Safety regulations

© Lift-Rite 242484-017

6

Operating and conduct while operating

• Avoid cornering at high speed.

• Pay particular attention to other personnel as well as fixed

and moving objects within the working area and thereby avoid

accidents.

• When the load impairs the line of vision, always drive with the

load to the rear.

CAUTION!

When operating on inclines the truck shall be operated with

the load downwards in the direction of the incline and driven

with extreme care.

CAUTION!

Adapt the speed according to the incline and surface.

WARNING!

Risk of overturning.

A loaded truck can overturn when attempting to turn on an

incline.

Never turn a loaded truck when driving on an incline.

• Always keep a safe distance from the edges of loading bays

and loading ramps. Be attentive to marked risk areas.

• Before the truck is driven on to a loading ramp ensure that the

ramp is correctly secured and has the necessary load bearing

capacity. Drive slowly and carefully across the ramp.

• Before the truck is driven into a lift, the operator must make

sure the lift is approved for the total weight of the truck, the

load, operator, and any other passengers in the lift. When

entering the lift, the load must enter first, not the driver. No

other personnel should be in the lift when the load or truck

enters or leaves the lift.

• Any accidents that have caused personal injury or damage to

buildings or equipment must be reported to the supervisor.

Incidents and faults on the truck shall also be reported.

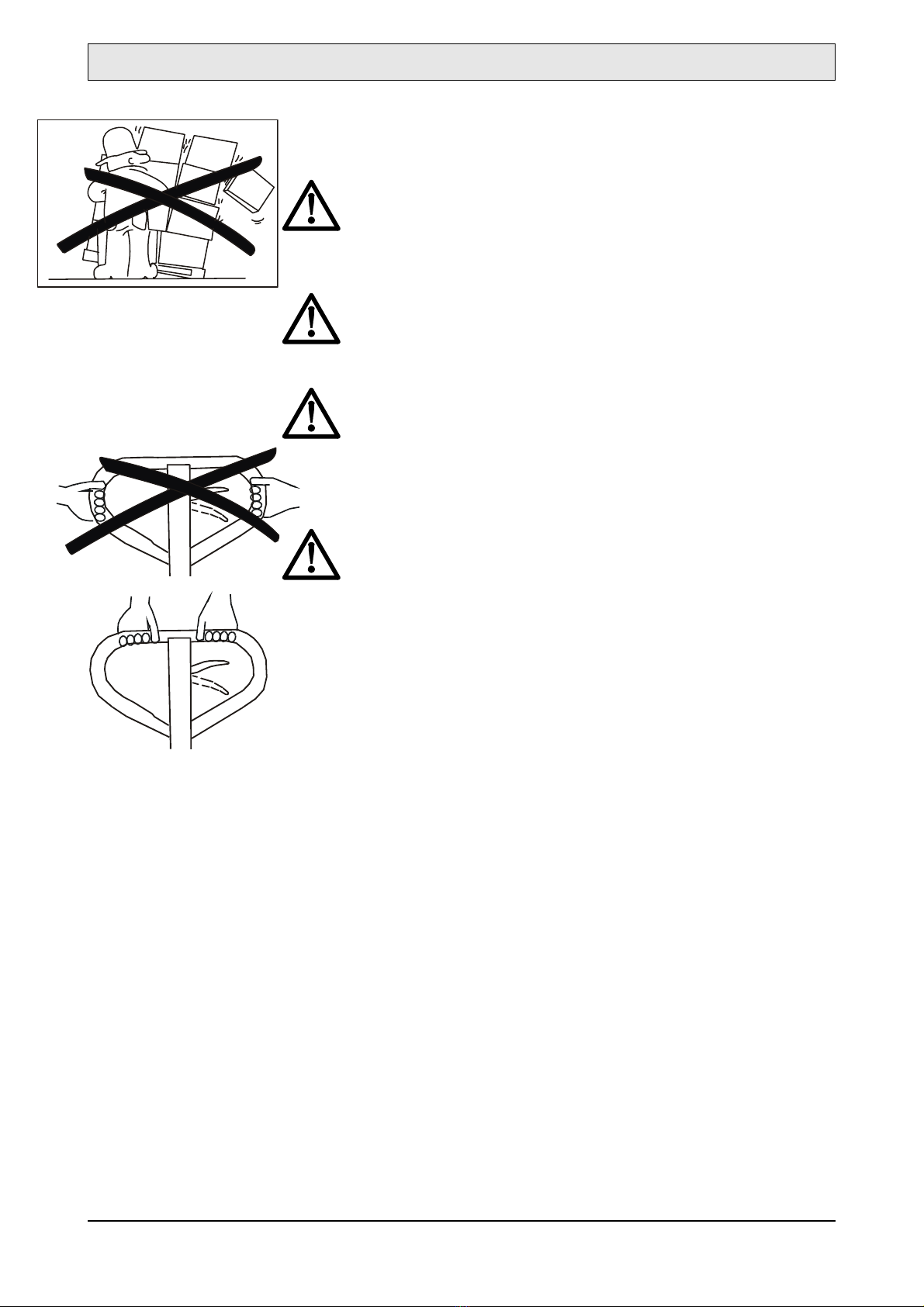

Handling loads

The weight of the load must be within the truck's permitted lifting

capacity, see the truck’s identification plate.

NOTE!

If a plate is unreadable a new plate must be ordered.

The length/width of the forks should be adapted to the load’s

shape and dimensions.