Herman Miller Canvas Office Landscape Metal Desk Installation instructions

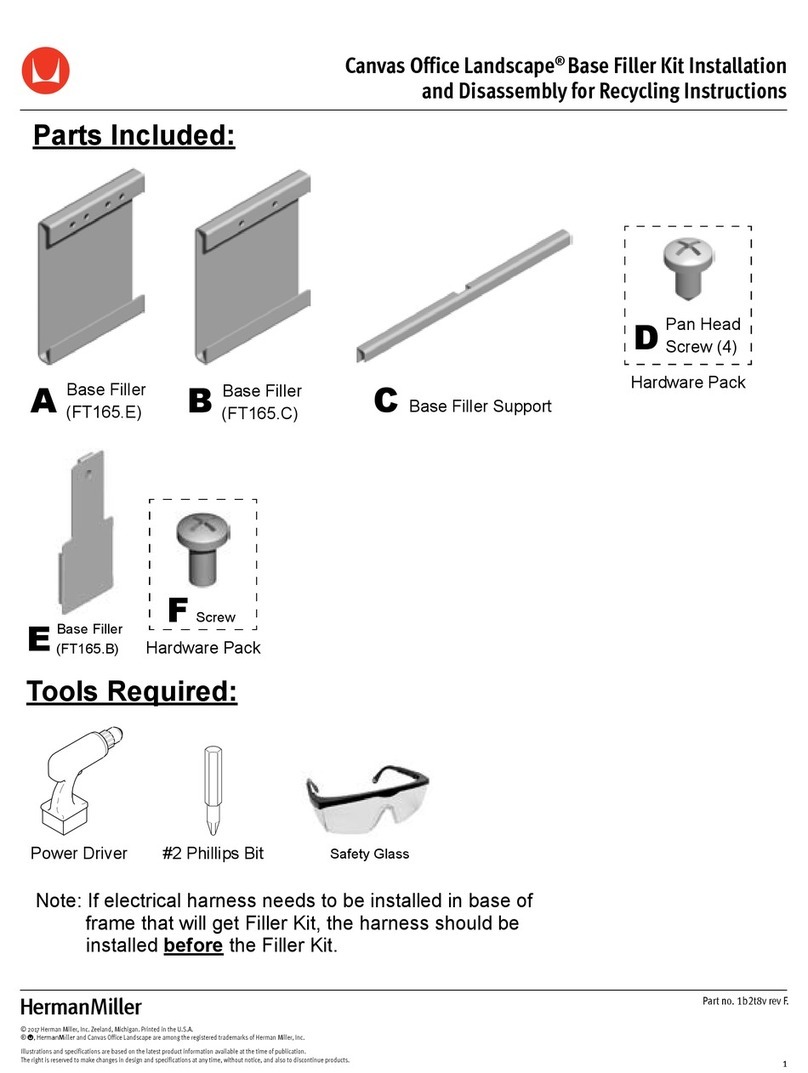

Parts Included - All Desks

Parts Included - Ganged Desks and Peninsulas

Parts Included - Corner Desks

Tools Required

HermanMiller

Canvas Oce Landscape®Metal Desk - Desk

Installation and Disassembly for Recycling

Instructions

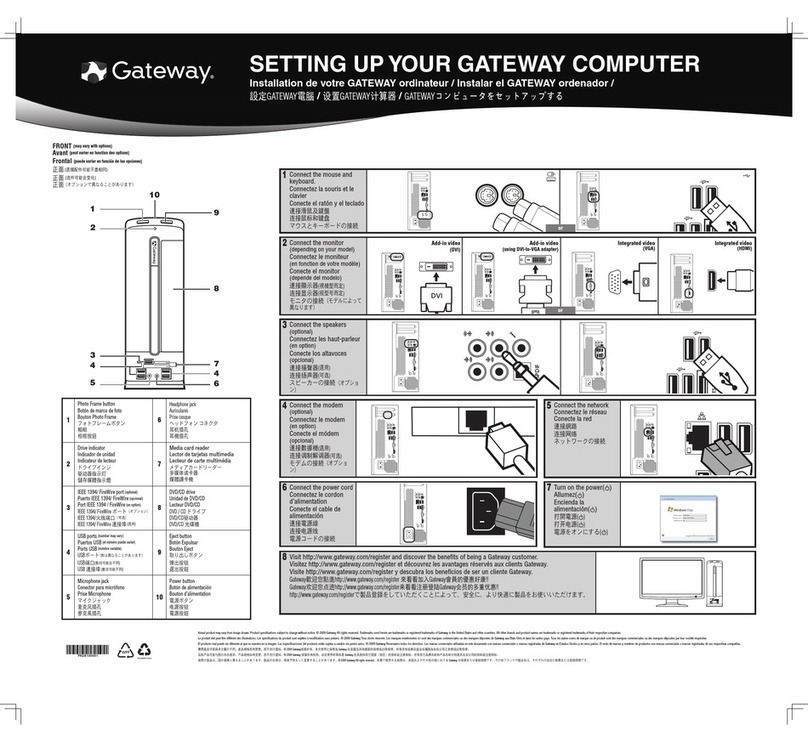

How to assemble your Desk.

Work Surface (FKS Modesty Panel (FK

Right Leg (FKE Le Leg (FKE

#14-10 x 3/4 Pan Head

Screw (Varies)

Stiener (FK6

Shared Leg (FKE

Shared Leg (FKE

Shared Leg Bracket (FKE

Corner Leg (FKC

Corner Work Surface (FKS, FKS, FKS

Ganging Plate (FKB

#10 X 1/2 Pan Head Sheet

Metal Screw (varies)

#10-12 x 3/4 Pan

Head Screw (varies)

#10-12 x 3/4 Pan

Head Screw (varies)

/” Drill Bit Safety Glass

. Assemble Legs to Modesty Panel with () Pan Head Sheet Metal Screws.

Position Modesty panel facing inward if desk is to be placed against wall.

Position Modesty Panel facing outward if desk is to be placed in open area.

Note: There should be ” gap between bottom of modesty panel and floor.

Step 1

Le Leg

(FKE) Le Leg

(FKE)

Right Leg

(FKE)

Right Leg

(FKE)

Modesty Panel

(FK)

Modesty Panel

(FK)

Pan Head Sheet

Metal Screw

Against Wall Placement Open Area Placement

Power Driver Phillips Bit

Stand Alone Desk

.”

HermanMiller Assembly Instructions11BPGDV rev C

HermanMiller Assembly Instructions21BPGDV rev C

. Place protective barrier (blanket, ect.) on floor surface.

. Place () shims on floor. shims should be between /” and /” thick,

approximately ” wide.

. Place worksurface face down onto shims. Shims should be flush with

outside edge of worksurface.

. Place worksurface stiener at center of worksurface. Location may dier

depending on specic application (under worksurface storage, ect.).

. While applying downward force to worksurface (by standing on backside

of worksurface to create opposing bow) predrill worksurface through stiener

hole locations. Note: Pilot hole size if /”. Standard screw is # X /

long.

. While maintaining downward force, insert screws. Start from center, work

outward, alternating sides. Install screws in all available holes in stiener.

Step 2

# Pan Head Screw

Stiener (FK

Shim

Shim

Work Surface (FKS

. Center Legs, le to right, (for typical applications) on Work Surface. Legs

should be positioned / inch sub-flush of rear edge of work surface (will

leave Leg / inch sub-flush to front edge of work surface.

. Using mounting brackets as guide, drill pilot holes for screws.

. Secure Leg Assembly to Work Surface with () # Pan Head Screws.

Step 3

Leg Assembly

(FKE

Wor Surface (FKS

# Pan Head Screw

Step 4

Wire Manager

. If Wire Manager was ordered, use it as guide to drill pilot holes for

screws.

. Attach Wire Manager to Work Surface with # Pan Head Screws.

# Pan Head Screw

HermanMiller Assembly Instructions31BPGDV rev C

Shared Leg Bracket

(FKE

Shared Leg

(FKE

# Pan Head Sheet

Metal Screw

Desk in Series

. Attach Shared Leg Brackets to Shared Legs with () # Pan Head Sheet

Metal Screws per leg.

Step 1 Step 2

Work Surface (FKS

End Leg Assembly (FKE

Step 3

. See step above for proper stiener installation onto Work Surface.

. Place Leg Assembly onto Work Surface. Shared leg should straddle work

surfaces.

. Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () # Pan Head Screws.

Shared Leg Assembly

(FKE

# Pan Head Screw

Modesty Panel

(FK

Pan Head Sheet

Metal Screw

Step 4

. Assemble End Leg and Shared Leg to Modesty Panel with () Pan Head

Sheet Metal Screws.

Note: There should be ” gap between bottom of modesty panel and floor.

.”

. Place Shared Leg Assembly or End Leg Assembly (shown) onto next Work

Surface. Pre-drill pilot holes in surface.

. Secure Leg Assembly to Work Surface with () or () # Pan Head

Screws.

Leg Assembly

(FKE)

# Pan Head Screw

Work Surface (FKS

HermanMiller Assembly Instructions41BPGDV rev C

Step 5 Step 6

. Position assembly onto shared leg of rst desk assembly.

. Align work surfaces. Hold tight together.

. Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () # Pan Head Screws.

Shared Leg Assembly

(FKE

# Pan Head Screw

. Position Modesty Panel to back of leg assemblies.

. Secure to legs with () Pan Head Sheet Metal Screws.

Modesty Panel

(FK

Pan Head Sheet

Metal Screws

Work Surface

(FKS, FKS,

or FKS

Corner Desk

. Attach Wire Managers and Stieners to Corner Work Surface as described

above.

. Position Corner Leg onto work surface.

. Drill pilot holes into work surface.

. Attach Corner Leg to work surface with # Pan Head Screws.

Step 1

Step 2

Wire Manager

# Pan Head Screw

# Pan Head Screw

Corner Leg (FKC

HermanMiller Assembly Instructions51BPGDV rev C

. Attach Shared Leg Brackets to Shared Legs with () # Pan Head Sheet

Metal Screws per leg.

Step 3

Shared Leg Bracket

(FKE

Shared Leg

(FKE

# Pan Head Screw

Step 4

. Place Shared Leg Assembly onto Work Surface. Make sure leg is centered

over edge of work surface.

. Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () # Pan Head Screws.

Shared Leg Assembly

(FKE

# Pan Head Screw

Step 5

. Place Shared Leg Assembly or End Leg Assembly (shown) onto next Work

Surface.

. Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () or () # Pan Head

Screws.

Leg Assembly (FKE

# Pan Head Screw

Step 6

. Position Modesty Panel to back of leg assemblies.

. Secure to legs with () Pan Head Sheet Metal Screws.

Modesty Panel

(FK

Pan Head Sheet

Metal Screws

HermanMiller Assembly Instructions61BPGDV rev C

Step 7

. Position other Modesty Panel to back of leg assemblies.

. Secure to legs with () Pan Head Sheet Metal Screws.

Modesty Panel

(FK

Pan Head Sheet

Metal Screw

Step 8

. Place Shared Leg Assembly or End Leg Assembly (shown) onto next Work

Surface.

. Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () or () # Pan Head

Screws.

Leg Assembly

(FKE

# Pan Head Screw

Step 9

. Position assembly onto shared leg of rst desk assembly. . Drill pilot holes into work surface.

. Secure Leg Assembly to Work Surface with () # Pan Head Screws.

. Position Ganging Plate under both worksurfaces. Drill pilot holes into

work surface.

. Secure plate to surfaces with () # Pan Head Screws.

Shared Leg Assembly

(FKE

# Pan Head Screw

# Pan Head Screw

Ganging Plate

(FKB

HermanMiller Assembly Instructions71BPGDV rev C

LH/RH Peninsula Leg installation

Step 10

Step 1

. Position Modesty Panel to back of leg assemblies.

. Secure to legs with () Pan Head Sheet Metal Screws. . Peninsula desk built separately with work surface face-down (work

surface & Legs/Modesty aligned & fastened - similar to standard Canvas

Metal Desk Unit).

Modesty Panel

(FK

Pan Head Sheet

Metal Screw

Step 2 Step 3

. Locate the End Leg on the bottom of the Work Surface.

• Inset Leg /” from Work Surface edge.

. Drill /” pilot holes centered in slots of the End Leg brackets (/” deep

max - do not drill through top of Work Surface).

. Using qty= # screws, attach the End Leg to the Work Surface in the

each of the slots.

End Leg (FKE

Worksurface

(FKS

” Shared

Leg (FKE

# Pan Head

Sheet Metal

Screws

. Attach the Modesty Panel to the End Leg using # screws - attaching

the round hole in the Modesty rst to properly locate the Panel in vertical

direction.

. Attach the Modesty Panel to the ” Shared Peninsula Leg using # Pan

Head Sheet Metal screws - attaching the round hole rst to properly locate the

Panel in vertical direction.

Add Note: Use ” spacer (not provided) under modesty panel while installing.

HermanMiller Assembly Instructions81BPGDV rev C

Step 4 Step 5

. Drill a /” pilot hole centered in slot of the ” Shared Peninsula Leg

bracket (/” deep max - do not drill through top of Work Surface).

. Using qty= # screw, attach the Peninsula Leg to the Work Surface

in slot.

. When attached to modesty panel, the ” shared peninsula leg will

be ~.” proud of edge of the peninsula work surface. This condition

is expected, as the shared peninsula leg will slide under the main work

surface when attaching the peninsula surface (steps & ).

. Adjust the Leg Levelers to the same height as Levelers on the main

Work Surface .

Leveler

/” Pilot hole

Step 6 Step 7

. Add Ganging Bracket FKB to the main Metal Desk Work Surface (/”

pilot holes recommended).

. Secure plate to worksurface with # Pan Head Screws.

# Pan had screw

. Align work surfaces

- Slide the Peninsula Work Surface into Main Work Surface so

there is no gap between surfaces. The ” Shared Peninsula Leg

will slide under the Main Work Surface.

. Adjust Levelers up/down to achieve work surface flushness.

No gap

Ganging Plate (FKB

HermanMiller Assembly Instructions91BPGDV rev C

Step 8

. Align ” Shared Peninsula Leg to End Leg

- Verify no gap between ” Shared Peninsula Leg and End Leg.

. Shi Leg/Modesty Assembly and Peninsula Work Surface

within the slots to achieve no gap conditions.

Step 10

. Attach remaining # screws to secure ” Shared

Peninsula Leg to Main Metal Desk Work Surface (/” pilot holes

recommended).

No gap

” Shared

Leg (FKE

End Leg

(FKE

Step 9

. While maintaining work surface flushness & no gap, attach the

FKB Ganging bracket to the Peninsula Work Surface (/” pilot holes

recommended).

Ganging bracket

(FKB

Disassembly and Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling

codes. Use these codes to identify material type for recycling. Non marked

components should be treated as mixed plastic. Ferrous metals can be

identied using a small magnet for recycling. Non-ferrous metals should be

separated and recycled separately.

To disassemble product, reverse the above installation steps.

Other Herman Miller Desktop manuals