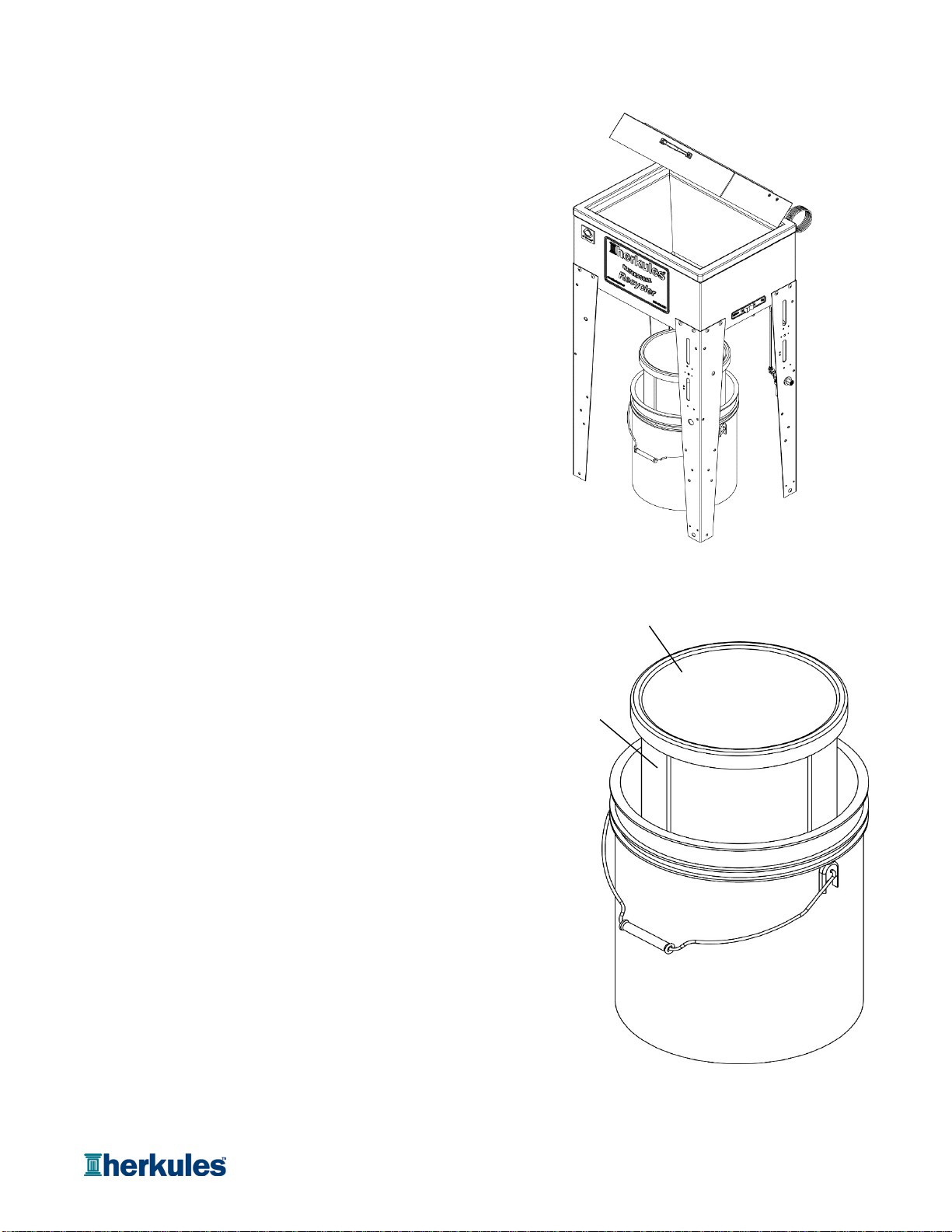

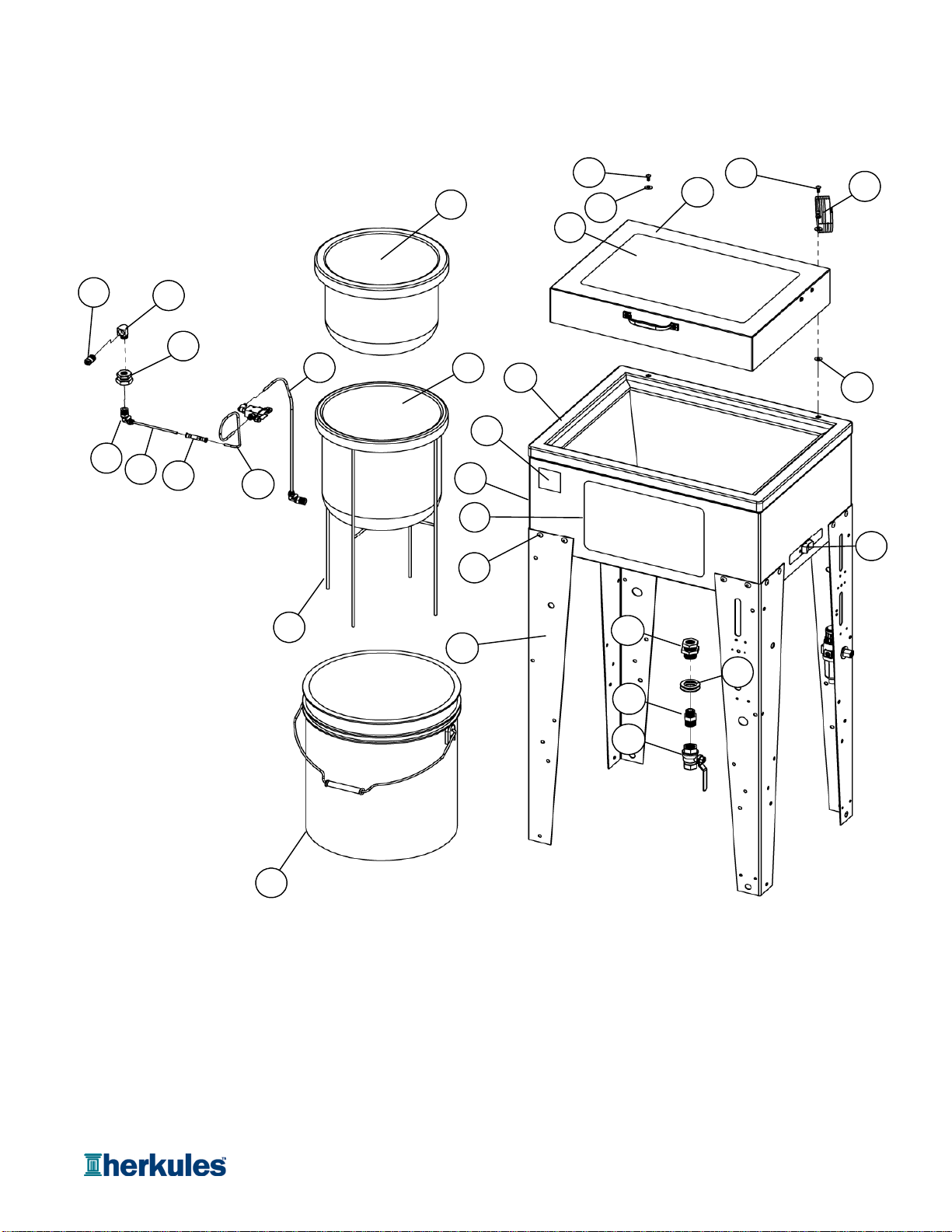

1) Pour the dirty paint mixture to be recycled into the tank.

Do not exceed the 5 gallon capacity of the tank.

2) Add flocculant / coagulant to the dirty paint mixture. (Herkules

CoAgent P/N CA01 recommended.

NOTE: Herkules CoAgent recycling coagulant along with inner

and outer filter bags can be purchased online at www.herkules.us

3) If using Herkules CoAgent P/N CA01, add 1 tablespoon

per 5 gallons of dirty paint mixture.

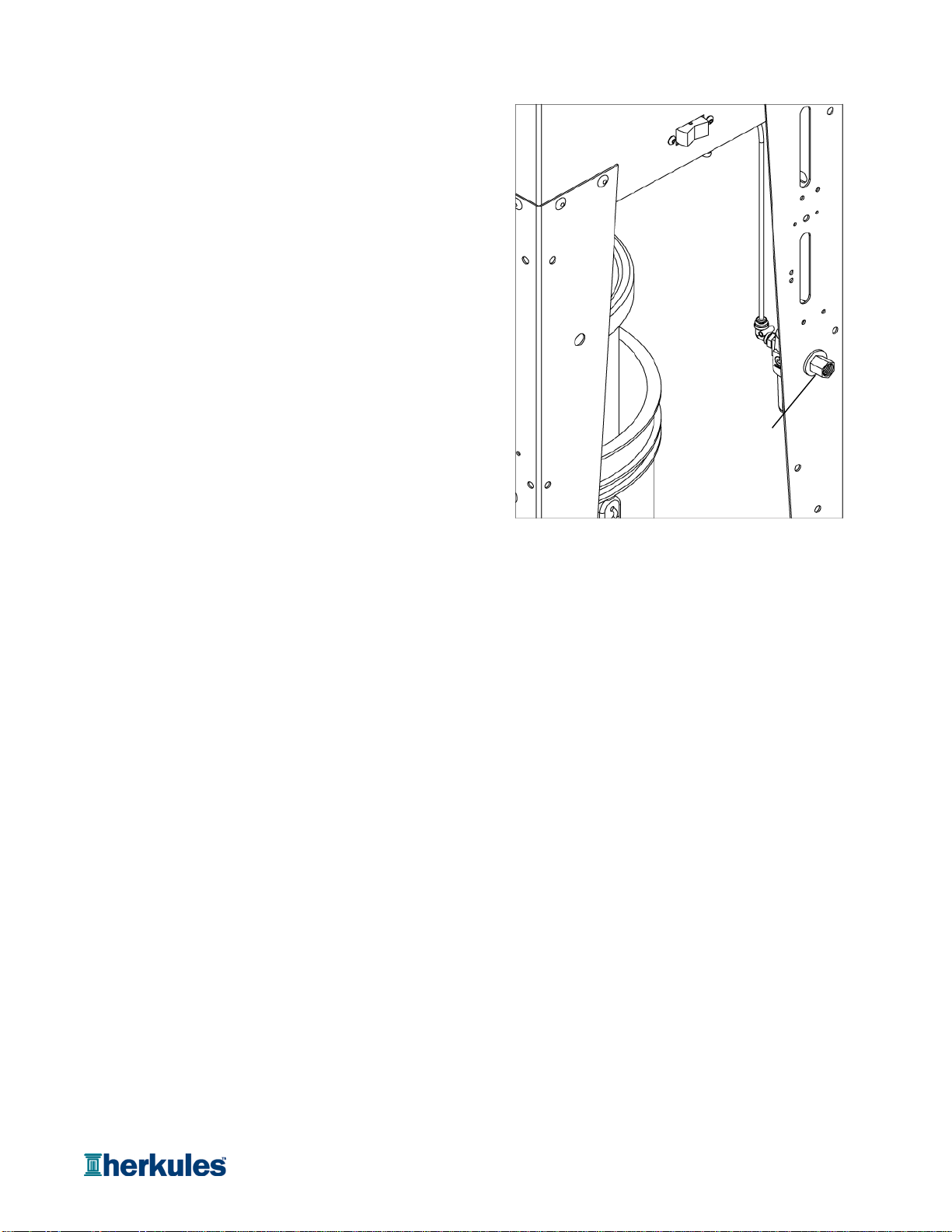

4) Set the switch on the side of the Recycler to Agitator.

Stir mixture for 30 seconds during agitation. Allow

the dirty paint mixture / flocculant mix to agitate

for 30 to 120 seconds (dependent upon quality of

flocculant). Let the mixture sit for 30 seconds.

Return the agitator switch to the Off position.

Note: Repeat process if adequate separation does not

occur (dependent upon quality of flocculant).

5) Open the ball valve to allow the mixture to drain

through the filter bags. The filter bags capture the

paint debris, and the bucket captures the filtered cleaning

solution / water mixture that can be reused for cleaning.

Note: Reuse the cleaning solution / water mixture until it

becomes tacky to the touch. Dispose of all waste materials

according to local, state, and federal regulations.

6) Empty the paint waste out of the inner filter. Place inner

filter back on the filter holder for up to 10 uses.

Note: place solid waste onto a piece of cardboard to finish

drying. This will speed the process as the cardboard will

absorb the moisture from the paint debris.

7) Close the ball valve. Replace filter bags (P/N 1003348

& P/N 1003351) as needed.

8) Dispose of all waste materials according to all local, state,

and federal regulations.

9) Wipe inner tank after each use.

Please refer to www.herkules.us/herkules/product-information/videos for a video on the coagulating and filtering process.

Operation

Filter Inner

P/N 1003348

Filter Outer

P/N 1003351

Page 8 of 12