promesstec UMU 100-A-B User manual

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

User manual:

UMU 100-A-B from page 01

UMU 100-B-B from page 34

User manual

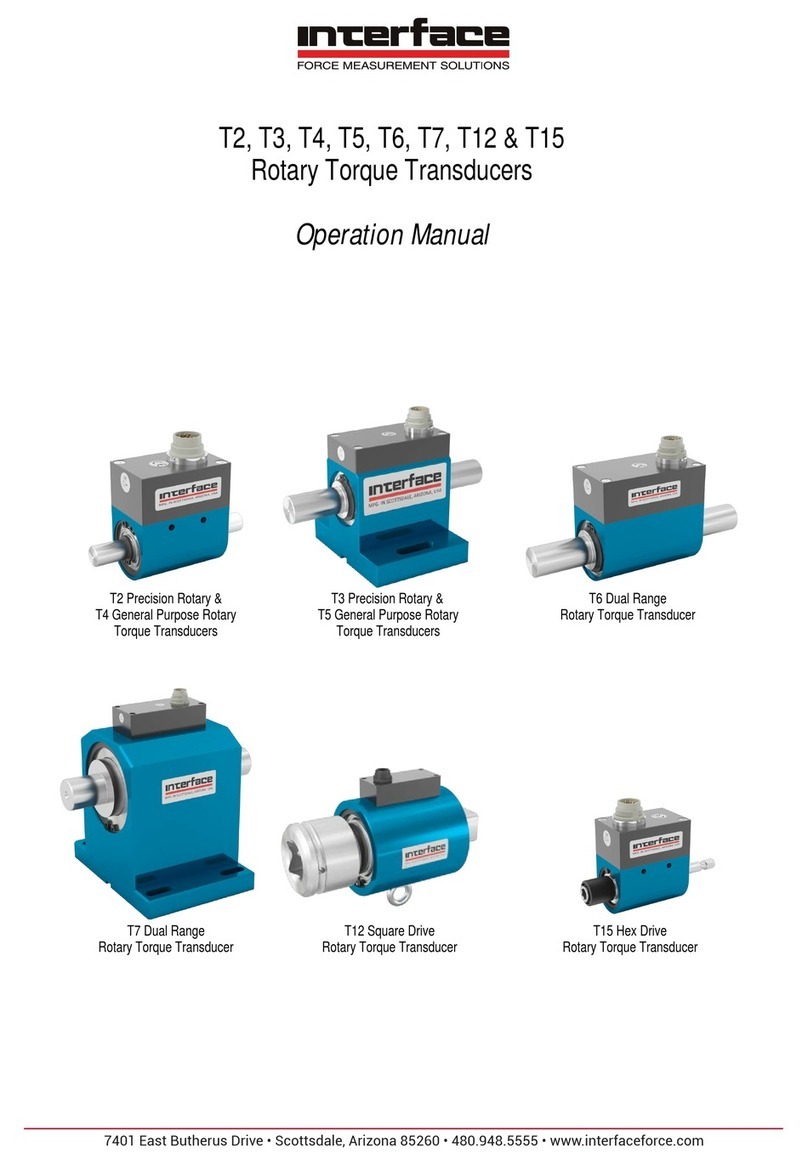

Universal measuring transducer UMU 100-A-B

version 2.1.1

2

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Content

1. General................................................................................................................ 5

1.1 For information .............................................................................................. 5

1.2 Signs and abbreviations................................................................................ 5

2. transport, packaging and storage........................................................................ 7

2.1 transport........................................................................................................ 7

2.2 packaging...................................................................................................... 7

2.3 storage .......................................................................................................... 7

3. Safety rules ......................................................................................................... 8

3.1 Intended use of the product........................................................................... 8

3.2 Personnel qualification .................................................................................. 9

3.3 Special hazards............................................................................................. 9

4. Commissioning and operation........................................................................... 10

4.1 Before mounting.......................................................................................... 10

4.2 Mounting / Installation / configuration.......................................................... 10

5. Decomposition of the system UMU 100-A-B.................................................... 11

6. Universal-measuring transducer UMU 100-A-B ................................................ 12

7. Applications....................................................................................................... 13

8. Front display / programming front UMU-FD....................................................... 14

9. Mounting / demounting the UMU-FD................................................................. 15

10. Electrical specifications................................................................................... 16

11. Visualisaton in the UMU-FD............................................................................ 20

12.Connections.................................................................................................... 22

13. Block diagram................................................................................................. 23

14. Configuration / operating the function keys..................................................... 24

14.1 Documentation for routing diagram.......................................................... 24

14.2 Further explanations................................................................................. 24

14.3 Signal- and Sensor error indication without display front.......................... 24

14.4 Advanced functions.................................................................................. 25

15. routing diagram............................................................................................... 27

15.1 Flussdiagramm, erweiterte Einstellungen (ADV.SET).............................. 30

16. Help text overview .......................................................................................... 31

17. Maintenance, Dismounting, Return, Liability, Cleaning and Disposal............. 32

17.1 Maintenance, Dismounting....................................................................... 32

17.2 Return ...................................................................................................... 32

3

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

17.3 Liability..................................................................................................... 32

17.4 Cleaning................................................................................................... 32

17.5 Disposal ................................................................................................... 32

18. Installation....................................................................................................... 33

19. order code....................................................................................................... 34

1. General.............................................................................................................. 39

1.1 For information ............................................................................................ 39

1.2 Signs and abbreviations.............................................................................. 39

2. Transport, packaging and storage..................................................................... 41

2.1 Transport..................................................................................................... 41

2.2 packaging.................................................................................................... 41

2.3 storage ........................................................................................................ 41

3. safety instructions.............................................................................................. 42

3.1 Intended product use................................................................................... 42

3.2 Personal qualification .................................................................................. 43

3.3 Special hazards........................................................................................... 43

4. Commissioning and operation.......................................................................... 44

4.1 Before mounting.......................................................................................... 44

4.2 Mouning / Installation / configuration........................................................... 44

5. How to demount the UMU 100-B-B................................................................... 45

6. Universal-transducer UMU 100-B-B.................................................................. 46

7. Applications....................................................................................................... 47

8. Front display / Programming front UMU-FD...................................................... 48

9. Mounting / demounting the UMU-FD................................................................. 49

10. Electrical specifications................................................................................... 50

11. Visualisation in the UMU-FD........................................................................... 55

12. Connections.................................................................................................... 57

13. Block diagram................................................................................................. 58

14. Configuration / operating the function keys..................................................... 59

14.1 Documentation for routing diagram.......................................................... 59

14.2 Further explanations................................................................................. 59

14.3 Signal- and sensor error info via display front UMU-FD........................... 60

14.4 Signal- and Sensor error indication without display front.......................... 60

14.5 Relay functions......................................................................................... 60

14.6 Latch ........................................................................................................ 61

14.7 Manuel deactivation of the latch function ................................................. 61

4

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

14.8 Advanced function.................................................................................... 62

15. routing diagram............................................................................................... 65

15.1 Routing diagram, advanced settings (ADV.SET) ..................................... 68

15.2 Routing diagram, manual deactivation of the latch function..................... 69

16. Help text overview .......................................................................................... 70

17. Grapic depiction.............................................................................................. 72

17.1 Grapic depiction of latch function setpoint................................................ 72

17.2 Graphic depiction of latch function window .............................................. 73

17.3 Graphic depiction of rely action setpoint................................................... 74

17.4 Graphische Abbildung der Relaisfunktion Fenster ................................... 74

18. Maintenance, Dismounting, Return, Liaility, Cleaning and Disposal............... 75

18.1 Maintenance, Dismounting....................................................................... 75

18.2 Return ...................................................................................................... 75

18.3 Liability..................................................................................................... 75

18.4 Cleaning................................................................................................... 75

18.5 Disposal ................................................................................................... 76

19. Installation....................................................................................................... 76

20. order code....................................................................................................... 77

5

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

1. General

1.1 For information

-These operating manual provides important information on handling the

measuring element. A prerequisite for safe working is compliance with all

specified safety notes and instructions for action.

-The qualified personnel must have read and understood these operating manual

before mounting and starting up the sensor.

-These operating manual is a component part of the product. Therefore, keep

them in a place that is accessible to all users at all times, close to the place of

use.

-The local regulations and safety rules applicable to the area of application of the

sensor must be observed.

-If the serial number on the type label is no longer readable (e.g.due to

mechnical damage), tracebility is no longer ensured.

-The sensors described in the user manual are developed and manufactured

according to the newest findings. All components are subject strict quality and

environmental criteria during production.

-The manufacturer shall not be liable if damage is caused by improper use,

non-observance of these operating instructions, use of insufficiently qualified

personnel and unauthorized modifications to the sensor.

1.2 Signs and abbreviations

Warning!

Non-observance can lead to injuries to persons and /or destruction of

the device. There may be danger to life.

Attention!

Non-observance can lead to incorrect operation of the device or

damage to property.

Information!

Non-observance can influence the operation of the device or cause

undesired device reactions.

Danger!

If the safety instructions are not observed, there is a risk of serious or

fatal injury from electric current

UMU 100-A-B

6

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Warning!

A dangerous situation may possibly occur, which can lead to burns

due to hot surfaces or liquids if they are not avoided.

Warning!

This device is designed for connection to hazardous electric

voltages. Ignoring this warning can result in severe personal injury or

mechanical damage. To avoid the risk of electric shock and fire, the

safety instructions of this manual must be observed and the

guidelines followed. The specifications must not be exceeded, and

the device must only be applied as described in the following. Prior to

the commissioning of the device, this manual must be examined

carefully. Only qualified personnel (technicans) should install this

device. If the equipment is used in manner not specified by the

manufacturer, the protection provieded by the equipment may be

impaired.

Warning!

No dangerous voltage may be connected to the device before its per-

manent installation has been completed, and the following measures

should only be carried out when the device is in a de-energized state

and under ESD-safe conditions:

Installation, assembly and disassembly of pipelines.

Troubleshooting the device.

Warning!

The front panel of the device must not be opened, as this may da-

mage the contacts for contacting the UMU-FD front display.

The device does not contain any internal DIP switches or program-

ming jumpers.

The UMU 100 must be mounted on a DIN rail according to DIN 60715.

7

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Triangle with exclamation mark: Warning / Regulation. Operations

that can lead to life-threatening situations. The manual must be read

carefully before installing and commissioning the device in order to avoid

serious injuries or mechanical destruction.

The CE-Mark is the visible sign that the device complies with the regula-

tions.

The double isulation symbol is the symbol that the device meets

special requirements for insulation.

2. transport, packaging and storage

2.1 transport

Inspect the device for a damage that may have occurred during transport. Report

obvious damage immediately.

2.2 packaging

Do not remove the packaging until immediately before assembly. Keep the packa-

ging, because it provides optimal protection during transport (e. g. changeable

installation location, return).

2.3 storage

Avoid the following influences during longer storage:

-Direct sunlight or close to hot objects

-Mechanical vibration, mechanical shock (hard set up)

-Soot, steam, dust and corrosive gases

If possible, store the device in the original packaging or appropriate packaging.

8

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

3. Safety rules

Further important safety instructions can be found in the individual

chapters.

Definitions:

Hazardous voltages have been defined as the range: 75...1500 Volt DC and

50...1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also

trouble-shoot technically correct and in accordance with safety regulations.

Operators, are persons who set or operate the pushbuttons or potentiometers of the

product during normal operation and who have been familiarized with the contents of

this manual.

Receipt and unpacking:

Unpack the device without damaging it and check the device type

corresponds to the one ordered. The packaging should always follow with the

device until this has been permanently mounted.

3.1 Intended use of the product

Environment:

Avoid direct sunlight, strong dust or heat, mechanical shocks and impacts; do not

expose the device to rain or strong humidity. If necessary, heating is excess of the

stated limits for ambient temperatures should be avoided by way of ventilation. The

device must be installed in pollution degree 2 or better.

9

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

3.2 Personnel qualification

Risk of injury due to insufficient qualification Improper handling can

lead to considerable personal injury and property damage.

The activities described in these operating instructions may only be

performed by qualified personnel with the following qualifications.

Keep unqualified personnel away from the hazardous areas.

For mounting and commissioning of the sensor, these persons must be familiar with

the applicable country-specific directives and standards, and have the appropriate

qualification. You must have knowledge of measurement and control technology, be

familiar with electrical circuits and be able to carry out the work described and recog-

nize possible hazards independently. Depending on the operating conditions, other

knowledge may also be required, e.g. about aggressive media.

3.3 Special hazards

Observe the country-specific regulations (e.g. standards) and, in the

case of special applications, observe the applicable standards and

directives (e.g. for hazardous media such as Acetylene, flammable

or toxic substances as well as refrigeration plants and compres-

sors).

If the relevant regulations are not observed, serious personal

injury and damage to property may result!

Electrostatic discharge (ESD) protection is required. Proper use of

grounded work surfaces and personal wrist straps is required when

working with open circuits (printed circuit boards) to prevent damage

to sensitive electronic components from electrostatic discharge.

There is danger to life from electric current. There is a immediate risk

of death if live parts are touched. Installation and mounting of

electrical equipment may only be carried out by qualified electricians.

When operating with a defective power supply unit (e.g. short-circuit

from mains voltage to output voltage), life-threatening voltages can

result at the device.

Residual media in devices that have been removed can be

hazardous to persons, the environmet and equipment. Sufficient

precautions must be taken. This device must not be used in safety or

emergency stop devices. Incorrect applications of the device can

lead to injuries. In case of a fault, aggressive media at extreme

temperatures and under high pressure or vacuum may be present at

the device.

10

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

4. Commissioning and operation

4.1 Before mounting

Check whether a completely assembled measuring transducer has

been supplied. Inspect the device for any transport damage that

may have occurred. If such damage ispresent, notify the carrier and

supplier immediately. Keep the packaging, as it provides optimum

protection during tranport. Make sure that the housing and the

connection contacts are not damaged.

4.2 Mounting / Installation / configuration

•Due to the extremely low power consumption, the units can be mounted side by

side without an air gap between them even at an ambient temperature of 60°C.

•Configuration, monitoring, 2-point process calibration and more are performed

with either the UMU-FD detachable displays.

•All programming can be password protected.

Calibration and adjustment

During calibration and adjustment, the measurement and connection of external vol-

tages must be carried out in accordance with this manual, and the technician must

use tools and instruments that are safe for this purpose.

Normal operation

The operating personnel may only set or operate the device if these are permanently

installed in control panels or similar in a justifiable manner so that the operation does

not involve any danger to life or material. I.e., there must be no danger from contact

and the device must be placed so that it can be easily operated.

11

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

5. Decomposition of the system UMU 100-A-B

First, disconnect dangerous voltage from the terminals.

The device is released from the DIN rail by loosening the lower catch.

When the front LED is red / display shows AO.ER

The device has been developed with a high level of safety. Therefore, a continuous

measurement of the output current takes place at the 4...20 mA output signal. When

the current is 0 mA, the device switches to error mode and the LED indicator lights

red. This function is not a standard option, but must be actively selected in the menu.

The error mode can only be reset by switching the power supply of the device off and

on again.

12

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

6. Universal-measuring transducer UMU 100-A-B

• input for WTH, TE, Ohm, potentiometer, mA and V

• 2-wire supply > 16 V

• FM approval for installation in Div. 2

• Outputs for current and voltage

• Universal supply with AC or DC

Application

•Electronic, linear temperature measurement with resistance sensor or

thermocouple sensor.

•Conversion of linear resistance change into a standard analog current / voltage

signal, e.g. from solenoid valves, butterfly valves or linear movements with

connected potentiometers.

•Power supply and signal isolator for 2-wire measuring transducer.

•Process control with standard analog output.

•Galvanic isolation of analog signals and measurement of signals that are not

grounded.

•Suitable for use in systems up to Performance Level (PL) "d" according to ISO -

13849

Technical characteristics

•When the UMU 100 is used in combination with the programming front, all opera-

tional parameters of the corresponding application can be adjusted. The UMU

100 is equipped with electronic hardware switches and it is not necessary to

open the device to set DIP switches.

•A green / red LED in the front of the device indicates normal operation and

malfunctions.

•Constant checking of important memory data for security reasons.

•2,3 kVAC galvanic isolation of the 3 ports.

13

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

7. Applications

Input signals:

Output signals:

Supply:

14

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

8. Front display / programming front UMU-FD

Functionality

The simple and easily understandable menu structure and the

explanatory help texts guide you effortlessly and automatically through

the configuration steps, thus making the product very easy to use.

Functions and configuration options are described in the section

„configuration / operating the function key“.

Application

•Communications interface for modification of operational parameters in UMU

100.

•Can be moved from one UMU 100 device to another and download the

configuration of the first unit to subsequent units.

•Fixed display for readout of process data and status.

Technical characteristics

•LCD display with 4 lines:

Line 1 (H = 5,57 mm) shows the Input signal.

Line 2 (H = 3,33 mm) shows the selected engineering unit.

Line 3 (H = 3,33 mm) shows analog output or TAG no.

Line 4 shows status for communication.

Programming access can be blocked by assigning a password. The password

is saved in the device. In order to ensure high degree of protection against

unauthorized modifications to the configuration.

15

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

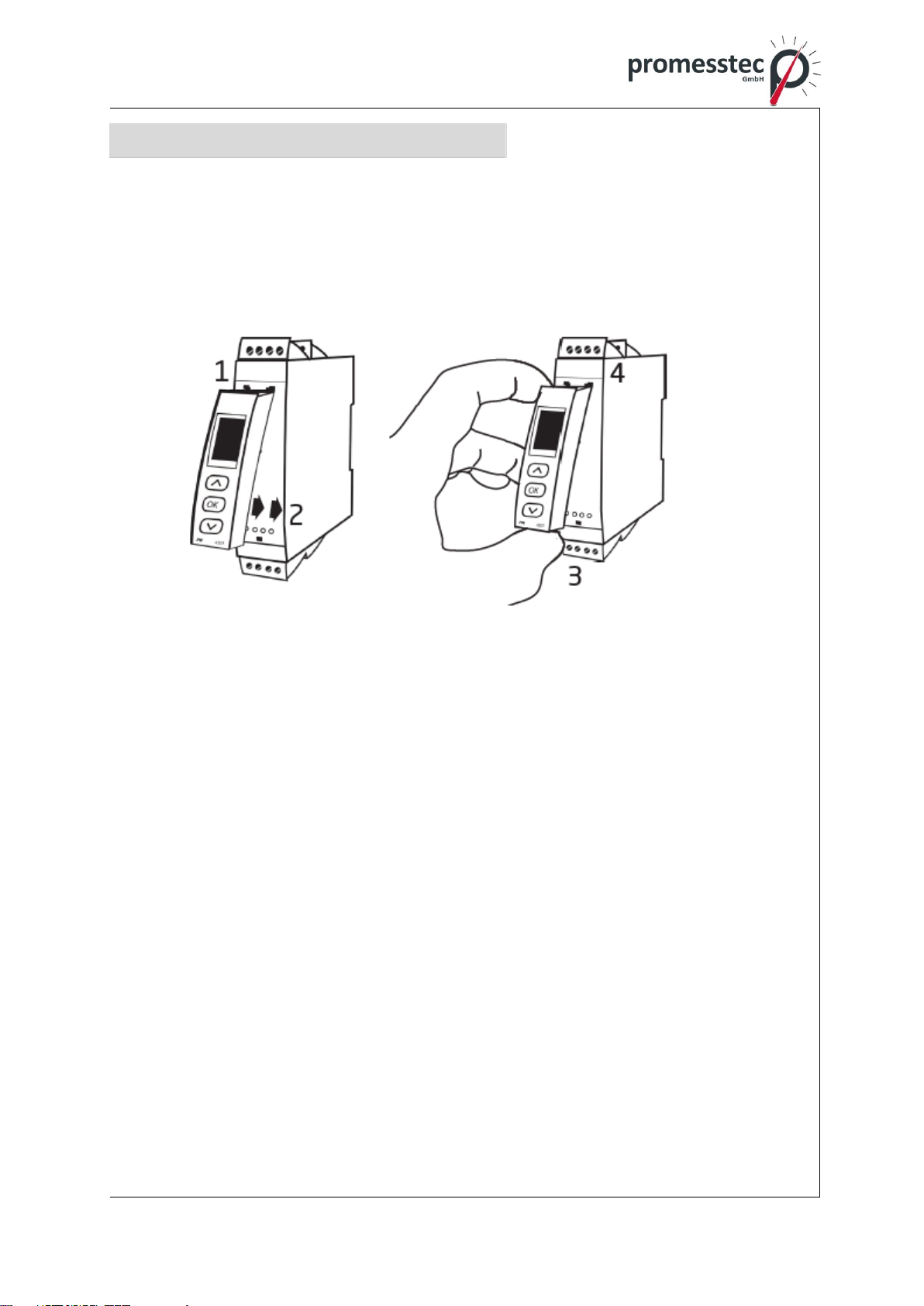

9. Mounting / demounting the UMU-FD

1: Insert the tabs of the UMU-FD into the holes at the top of the UMU 100.

2: Hinge the UMU-FD down until it snap into place.

Demounting of the UMU-FD

3/4: Press the release of the UMU-FD on the underside and carefully remove the

UMU-FD.

16

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Order

UMU 100 = Universal-measuring transducer

UMU-FD = Display- / programming front

UMU-CJC = CJC-connector

10. Electrical specifications

Environmental conditions

Specification area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20°C to +60°C

Storage temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . -20°C to +85°C

Calibration temperature . . . . . . . . . . . . . . . . . . . . . . . . . .20...28°C

Relative humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . < 95% RF (non cond.)

Protection degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP20

Installation in pollution degree 2 & measurement / overvoltage category II

Mechnical specification

Dimensions (HxWxD) . . . . . . . . . . . . . . . . . . . . . . . . . . 109 x 23,5 x 104 mm

Dimensions (HxWxD) with UMU-FD. . . . . . . . . . . . . . . .109 x 23,5 x 116 / 131 mm

Weight, approx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 g

Weight with UMU-FD (approx.). . . . . . . . . . . . . . . . . . . .170 g / 185 g

DIN rail type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DIN EN 60715/35 mm

Cable cross section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,13...2,08 mm2 / AWG

26...14 stranded wire

Screw terminal torque. . . . . . . . . . . . . . . . . . . . . . . . . . . 0,5 Nm

Vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IEC 60068-2-6

2...13,2 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1 mm

13,2...100 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0,7 g

Common electrical specifications

Supply voltage, universal . . . . . . . . . . . . . . . . . . . . . . . . 21,6...253 VAC, 50...60 Hz

or 19,2...300 VDC

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 mA SB / 250 VAC

Max. required power. . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 2,0 W

Max. power dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 2,0 W

Isolation voltage, test. . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3 kVAC

Isolation voltage, working . . . . . . . . . . . . . . . . . . . . . . . .250 VAC (reinforced) / 500

VAC (basic)

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . UMU-FD

Signal dynamics, input / output . . . . . . . . . . . . . . . . . . . .24 Bit / 16 Bit

Signal- / noise ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .> 60 dB (0...100 kHz)

Responsing time (0...90%, 100...10%):

Temperature Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 1 s

mA- / V-input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 400 ms

Auxiliary supplies

2-wire-supply (terminal 44...43) . . . . . . . . . . . . . . . . . . . .25...16 VDC / 0...20 mA

17

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Accuracy, the greater of general and basic values:

General values

Input type

Absolute accuracy

Temperature coefficient

All

≤ ±0,1% of span

≤ ±0,01% of span / °C

Basic values

Type

Basic accuracy

Temperature coefficient

mA

≤ ± 4 µA

≤ ± 0,4 µA / °C

Volt

≤ ± 20 µV

≤ ± 2 µV / °C

Pt100

≤ ± 0,2 °C

≤ ± 0,01 °C / °C

Linear resistance

≤ ± 0,1 Ω

≤ ± 0,01 Ω / °C

Potentiometer

≤ ± 0,1 Ω

≤ ± 0,01 Ω / °C

TC type:

E, J, K, L, N, T, U

≤ ± 1 °C

≤ ± 0,05 °C / °C

TC type: R, S, W3,

W5, LR

≤ ± 2 °C

≤ ± 0,2 °C / °C

TC type: B

85...200°C

≤ ± 4 °C

≤ ± 0,4 °C / °C

TC type: B

200...1820°C

≤ ± 2 °C

≤ ± 0,2 °C / °C

EMC –immunity influence . . . . . . . . . . . . . . . . . . . . . . . .<±0,5% of span

Extended EMC immunity:

NAMUR NE 21, A criterion, burst . . . . . . . . . . . . . . . . . . .<±1% of span

Input specifications

RTD-, linear resistance- and potentiometer input

Input for RTD types:

Pt10, Pt20, Pt50, Pt100, Pt200, PT250, Pt300, Pt400, Pt500, Pt1000

Ni50, Ni100, Ni120, Ni1000, Cu10, Cu20, Cu50, Cu100

Input type

Min. value

Max. value

Standard

Pt10…Pt1000

-200°C

+850°C

IEC 60751

Ni50…Ni1000

-60°C

+250°C

DIN 43760

Cu10…Cu100

-200°C

+260°C

= 0.00427

Lin.R

0 Ω

10000 Ω

-

Potentiometer

10 Ω

100 kΩ

-

18

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Cable resistance per wire (max.), RTD. . . . . . . . . . . . . . . . . . .50 Ω

Sensor current, RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 0,2 mA

Effect of sensor cable resistance (3- / 4-wire), RTD . . . . . . . .< 0,002 Ω / Ω

Sensor error detection, RTD . . . . . . . . . . . . . . . . . . . . . . . . . . Ja

Short circuit detection, RTD. . . . . . . . . . . . . . . . . . . . . . . . . . . < 15 Ω

TE-input

Type

Min. value

Max. value

Standard

B

0°C

+1820°C

IEC 60584-1

E

-100°C

+1000°C

IEC 60584-1

J

-100°C

+1200°C

IEC 60584-1

K

-180°C

+1372°C

IEC 60584-1

L

-200°C

+900°C

DIN 43710

N

-180°C

+1300°C

IEC 60584-1

R

-50°C

+1760°C

IEC 60584-1

S

-50°C

+1760°C

IEC 60584-1

T

-200°C

+400°C

IEC 60584-1

U

-200°C

+600°C

DIN 43710

W3

0°C

+2300°C

ASTM E988-90

W5

0°C

+2300°C

ASTM E988-90

LR

-200°C

+800°C

GOST 3044-84

Cold junction compensation (CJC):

Via external sensor in connector CJC. . . . . . . . . . . . . . . . 20...28°C ≤ ± 1°C

-20...20°C / 28...70°C ≤±2°C

Via internal CJC sensor . . . . . . . . . . . . . . . . . . . . . . . . . .±(2,0°C + 0,4°C * Δt)

Δt = internal temperature - ambient temperature

Sensor error detection, all TE-Types . . . . . . . . . . . . . . . .Yes

Sensor error current:

When detecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Nom. 2 μA

else. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 μA

Current input

Measurement range. . . . . . . . . . . . . . . . . . . . . . . . . . . . .0...23 mA

Programmable measurement ranges. . . . . . . . . . . . . . . .0...20 and 4...20 mA

Input resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 20 Ω + PTC 50 Ω

Sensor error detection:

Loop break 4...20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . Yes

Voltage input

Measurement range. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0..12 VDC

Programmable measurement ranges. . . . . . . . . . . . . . . 0...1 / 0,2...1 / 0...5 / 1...5 /

0...10 and 2...10 VDC

Input resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 10 MΩ

19

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Output specifications

Current output

Signal range (span) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0...23 mA

Programmable signal ranges . . . . . . . . . . . . . . . . . . . . . 0...20 / 4...20 / 20...0

and 20...4 mA

Load (max.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 800 Ω

Load stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 0,01% of span / 100 Ω

Sensor error detection . . . . . . . . . . . . . . . . . . . . . . . . . . .0 / 3,5 / 23 mA / none

NAMUR NE 43 Up- / Downscale . . . . . . . . . . . . . . . . . . .23 mA / 3,5 mA

Output limitation:

4...20 and 20...4 mA signals . . . . . . . . . . . . . . . . . . . . . . 3,8...20,5 mA

0...20 and 20...0 mA signals . . . . . . . . . . . . . . . . . . . . . . 0...20,5 mA

Current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 28 mA

Voltage output

Signal range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0...10 VDC

Programmable signal rages . . . . . . . . . . . . . . . . . . . . . . 0...1 / 0,2...1 / 0...10 / 0...5 /

1...5 / 2...10 / 1...0 / 1...0,2 / 5...0 / 5...1 / 10...0 and 10…2 V

Load (min.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 kΩ

Of span. = of the currently selected measurement range

20

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

11. Visualisaton in the UMU-FD

Sensor error detection and input signal outside range

Sensor error check:

Device

Configuration

Sensor error detection:

UMU 100-A-B

OUT.ERR=NONE.

OFF

Else:

ON

Outside range readout (IN.LO, IN.HI):

If the valid of the A/D converter or the polynomial is exceeded

Input

Range

Readout

Limit

Volt

0…1 V / 0,2…1 V

IN.LO

< - 25 mV

IN.HI

> 1,2 V

0…10 V / 2…10 V

IN.LO

< - 25 mV

IN.HI

>12 V

CURR

0…20 mA / 4…20 mA

IN.LO

< - 1,05 mA

IN.HI

> 25.05 mA

LIN.R

0…800Ω

IN.LO

< 0 Ω

IN.HI

> 1075 Ω

0…10 kΩ

IN.LO

< 0 Ω

IN.HI

< 110 kΩ

POTM

-

IN.LO

< - 0,5 %

IN.HI

> 100,5 %

TEMP

TC / RTD

IN.LO

< temperature range -2°C

IN.HI

> temperature range +2°C

Display readout below min. / above max. (-1999, 9999):

Input

Range

Readout

Limit

All

All

-1999

Display readout <-1999

9999

Display readout > 9999

Sensor error detection limits

Sensor error detection (SE.BR, SE.SH):

Input

Range

Readout

Limit

CURR

Loop break (4…20 mA)

SE.BR

<= 3.6 mA; > = 21 mA

POTM

All, SE.BR on all 3-wire

SE.BR

> ca. 126 kΩ

LIN.R

0…800 Ω

SE.BR

> ca. 875 Ω

0…10 kΩ

SE.BR

> ca. 11 kΩ

TEMP

TC

SE.BR

> ca. 750 kΩ/ (1.25 V)

RTD, 2-, 3-, and 4-wire

No SE.SH for Cuxx, Pt10,

PT20 and Pt50

SE.BR

> Ca. 15 kΩ

SE.SH

< ca. 15 kΩ

UMU 100

This manual suits for next models

1

Table of contents

Other promesstec Transducer manuals