HENSCHEL Antriebstechnik DURUMAX TGE User guide

Operating and Servicing Instructions

for

Co-Rotating

Twin Screw Extruder Gearbox

DURUMAX

TGE

DURUMAX

T1MAX

Date: October 2003

Operating and servicing instructions

2 / 24

Table of contents

1 Copyright..................................................................................................................................... 3

2 General instructions .................................................................................................................... 3

3 Safety instructions....................................................................................................................... 4

4 Rating plate ................................................................................................................................. 5

5 As-delivered condition, transport and storage............................................................................. 5

5.1 As-delivered condition and conservation ............................................................................ 5

5.2 Transport............................................................................................................................. 6

5.3 Storage................................................................................................................................ 6

6 Installation ................................................................................................................................... 6

6.1 General installation instructions .......................................................................................... 6

6.2 Foundation........................................................................................................................... 7

6.3 Shafts .................................................................................................................................. 7

6.4 Shaft seals........................................................................................................................... 8

6.5 Sleeves for coupling on the output...................................................................................... 8

6.6 Input clutches ...................................................................................................................... 9

6.7 Belt pulleys.......................................................................................................................... 9

6.8 After installation................................................................................................................... 9

7 Oil system.................................................................................................................................. 10

8 Commissioning the gearbox...................................................................................................... 10

8.1 Filling with lubricant........................................................................................................... 10

8.2 Checking the gearbox ....................................................................................................... 11

8.3 The first run ....................................................................................................................... 11

8.4 Monitoring the torque ........................................................................................................ 11

8.5 Monitoring the axial load ................................................................................................... 12

9 Operation................................................................................................................................... 12

10 Down times................................................................................................................................ 12

11 Technical description................................................................................................................. 13

11.1 General description ........................................................................................................... 13

11.2 Housing ............................................................................................................................. 13

11.3 Gear parts and shafts........................................................................................................ 13

11.4 Bearings ............................................................................................................................ 13

11.5 Seals.................................................................................................................................. 13

11.6 Lubrication......................................................................................................................... 13

11.7 Noises................................................................................................................................ 13

12 Servicing and inspection ........................................................................................................... 14

12.1 Servicing table................................................................................................................... 14

12.2 Topping up the oil.............................................................................................................. 15

12.3 Changing the oil................................................................................................................. 15

12.4 Inspection.......................................................................................................................... 16

13 Malfunctions – causes and rectification .................................................................................... 17

14 Lubricants.................................................................................................................................. 18

14.1 Recommended lubricant - mineral oil................................................................................ 19

14.2 Recommended lubricant – Poly-Alpha Olefin (PAO) ........................................................ 20

14.3 Ordering addresses for recommended lubricant suppliers ............................................... 21

15 Spare parts................................................................................................................................ 23

Table of contents

Operating and servicing instructions

3 / 24

1 Copyright

The copyright to these operating and servicing instructions lies with Henschel Industrietechnik.

These operating and servicing instructions contains instructions and drawings of a technical nature

that are not allowed to duplicated, distributed or used for competitive purposes, or provided to oth-

ers, either in full or in part.

Henschel Antriebstechnik

Henschelplatz 1

D-34127 Kassel

Tel.: +49 (0)561/801-6118

Fax.: +49 (0)561/801-6711

Mail: Antriebstechnik@Henschelgroup.com

2 General instructions

The complete technical documentation is always to be kept near the machine. Errors on the gear-

boxes can only be avoided and correct operation ensured with adequate knowledge of the operat-

ing and safety instructions.

•Every person who is involved in the installation, operation, servicing and repair of the gearbox

must have read and understood the operating and servicing instructions, and must also observe

the operating instructions. We accept no liability for damage and malfunctions in operation that

are caused by failure to observe the operating instructions. In case of doubt, the original Ger-

man version of the operating and servicing instructions is legally binding.

•We reserve the right to make changes to individual modules and accessories compared to the

illustrations and information given in these operating and servicing instructions as necessary for

the improvement of the gearbox.

•The gearboxes are designed for the application that is given in the gearbox datasheet in these

operating and servicing instructions. These operating and servicing instructions can be supple-

mented with additional agreements and instructions. Operation in a different application is not

allowed.

•Before the gearbox is used outside the contractually defined application, after sales service is to

be consulted as otherwise the warranty will be void. Different operating conditions require new

contractual agreements.

Operating and servicing instructions

4 / 24

3 Safety instructions

All work on the gearboxes is to be performed while paying special attention to the aspect of "health

and safety". It is to be refrained from working in any way that endangers the safety of persons and

the gearbox. The gearbox is only allowed to be operated, serviced and repaired by authorized,

trained and appropriately instructed personnel. Work on the gearboxes by unauthorized persons is

to be prevented by the operating organization.

•The applicable regulations for health and safety, the prevention of accidents and the protection

of the environment apply.

•It is imperative that information on the gearbox such as the direction of rotation arrows, rating

plates and the like is observed.

•Rotating input and output components such as couplings, gearwheels, belt drives and the like

must be protected against accidental contact by means of appropriate safety guards.

•Prior to commissioning it is to be checked whether all safety guards are fitted.

•It is not allowed to perform any welding work on the gearbox. The gearbox is also not allowed to

be used as an earthing point for welding work. Damage to the gear teeth or bearings could re-

sult.

•It is not allowed to clean the gearbox with high-pressure cleaning equipment.

•All work on the gearbox is only allowed to be performed when the gearbox is stationary. The

drive unit must be secured against inadvertent switch on.

•The operating organization has the obligation to only operate the gearbox when it is in correct

working order. The drive unit must be switched off immediately if changes on the gearbox are

noted during operation, e.g. elevated operating temperatures, changes in the noises from the

gearbox or leaks.

•Spare parts are always to be procured from Henschel Industrietechnik.

•Unauthorized modifications and changes that affect the safety or function of the gearbox are not

allowed.

•When changing the oil, the used oil is always to be collected in a container. Any oil spills are to

be removed immediately.

•Conservation agents are to be stored separately to used oil.

•Conservation agents, oil binding agents, used oil and oil-soaked cloths are to be disposed of in

accordance with the applicable regulations for the protection of the environment.

The operating organization is responsible for the correct installation of the gearbox. It is a

prerequisite for the assured properties of the gearbox and acceptance of any warranty

claims that the instructions in these operating and servicing instructions are observed.

Observance of the manufacturer's instructions in these operating and maintenance instruc-

tions is a prerequisite for the acceptance of warranty claims.

The performance and properties of the gearbox stated by the manufacturer can only be pro-

vided on observance of the stipulated handling and servicing.

Operating and servicing instructions

5 / 24

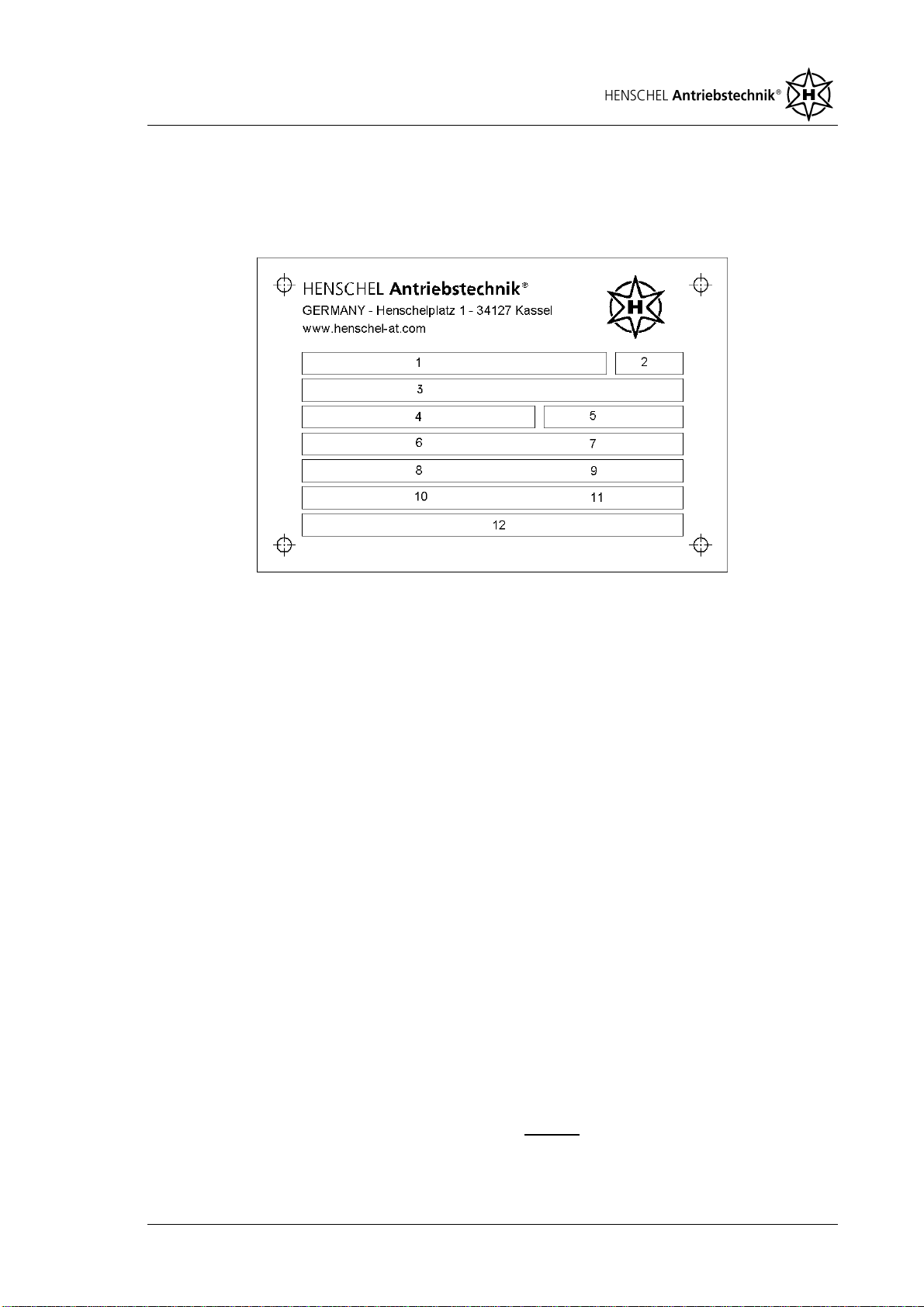

4 Rating plate

The rating plate on the Henschel Industrietechnik twin screw extruder gearbox includes key techni-

cal data. Other data is to be found in the assembly drawings and any technical data sheets en-

closed.

1 Type

2 Year of manufacture

3 Factory number

4 Rating (kW)

5 Weight (kg)

with attachment parts and without oil

filling

6 Input speed (min

-1

)

7 Transmission ratio

8 Lubricants in accord. with DIN 51 517

9 Oil capacity (l)

10-12 Additional information on possible

axial force measurement and torque

monitoring

•When making queries, it is imperative that the information on the rating plate is supplied

•The rating plate is not allowed to be removed; it is to be kept clear of dirt and paint. Missing

plates must be replaced without delay

5 As-delivered condition, transport and storage

5.1 As-delivered condition and conservation

All twin screw extruder gearboxes are subject to a test run and acceptance prior to delivery. Ac-

ceptance is performed in accordance with Henschel regulations or as per the related requirements

agreed in the contract. The paint finish on the interior and exterior of the gearbox comprises a thick-

film epoxy metal primer RAL 7032 (pebble grey). The manufacturer reserves the right to use other

products in special cases. An additional topcoat can be agreed. All bare exterior parts and surfaces

are coated with a wax conservation agent, e.g. Tectyl 846. The conservation on the exterior of the

gearbox is to be removed using suitable means. During this process the corresponding regulations

on waste disposal are to be observed. The conservation inside the gearbox is matched to the type

of oil given in the gearbox data sheet. It is not necessary to remove the conservation agent inside

the gearbox. Given proper storage, the conservation is effective for 6 months. For longer periods of

storage, the conservation inside the gearbox and on the exterior is to be checked and renewed if

necessary.

The gearboxes are delivery ready to use, however without oil filling. Prior to commissioning,

the gearboxes are to be filled with a suitable lubricant (see information on the gearbox data

sheet).

Operating and servicing instructions

6 / 24

5.2 Transport

The gearbox is packed to suit the type of transport such that it can be transported without damage.

The gearbox is equipped with holes for ring bolts as per the installation drawing. Appropriate ring

bolts are to be fitted such that they are tight against the bearing surface. On some models, special

hooks for lifting tackle are fitted to the lower part of the housing.

The ends of shafts and attachment parts such as pipes and coolers are not allowed to be

used for transport.

For transport, ropes with adequate carrying capacity are to be attached to the ring bolts/hooks (the

weight of the gearbox is to be taken from the rating plate or the gearbox data sheet). For types with

an adapter housing, the ropes can be placed through the opening on the adapter housing.

•Only the ring bolts or the hooks are designed for the transport of the gearbox. Transporting the

gearbox using attachment parts already fitted is not allowed.

•It is only allowed to lift and set down the gearbox using suitable lifting gear.

•All transport aids fitted are to be used. During transport the gearbox is be kept horizontal so that

all points are evenly loaded.

•During transport it is to be ensured that any attachment parts, e.g. pumps, coolers or pipes are

not damaged.

•Transport is to be performed with extreme care to avoid injury. Damage to the gearbox, e.g. due

to impacts on the open ends of shafts or due to setting down hard is to be avoided.

5.3 Storage

Proper storage of the gearbox will prevent premature damage and problems during later commis-

sioning.

•The gearbox is to be stored in place free of vibration and protected from the weather.

•Vibrations and shocks can cause damage. Moisture and other substances can impair the func-

tionality of the gearbox.

•It is not allowed to stack gearboxes on top of each other.

•The gearbox and the attachment parts are to be protected from mechanical, chemical and

thermal damage, as these can cause corrosion.

6 Installation

6.1 General installation instructions

During the installation of the gearbox, it is imperative that the instructions in section 3 "Safety in-

structions" are observed. Damage cause by incorrect installation is excluded from the warranty.

•Installation is only to be performed by trained, authorized and appropriately instructed person-

nel.

•The gearbox is to be installed in a suitable place such that there is sufficient space for the in-

stallation work and subsequent servicing work.

Operating and servicing instructions

7 / 24

•Oil drain and oil level gauge must be easily accessible.

•The gearbox is to be protected from strong sunlight so avoid over-heating.

•During transport, it is imperative that the instructions in section 5.2 are observed.

•Bangs and knocks are to be avoided, as these can damage shafts, bearings, gears and seals.

6.2 Foundation

•The gearbox is to be installed on a flat, rigid and torsionally stiff foundation. The foundation

must be designed such that there are no resonances and no vibration/shocks can be picked up

from other foundations. When installing the gearbox, it is imperative that the directive VDI 2726

"Ausrichten von Getrieben" (Aligning Gearboxes) is observed.

•Prior to installation, the underside of the gearbox feet and the foundation frame are to be

cleaned.

•The gearbox is, depending on the type, to be attached to the foundation at all the fastening

points provided for this purpose.

•It is imperative that the mounting position agreed in the order is maintained. An incorrect

mounting position can result in inadequate lubrication and thus to complete failure.

•Fastening bolts must have a minimum strength class of 8.8.

•The gearbox is not allowed to be placed under stress when the fastening bolts are tightened.

•The alignment of the gearbox must be re-checked after tightening the fastening bolts.

•If external forces act on the gearbox, it is appropriate to prevent movement using lateral stops.

•All fastening features on the gearbox are to be utilized.

6.3 Shafts

•The coating of conservation agent applied to the shafts is to be entirely removed using an ap-

propriate, approved cleaning agent. During this process appropriate ventilation is to be pro-

vided. ATENTION, risk of explosion.

•It is to be ensured that the shaft sealing rings are not wet with the solvent when removing the

conservation agent, as otherwise leaks may result.

•Input and output parts (e.g. couplings) are to be tightened and locked. Here suitable devices are

to be used. Shaft seals and their contact areas on the shaft must not be damaged.

•Fitting couplings or other attachment parts by hitting or striking is not allowed as this can result

in damage to the bearings, gears and seals.

•If heating is necessary for fitting attachment parts, this can be performed inductively, with a gas

torch, or in an oven. It is to be ensured that the shaft seals are protected from damage and from

heating to more than +100°C during this process.

Operating and servicing instructions

8 / 24

6.4 Shaft seals

The shafts are sealed with single or double shaft seals. On certain types, labyrinth seals, special

cassette seals or a combination of various systems can also be used.

•The shaft seals must not come into contact with solvents or unsuitable cleaning agents, as this

can result in leaks.

•Corrosion on the shaft due, for example, to high atmospheric humidity limits the life of the shaft

seals.

•During painting, the shaft seals and the contact areas are to be masked using suitable means.

Remnants of paint are not allowed in the area of the seal, as they can cause damage and thus

leaks.

•The operating temperatures stipulated on the gearbox data sheet are not allowed to be ex-

ceeded, as elevated operating temperatures can cause premature damage to the seals.

•The shaft seals must be protected from the mechanical action of tools or other objects.

•Replacement seals are to be procured from Henschel Industrietechnik. We only guarantee

spare parts that we have supplied. A warranty is only provided for the spare parts supplied by

the manufacturer.

6.5 Sleeves for coupling on the output

Sleeves for coupling are used to adapt the extruder screws to the gearbox. The design and align-

ment of the sleeves for coupling is customer and gearbox-specific. The related items are to be

found on the installation drawing.

It is not possible to interchange sleeves for coupling from different gearboxes.

•For the adaptation of the two extruder screws, the two sleeves for coupling must be placed in

the corresponding position as per the installation drawing. If not otherwise requested, Henschel

Industrietechnik will supply the gearbox with matched sleeves for coupling.

•The two sleeves for coupling must always remain with the related gearbox because they have

been specially matched to the related gearbox.

•In the case of damage to the gearbox, the sleeves for coupling are also to be returned to the

gearbox manufacturer.

•The sleeves for coupling are only allowed to be matched to the gearbox using the alignment

device for this purpose and by trained personnel.

•The factory number and the sequential gearbox number are used for identification. As a rule,

the two sleeves for coupling are also marked with the letters R and L (right and left in the direc-

tion of extrusion).

•The reference surfaces on the two output shafts are aligned under axial loading. The tolerances

on the alignment are to be found in the installation drawing. In the unloaded state, the toler-

ances given may be exceeded due to the pre-tensioning forces in the springs.

Operating and servicing instructions

9 / 24

6.6 Input clutches

Safety clutches are to be used for the gearbox input. The use of rigid couplings or other input ele-

ments that can exert radial and/or axial forces must be agreed with Henschel Industrietechnik. The

contractually assured type of input is to be found in the gearbox data sheet.

When using clutches, the following is to be observed:

•Drive unit and gearbox must be accurately aligned. Incorrect axle or angular offset can result in

premature failure. The limits from the supplier of the clutch apply.

•From a peripheral speed of 30m/s at the outside diameter on the clutch, dynamic balancing is

required. Here the information from the clutch manufacturer must be observed.

6.7 Belt pulleys

For certain types, it is possible to provide drive using a belt pulley.

A belt pulley is only allowed to be used if this input variant is recorded in the gearbox data

sheet.

The unauthorized fitting of a belt pulley can result in shafts shearing, bearing and gear damage.

•Belt pulleys are to be fitted to the end of the input shaft with the aid of thrust plates and bolts

using thread centering or by other suitable means.

•Fitting by hitting and striking is not allowed as parts inside the gearbox may be damaged in this

way.

•The maximum permissible belt tension (force applied at the middle of the key) must not be ex-

ceeded, as otherwise the input shaft may be subject to excessive bending and damage caused

to the bearings and seals. The values given in the gearbox data sheet are general figures. In

case of doubt, consult Henschel Industrietechnik.

•The belt is only allowed to be tensioned in the directions given by Henschel Industrietechnik.

Failure to observe this instruction can result in premature damage. In case of doubt, consult

Henschel Industrietechnik.

•Belt tension must always be applied at the middle of the key. The use of excessively wide belt

pulleys is to be avoided.

•The holes on the belt pulleys used should not have sharp edged transitions at the front face.

Belt pulleys with rounded transitions reduce stressing at the edges and thus help to prevent

damage to the input shafts.

•Following installation, the V-belt is to be protected against accidental contact by means of a

suitable safety guard.

6.8 After installation

•Following installation, all rotating parts are to be protected against accidental contact by means

of suitable safety guards.

•Any guard supplied, if removed, must be re-fitted.

•By referring to the delivery paperwork and the assembly drawing, it is to be checked whether all

devices that may have been removed from transport or other reasons have been re-fitted.

Operating and servicing instructions

10 / 24

7 Oil system

The gearbox is to be connected to a suitable oil system. The necessary data are to be found in the

gearbox data sheet in these operating and servicing instructions. Suction and pressure connections

are fitted to the gearbox in the form of threaded holes. The position and the connection data are to

be found in the installation drawing.

•The threaded holes are sealed with plugs for transport. These plugs are to be retained and re-

fitted if the gearbox is removed.

•It is to be checked whether all monitoring devices fitted to the oil system function correctly.

•The oil system must comply with the technical requirements listed in the gearbox data sheet.

•The system is to be equipped with pressure switches for monitoring the oil pressure, if the oil

pressure drops below 0.5bar the main motor is to be shut down.

•The temperature of the oil is to be monitored. For fitting a temperature sensor, depending on

the order, there is a threaded hole G1/2" in the lower part of the base gearbox housing.

•The oil filter must have the filter mesh required in the gearbox data sheet and be tested for cor-

rect function.

•The system is to be checked for oil leaks at operating temperature.

•All threaded fittings are to be checked for tightness.

8 Commissioning the gearbox

When commissioning the gearbox, it is imperative that the instructions in section 3 "Safety instruc-

tions" are observed.

•Prior to commissioning, the rest of the conservation oil or the running-in or test oil is to be

drained from the gearbox and disposed of in accordance with regulations.

•Flushing with petrol or other cleaning agents is forbidden, as the residue left in the gearbox can

cause decomposition.

8.1 Filling with lubricant

Prior to commissioning, the gearbox is to be filled with fresh oil via the threaded hole for the vent

screw or via the inspection holes.

When filling the gearbox, the lubricant is to be filtered with the aid of a funnel with filter (filter

mesh 40µm). Dirty oil can cause premature damage to bearings and gears.

•Only the lubricants given in the attached lubricant table (section 14) for twin screw extruder

gearboxes from Henschel Industrietechnik are allowed to be used. The use of other lubricants is

only allowed following consultation and agreement with Henschel Industrietechnik.

•The approximate oil capacity, the oil type and the oil viscosity are to be found in the instructions

on the rating plate.

Operating and servicing instructions

11 / 24

•The oil capacity given on the gearbox rating plate is an approximate quantity. The gearbox is to

be filled until the oil is at least up to the middle of the oil sight glass.

•To ensure that the oil level is correct, after filling with lubricant the oil system is to be placed in

operation for approx. 5 minutes. If the oil level drops during this process, the oil is to be topped

up.

•Any oil spilt is to be removed immediately with an oil binding agent.

•After filling, the air filters are to be re-fitted and the inspection holes securely closed.

It is imperative to ensure that no dirt enters the gearbox during an oil change.

8.2 Checking the gearbox

Prior to initial commissioning, the gearbox is to be carefully inspected to avoid damage due to incor-

rect installation.

•All mechanical parts, e.g. inspection hole covers, guards, foundation threaded fittings and oil

supply pipes must be tight.

•Check the oil level at the oil sight glass.

•There must not be any leaks on the gearbox.

•All supply pipes must be correctly connected.

•The gearbox must be securely fastened to the foundation (section 6.2).

•All rotating parts must be covered in accordance with regulations and secured against acci-

dental contact (section 3).

8.3 The first run

The gearbox can only be operated in one direction of rotation (see installation drawing and gearbox

data sheet).

Operation in the opposite direction of rotation is not allowed.

The gearbox is only allowed to be placed in operation and operated when the oil system is

running.

If the oil system fails, the gearbox is to be shut down immediately.

The lubricant in the oil system must be pre-heated to the minimum operating temperature. It

is recommended to leave the oil system running for at least 10 minutes prior to starting the

drive unit. Here it is to be ensured that inadmissible foaming does not occur.

8.4 Monitoring the torque

Henschel Industrietechnik twin screw extruder gearboxes can transmit very high torques via the two

output shafts. The maximum permissible torques are to be found in the gearbox data sheet.

It is possible to monitor the torques at the output shafts with the aid of torque measuring shafts. The

shafts are checked and calibrated. The calibration log is included with the gearbox. The part num-

bers for the measuring shafts as well as the number of the calibration log are noted on the rating

plate.

Operating and servicing instructions

12 / 24

8.5 Monitoring the axial load

The twin screw extruder gearboxes built by Henschel Industrietechnik can absorb high axial thrust

loads on both output shafts. The maximum permissible thrusts and the thrust loads are to be found

in the gearbox data sheet.

Depending on the order, the gearbox can be supplied with axial force monitoring. The forces are

monitored using a load cell or a bonded strain gauge. All measuring devices are checked in ad-

vance and calibrated. The calibration log is included with the gearbox.

The type of axial force monitoring is to be found on the rating plate. The number of the calibration

log is also noted here. On the use of load cells, the serial number is also given.

9 Operation

It is to be ensured that the performance data and parameters in the data sheet and on the rating

plate are observed. Only in this way is the reliability and long service life of the gearbox assured.

•If the gearbox is equipped with an oil supply system, the gearbox is never allowed to be placed

in operation without the oil supply system running.

•The servicing work listed in section 12.1 must be performed conscientiously.

•An exact oil level check is only possible with the system stationary. When the oil is warm the oil

level can be somewhat higher. It is not allowed to let the oil level drop below the minimum mark

– in this case the oil must be topped up (section 12.2).

If irregularities occur during the operation, the system is to be shut down immediately. The cause of

the malfunction is to be determined and rectified before the gearbox is placed back in operation.

Section 13 provides an overview of the possible causes of malfunctions and their rectification. If the

reason for the malfunction cannot be correctly determined, after sales service at Henschel Indus-

trietechnik is to be contacted.

10 Down times

During down times of several months, the gearbox is to be run at no load and nominal speed for a

short time every approx. 4 weeks. If this is not possible, the gearbox must be protected with a suit-

able conservation agent. Henschel Industrietechnik after sales service will provide assistance with

the interior and exterior conservation.

Storage for more than 24 months can result in degradation of the gearbox components. In these

cases it is advisable to consult Henschel Industrietechnik.

Operating and servicing instructions

13 / 24

11 Technical description

11.1 General description

These operating and servicing instructions only apply to twin screw extruder gearboxes manufac-

tured by Henschel Industrietechnik. The gearboxes described are spur gearboxes with one input

shaft and two output shafts as marketed by Henschel Industrietechnik with the identifier TGE or

T1MAX.

11.2 Housing

All housing parts comprise thick-walled grey cast iron with optimized internal ribbing. If necessary,

certain parts may also be manufactured from steel. The housing parts are joined together using

bolts and alignment dowels. The torsion resistant design has optimized noise behavior. Inspection

hole covers on the top of the gearbox enable the gears to be checked. An oil sight glass enables

the oil level to be checked.

11.3 Gear parts and shafts

The gear parts are manufactured from high-alloy hardened steel, case hardened, ground and de-

signed for durability. High contact ratios and high gear quality ensure low noise running.

The transmission of torque from the spur gears to the shafts is force-locked. The shafts are manu-

factured from high-alloy heat treated steel and transmit the torque with adequate safety.

11.4 Bearings

All shafts have bearing at both ends. Axial bearings of varying types are used for absorbing the

axial forces from the screws. The minimum theoretical bearing service lives for the roller bearings

and the thrust bearings are given in the gearbox data sheet. These are calculated based on the

nominal torque and nominal speed. Collective load, impacts and lubricant effects are not taken into

account here.

11.5 Seals

The inspection hole covers are sealed with an asbestos-free gasket, the bearing surfaces for all

other covers and housing joints are sealed with a durable sealant. The shafts are sealed with single

or double shaft seals. On certain types labyrinth seals, special cassette seals or a combination of

various systems are used.

11.6 Lubrication

A combined splash and forced-feed circulatory lubrication system supplies the gearbox with suffi-

cient oil. Internal pipework feeds the oil to the meshing gears and the roller bearings. The gearbox

housing also serves as an oil reservoir to which the oil filler openings, oil drain plug and oil level

gauge are fitted.

11.7 Noises

Sound pressure levels have been measured at the gearboxes for the operating conditions stated in

the gearbox data sheet. The magnitude of the sound pressure level is to be found in the gearbox

data sheet.

Operating and servicing instructions

14 / 24

12 Servicing and inspection

Malfunctions that are caused by inadequate or improper maintenance can result in high repair costs

and unnecessarily long gearbox down times. Regular servicing and inspection work are therefore

imperative.

All servicing and repair work is only allowed to be performed with the gearbox stationary and by

trained, authorized and appropriately instructed personnel. It is imperative that all safety instructions

(section 3) are observed.

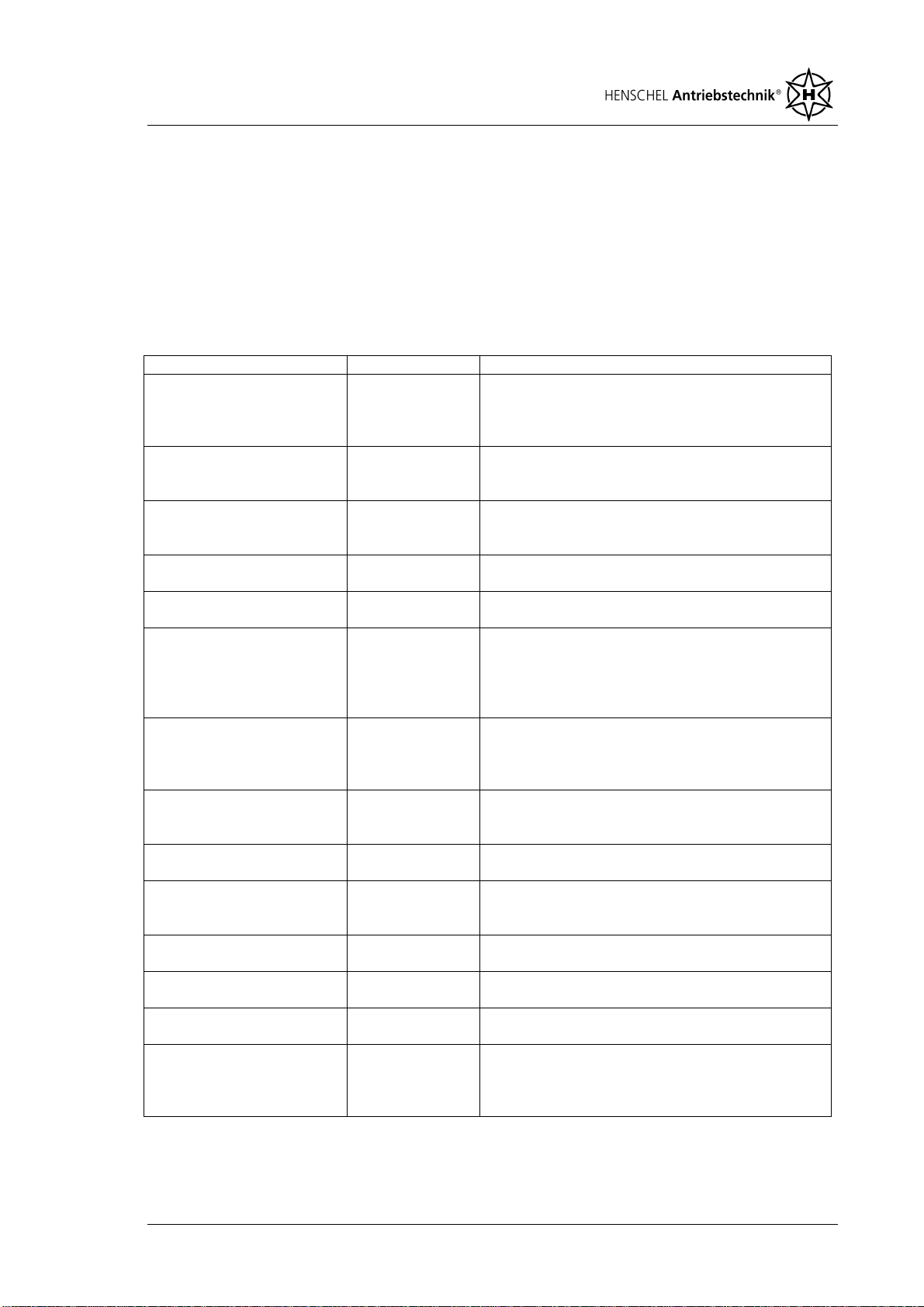

12.1 Servicing table

Work to be performed Frequency Comment

Check the oil temperature daily Excessively high temperatures are a sign of

malfunctions or damage to the gearbox or the oil

system. They reduce the service life of the oil and

can result in the premature failure of the gearbox

Check the noise made by

the gearbox for changes daily Changes in the noises made by the gearbox can

be indicative of damage to the parts inside the

gearbox

Check the oil level weekly An oil level that is too low can result in inade-

quate lubrication of the gearbox and thus to fail-

ure of bearings or gears

Check the gearbox for

leaks monthly Leaks that go unnoticed can result in inadequate

lubrication

First oil change after approx. 250

operating hours See section 12.3

Subsequent oil change every 4000 to

8000 operating

hours, at the

latest however

after 12 months

See section 12.3

Visual inspection of the

gears quarterly The visual inspection of the gears can be per-

formed by removing the inspection hole covers.

In case of damage or irregularities, the manu-

facturer must be consulted

Check used oil for foreign

bodies and coloration quarterly Unusually high quantities of foreign bodies, e.g.

metal particles can be indicative of damage.

Coloration is a sign of reduced quality oil

Clean the air filter quarterly Regular cleaning with suitable cleaning agents

prevents clogging of the filter

Check the oil filter quarterly (daily

with autom. dis-

play)

Unusually high quantities of foreign bodies, e.g.

metal particles can be indicative of damage, it is

then necessary to replace the filter

Check the oil viscosity class before every oil

change The viscosity is to be found on the rating plate

and the gearbox data sheet

Clean the gearbox housing after every oil

change Prevents premature aging and undesirable corro-

sion

Check all fastening bolts annually Checking all fastening bolts for tightness in-

creases safety and reliability

Service the complete gear-

box Every 2 years Regular servicing by Henschel Industrietechnik

after sales service enables worn parts to be re-

placed in a timely manner and thus ensures long

gearbox service life

Operating and servicing instructions

15 / 24

12.2 Topping up the oil

The oil level is to be checked regularly. It must never be below the bottom mark. In the case that the

oil level drops below the minimum, it is imperative that the lubricant is topped up. The oil is only

allowed to be topped up with the drive units shut down.

•A funnel with a filter is to be used for topping up (filter mesh 40µm).

•The gearbox is always to be filled with the same type of oil as used previously (see section 8.1).

It is not allowed to mix different oils or oils from different manufacturers.

12.3 Changing the oil

The effectiveness of the oil reduces with increasing use due to soiling (foreign bodies and water)

and chemical changes (ageing products). When the soiling and/or ageing is/are excessive, it is

necessary to change the oil. Regular oil analyses provide information on the effectiveness of the

gearbox oils. For larger quantities of oil it is recommended to make oil changes dependent on the

results of an oil analysis. A missed oil change increases the risk of damage and can result in pre-

mature failure of the gearbox.

The first oil change should be made at approx. 250 operating hours. Subsequent oil changes de-

pend on the state of the oil and are to be performed every 4,000 to 8,000 operating hours, however

at the latest after one year.

•As a matter of principle the gearbox is always to be filled with the type of oil used previously. It

is not allowed to mix different oils or oils from different manufacturers.

•A funnel with a filter must be used to fill the gearbox (filter mesh 40µm). Dirt can result in pre-

mature damage to bearings and gears.

•When changing the oil, the old gearbox oil is to be drained, if possible when still warm, using

the oil drain plug provided for this purpose.

•The drained gearbox is to be cleaned of oil sludge, dirt and remnants of old oil using flushing oil.

The same type of oil is to be used here.

•On every oil change the oil drain plug is to be cleaned. If the plug is very dirty, the source of the

dirt is to be determined. There may be damage.

•Also, on every oil change the filter element in the oil filter is to be cleaned or replaced, as a dirty

filter can degrade the reliable function and expected service life of the gearbox and the oil sys-

tem.

•The gearbox vent filter is also to be cleaned.

•All instructions in section 8.1 are to be observed.

•When the oil is changed, all tooth flanks are to be visually inspected. In case of damage or ir-

regularities, the manufacturer is to be consulted.

•When refilling the gearbox, it is to be ensured that the oil level is in the area marked on the oil

sight glass. To ensure that the oil level is correct, after filling the oil system is to be placed in

operation for approx. 5 minutes so that the fresh oil can fill the pipes and the cooler. If the oil

level drops, the oil is to be topped up.

It is imperative to ensure that no dirt enters the gearbox during the oil change.

Operating and servicing instructions

16 / 24

12.4 Inspection

To counteract damage on the gearbox, regular inspections should be performed. The after sales

service department at Henschel Industrietechnik offers the following checks:

•Checking the contact pattern on the individual teeth,

•Checking whether there is any damage to the parts of the gears, e.g.:

- Pittings and micro pittings on the tooth flanks (due to gearbox overloading)

- Scratches and indentations (due to the action of dirt)

- Fretting (due to inadequate lubrication or overload)

•Visual inspection of the roller bearings

•Checking the oil supply to the meshing gears and to the roller bearings in the gearbox

In case of damage, the related parts are replaced. Malfunctions are rectified. Please contact our

after sales service department.

Operating and servicing instructions

17 / 24

13 Malfunctions – causes and rectification

Regular servicing of the gearbox, as described in section 12, is imperative. It is only in this way that

irregularities can be detected and more serious consequent damage avoided. If malfunctions occur

during the warranty period and repair is necessary, the after sales service department at Henschel

Industrietechnik is to be contacted. For repairs that were not approved by Henschel Industrietech-

nik, no warranty or guarantee for the subsequent operation of the gearbox can be provided.

The rectification of malfunctions is only allowed to be performed with the gearbox stationary and by

trained personnel. It is imperative that all safety instructions (section 3) are observed.

Possible malfunctions:

Malfunctions Causes Rectification

Oil level is too high Check oil level and adjust

Oil is too old Check when the oil was last changed and if nec-

essary have the oil analyzed and change the oil

Oil is very dirty Change the oil

Cooling is insufficient Check the cooling system feed and return, if nec-

essary increase the cooling (higher flow of cool-

ing water, lower temperature)

Oil flow rate is inade-

quate Check the feed and return, clean oil filter or re-

place

Elevated oil tem-

perature

Oil pump is faulty Check pump, if necessary replace

Oil level is too low Check oil level and adjust

Oil is too old Check when the oil was last changed and if nec-

essary have the oil analyzed and change the oil

Bearing faulty Seek advice from Henschel Industrietechnik after

sales service

Elevated bearing

temperature

Oil pump faulty Check pump, if necessary replace

Noises Bearing or gear dam-

age Seek advice from Henschel Industrietechnik after

sales service

Inadequate fastening to

the foundation Re-tighten bolts, if necessary replace

Leaks Inadequate sealing Check radial shaft seals and other seals, if nec-

essary replace, renew sealing of joints (on this

topic seek advice from Henschel Industrietechnik

after sales service)

Water in the oil Oil cooler faulty Repair/replace oil cooler

Condensed water Fit suitable thermal insulation, close vent, moist

air filter

Elevated quantity of

particles in the oil Bearing or gear dam-

age or faulty oil pump Seek advice from Henschel Industrietechnik after

sales service

Oil foaming Oil incompatible with oil

residue Change the oil

Operating temperature

too low Shut down plant, leave oil to de-gas, pre-heat oil

to operating temperature (if necessary shut off

cooling water feed briefly)

Water in the oil Have the oil analyzed, if necessary change the oil

Operating and servicing instructions

18 / 24

14 Lubricants

The oil types and oil viscosity class stipulated by Henschel Industrietechnik can be found on the

rating plate and the data sheet for the related gearbox. This information applies for the operating

data given in the gearbox data sheet. If these data change, Henschel Industrietechnik in Kassel is

to be consulted prior to commissioning. If a different viscosity class is used or gearbox oil different

to that recommended is used, the responsibility for the technical suitability lies with the operating

organization.

Only CLP quality oils are allowed to be used for our gearboxes. They must comply with the mini-

mum requirements in DIN 51517-3 (draft January 2002). In addition, the oil must have increased

safety against micro pittings. The oils must be suitable for the elastomeric materials in the shaft

seals and the usual gaskets that are used between bolted surfaces.

The use of lubricants that do not comply with the stipulated quality requirements may render the

warranty void.

The mineral oils listed in section 14.1 can be used in a temperature range from –10°C to +90°C

(100°C briefly). For the poly-alpha olefins (sectio n 14.2) the temperature range is between –20°C

and +100°C (110°C briefly).

Lubricants from different manufacturers are never allowed to be mixed together.

Furthermore, flushing with petrol or other cleaning agents is not allowed, as the residue left

in the gearbox can result in decomposition.

Operating and servicing instructions

19 / 24

14.1 Recommended lubricant - mineral oil

Lubricant Mineral oil

Code letter in accordance with DIN 51502 CLP

Identifier in accordance with DIN 51517-3 CLP 220 CLP 320 CLP 460

Identifier in acc. with DIN ISO 3498 CC 220 CC 320 CC 460

ISO viscosity class in acc. with DIN 51519 ISO-VG 220 ISO-VG 320 ISO-VG 460

Kinematic viscosity at 40°C [mm

2

/s] 220 320 460

Manufacturer Degol BG 220 Plus Degol BG 320 Plus Degol BG 460 PlusAral

Degol BMP 220 * Degol BMP 320 * Degol BMP 460 *

Castrol Alpha SP 220 Alpha SP 320 Alpha SP 460

Renolin CLP 220

Plus Renolin CLP 320

Plus Renolin CLP 460

Plus

Fuchs

Renolin CLP 220 Renolin CLP 320 Renolin CLP 460

Mobil Mobilgear XMP

220 Mobilgear XMP

320 Mobilgear XMP

460

Shell Shell Omala F 220 Shell Omala F 320 Shell Omala F 460

Optimol Optigear

BM 220 Optigear

BM 320 Optigear

BM 460

Tribol Tribol 1100/220 Tribol 1100/320 Tribol 1100/460

* High-performance CLP oil with molybdenum disulphide (MoS

2

)

Operating and servicing instructions

20 / 24

14.2 Recommended lubricant – Poly-Alpha Olefin (PAO)

Lubricant Poly-Alpha Olefin (PAO)

Code letter in accordance with DIN 51502 CLP HC

Identifier in accordance with DIN 51517-3 CLP HC 220 CLP HC 320 CLP HC 460

Identifier in acc. with DIN ISO 3498 CC 220 CC 320 CC 460

ISO viscosity class in acc. with DIN 51519 ISO-VG 220 ISO-VG 320 ISO-VG 460

Kinematic viscosity at 40°C [mm

2

/s] 220 320 460

Manufacturer

Aral Degol PAS 220 Degol PAS 320 Degol PAS 460

Castrol Alphasyn EP 220 Alphasyn EP 320 Alphasyn EP 460

Fuchs Renolin Unisyn

CLP 220 Renolin Unisyn

CLP 320 Renolin Unisyn

CLP 460

Mobilgear SHC 630 Mobilgear SHC 632 Mobilgear SHC 634Mobil

Mobilgear SHC

XMP 220 Mobilgear SHC

XMP 320 Mobilgear SHC

XMP 460

Shell Shell Omala HD

220 Shell Omala HD

320 Shell Omala HD

460

Optimol Optigear

Synthetic A 220 Optigear

Synthetic A 320 Optigear

Synthetic A 460

Tribol Tribol 1710/220 Tribol 1710/320 Tribol 1710/460

This manual suits for next models

1

Table of contents