HENNING LP User manual

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 1 Ed t on 3.3.1 EN of 03.04.2017

Operating Instructions for Elevator Buffers type LP

Scope of application

The Elevator Buffer type LP s an energy dissipation type buffer accord ng to EN 81-1/2, EN 81-20, EN

81-50 5.5 and therefore can be un versally used for all appl cat ons n the construct on of elevators. The

EC type exam nat on perm ts the use n passenger and fre ght elevators both under the elevator car and

under the counter we ght.

2 Functional description

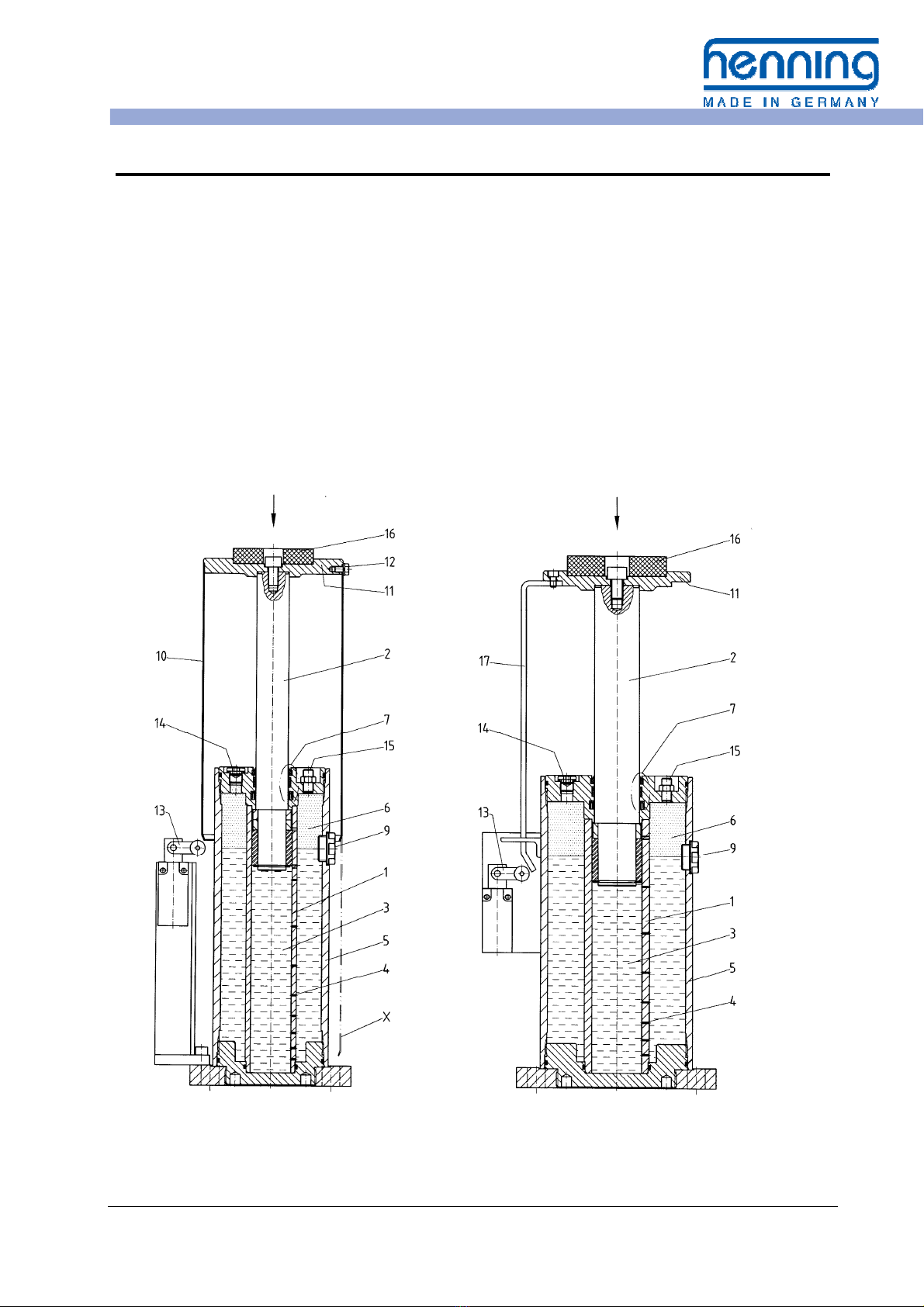

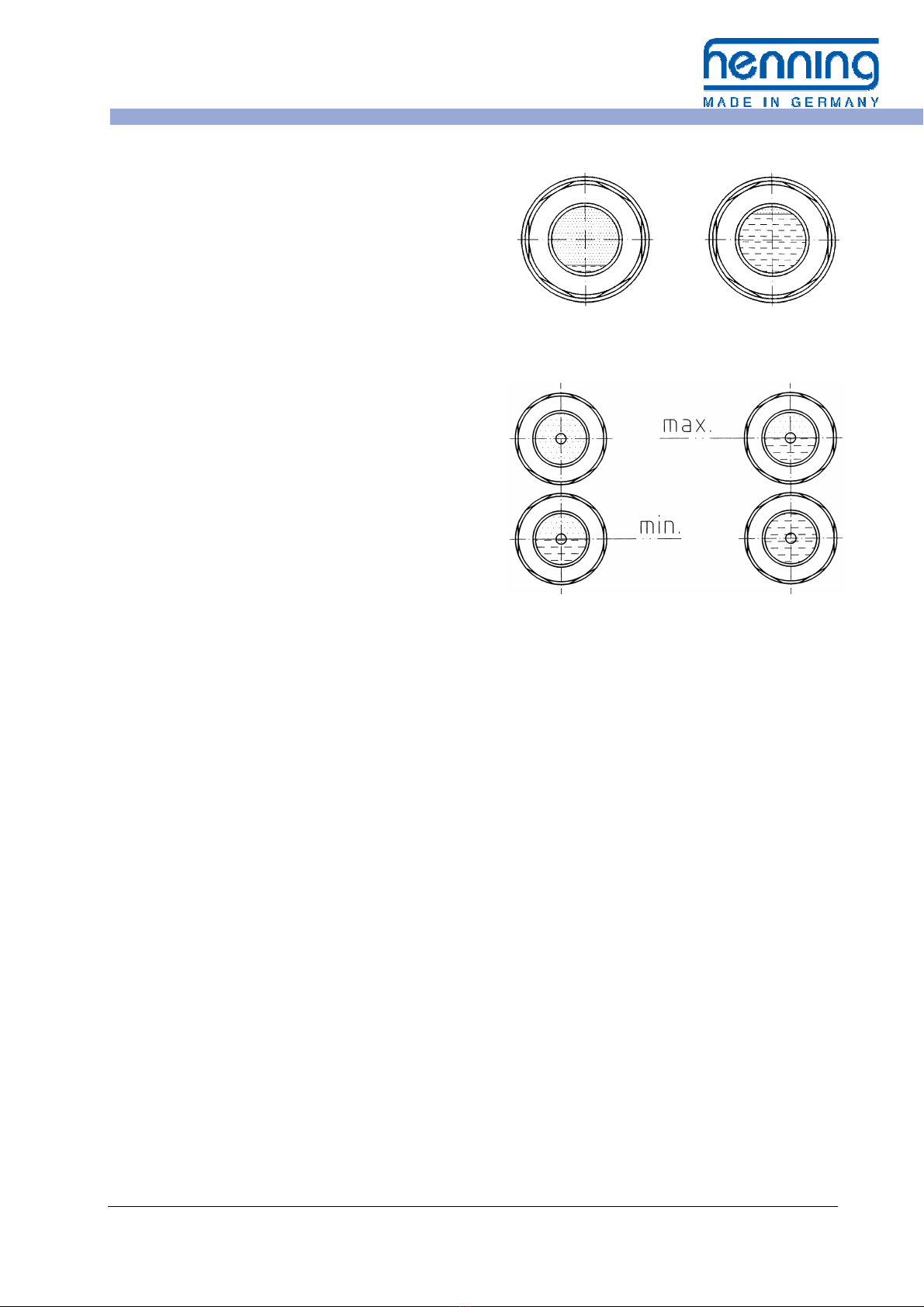

F g. 1a: Buffer w th Protect on Tube F g. 1b: Buffer w th L near Sl de

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 2 Ed t on 3.3.1 EN of 03.04.2017

In the case of a buffer stroke the p ston rod 2 s

forced nto the cyl nder tube and the hydraul c

flu d 3 n the tube s d splaced and forced to the

outs de through small throttl ng ports 4 n the

tube wall. The flu d accumulates w th n the jack-

et tube 5.

At the same t me the gas volume 6 above the

hydraul c med um s further compressed. The

seal ng system 7 ma nta ns a rel able seal be-

tween the hard chrom um-plated p ston rod and

the atmosphere.

After the buffer stroke and return to hydraul c

balance the compressed gas volume forces the

d splaced flu d back nto the cyl nder and ex-

tends the p ston rod.

The level of the hydraul c flu d at the gas nter-

face can be read at any t me through the s ght

glass 9 w thout open ng the un t.

An elast c mpact plate 6 damps the mpact and

reduces the no se.

The l m t sw tch 3 mon tors the extended ready

pos t on of the buffer. The l m t sw tch s actuated

by pressure on the p ston rod by the l near sl de

7 or the protect on tube 0 respect vely.

In the case of buffers equ pped w th a protect on

tube 0, for ma ntenance work the screws 2 on

the buffer head are removed. Subsequently,

the protect on tube can be lowered, wh ch s mul-

taneously actuates the sw tch 3. The o l f ller

screw 4 and the gas-f ll ng valve 5 w ll then be

access ble.

In the normal operat ng state the protect on tube

avo ds damage and contam nat on of the p ston

rod.

3 General Instructions

If people are work ng n the elevator shaft a

su table refuge must be ensured.

For th s purpose the general safety nstruct ons

of the elevator manufacturer have to be ob-

served.

Warning!

Buffers are safety devices. Mounting, inspection and maintenance work

may only be carried out by expert personnel! Observe the

applicable safety instructions!

4 Preparations

4. Design Data

Among the data on the buffer type plate there s

ncluded:

• P ston d ameter and stroke

• M n mum mpact mass,

• Max mum mpact mass and

• Rated speed

4.2 Ambient Temperature Limit

The amb ent temperature should be between

-10 °C and 50 °C.

The buffer can be suppl ed n a spec al des gn

f lled w th a spec al hydraul c o l for low amb ent

The f rst check should be to ensure that the op-

erat ng cond t ons do not exceed th s des gn

data.

temperatures. Th s buffer can be used between

-20 °C and +40 °C and s labelled w th a spec al

des gnat on for th s temperature range. An en-

hanced EC type exam nat on s also prov ded.

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 3 Ed t on 3.3.1 EN of 03.04.2017

4.3 Place of Installation

The place of nstallat on should be n a clean

and dry cond t on.

Ver fy the place of nstallat on of the buffer and

the bear ng capac ty of the mount ng surface.

Ver fy the s ze of the rema n ng lower refuge. For

an ent rely pressed- n elevator car buffer a suff -

c ently d mens oned refuge must be prov ded

below the elevator car n compl ance w th the

respect ve code.

The p ston rod should not be contam nated by

external mpact.

Dur ng operat on of the elevator t has to be en-

sured that the surface of the p ston rod s free of

adherences of snow and/ or ce and not frosted.

In case of d ssent ng operat on cond t ons,

please contact Henn ng GmbH & Co KG.

5 Mounting

!

Safety Instruction:

Prior to all mounting and maintenance work, an appropriate measure to prevent au-

tomatic switching on or automatic start-up of the drive must be in place!

1. The buffer s suppl ed ready for nstallat on

complete w th o l f ll ng.

2. If the buffer s suppl ed w th pressed- n p s-

ton rod, the secur ng dev ces should be re-

moved. Cut the secur ng straps at the s de

when the buffer s stand ng upr ght.

Warning! The extending piston rod can

cause injury!

3. Fasten ng mater al should be ordered sepa-

rately. Su table means are heavy-duty dow-

els or rag bolts M 16x160 DIN 529 w th nuts

and washers 18 DIN 126.

4. Fasten ng should be made n the upr ght

cond t on d rectly on the ground or on a su t-

able console. The buffer p ston rod should

be accurately mounted n the vert cal pos -

t on. Therefore, mount ng must be made on

a hor zontal surface or su table sh ms should

be used.

5. The buffer should be f xed exactly under the

centre of grav ty of the elevator car or coun-

terwe ght respect vely. If several buffers are

used, these must be d str buted symmetr -

cally to the centre. Check the al gnment of

the buffer e. g. us ng a water level. The p s-

ton rod has to po nt vert cal up.

6. Press- n the p ston rod several t mes by

hand. Th s perm ts transport-caused a r

bubbles to escape from the hydraul c flu d.

Subsequently, the p ston rod must be com-

pletely extended and the o l level correct.

If buffers may be d s-

placed for serv ce work

at the elevator e. g. by

1. The elevator may only be set nto operat on aga n f the buffer

s replaced to ts work ng pos t on and fastened correctly. We

recommend nstall ng a su table electr cal controll ng dev ce.

2. Then press- n the p ston rod of the buffer at least two t mes.

Th s allows a r bubbles escap ng from the hydraul c cyl nder.

3. F nally check, that the p ston rod s fully extended and the o l

level s correct.

4. F x su table nstruct ons for act ng near the po nt of nstallat on.

• sw ng ng to a serv ce pos t on

or

• remov ng

please note:

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 4 Ed t on 3.3.1 EN of 03.04.2017

5. Electric Connection

Dangerous Voltage!

During connection work the installation must be de-energised!

Carry out the electr c connect on to the l m t

sw tch 3 (F gures 1a or 1b). Dur ng w r ng the

work ng range of the l near sl de 7 and the

protect on tube 0 dur ng buffer stroke must be

observed.

6 Commissioning

!

Safety Instruction:

During buffer testing no persons are allowed

to stay in the elevator shaft!

1. Ver fy the extended pos t on of the p ston

rod and the o l level.

2. Carry out a f rst buffer test w th reduced

speed and w thout add t onal load.

3. Ver fy the electr cal s gnal of l m t sw tch 13.

4. Wa t for approx. 1 - 2 m nutes and then re-

l eve the buffer.

5. Ver fy the extended pos t on of the p ston

rod and the o l level. Check the buffer and

the mpact po nt for poss ble damage and o l

leaks.

6. If no defects are found, carry out a second

buffer test. Th s test should be carr ed out, f

poss ble, w th rated speed and max mum

load.

7. Repeat po nts 4. and 5. .

If no defects are found, the buffer s ready for

operat on.

7 Regular inspections

Dur ng regular nspect ons of the elevator nstal-

lat on or for trouble shoot ng the follow ng

nspect ons are poss ble for wh ch all the a/m

safety nstruct ons must be observed:

7. Inspection of the extended piston rod

Buffer w th protect on tube to F g. 1a:

• The s ght glass 9 s not masked by the pro-

tect on tube 0.

• The l m t sw tch 3 s not actuated.

Buffer w th l near sl de to F g. 1b:

• The l m t sw tch 3 s not actuated.

• The v s ble part of the p ston rod s as long

as the respect ve stroke (see nd cat on on

the type plate).

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 5 Ed t on 3.3.1 EN of 03.04.2017

7.2 Oil level check

The elevator buffers ser es LP are equ pped

w th a s ght glass as an o l nd cator. Therefore,

the buffer does not need to be opened for the o l

level check! Th s nspect on should only be car-

r ed out w th fully extended p ston rod (see a/m

po nt 7.1).

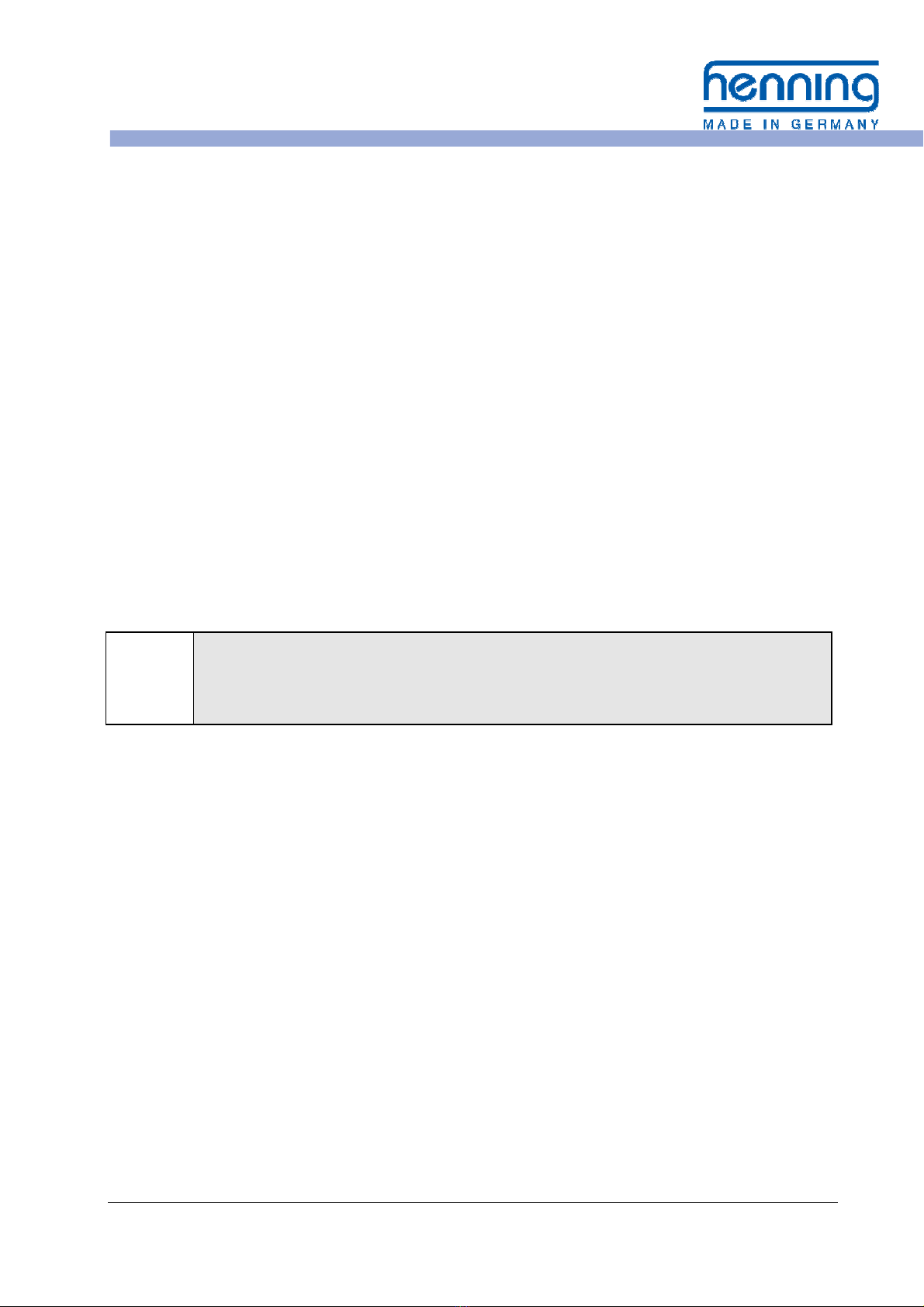

a) Buffer w th one s ght glass

The o l level should be v s ble n the

s ght glass 9, see F g. 2a

b) Buffer w th two s ght glasses

- m n mum: the o l level s v s ble n

the lower s ght glass

- max mum: the o l level s below the

top edge of the upper

s ght glass

see F g. 2b

Factory o l f ll ng for buffers w th one s ght glass

s up to the centre of the s ght glass (at amb ent

temperatures of 16 °C to 22 °C).

Factory o l f ll ng for buffers w th two s ght glass-

es s below the top edge of the upper s ght

glass.

The o l level s depend ng on temperature. At

amb ent temperatures around freez ng po nt, the

o l level can drop near the m n mum. H gh amb -

ent temperatures let the o l level r se.

If dur ng the o l level check the o l level s found

to be too h gh, a r bubbles m ght be n the o l. In

th s case f rst press the p ston rod of the (upr ght

stand ng) buffer several t mes as far as poss ble.

If the o l level s not fall ng although the p ston

rod s fully extended, o l must be removed.

If the o l level s too low, o l must be added (see

po nt 8.3 "Correct on of the o l level"). In th s

case check the buffer for leakage.

7.3 Gas pressure check

For resett ng the p ston rod after a buffer stroke

the buffer s f lled w th n trogen. The gas pres-

sure at extended p ston rod s 5 bar.

The gas pressure may be checked w thout us ng

a measur ng nstrument. For th s purpose press

the p ston rod by hand for some cent metres.

If the p ston rod then returns automat cally to ts

n t al pos t on, the gas pressure s suff c ent.

Otherw se proceed as descr bed under po nt 8.4

"Gas ref ll ng".

7.4 General visual inspection

Pay attent on to o l spots on the floor or on the

buffer. An o l f lm on the p ston rod 2 s normal.

Check the p ston rod surface for damage and

t ghtly adherent contam nat ons.

Check the state and funct on of the l m t

sw tch 3.

If leaks or damage s found, the buffer must be

exchanged or repa red.

O l level m n mum O l level max mum

F g. 2a: O l level nd cat on w th one s ght glass

O l level m n mum O l level max mum

F g. 2b: O l level nd cat on w th two s ght glasses

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 6 Ed t on 3.3.1 EN of 03.04.2017

7.5 Check the piston rod for icing

If the buffer s operated at amb ent temperatures

below the freez ng po nt, the p ston rod must be

protected from the accumulat on of frost, snow

or ce. It s necessary to check whether the

measures taken to prevent c ng are funct on ng

properly.

8 Maintenance

Under normal operat ng cond t ons the elevator

buffer LP does not requ re ma ntenance. How-

ever, f dur ng the a/m checks defects are de-

tected, these can be removed as descr bed n

the follow ng.

Every t me, safety measures must be taken

aga nst un ntent onal sett ng n mot on of the

elevator!

8. Removing the protection tube

For buffers w th a protect on tube (F g. 1a) th s

should be removed for ma ntenance work. For

th s purpose remove the three hexagonal screws

2. Push the protect on tube 0 downward nto

the serv ce pos t on "X". The o l f ll ng screw 4

and the gas f ll ng valve 5 are now access ble.

At the same t me the l m t sw tch 3 s actuated.

After term nat on of the ma ntenance work the

protect on tube s mounted n reverse order.

!

Warning!

The buffer is pressurised.

Prior to opening the buffer and for oil refilling the pressure must be released!

8.2 Relieving gas pressure

Remove the valve cap from the gas f ll ng valve

5 n order to uncover the valve open ng.

Place a t re f ll ng dev ce on the f ll ng valve and

let the gas escape. As an alternat ve you can

press n the valve cone w th a su table po nted

object and let the gas escape.

.

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 7 Ed t on 3.3.1 EN of 03.04.2017

8. 3 Correction of the oil level

• Remove the o l f ll ng screw 4 after hav-

ng rel eved the gas pressure.

• For ref ll ng use the follow ng o l types

only:

a) buffer standard model (- 0 °C up to

+50 °C):

Hydraul c o l DIN 51524-2 HLP re-

spect vely ISO 6743/4 HM v scos ty ISO

VG 46

b) buffer with low temperature design

(-20 °C up to +40 °C, see label):

Hydraul c o l DIN 51524-3 HVLP respec-

t vely ISO 6743/4 HV v scos ty ISO VG

22

• Ref ll the hydraul c o l:

- buffers w th one s ght glass: unt l the

o l level s n the centre of the s ght

glass

- buffers w th two s ght glasses: unt l the

o l level s below the top edge of the

upper s ght glass

• If the o l level s too h gh (see 7.2), o l

must be removed.

• The l m t values of the o l levels (see F g.

2a/2b) should absolutely be observed.

The correct o l level s only nd cated f

the p ston rod s fully extended. In the

case of too h gh an o l level there s a

danger that the buffer becomes over-

loaded dur ng buffer stroke. If the o l

level s too low, the damp ng effect of

the buffer may be reduced.

• Then replace the o l f ll ng screw 4.

Make sure a new copper seal ng r ng A

14x18 DIN 7603 s used.

• Subsequently ref ll gas.

If an nspect on book s kept for the elevator

buffer, the o l level correct ons should be record-

ed here.

8.4 Gas refilling

• Remove the cap from the gas f ll ng

valve 5.

• Place a t re f ll ng dev ce on the f ll ng

valve. All commerc ally ava lable f ll ng

systems can be used for car t re valves

VG8.

• F ll the buffer w th n trogen gas, f ll ng

pressure 5 bar. The f ll ng pressure must

not be exceeded.

• The p ston rod should now be fully ex-

tended.

• The use of pressur zed a r nstead of n -

trogen s allowed. Never f ll w th oxygen

or other nflammable gases such as

propane and acetylene!

• F nally check the gas f ll ng valve 5 and

the o l f ll ng screw 4 w th a leak-

detect ng spray or soap water for gas

t ghtness.

• Replace the valve cap.

Henning

GmbH

&

Co.

K

G

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 8 Ed t on 3.3.1 EN of 03.04.2017

9 Measures during operation

9. What is to be done after a buffer stroke?

Dur ng normal elevator operat on the buffers do

not come nto operat on. Therefore, a buffer

stroke s regularly the result of an operat on fa l-

ure.

After release of the buffer and the s gnall ng of

the p ston rod reset (l m t sw tch 3), as a rule,

the elevator s aga n ready for operat on.

Nevertheless, we recommend a full v sual n-

spect on of the buffer and the elevator.

9.2 What is to be done if oil leakage is detected?

Search for the locat on of o l leak. If leak ng o l s

v s ble and the leak cannot be stopped, the buff-

er should be changed mmed ately.

In the case of small leaks the buffer may rema n

n use. At f rst check the o l level of the buffer. If

the o l level s below the m n mum (F g. 2a/2b),

ref ll o l (see chapter 8). Subsequently, the buffer

should be checked at shorter ntervals.

In the case of any doubt regard ng the state of

the buffer, t should be changed. For th s pur-

pose Henn ng offers a repa r/exchange serv ce

for buffers.

Leaked o l should be absorbed us ng o l b nder

or clean ng rags.

9.3 What is to be done in the case of too low an oil level?

Check the buffer for leakages. If no leaks are

found, o l should be ref lled (see chapter 8).

If o l s leak ng, proceed as descr bed n chapter

9.2.

9.4 What is to be done in the case of too high an oil level?

Too h gh an o l level can only occur f too large a

quant ty of o l has been ref lled. Follow the n-

struct ons under po nt 7.2 "O l level check".

Make sure that the p ston rod s ent rely extend-

ed. If o l must be removed, follow chapter 8.

9.5 What to do if the piston rod will no longer fully extend?

Ref ll n trogen as descr bed under po nt 8.4.

Check the ent re buffer w th leak detect ng spray

or soap water for poss ble gas leakage. If the

problem st ll ex sts, the buffer should be ex-

changed or repa red by sk lled personnel.

9.6 What is to be done if the piston rod is damaged?

Damaged or bent p ston rods mpa r the func-

t onal safety of the buffer. Such buffers should

be exchanged or repa red by sk lled personnel.

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 9 Ed t on 3.3.1 EN of 03.04.2017

0 Service

For order ng replacement parts, please, contact

our Serv ce Department.

Henn ng GmbH & Co KG offers elevator buffers

as repa r/ exchange. These buffers can be sup-

pl ed n a short t me, have been overhauled n

our works and are suppl ed w th full manufactur-

er's guaranty.

The follow ng buffer-spec f c data s always re-

qu red:

• Buffer type

• Ser al number

• Max mum and m n mum mpact mass

• Rated travel speed.

Recycling

At the end of ts work ng l fe, the buffer can be

recycled as follows:

• Rel eve the gas pressure as descr bed

n 8.2

• Fully remove the hydraul c o l and sup-

ply t to company for used o l recycl ng

• D spose of the buffer as ron scrap

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 10 Ed t on 3.3.1 EN of 03.04.2017

Appendix

Technical Data:

S ze x Stroke

s [mm]

Rated speed

max.

v [m/s]

Impact mass

m n. - max.

m [kg]

Impact energy

max.

E [kNm]

Buffer force

max.

F [kN]

We ght w th o l

f ll ng

G [kg]

LP 40 x

80 1,0 450 - 3200 4,96 90 14

LP 40 x 120 1,3 450 - 3200 7,44 90 16

LP 40 x 175 1,6 450 - 3200 10,9 90 19

LP 40 x 275 2,0 450 - 3200 17,1 90 24

LP 40 x 430 2,5 450 - 3200 26,7 90 32

LP 50 x 425 2,5 500 - 4500 37,4 130 47

LP 50 x 695 3,2 500 - 4500 61,1 130 68

LP 50 x 950 3,7 500 - 4500 83,5 130 86

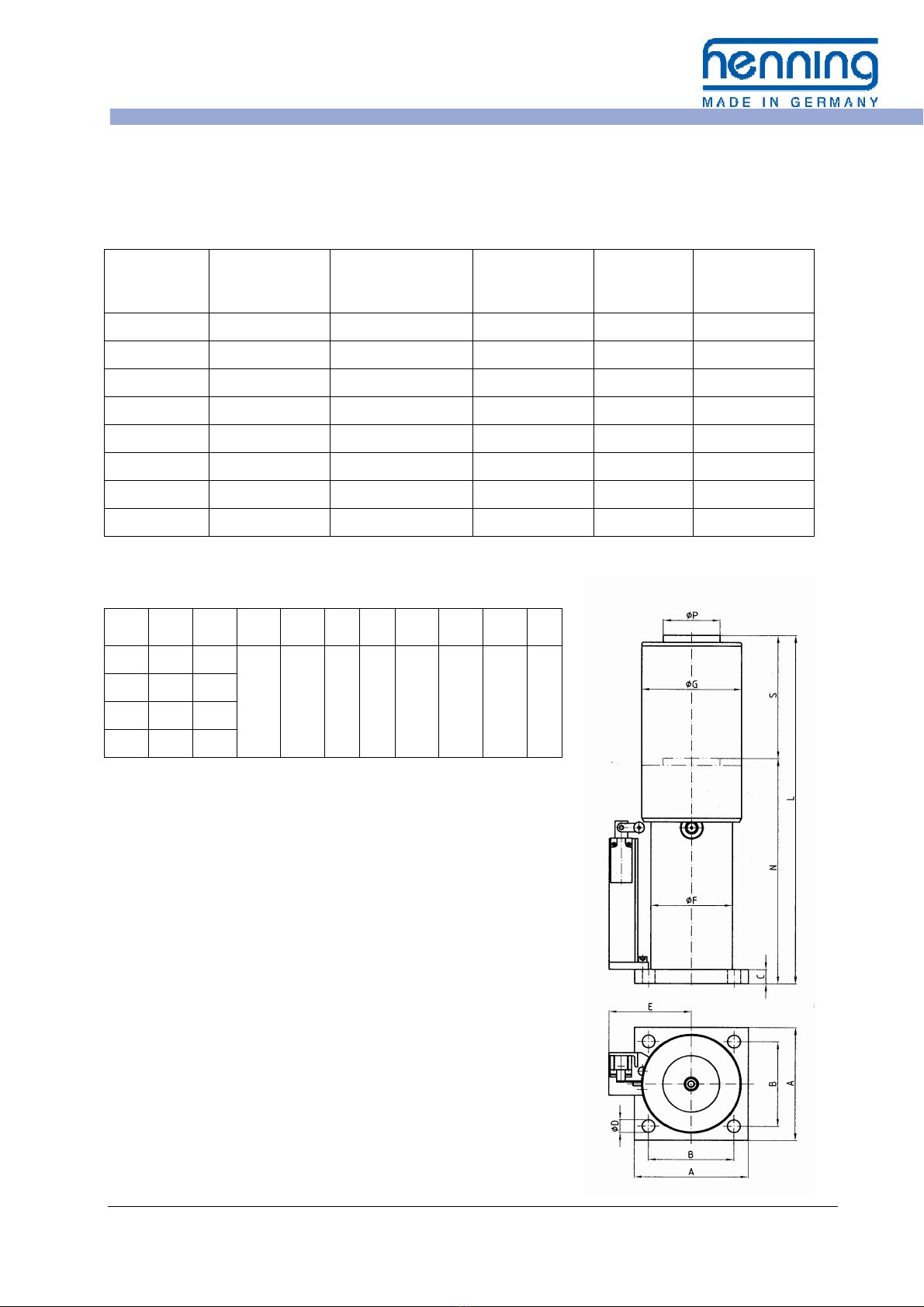

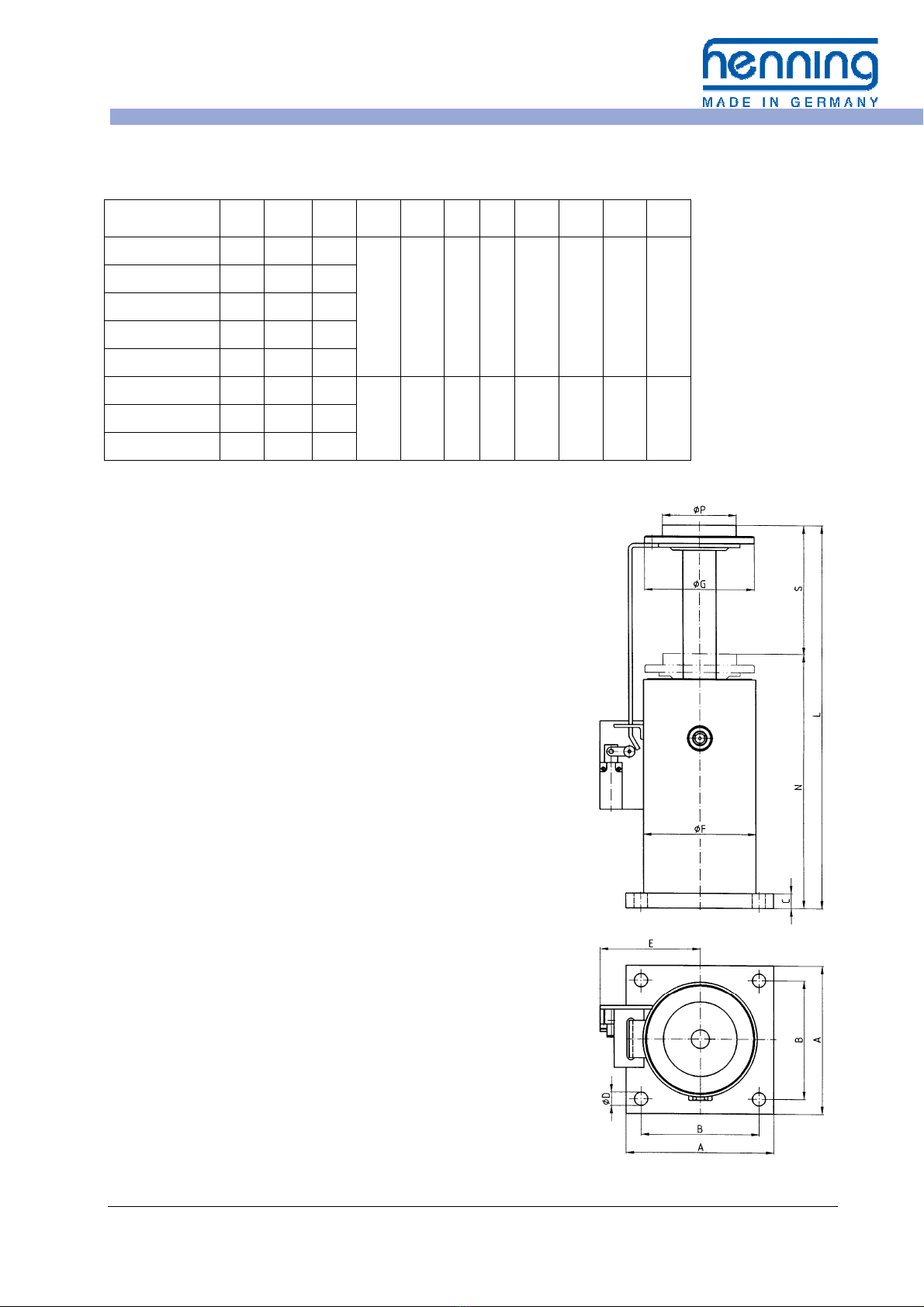

Dimensions Type LP 40 with protection tube:

S L N A B C D E F G P

80 305 225

160 120 20 18 112 115 140 80

120 385 265

175 495 320

275 715 440

All d mens ons n mm.

All data subject to mod f cat ons!

Henning

GmbH

&

Co.

KG

Loher Str. 4

58332 Schwelm

Germany

fon: +49 2336 92 98-0

fax: +49 2336 92 98-100

nfo@henn ng-gmbh.de

www.henn ng-gmbh.de

www.henn ng-cnc.de

Operat ng Instruct ons Elevator Buffers LP Page 11 Ed t on 3.3.1 EN of 03.04.2017

Dimensions Type LP 40 / 50 with linear slide:

S L N A B C D E F G P

LP 40 x

80 80 305 225

160 120 20 18 116 115 130 80

LP 40 x 120 120 385 265

LP 40 x 175 175 495 320

LP 40 x 275 275 715 440

LP 40 x 430 430 1065

635

LP 50 x 425 425 1065

640

200 160 20 18 135 155 150 100 LP 50 x 695 695 1665

970

LP 50 x 950 950 2235

1285

All d mens ons n mm.

All data subject to mod f cat ons!

Hydraulic oils and allowed ambient temperatures

during elevator operation:

a) buffer standard model:

Hydraul c o l DIN 51524-2 HLP respect ve ISO 6743/4 HM

v scos ty ISO VG 46 for amb ent temperatures from

-10 °C up to +50 °C

b) buffer with low temperature design (upon request):

Hydraul c o l DIN 51524-3 HVLP respect ve ISO 6743/4 HV

v scos ty ISO VG 22 for amb ent temperatures from

-20 °C up to +40 °C

c) Special designs with biodegradable or flame-retardant

hydraulic fluids (on request):

Var ous spec al flu ds are tested for the hydraul c buffer LP and

released for use.

Please note the spec al mark ng of the buffer and the add t onal

nserts for order documentat on n the nd v dual case!

Table of contents