second person who is vaccinating them with min. time

lapse between applying the device to the skin of the piglet and the

injection itself. Press and hold the left display button to select the

alternative setting “Delay ?? s”, which offers vaccination of the piglets

by only one person and leaving the piglets on the floor during

injection. If vaccinating on the floor, a preferred time between skin

contact and injection can be selected, to enable the worker to ensure

proper contact between the device and the piglet before the injection

is released. The device offers settings from 0.1s to 1s by tenths.

On the fourth page, Bluetooth can be controlled. Press the left display

button to disable or enable the Bluetooth antenna. If using the EPIG®

App, enabled Bluetooth is required. If not using the EPIG® App,

disabled Bluetooth is recommended and will help to conserve battery

power.

The fifth page shows date and clock

. The format of the clock is

hh:mm:ss and the format of the date is dd.mm.yyyy. By pressing the

left display button, you can set the date and clock.

On the last page, the serial number (PT1.0x) and the software version

is shown. Press the right display button to return to the “Settings”

page of the user menu. Press the right display button again to reach

the initial display of the user menu.

EN - EPIG User manual 11

11

8. Sensors

The EPIG® device is equipped with several sensors to guarantee an optimal vaccination result.

8.1. Position Sensor

This sensor allows for continuous control of the correct holding

position of the device. Once the trigger has been pushed, before

allowing liquid to be drawn into the device the position sensor will

check if it is held upright in order to avoid drawing in air. If the device

is held in the correct angle, which is indicated by the small circle being

inside the big circle, liquid from the attached bottle will be drawn in.

Once the device is fully loaded with liquid, the holding position is no

longer relevant until the trigger is activated again.

Please note: When using the tubing adapter to deliver vaccine, no position sensor reading is needed

because there is no bottle mounted on top of the device. In this case, the position sensor can be

disabled (user menu

settings

position sensor

off).

8.2. Air Detection Sensor

This sensor measures whether fluid or air is drawn into the device. If

air is drawn in, e.g. by emptying the bottle and not fitting a new one

in time, a warning “Air detected” is shown. Afterwards, only rinsing is

possible, indicated by blue flashing LED bars, until the air exits at the

injection head. This takes a minimum of 3 rinsing cycles, as the liquid

circuit has a volume of a little less than 6 ml and one rinsing cycle

moves a volume of 2 ml. After the rinsing process, you will be able to

vaccinate again (indicated by white flashing LED bars).

8.3. Nozzle Sensor

This sensor enables an extra safety precaution when using the injector. Once the EPIG® device is ready

for vaccination (white flashing LED bars), push and hold the trigger. When the device is applied to the

skin of the piglet, the safety sleeve around the injection head will slide back, releasing the vaccine. If

either the trigger is not pushed or the safety sleeve around the injection head does not slide back, no

vaccine will be released. This allows for a high level of user safety.

Furthermore, the nozzle sensor measures if the minimum contact

time between device and piglet for administration of the full dose is

fulfilled. If the injector is released too early, implicating an underdose,

the device will give an optical warning via red flashing LED bars and a

written notification on the display.

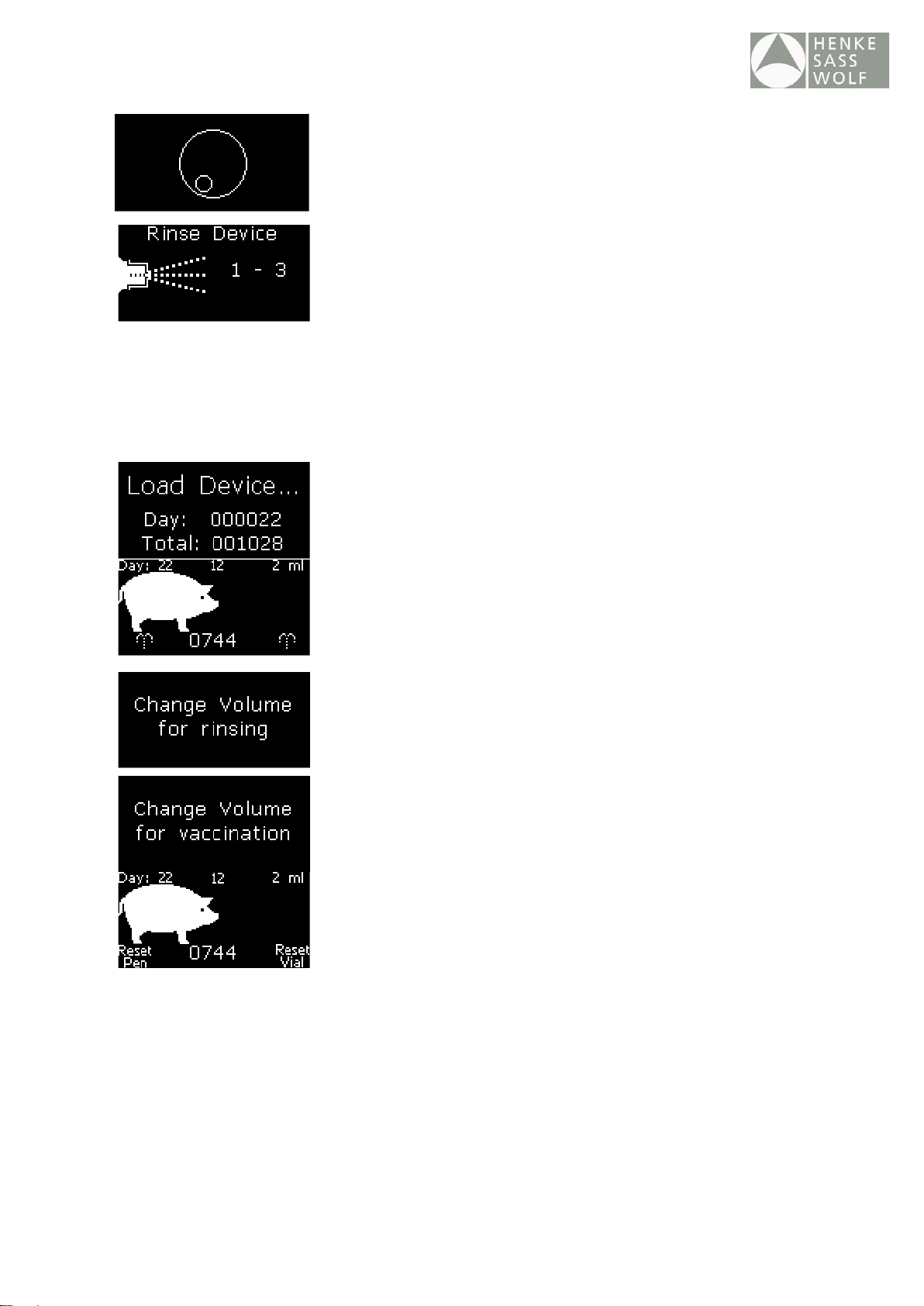

9. Vaccination Process

Press the trigger to load the device. The position sensor indicates

the position of the bottle in the holder of the EPIG®.

EN - EPIG User manual 12

12

When the EPIG® is held in the right position, the small circle is inside

the big circle and the device begins to load. This function helps to

reduce the risk of drawing air into the system.

At the first run of a new session or after every restart of the device,

the EPIG® will be rinsed for three (3) times to flush out remaining

rinsing fluid inside the system and to fill the cylinder with vaccine. No

vaccine will be wasted during this procedure as approximately three

(3) doses of liquid fit into the liquid circuit of the device. The display

will let you know, once the third and last rinsing cycle is completed.

Rinsing is indicated by a blue light LED. If you are changing the battery

and the changeover between removing the empty battery and

inserting the new one takes less than 5 minutes, the rinsing will be

skipped as vaccine is already in the device.

After three (3) rinsing cycles, press and hold the trigger to load the

device for the first injection. During loading, “Load Device

" is

displayed.

After loading, the device is ready to vaccinate, which is indicated by a

white flashing LED and an illustration of walking piglets

on the

display. At this stage, (1) the first injection cycle can be started, (2)

another rinsing cycle can be carried out or (3) the pen counter or vial

level indicator can be reset.

With option (2) above, another rinsing cycle can be carried out by

pressing one of the display buttons and simultaneously pushing the

trigger. If the dose is set to 1 ml, the device will automatically change

the volume back to 2 ml for rinsing. If the dose is set to 2 ml, rinsing

will be carried out without a change of volume.

The device will automatically switch back to the set dose after the

rinsing cycle, which is indicated by yellow flashing LED bars. This is

only relevant when the dose was set to 1 ml prior to rinsing.

For the option (3) above, to reset the pen counter

or vial level

indicator, press the according display button without simultaneously

pushing the trigger.

EN - EPIG User manual 13

13

In option (1), an injection cycle is released once the trigger on the

handle is pressed and held while counter-pressure is generated on

the safety sleeve around the injection head (the two-way security

mechanism) by applying and pressing the injection head onto the skin

of a piglet.

1. Press and hold trigger on the handle of the device.

2. Apply the injection head (A) to the skin of the piglet

perpendicularly (!), add a certain pressure to make the safety

sleeve (B) move backwards and release the injection.

3. During injection, the display will indicate that the device is

currently injecting by showing “Vaccination”. The required

time per injection is 0.1 sec for 1 ml and 0.2 sec for 2 ml.

During this time, make sure that the nozzle of the device stays

pressed onto the skin of the piglet perpendicularly.

4. The device will indicate that the injection was administered

successfully by a green light LED and a notification on the

display. If the device was removed from the skin of the piglet

too early, the device will indicate this by a red light LED. Thus,

the classification into good or bad injection is based on a time

measurement (see point 3 above).

5. After each injection, release the device from the skin of the

piglet to enable the next loading cycle and injection. When

kept in contact with the piglet’s skin after an injection and still

reloading, the device will show “Please rele

ase Nozzle”

before another injection can go into the same piglet by

mistake. Additionally, the LED bars will flash white and red in

alternation.

By keeping the trigger continuously pressed, EPIG® automatically prepares itself for the next

vaccination. The next pig can now be vaccinated by pressing the nozzle against its skin.

After administering a vaccination, a small residue of vaccine is visible on the piglet's skin. This is normal

with needle-free intramuscular vaccination and does not affect vaccine efficacy.

10 Device Cleaning

10.1 Rinsing

The cleaning procedure mentioned hereafter should be carried out after each vaccination session.

•Leave the battery attached to the device.

•Disconnect the vaccine bottle (vial).

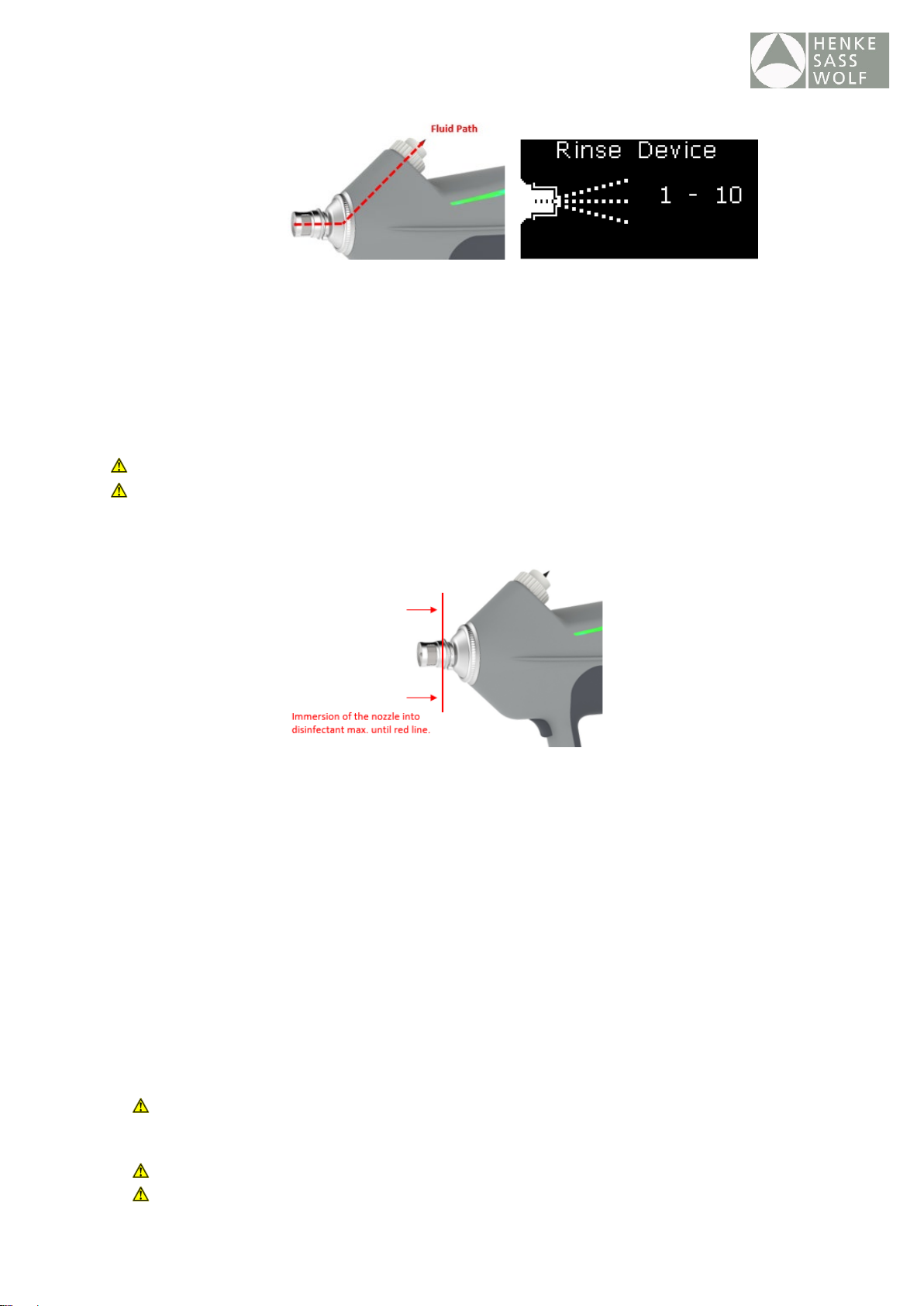

•To clean the fluid path inside the device (section between bottle attachment and nozzle, shown

in picture below), mount a bottle of Isopropanol or a mix of demineralized water and detergent

to the device, using the 100ml PET bottle and threaded bottle adapter supplied. Start the

rinsing program by pressing both display buttons at the same time for 2 seconds. This way, the

device will automatically perform ten (10) rinsing cycles in a row without any further action

required.

EN - EPIG User manual 14

14

•Disconnect the bottle of Isopropanol or soap solution from the device and connect a bottle of

clear demineralized water or PBS (phosphate buffered saline). Start the rinsing program again

(10 rinsing cycles) to make sure that all residuals of isopropanol or soap solution are flushed

out of the device. This step will avoid any harm to / chemical reaction with the vaccines

attached after cleaning.

10.2 Cleaning of the device

Prior to cleaning your device from the outside, remove the battery (!) at the bottom of the handle.

The below mentioned cleaning procedure should be carried out after each vaccination session.

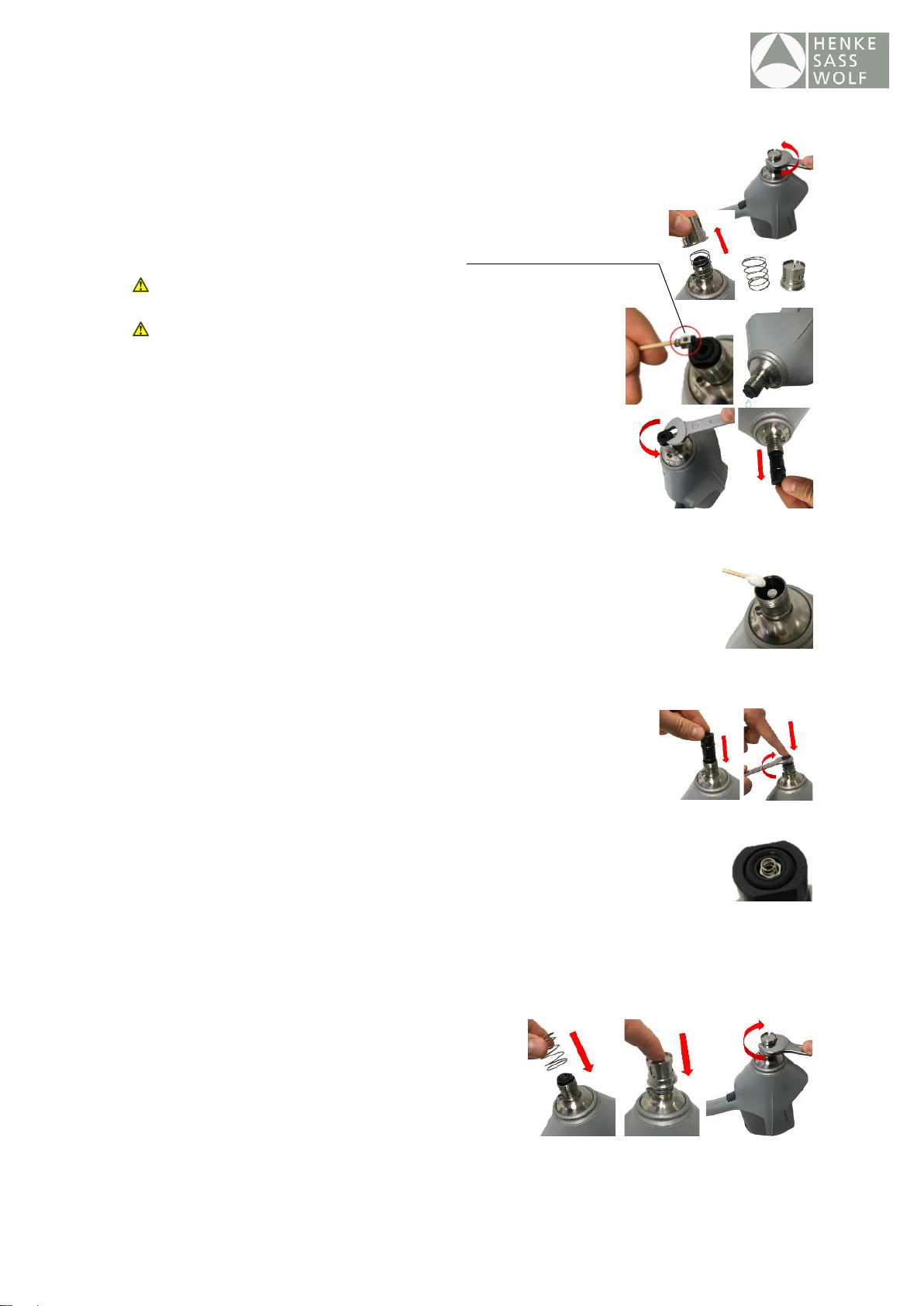

•Immerse the nozzle / front part into any commercially available disinfectant while wearing

rubber gloves and turning / moving the safety sleeve around the injection head to remove all

traces of dirt.

•Clean the grey housing and the battery

either by wipe disinfection (e.g. Meliseptol wipes), or by using a sponge soaked with a water-

detergent mix. The device is water resistant according to IP protection class 54.

•After cleaning, dry the device with a clean cloth / towel.

•Make sure your EPIG® device is completely dry before putting it back into the case.

11. Maintenance and Repair

11.1. Cylinder Service

Service of the EPIG® is required after 12,000 injections. When service is due, the message “Service

due” will appear on the EPIG® display.

For maintenance, the cylinder needs to be replaced by the included spare cylinder using a 22 mm and

a 15 mm wrench. Maintenance should be done in a clean environment.

This step-by-step instruction is in addition to the user instructions delivered with the EPIG®

device. Please read the user instructions carefully before operating the device and/or

performing cylinder service.

Always remove battery before doing cylinder service!

Make sure, that no bottle with rinsing/cleaning fluid is placed in the bottle holder of the device.

EN - EPIG User manual 15

15

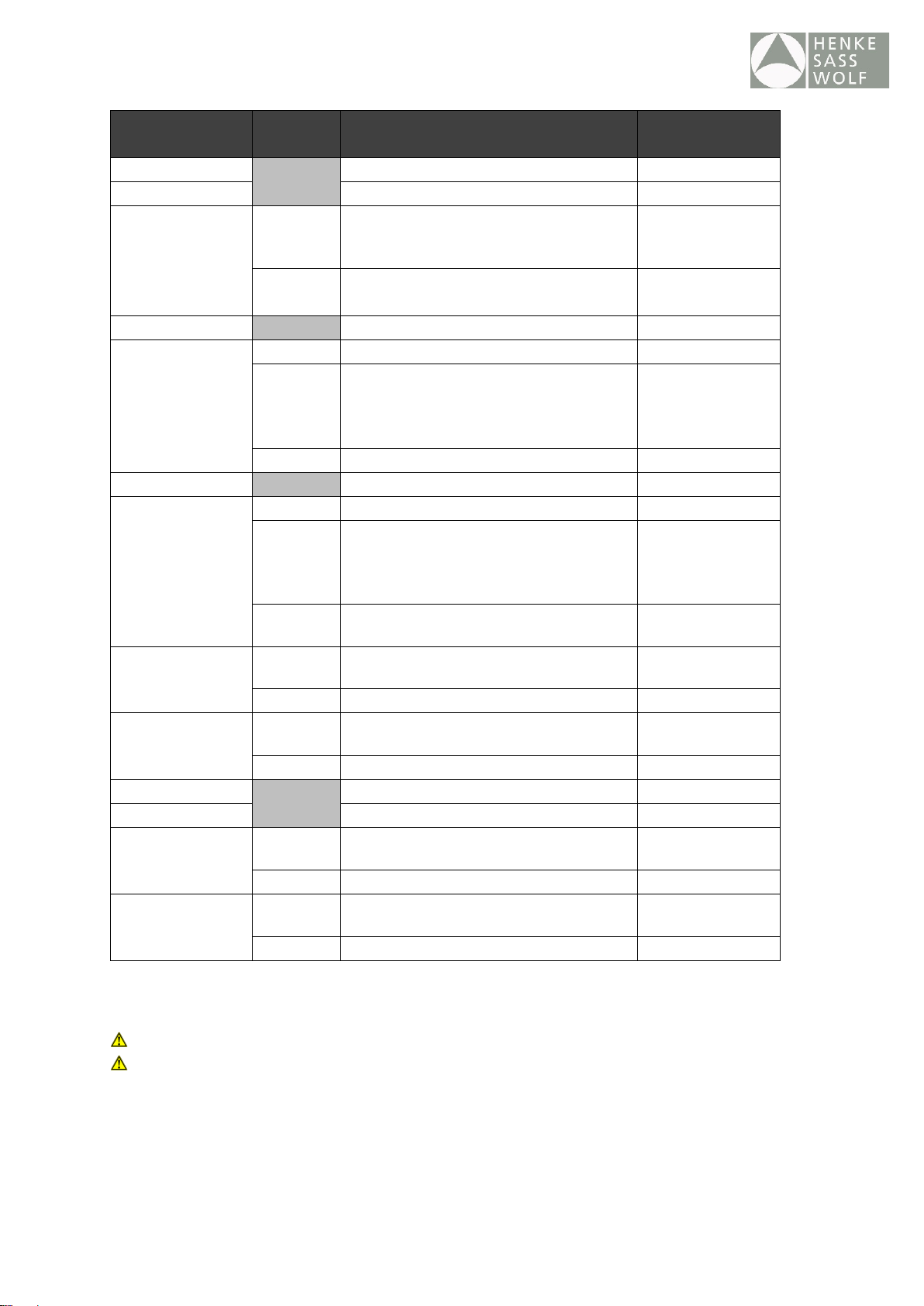

Step 1: Unscrew injection head

•Place the device on a solid surface.

•Carefully unscrew the injection head with a 22 mm wrench.

•If the wrench does not hold the injection head properly, rotate

the safety cylinder slightly.

•Remove injection head (incl. safety sleeve) and spring.

•Remove the valve (valve body and spring).

As soon as injection head and valve are dismounted: Ensure that the

exposed tip of the EPIG® is protected from dirt.

Hold the device with the head facing downwards in order to drain

residues of vaccine or rinsing fluid.

Step 2: Remove old cylinder

•Unscrew the old cylinder with a 15 mm wrench.

•Hold the device with the head facing downwards and only then (!)

remove the cylinder from the device by pulling. This will allow you

to drain remaining vaccine or rinsing fluid.

Step 3: Lubricate the piston rod

•Prior to lubrication, clean the piston chamber and piston rod by wiping it with

a cotton cloth or Q-tip/cotton bud.

•Lubricate the tip of the piston rod using a fingertip or Q-tip/cotton bud soaked

in the supplied white oil.

Step 4: Insert new cylinder

•Lubricate the o-rings on the exterior wall of the new cylinder with

white oil.

•Insert the new cylinder into the opening of the piston chamber and

press down until it sits firmly.

•Remove the yellow protection cap, taking care that the o-ring

and valve below the protection cap will stay in place.

•Tighten the new cylinder with a 15 mm wrench while pressing

the cylinder down until the thread will engage.

Step 5: Tighten the injection head

•Put the large spring in between the front part of

the device and the injection head.

•Clean (!) the injection head and then carefully

tighten it with the safety sleeve over it by using a

22 mm wrench and pushing the injection head

down until the thread will engage.

EN - EPIG User manual 16

16

Step 6: Check the injection head

•Check if the injection head is sitting correctly and if the safety cylinder

around the injection head (marked yellow) is moving smoothly.

Step 7: Flush

•Fit a bottle with rinsing/cleaning fluid into the holder and rinse until a clean and continuous

jet is coming out of the injection head. (Use rinsing program, see 10.1)

Step 8: Check functionality

•If the injection head is not operating properly (no clean and continuous jet of rinsing fluid is

coming out), please repeat cylinder service.

Step 9: Reset Service Counter

•After successful completion of cylinder service, please

reset service counter.

•Starting from the initial screen, push the right button three

times until reaching menu point “Service Counter”.

•Press button “Reset” for at least 3 seconds.

•The counter returns to "0".

11.2. Maintenance and repair service

For certain problem reports, maintenance or repair in an approved service point is necessary. The

message “Factory Service” will appear on the EPIG® display. The EPIG® device has to be sent to an

approved service point. Details can be found in the table on the following page. Please contact Henke-

Sass, Wolf to arrange return of the device and fill out the supplied return form.

CAUTION:In case of a necessary return of the device to the manufacturer, please remove

the batteries from the case (as per dangerous goods regulation of all common forwarders)!

To learn more on what sort of failure occurred, download the EPIG® App for iOS or Android and run a

self-diagnosis by starting the App, connecting the App to your device and thereafter pushing the button

“Run diagnosis” in the App.

EN - EPIG User manual 17

17

Defect

Action

sequence Action Service Point

Display button

Replacement of Display button

Henke-Sass, Wolf

Display

Replacement of Display

Henke-Sass, Wolf

Nozzle Sensor

1

Cylinder Service + Replacement of safety

sleeve around injection

head

Farm / User

2

Replacement of Nozzle Sensor (if sensor

itself is defective)

Henke-Sass, Wolf

Trigger

Replacement of Trigger

Henke-Sass, Wolf

Battery

1

Charge battery (100%)

Farm / User

2

Use second battery and compare

perfomances (indicates whether the

defect is caused by the battery or the

device itself)

Farm / User

3

New battery (available as spare part)

Farm / User

Charger

New charger (available as spare part)

Farm / User

Air detection

1

Cylinder service

Farm / User

2

Mount included 100ml PET bottle filled

with destilled water and press the bottle

during loading to increase suction

pressure

Farm / User

3

If both doesn't help, repair through

manufacturer

Henke-Sass, Wolf

Position sensor

1

Optionally, use device without position

sensor

Farm / User

2

Replacement of position sensor

Henke-Sass, Wolf

Bluetooth

1

Restart device and check if Bluetooth

works now

Farm / User

2

Replacement of Bluetooth module

Henke-Sass, Wolf

Device storage

Repair

Henke-Sass, Wolf

Motor

Repair

Henke-Sass, Wolf

Ambient Light

Sensor

1

Optionally, use device without ambient

light sensor

Farm / User

2

Replacement of ambient light sensor

Henke-Sass, Wolf

LED (complete or

single colors)

1

Optionally, use device without LED

functions

Farm / User

2

Repair of LED

Henke-Sass, Wolf

NOTE: Repair or maintenance by unauthorized persons will lead to a loss of warranty!

Unauthorized opening of EPIG® devices or battery packs may cause harm and is not allowed!

All works on the electrical system may only be carried out by qualified electricians of the

manufacturer.

EN - EPIG User manual 18

18

12. Dismantling

The EPIG® device may only be dismantled by authorized service engineers. In case of unauthorized

dismantling, the device will lose its warranty.

Do not open the EPIG® device by yourself due to health and safety risks!

EN - EPIG User manual 19

19

13. The battery and the charger

Battery

The battery of the EPIG® is a rechargeable Lithium Ion (Li-Ion) battery. At least 1,000 injections can be

administered by using a fully functioning and charged battery.

The battery should be slotted into the opening in the base of the EPIG® device:

A fastening button will hold the battery in position. The battery can be removed from the base by

pushing down the button at the front of the battery and by pulling out the battery.

Use only appropriate batteries in the EPIG®. The use of other batteries can lead to injuries and

fire hazard.

Do not expose the battery to mechanical shocks.

Stop using the battery if it becomes abnormally hot, or if discoloration, deformation or abnormal

conditions are detected during use, charge or storage.

Replace the battery when its running time between charges becomes much shorter than usual.

It is recommended that batteries are not recharged before falling below 50% loading capacity.

Never store empty batteries as this could damage them and make them unusable.

Never send/ ship defective batteries to any destination. Instead, please dispose of them correctly.

Charger

Charge the battery using only the charger supplied. Connect the battery to the charger and connect

the charger to an electric socket. When connected correctly, the charging process will start

automatically.

Check the charger regularly for damage, especially the connection cable and the housing. Do not

use damaged battery chargers.

Always grasp the plug, not the cable, when removing the mains plug from the socket.

Faulty electrical installation or too high mains voltage can lead to electric shock. Only connect the

battery charger to an easily accessible socket, so that you can quickly disconnect it from the power

supply in the event of fault.

EN - EPIG User manual 20

Table of contents

Languages: