Heyl EcoControl DO10 User manual

EcoControl DO10

Desalination and Dosing Controller

Operating Instructions

Table of Contents

General Notes ........................... 1

Introduction .................................1

Handlingnotes...............................1

Safetynotes.................................1

Installation and commissioning ..................1

General Description ...................... 2

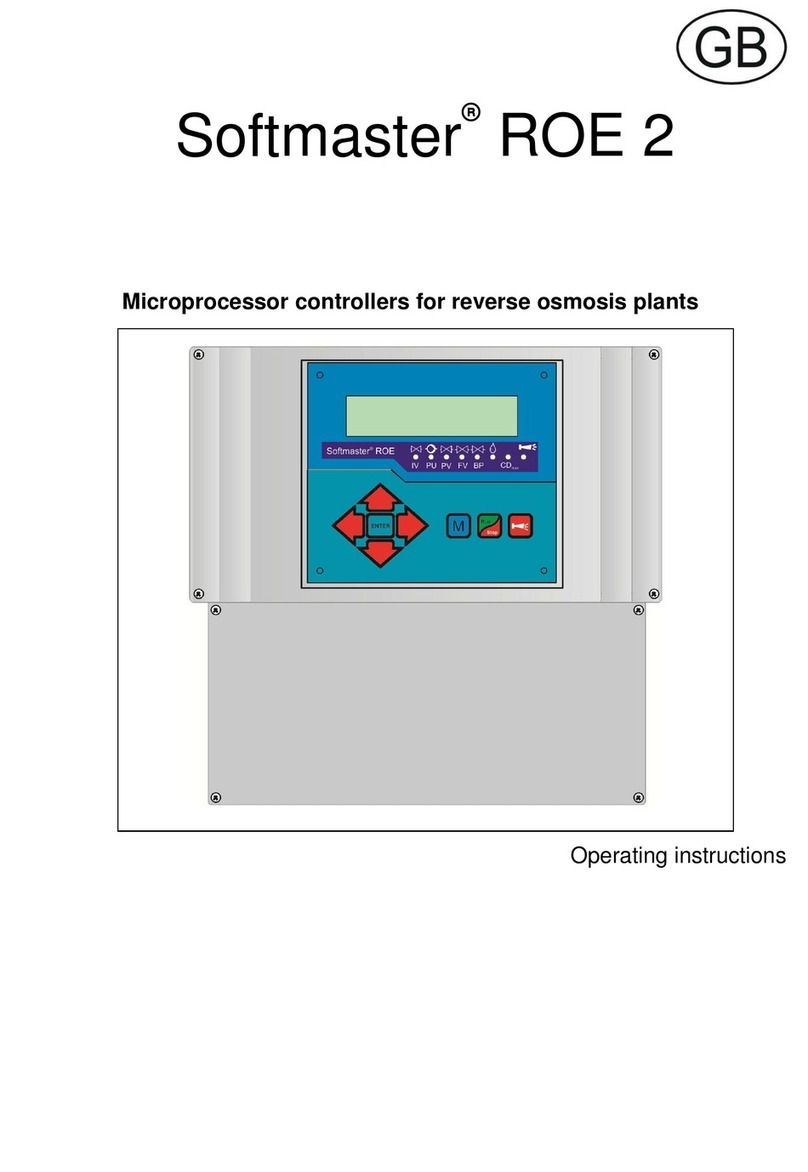

Viewoftheunit ..............................2

Description of the display and operating features ....3

OperatingDisplays ..........................3

Error Messages .............................4

Bottomlinedisplay............................4

Terminal Block Indentification ............. 5

Functions ...................................5

Description of the Relay Outputs ...............6

AV desalination valve ............................ 6

DO dosing output ............................... 6

EV input valve .................................. 6

AL error message output (“Alarm“) .................. 6

Description of the Signal Inputs ................7

WMcontactwatermeter .......................... 7

FC monitoring input desalination valve ............... 7

LLdosingmediumcontainerempty ................. 8

Programming ........................... 8

Menu start ...................................... 8

Menu selection / Selection .......................... 8

Input ........................................... 8

Endmenu ...................................... 8

InformationMenu............................8

Programming ...............................8

Enterpassword .................................. 8

Change password ................................ 8

Description of functions and Programming . . 9

Switching on and voltage loss ....................... 9

Operation....................................... 9

Desalination..................................... 9

Dosing ........................................ 10

Watermeter.................................... 10

Function “empty” (input LL) ........................ 11

Desalination monitoring (input FC) ................... 11

OutputAL/EV(“draining”function)................... 11

Language ...................................... 12

Password...................................... 12

Service Menu .................................... 12

Manual desalination ............................ 12

Autodesalination............................... 12

Manual impulses ............................... 12

Operatinginfo ................................. 13

Date/Time .................................... 13

Errorhistory................................... 13

Diagnosis .................................... 14

Softwarestatus ................................ 14

Draining...................................... 14

ProgrammMenu "M"............................. 15

Menu structure overview ......................... 15

Technical Appendix ..................... 16

Exampleofasimplecirculatingcoolant...........16

Connection example .........................16

Technicaldata ..............................17

1/17

General Notes

Introduction

These operating instructions describe the installation, operation and programming of EcoControl DO10.

We recommend that, whilst familiarising yourself with the operation of the unit aided by this manual, you have immediate

access to the operable controllerin order to perform the functions and combinations as described. Ascertain functions are

interrelated, it is advisable to follow the instructions in the given order.

Should problems or questions arise which are not described in this manual and/or cannot be solved, our customer service

is always at your disposal.

Try to identify the problem as accurately as possible and record the actions and conditions under which it occurred. This

will enable us to offer you swift effective assistance.

Handling Notes

Quick, repeated switching on/off of the controller should be avoided. Wait at least 5 seconds before switching the unit

either 'on' or 'off' at the main switch.

Only operate the controller in compliance with the ambient conditions (e.g. temperature, moisture) stated in the chapter

entitled technical data. Especially protect the controller against moisture.

The controller should not come into contact with splash or condensation water.

The original seals attached during manufacture (trimmer fixing point, EPROM labels) must not be broken; otherwise all

warranty claims will be withdrawn.

Before dismantling a defective controller, always write down the description of the error (failure effect). Repair work

(irrespective of the guarantee period) is only possible after the unit has been dismantled and returned to us with a

description of the error.

The allowed maximum electrical load capacity of the switching outputs and the total power rating of the plant must not be

exceeded.

The controller should only be used for its specified intended purpose.

Safety notes

Always pay attention to the following safety notes:

The controller must be installed and operated in compliance with relevant standards (e.g. DIN, VDE, UVV), or in

accordance with the regulations laid down by the individual country.

Some functions (e.g. manual desalination) allow direct manipulation of the plant (valves, pumps, etc.) without locking or

monitoring. These functions should only be used by trained personnel.

If you observe malfunctioning of the controller, switch it off immediately and inform the service personnel.

Do not attempt to repair the controller yourself (loss of warranty rights), instead always contact authorised personnel. This

is the only way that reliable and safe operation of the plant can be ensured.

After protective equipment (safety fuse) has been triggered, attempt, at first, to eliminate the cause of malfunctioning (e.

g. motor valve stuck) before reactivating the protective equipment. Frequent triggering is always due to an error which, in

certain circumstances, may also cause damage to the controller.

Non-observance of these notes can result in damage to the controller as well as the plant and may result in a loss of

warranty.

Installation and commissioning

Installation and commissioning should only be carried out by authorised personnel!

The connecting cables to the sensors should be kept as short as possible and clear of power cables. Close proximity to

strong electromagnetic radiators can lead to display interferences; in this case, separate interference suppression

measures should be carried out.

Afterinstallation,programtheunitwith the plant-specific features and data (e.g. switch functions, desalination times, etc.).

The data is permanently stored (also during voltage loss).

2/17

General Description

View of the unit

Mains switch >

Terminal box

Internal view

F1: Fuse M0.08A

F2: Fuse T4A (visible type fuse 20 x 5)

F3: Fuse M0.2A

3/17

Operation

2.73m3

Operation *

2.74m3

Description of the display and operating features

A On/Off switch

Only the surface-mounted variant is equipped with an

On/Off switch. Use this switch to switch the unit on or off.

B LC Display

Two lines with 16 characters, backlit.

C LED “Alarm”

Indicates an error message. The LED flashes if the output

AL has not been activated.

D LED “Desalination”

Indicates a current desalination.

E "ENTER" key

Confirm inputs and trigger functions via the ENTER key.

F Arrow keys

Use these keys to operate the menu drive in the display

and to enter values and programming data.

G "M" key

Call the menu and return to the submenu levels

H "Fault OFF" key

Deletes the alarm signal at the output AL (Alarm), a fault

display can only be deleted once the fault has been

eliminated.

Operating Displays

Each status change is stored in the status history (e.g. manual or automatic desalination).

Plantisinoperationwith2.73m3additional water consumption (supply quantity).

Plantisinoperation with 2.74m3additional water consumption (supplyquantity).

* = Dosing output is switched for the programmed time.

4/17

Voltage loss

Desal.monitor.

Des.val. OPEN !

Desal.monitor.

Des.val. CLOSED !

Draining

145m

Desalination

mm:ss 1:28

Draining has been activated, remaining time 145 minutes.

Desalination has been activated, remaining time 1 minute and 28 sceonds.

LED desalination is also lit.

The * for an active dosing output can also be displayed.

Error Messages

In addition to the displayed error messages, the red LED “Alarm” lights up or flashes.

Alternate display of all error messages and operating displays.

Each occurred error is stored in the error history.

If the output AL/EV is programmed as the input valve EV (“draining” function),

there is no alarm contact available !

Error message “Voltage loss”

Message each time the unit is switched on, unit was without voltage.

After switching on or after voltage recovery, the controller starts with the basic status “operation”. Desalination carried out

prior to the voltage loss is not continued.

Check the plant for possible negative results of the voltage loss (e.g. drainage of the circuit due to an open motor valve).

All stored values, such as the water volumeter, remain even during a voltage loss. The real-time clock is battery buffered

and thus keeps on running.

Confirm the fault display via the “Alarm” key.

Error message “Des.val.OPEN”

You have activated desalination monitoring, desalination has been completed

but water still flows through the desalination valve after the programmed test

time (desalination monitoring). Triggering of desalination monitoring via contact

at the FC (flow controller) input. Dependingon the programming, the alarm relay

is switched in addition to the display.

Adjust the test time to the closing or opening time of the valve when using motor valves.

Determine and eliminate the error and confirm the error message via the “Alarm” key.

Error message “Des.val.CLOSED”

You have activated desalination monitoring, desalination has been started but

still no water flows through the desalination valve after the programmed test

time (desalination monitoring). Triggering of desalination monitoring via contact

at the FW (flow controller) input. Depending on the programming, the alarm

relay is switched in addition to the display.

Adjust the test time to the closing or opening time of the valve when using motor valves.

Determine and eliminate the error and confirm the error message via the “Alarm” key.

5/17

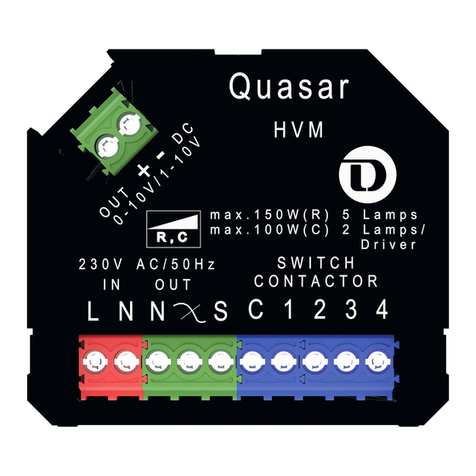

Terminal Block Identification

Functions (IN = input, OUT = output)

No. Terminal Type Function Comment

PE IN Mains protective earth

N

LIN Mains, N = Neutral

Mains, L = Live Mains input

230 - 240 V AC

n

lOUT 3x Neutral, switched

3x Live, switched Mains voltage, max. 4 A

10

11

12 AV OUT Desalination valve, c - contact

Desalination valve, nc - normally closed

Desalination valve, no -normally open

Volt-free relay output

max. load 240 V AC, 4 A

13

14

15 DO OUT Dosing output, c - contact

Dosing output, nc - normally closed

Dosing output, no - normally open

Volt-free relay output

max. load 240 V AC, 4 A

16

17

18 AL/EV OUT Output alarm/input valve, c - contact

Output AL/EV, nc - normally closed (*)

Output AL/EV, no - normally open (*)

Volt-free relay output

max. load 240 V AC, 4 A

19

20 --

-

-not used !

21

22 WM (+)

WM ( - ) IN Water meter input

Common load for water meter input Connect volt-free contact water

meter!

23

24

25

-

-

RS232 - Gnd --

-

-not used !

26

27 LL ( - )

LL (+) IN -Empty message dosing container

-Common load for empty-message input Connect volt-free switching contact!

28

29 FC ( - )

FC (+) IN -Common load for empty-message input

-Flow message desalination valve Connect volt-free switching contact

(flow-controller)!

30

31 RS232 - TxD

RS232 - RxD OUT/

IN -

-not used !

(*) please observe description of the alarm output AL/EV !

6/17

Description of the Relay Outputs

Please ensure that the outputs are volt-free.

AV desalination valve

Connect the desalination valve (solenoid or motor valve) to this relay output.

The idle position of the relay is the same in the case of a currentless controller and in the operating position: Contact to

terminals 10-11.

Set the time for desalination under menu option

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºDESALINATION ºDesalination time.

DO dosing output

Connect a dosing pump at this relay output (solenoid or motor dosing pump).

The idle position of the relay is the same in the case of a currentless controller and in the operating position: Contact to

terminals 13-14.

Set the time for the dosing impulse under menu option

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºDOSING ºImpulse Duration.

Set the impulse ratio, for which quantity of water dosing should be carried out, under menu option

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºDOSING ºLitre/Impulse.

Example:

A one second impulse should be provided per 50 litres:

Litre/Impulse = 50.0, Impulse = 1.0sec

Alternatively, the output can emit a certain number of impulses with a settable impulse pause and duration for the

measured quantity of water.

Set the number of impulses under menu option

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºDOSING ºNo. of Impulses.

Example:

4 one second impulses with a 3 second pause should be provided per 50 litres.

Litre/Impulse = 50.0, Impulse duration = 1.0sec, Impulse pause = 3.0sec, No. of impulses = 4

Note!

The impulse ratio in litres/impulse should not be less than the basic number of the water meter.

EV input valve

This output is not available if you have programmed the “Draining” function !

Connect the input valve (solenoid or motor valve) for shutting off the supply to this relay output.

Set the time (time and weekday) and the duration for draining the system under the menu option

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºOUTPUT AL/EV.

AL error message output ("Alarm")

This output is not available, if you have programmed the “Draining“ function !

Output "AL" is a volt-free change-over relay contact. During trouble-free operation, the contact between terminals 16 - 18

is closed and the one between terminals 16 - 17 is open. During voltage loss or if an error occurs, the contact between

terminals 16 - 17 is closed and the one between terminals 16 - 18 is open.

Output "AL" remains activated (terminals 16 - 17 closed) until the error ceases or until it is confirmed via the “Alarm” key.

- An error is displayed via the red LED "Error message" and on the display.

- The error message signal at output "AL" is deleted after confirming the error via the "Alarm" key.

- The error display can only be deleted once the error has been eliminated.

The following errors activate output "AL" and are displayed if the plant has been equipped with the appropriate contacts:

7/17

AL error message output ("Alarm"), continued

Statuses which always trigger an error message:

Voltage loss

Programming-dependent error messges:

Dosing medium container empty

Desalination valve remains open

Desalination valve remains closed

See page 8 for further descriptions of error messages and programming.

Description of the Signal Inputs

Note

Only connect the signal inputs "WM", "LL" and "FC" to volt-free contacts!

WM contact water meter

For registering additional water (quantity of supplied fresh water).

Set the basic number in the menu option "M" ºBasic program ºProgram value ºWater meter.

Function Type / Basic Number Functions

WM

SContact water meter

0.1 - 999,999

Litre/Impulse

STriggering of desalination once the start

volume is reached (additional quantity of water

since last desalination)

SAdditional quantity of water

SQuantity of desalination water

STotal quantity of additional water

SQuantity of evaporation water

FC monitoring input desalination valve (flow controller)

Monitors whether the desalination valve is closed and no water flows through it after completion of desalination AND

whether the desalination valve is open and water flows through it after commencing desalination, connect a flow controller

to the “FC” input.

Activate the control function, enter the desired effect of the contact (active as normally closed or normally open) and set

the time from which a test should be carried out under menu option "M" ºBasic program ºProgram

values ºFunctions ºDesalination Monitoring

.

An operational error is monitored by the controller and, depending on the programming, evaluated.

Function Test Time Type of Contact Type of Contact

Connection Action

FC

SMesage contact from the

flow controller for

desalination monitoringl

0 - 99 sec. Normally closed Contact without flow SError message

SEntry in the error list

SContinuous alarm if

programmed

Normally open Contact for flow

8/17

MENU

Service

Information

Basic program

"M"

LL dosing medium container empty

Connect a float switch or similar device here to monitor the dosing medium container.

Enter the desired effect of the contact (active as normally closed or normally open) and set the delay time used for testing

in menu "M" ºBasic Program ºProgram Values ºFunctions ºFct. Empty

If, in addition to the error message in the display, the alarm relay should also switch during an empty message, program

the alarm function.

Also enter a delay time to ensure evaluation for bouncing contacts.

Function Type of Contact Test Time Action

LL

SLevel transmitters input:

Dosing medium container

EMPTY

programmable

normally

closed/normally open

programmable

00 - 99 seconds

SError message

SEntry in error list

SContinious alarm if programmed

Programming

Menu start

Call the menu via the "M" key.

Menu selection / Selection

The current line position is displayed as a heading in CAPITAL LETTERS. Activate

the selected/displayed menu option via the "ENTER" key, i.e. you "jump" into a

submenu. Call the next menu option via the "DOWN" arrow key: "Scroll" through the

menu this way.

Input

Inputs are only possible in the BASIC PROGRAM menu and in some SERVICE

menu options.

Select a programming step via the “DOWN" and "UP" arrow keys and activate the

input function via the "ENTER" key.

When entering digits, the digit/position to be changed flashes.

Change to the next or previous digit (now flashing) via the "Right" and "Left" arrow

keys.

Change the value or selection via the "UP" and "DOWN" arrow keys.

Selection functions are marked with a Tif selection is possible.

Terminate the input function via the "ENTER" key.

Change to the higher-order menu via the "M" key.

End menu

Return to the higher-order menu via the "M" key. After returning from the highest menu level, the unit is once again in the

display function. The controller returns to the normal operating display (automatic menu end) after 2 minutes if no key is

pressed in the menu.

Information Menu

"M" ºInformation

Request the current settings without entering a password in the information menu.

The information menu is still displayed even if an incorrect password has been entered.

9/17

Programming

"M" ºBasic program

Enter password

The programming menu is protected by a 3-digit password (number between 000 and

999) in order to prevent unauthorised programming intervention.

Enterthepasswordunder"M" ºBasic program ºPassword inputand

confirm the input via the “ENTER” key.

You are now in the menu BASIC PROGRAM

Change password

As soon as you are in the basic program you can enter your individual password in the submenu “Extras”.

Description of Functions and Programming

Switching on and voltage loss

After switching on the unit and after each voltage loss, the plant automatically returns to the initial position (desalination

off, no dosing).

Operation

The water meter impulses are continuously added up and, depending on the programming, the dosing output is switched.

Desalination is triggered once the additional quantity of water required to trigger desalination (start volume) has been

reached.

Desalination

Automatic desalination

The water meter impulses are added up. After reaching the preset quantity of water

(start volume in litres = sum of impulses x basic number of the water meter), the

desalination valve AV (relay K1) is switched for the set switching time (desalination

time).

• The desalination time can be programmed between 0 and 99 minutes and 59

seconds (as mm:ss).

• Due to the start of desalination the volume memory for the quantity of start water

is reset to 0 litres.

• During current desalination, the lamp "Desalination" lights up, the message

"Desalination" is shown on the display and the remaining running time is

displayed in the bottom line in minutes and seconds (mm:ss).

• The water meter impulses are also registered and processed during current

desalination (metering and dosing).

• During drainage and subsequent refilling of the system, desalination and

metering of the water meter impulses are disabled/locked.

Menu:

BASIC PROGRAM

Password input

PASSWORD INPUT

Password 000

DESALINATION

Start volume

Desal.time

02000 l

START VOLUME

DESAL.TIME

mm:ss 02:30

10/17

Manual desalination / TEST

For simulation, commissioning or testing purposes it is possible to manually open the desalination valve:

1. Select the option “Manual desalination“ in the menu “Service” and open the desalination valve via the “ENTER”

key. The display “Des. val. OPEN” is shown until you exit the manual function via the ”ENTER” or “M” key and thus

close the desalination valve.

2. Select the option “Auto desalination“ in the menu “Service” und start automatic desalination via the “ENTER” key.

The display “Desalination” appears and the desalination valve remains open for the period programmed under

“Desalination time“. The menu is automatically exited after starting desalination and the operating display for the

current desalination appears.

In both cases the following occurs:

SThe volume memory for the quantity of water is set to 0.

SThe water meter impulses are still processed for dosing even during manualdesalination, however, they are not added

up for the following desalination.

Termination of desalination

You can cancel/stop desalination at any time by pressing the “ENTER“ key in the operating display (not in the menu !) for

5 seconds; the valve will then close immediately (!).

Dosing

You can use the dosing valve or solenoid or motor dosing pumps. Select the

controller according to the requirements.

Single impulse

For the single impulse: The dosing output (relay K2) is switched for the set time

(duration of dosing impulse) once the programmed quantity of water has been

reached. Program the duration of the impulse between 0.2 and 9 seconds and 1 as

the number of impulses.

Multiple impulses

For multiple impulses: Impulses for the set time (duration of impulse) with the

programmed pauses are emitted once the programmed quantity of water has been

reached. Program the duration of the impulse between 0.2 and 9 seconds, the

impulse pause between 0.2 and 9 seconds and the number of impulses between 2

and 9.

Menu:

Example of dosing:

as a single impulse as multiple impulses (4 four-second impulses and a 10-

second pause:

Dosing impulses are displayed via the asterisk which lights up on the display.

The water meter impulses should not occur quicker than the dosing impulses are processed.

Water meter

Set the number of impulses for the contact water meter in the menu:

Call the recorded quantities in the “Service” menu, e.g.:

"M" ºService ºOperating Info ºWM Desalination: 43 m3

"M" ºService ºOperating Info ºWM Total: 363 m3

"M" ºService ºOperating Info ºWM Additional Water: 160 m3

DOSING

Imp.duration

Litre/Impulse

Impulse pause

No.of impulses

WATER METER

L/Imp. 100.000

11/17

Functions

Funct. empty (LL input)

The “LL" input is designed as a level transmitter input for the “EMPTY“ level of the dosing

medium container.

Program the desired effect of the contact, the delay and the alarm function.

If the input is active after the test time “Delay“, an error message occurs.

If you have activated “Alarm” but no draining function, the output AL switches in addition to

the error message.

Desalination monitoring (FC input)

The “FC" input is designed to monitor the desalination valve.

Program the desired effect of the contact, the test time and the alarm function.

The desired effect relates to an active flow controller (for flow through).

Diagram of desalination monitoring:

Output AL/EV (“draining” function)

Program the function EV to activate the “Draining” function:

The input valve is closed and the desalination valve opened for the programmed period at

the start time (time) on the respective weekday or daily. This drains the system. The

message “Draining” and the remaining time appear on the display.

The desalination valve closes, the input valve opens and the system is filled after the

draining period. After a set filling time of one hour, the desalination lock is released.

FCT. EMPTY

Norm.closed -

Norm.open *

Delay 10s

Alarm *

active -

DESAL.MONITOR.

Norm.closed -

Norm.open *

Test time 30s

Alarm -

Function EV -

OUTPUT AL/EV

Duration 54h

Start time18:00

Daily -

Monday -

Tuesday -

Wednesday -

Thursday -

Friday *

Saturday -

Sunday -

12/17

Extras

Language

Selection of the desired display language:

At present these four “standard” languages available. However, other languages are

available if desired by customers.

Password

Changing the entered password:

SERVICE menu

Request and change current settings and statuses of the unit in the service menu.

Manual desalination

Open the desalination valve via the “ENTER” key:

The display “Des. val. OPEN” appears and the “Desalination” lamp lights up.

The volume memory for the quantity of water is reset to 0.

The water meter impulses are still processed for dosing even during manual desalination,

however, they are not added up for the following desalination.

Press the “ENTER“ or “M“ key again to close the desalination valve and to exit the manual

function.

Auto desalination

Press the “ENTER” key to start desalination with the programmed desalinaton time:

The menu is exited, the operating display “Desalination” appears and the “Desalination”

lamp lights up.

The volume memory for the quantity of water is reset to 0.

The water meter impulses are still processed for dosing even during manual desalination, however, they are not added up

for the following desalination.

Press the “ENTER“ key for 5 seconds to terminate desalination.

Manual impulses

Release the function via the “ENTER” key:

Subsequently simulate water meter impulses via the “UP” key. The number of manually

entered impulses is displayed:

Caution!

The water meter impulses are also processed for the volume memory and for dosing.

LANGUAGE

German *

English

French

Italian

PASSWORD

New: 000

MAN.DESALINAT.

Start (ENTER)

MAN.DESALINAT.

Des.valve open

AUTO DESALINAT.

Start (ENTER)

MANUAL IMPULSES

Start (ENTER)

MANUAL IMPULSES

Impulses: 2

13/17

Operating info

You can request the current counter statuses here.

Desalination

Displays the number of desalinations since the last counter reset.

Reset

In this menu you have to reset the regeneration meter to the initial value via the “Reset

(ENTER) “key.

Operating hours

The unit records the operating hours of the plant/controller.

Reset

You can reset the current operating time to 0 hours:

"M" ºService ºOperating Hours ºReset

Water quantities

The unit records the following water quantities:

WM total

The total quantity of supplied water since the last reset.

The counter restarts at 0 if 99999.9m3is exceeded.

WM desalination

The quantity of suppled water during desalination since the last reset.

The counter restarts at 0 if 99999.9m3is exceeded.

WM additional water

The difference between the total quantity of water and the quantity of water during

desalination

Time / Date

Please observe that the integrated clock only continues to run if the unit is switched on.

Correct, if necessary, the time and date after a longer period of voltage loss or if the plant

has been switched off.

Anzeige: "M" ºService ºTime Date

The display shows the date and time of the controller.

Set: Press the “ENTER“ key under menu "M" ºService ºTime Date.

Set and change the time and date by selecting the desired position via the arrow keys. Press the "ENTER" key to save the

setting and to return to the display function.

Error history

Open the error history via “display”. The error history is a list of errors and statuses which

have occurred during current operation.

An error is recorded with the time and date,

e.g.: Voltage loss

06:56 16.12.04

The list is not deleted after voltage loss.

The buffer of the error history is deleted and recording restarted via “delete“.

Please see the section “Error messages” for further information.

OPERATING INFO

Operating hours

Desalinations

WM total

WM desalination

WM add. water

Reset? (Enter)

OP.HRS. 125h

Reset? (Enter)

WM TOT. 412.3m

3

Reset? (Enter)

WM DES. 1.1m

3

Reset? (Enter)

WM ADD.: 12.3m

3

TIME DATE

10:23 21.01.05

ERROR HISTORY

Display

Delete

14/17

Diagnosis

The diagnosis menu displays the current statuses of the inputs and outputs. For test

purposes(e.g.during commissioning), theoutputstatusescan be manuallymanipulatedvia

the ”–” and “•” keys. Please ensure that downstream plant parts cannot be damaged.

Active statuses (switched relay, switched input) are displayed as “on”, inactive statuses as

“off”, e.g.:

OUTPUT AV or INPUT FC

off on

Software status

Call the current software status here:

Draining

Start the “Draining“ function via the “ENTER” key.

The display “Draining” appears, the desalination valve opens and the input valve closes.

Manually terminate draining in the following menu option:

DIAGNOSIS

Output

Input

Output AV

Output AL/EV

Output DO

Input empty

Input FC

OUTPUT

INPUT

Input WM

SOFTWARE STATUS

84M001 25.12.04

DRAINING

Start? (Enter)

DRAINING

End? (Enter)

15/17

Menu structure

active -

Reset? (Enter)

01.0sec

ENTER

ENTER

ENTER

MENU

Service

Output AV

Output AL/EV

Output DO

SERVICE

Auto desalinat.

AUTO DESALINAT.

M

Error history

Manual impulses

Operating info

Input empty

Input FC

TIME DATE

10:23 21.01.05

OP.HRS. 125h

DIAGNOSIS

ERROR HISTORY

Display

BASIC PROGRAM

Password input

Man.desalinat.

Information

FUNCTIONS

Desalination

Functions

DOSING

DESALINATION

ENTER

Dosing

Start volume

Fct. empty

Desal.monitor.

WATER METER

L/Imp. 100.000

LANGUAGE

German *

English

French

Italian

Extras

PROGRAM VALUES

Time Date

Diagnosis

Software status

SOFTWARE STATUS

84M001 25.12.04

Delete

Basic program

ECO-Control DO10

Last update: 11.04.05

Water meter

MANUAL IMPULSES

Desalination

12:03

02000 l

DESAL.TIME

mm:ss 02:30

START VOLUME

Desal.time

Imp.duration

Litre/Impulse

Impulse pause

No.of impulses

FCT. EMPTY

Norm.closed -

Norm.open *

Delay 10s

DESAL.MONITOR.

Norm.closed -

Norm.open *

Test time 30s

EXTRAS

Language

Password

PASSWORD

New: 000

Alarm *

LITRE/IMPULSE

300.000

IMP.DURATION

01.0sec

IMPULSE PAUSE

1

NO.OF IMPULSES

OPERATING INFO

Operating hours

Desalinations

WM total

Output

Input

OUTPUT

INPUT

Input WM

Start (ENTER)

MAN.DESALINAT.

Start (ENTER)

Alarm -

NO.OF DES. 8

Reset? (Enter)

Reset? (Enter)

WM ADD.: 12.3m

3

WM desalination

WM add. water Reset? (Enter)

WM TOT. 412.3m

3

Reset? (Enter)

WM DES. 1.1m

3

Start (ENTER)

MAN.DESALINAT.

Des.valve open

Desalination

12:03

Function EV -

OUTPUT AL/EV

Duration 54h

Start time18:00

Daily -

Monday -

Output AL/EV

Tuesday -

Wednesday -

Thursday -

Friday *

Saturday -

Sunday -

M - key

Operation

12.32m

3

16/17

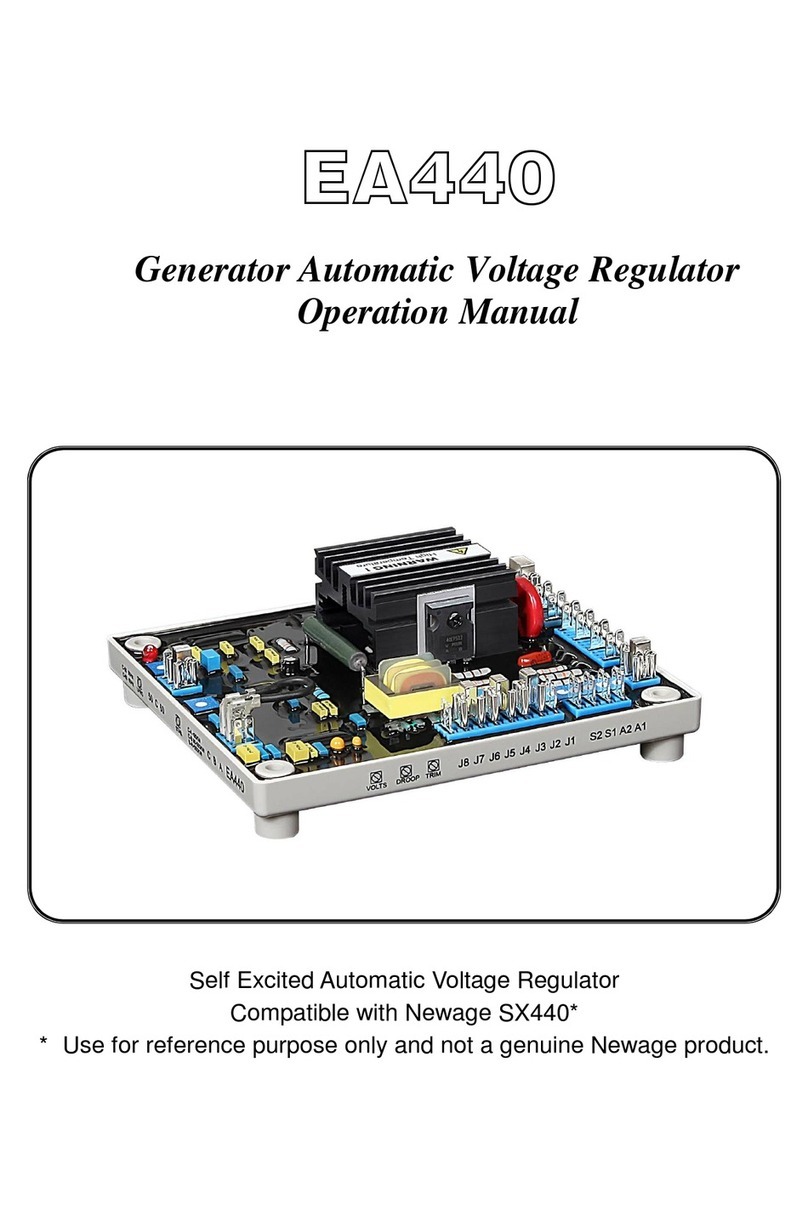

Technical appendix

Example of a simple circulating coolant

Connection example

17/17

Technical data

Power supply: 230 - 240 V or 24 V +/-10% 50 -6 0 Hz, safety fuse T4A

Power consumption without external load: max. 6 VA

Degree of protection: IP54

Protection class: I

Conformity: EN 50081-1, EN 50082-2, EN 61010-1

Ambient temperature: 10 - 45/C

Dimensions EcoControl DO10: W x H x D = 175 x 165 x 135 mm

Weight: approx. 0.8 kg

We reserve the right to make changes in the interest of constantly improving our products!

Art.-Nr.:xxxxx KF ECO Control_DO10_GB_051020.wpd

Table of contents

Other Heyl Controllers manuals

Popular Controllers manuals by other brands

Pegasus Astro

Pegasus Astro EZY FOCUS product manual

Logitech

Logitech FLIGHT SWITCH PANEL user guide

Planet

Planet NMS-500 Quick installation guide

Oriental motor

Oriental motor SCX10 Startup manual

Timeguard

Timeguard PDRS1500N Installation & operation instructions

Silent Gliss

Silent Gliss Move Original operating instructions