Flush & Fill Cart SFFC-70/2 | 3

Table of Contents MANUAL OVERVIEW � � � � � � � � � � � � � � � � � � � � � � � � � � 7

SECTION 1 | GENERAL INFORMATION & OPERATING

PROCEDURES � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

1�1 | Description � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

1.1.1 | Equipment Systems and Components . . . . . . . . . . . . . . . . . . . 11

1.1.1.1 | Cart Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

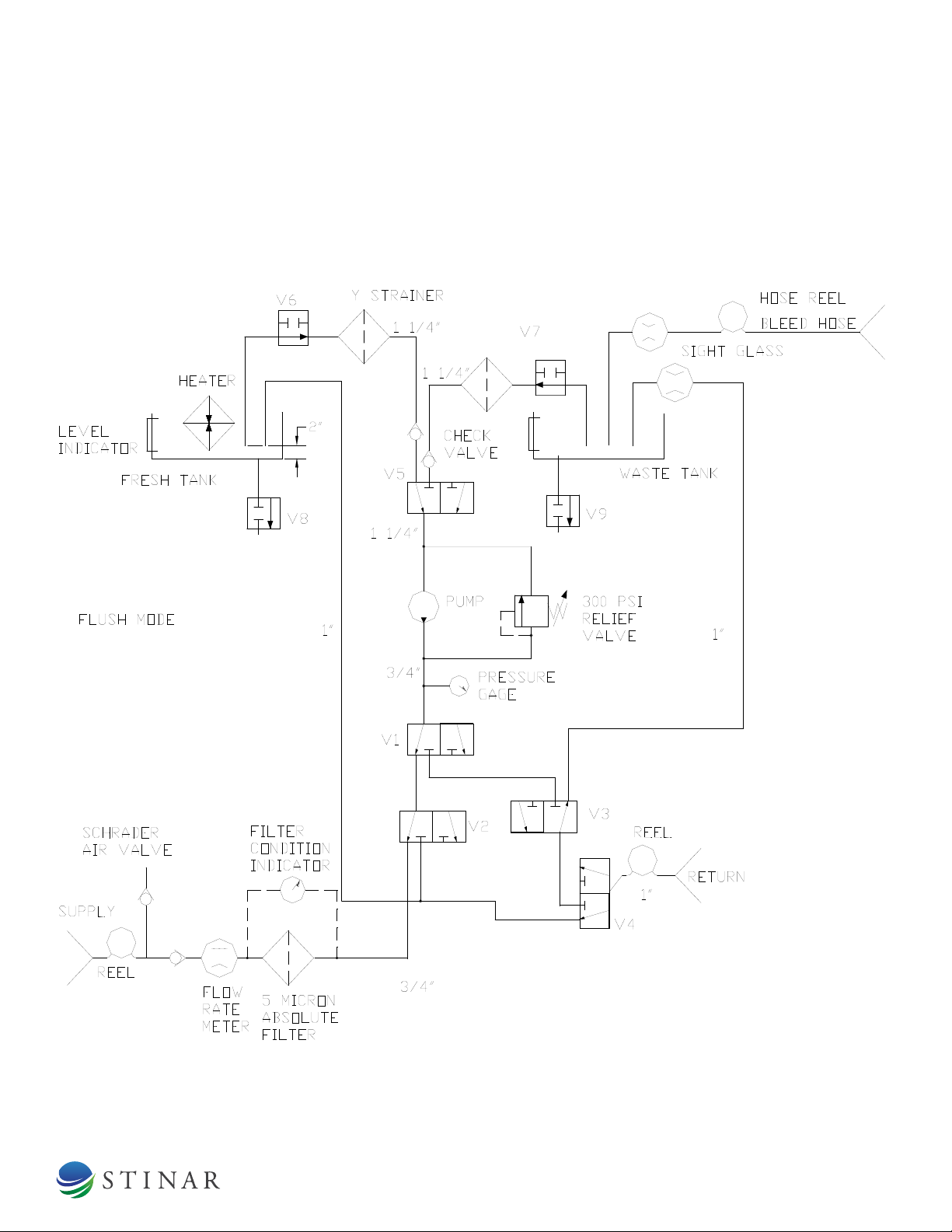

1.1.1.2 Coolant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 1.1.1 | Flush & Fill Cart Model SFFC-70/2 . . . . . . . . . . . . . . . . . . . . . .13

Figure 1.1.1.2 | Coolant System (Fill Mode) . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.1.1.3 | Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1.1.4 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 1.1.1.4 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1�2 | Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

1.2.1 | Operating Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . 18

1.2.1.1 | Flush and Fill Cart System Controls and Indicators. . . . . . . . . . . 18

1.2.2 Pre-Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2.3 | Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2.3.1 | Filling the Coolant Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2.3.2 | Draining the contaminated coolant from the aircraft . . . . . . . 19

Figure 1.2.3 | Coolant Tank operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 1.2.3.2 | Handle Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1.2.3.3 | Flushing the system (Figure 1.2.3.3 A) . . . . . . . . . . . . . . . . . . . . . 22

1.2.3.4 Filling the Aircraft with Coolant (figure 1.2.3.3) . . . . . . . . . . . . . . . 22

Figure 1.2.3.3 A | Flush and Fill Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 1.2.3.3 B | Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 1.2.3.4 | Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.2.3.5 | Deaerate (figure 1.2.3.5 A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.3.6 | Pumping out Waste tank (figure 1.2.3.6) . . . . . . . . . . . . . . . . . . . 26

1.2.3.7 | Towing the Flush and Fill Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 1.2.3.5 A | Deaerate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 1.2.3.5 B | Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 1.2.3.6 A | Pumping out of the Waste tank . . . . . . . . . . . . . . . . . . . .29

Figure 1.2.3.6 B | Valve Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

1.2.3.7 Storing the Flush and Fill Cart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.3 | Specications and Capabilities � � � � � � � � � � � � � � � 32

1.3.1 | General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.3.2 | Electric Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.3.3 | Coolant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 2 | SERVICING THE FLUSH AND FILL CART � � � � � � � � 34

2�1 | Servicing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

2.1.1 | Cart Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1.1.1 | Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1.1.1 | Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1.1.1 | Sheet, Bar and Tubular Member (Non-Load Bearing). . . . . . . . 35