HFE vacuum systems HENKOVAC HV-40/60 User manual

Art. no. 96.06.5.0805/11.06

User manual

Diptank

"HV-40/60"

"HV-55/75"

Manufactured by:

Het Sterrenbeeld 36, 5215 ML 's-Hertogenbosch, The Netherlands

P.O.Box 2261, 5202 CG 's-Hertogenbosch, The Netherlands

tel: +31(0)73-6271271, fax: +31(0)73-6271200

2 96.06.5.0805-IM-GB/11.06

2011 HFE Vacuum Systems BV

All rights reserved.

No part of this document may be reproduced and/or published by means of printing, photocopy, microfilm or any other method, without the

prior written permission of the manufacturer. This also applies for the accompanying illustrations and/or diagrams and schematics.

The information in this document is based on the general data associated with the construction, material qualities and working methods,

known at the moment of publication, so that we reserve the right to make changes without giving prior notice.

This document is applicable to the indicated models of the Henkovac packing machine in the version supplied. The manufacturer therefore

does accept any liability for any form of damage or injury resulting from deviating from the specifications of these machines as supplied to

you.

All possible care was taken when creating this document, but the manufacturer accepts no liability for mistakes or any consequences

thereof.

TAKE THE TIME TO READ THIS DOCUMENT THOROUGHLY TO ACQUAINT YOURSELF WITH THE

CORRECT AND APPROPRIATE USE OF THE HENKOVAC PACKING MACHINES.

2011-06

PREFACE

96.06.5.0805-IM-GB/11.06 3

PREFACE

U

SE OF THE MANUAL

This manual is intended as a reference for users and technicians, who can install, use and maintain the

machine(s) stated on the front of this document in a safe way.

P

ICTOGRAMS AND SYMBOLS AT THE MACHINE

At the machine the following pictograms and symbols are attached to the machine:

Suggestions and advice to make carry out the particular tasks or actions easier.

WARNING

Procedures that can result in damage to the machine, the surroundings and the environment or

physical injury when not carried out carefully.

DANGER

Danger of electrical shock!

DANGER

Residual substances can contain valuable substances and materials that can be suitable for

recycling. Waste may also contain substances that are harmful to the environment.

I

LLUSTRATIONS

Because of the number of types and models it is impossible for practical reasons to illustrate every variation.

Nevertheless, the illustrations used show the principles of operation of the machine identified on the front of this

document.

S

ERVICE AND TECHNICAL SUPPORT

For information concerning specific settings, maintenance or repair work that is outside the scope of this

manual, contact the supplier of the machine. He is always ready to help you. Make sure that you have the

following data available:

machine type

serial number

This data can be found on the identification plate.

PREFACE

4 96.06.5.0805-IM-GB/11.06

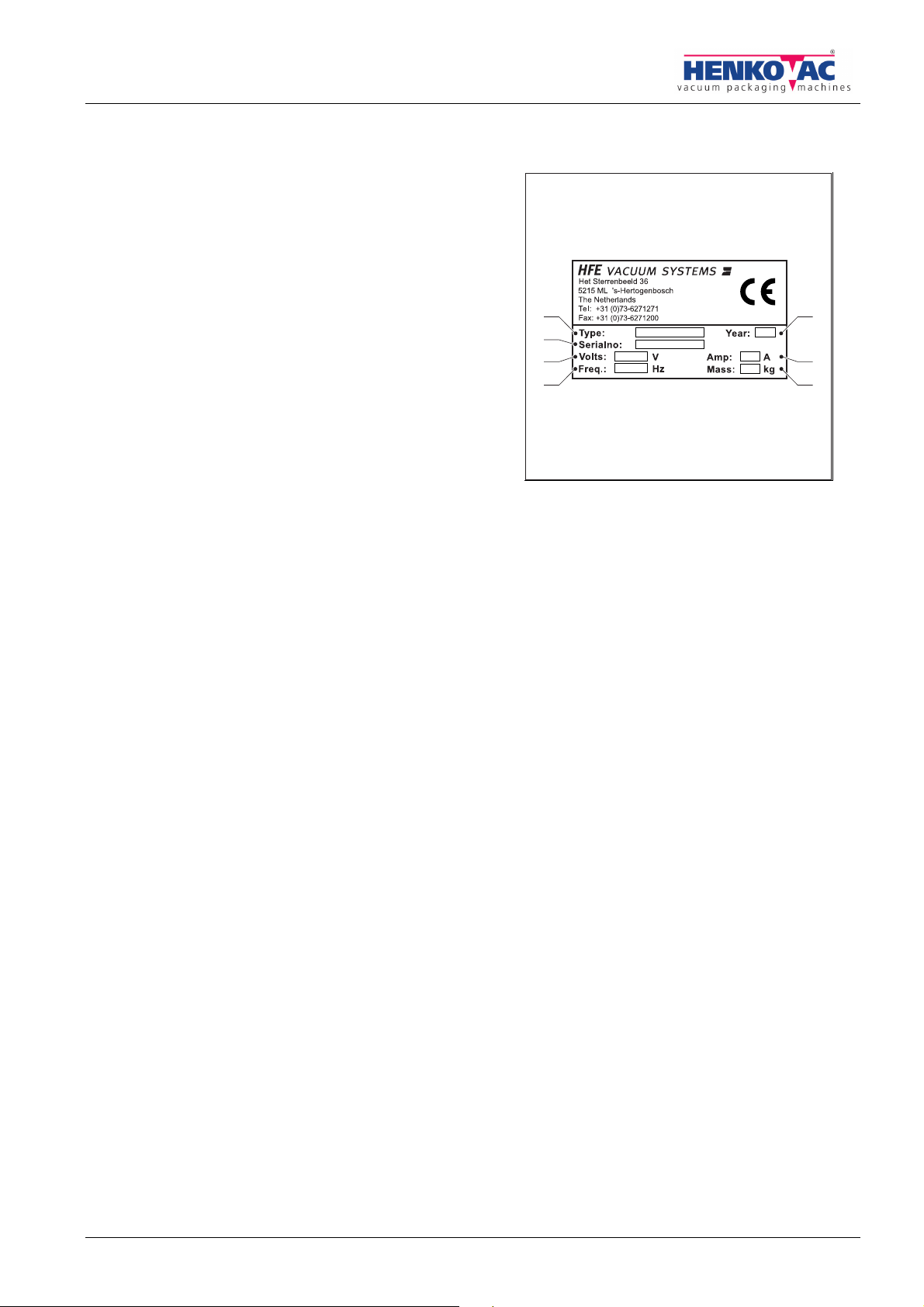

I

DENTIFICATION OF THE MACHINE

The identification plate contains the following data:

A Type

B Serial number

C Year of manufacture

D Number of phases-

Voltage

Volt V

E Frequency Hertz Hz

F Current Ampere A

G

Weight kilogram kg

E

A

B

D

G

C

F

CONTENTS

96.06.5.0805-IM-GB/11.06 5

CONTENTS

PREFACE..........................................................................................................................................3

SAFETY INSTRUCTIONS AND DANGER WARNINGS...................................................................6

SAFETY REGULATIONS IN THE DIPTANK....................................................................................8

MACHINE AND THE ENVIRONMENT..............................................................................................9

1.THE DIPTANK..............................................................................................................................10

1.1.

E

XECUTION DIPTANK

..................................................................................................................10

1.2.

M

AIN COMPONENTS DIPTANK

......................................................................................................10

2.INSTALLATION............................................................................................................................11

2.1.

I

NSTALLATION

...........................................................................................................................11

2.2.

P

REPARE FOR USE

....................................................................................................................11

3.CONTROL ....................................................................................................................................12

3.1.

C

ONTROL PANEL

.......................................................................................................................12

3.2.

S

WITCHING ON

..........................................................................................................................12

3.3.

T

HERMOSTAT

............................................................................................................................12

3.3.1.

Adjust working temperature................................................................................12

3.3.2.

Control working temperature..............................................................................13

3.3.3.

Control working thermostat ................................................................................13

3.4.

U

SE

..........................................................................................................................................13

4.MAINTENANCE ...........................................................................................................................14

4.1.

C

LEANING OF THE TANK

.............................................................................................................14

4.2.

C

ONNECTION CABLE

..................................................................................................................14

5.FAULTS........................................................................................................................................15

6.TECHNICAL DETAILS.................................................................................................................16

7.CE-DECLARATION................................................................... Fout! Bladwijzer niet gedefinieerd.

SAFETY INSTRUCTIONS

6 96.06.5.0805-IM-GB/11.06

SAFETY INSTRUCTIONS AND DANGER WARNINGS

G

ENERAL

The manufacturer accepts no liability whatsoever for damage or injury caused by not (strictly) following the safety

directions and instructions in this manual, or carelessness during the installation, use, maintenance and repair of

the machines identified on the front of this document and any accompanying options.

The owner of the machine is responsible at all times for observing the locally applicable safety

regulations and guidelines.

Obey all safety instructions and guidelines as given in this manual.

U

SER MANUAL

Every user should be informed of the contents of this manual and follow the instructions in it carefully.

Management must train personnel on the basis of this manual and obey all directions and indications.

They should not be damaged or removed and they should remain present and readable throughout the entire

life span of the machine.

Replace or repair unreadable or damaged pictograms, warnings and instructions immediately.

Always keep the manual in the proximity of the machine.

P

ICTOGRAMS AND INSTRUCTIONS ON THE MACHINE

The pictograms, warnings and instructions that have been attached to the machine are part of the safety

measures taken.

They should not be damaged or removed and they should remain present and readable throughout the entire

life span of the machine.

Replace or repair unreadable or damaged pictograms, warnings and instructions immediately.

SAFETY INSTRUCTIONS

96.06.5.0805-IM-GB/11.06 7

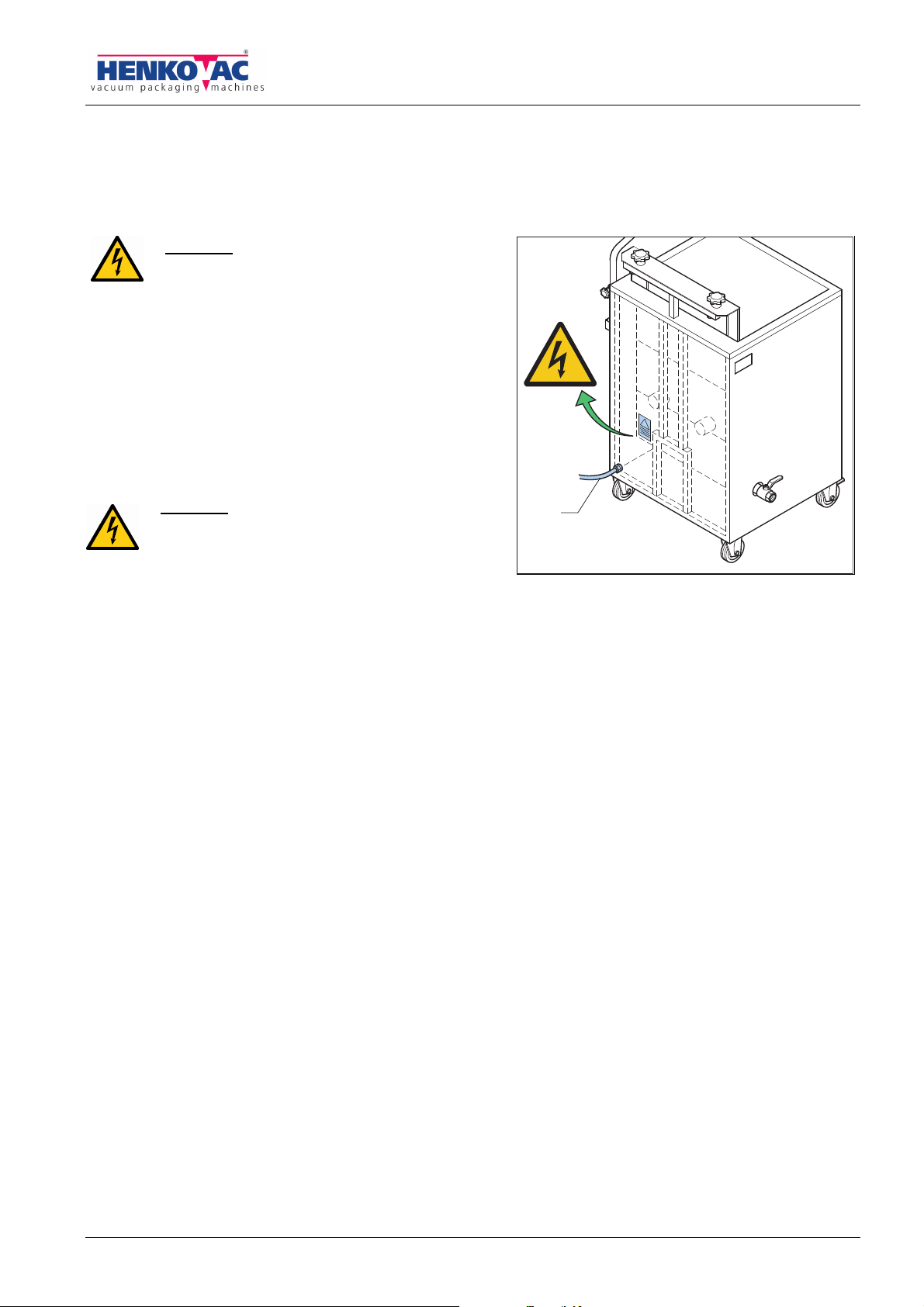

P

ICTOGRAMS ON THE DIPTANK

On the machine the following pictograms are attached.

DANGER

Before opening: remove the plug from the wall

socket!

Only qualified personnel are allowed to open

the unit.

C

ONNECTIONS TO THE DIPTANK

The diptank is equipped with a power cable. A plug

suitable for the local power requirements has to be

connected to the power cable.

DANGER

The plug can only be connected by qualified

electricians only.

U

SE OF THE MACHINE

*1

The diptank has been designed to shrink shrink bags, in which products have been packed under vacuum,

under influence of head.

Any other or extended use is not according to the purpose. The manufacturer accepts no liability for damage or

injury resulting from this. Use the machine only in a technically perfect condition, in accordance with the purpose

described above.

T

ECHNICAL SPECIFICATIONS

The specifications stated in this manual may not be changed.

M

ODIFICATIONS

Modifications of (parts of) the diptank are not allowed.

By modifications executed by others than HFE vacuum systems b.v.:

•The guarantee expires

•The liability of the manufacturer expires

*1 The “Use in accordance with purpose” as established in EN 292-1 is the use for which the technical product is suitable according to the

statement by the manufacturer – including his directions in the sales brochure -. When in doubt it is the use that appears to be the most

usual from the construction, model and function of the product. Use in accordance with the purpose means observing the instructions in

the user manual.

A

SAFETY INSTRUCTIONS IN THE DIPTANK

8 96.06.5.0805-IM-GB/11.06

SAFETY REGULATIONS IN THE DIPTANK

BOILING DYR SECURITY

The machine is equipped with a float switch (A) that

secures the diptank against boiling dry. Because of the

vaporizing of warm water and as there is always some

water left in the packing, the water level in the diptank will

decrease. When the water level will be too low, the

heating will switch off automatically.

Switching on again of the diptank:

•Add water.

•Press the pushbutton to switch on the diptank.

TEMPERATURE SENSOR

The temperature sensor (B) in the diptank guards the

temperature set.

U

SE

•Inspect the diptank before use and check it for damage.

•Remove the plug from the diptank from the wall socket after every use. Because of this you will not have

tension on the diptank.

•Never use sharp objects to operate the keys.

•Do not allow unauthorized persons into the working environment.

•Always ensure there is adequate ventilation, especially in confined places

•Wear clothing that is suitable for the work. Loose clothing or jewelry can get between the cover and the

vacuum chamber.

•Never use the machine in an environment in which there is an explosion risk.

•Replace the supply cable if it is damaged

•Make sure that the supply cable cannot be damaged by trapping this cable.

H

YGIENE

•Cleaning the machine is of the utmost importance when food products are wrapped. Clean the machine

regularly and thoroughly, preferably every day, sees “maintenance”.

•Work hygienically and prevent direct contact between the product and the machine as much as possible.

•Keep the operating controls free of dirt and grease.

•Hold long hair together.

S

ERVICE

,

MAINTENANCE AND REPAIR

A clear distinction is made in this manual between the service, maintenance and repair work that can be carried out by

the user, and that which is reserved for trained and qualified service technicians only.

A

B

SAFETY INSTRUCTIONS IN THE DIPTANK

96.06.5.0805-IM-GB/11.06 9

•Make sure there is adequate lighting.

•Always switch off the machine at the main switch during maintenance and/or repairs and/or remove the plug

from the socket.

•Observe the maintenance intervals specified. Overdue maintenance can lead to high costs for repair and

servicing and the right to guarantee can be lost.

•Always use parts, materials, lubricants and service techniques approved by the manufacturer.

•Never use worn tools and do not leave any tools inside the machine.

•Do not carry out service, maintenance or repair work to the machine, when it is indicated that the dealer or

qualified service technician should carry it out.

•Always have a recognized Henkovac dealer carry out repair and maintenance work.

•Safety measures that have been removed in order to carry out service, maintenance or repairs must be

refitted immediately after this work and they must be checked for correct operation.

MACHINE AND THE ENVIRONMENT

PACKING

The packing that is for the transportation and protection of the machine is mainly made of cardboard

and/or wood, which are suitable for recycling. Do not dispose of the packaging as industrial waste but

ask the sanitation department of your local government authority where you can hand in the material.

MACHINE

When you dispose of your machine, it can still contain valuable substances and materials. Do not

dispose of the machine as industrial waste, but enquire at your local government authority about the

possibilities for recycling or environmentally friendly disposal of the material.

•Most parts of the machine have been manufactured from stainless steel and can be disposed of as

scrap metal in the normal way. From health and environmental considerations, no asbestos has been

used.

•The printed circuit boards and the components mounted on them are electronic waste.. Deliver old

printed circuit boards to specialized companies for environmentally friendly processing.

OIL

Ask the sanitation department of your local government authority where you should take the used oil for

an environmentally friendly processing.

THE DIPTANK

10 96.06.5.0805-IM-GB/11.06

1. THE DIPTANK

1.1. Execution diptank

In a diptank products can be final processed which are vacuum packed in shrink bags. Shrink bang are vacuum

bags which shrink when being heated.

A diptank is a machine with a water reservoir. The water will be heated till the adjusted temperature. After

vacuum packing of products the package shows folds and wrinkles. When a packed product in a shrink bag is

dipped in hot water, the pouch shrinks and straightens out the folds. The result is a tight packed product with a

second skin effect.

In the diptank there is a platform, where products should be placed on when it is in its highest position. After

placing the products on the platform, the push button has to be pressed. The platform will automatically descend

and rise automatically where the products have been dipped in the warm water. The final processed products

have to be removed manually from the platform.

1.2. Main components diptank

A. Control panel

B. Platform

C. Wheel with brake

D. Wheel

E. Drainer

F. Connection cable

G. Identification plate

G

F

E

D

A

C

B

INSTALLATION

96.06.5.0805-IM-GB/11.06 11

2. INSTALLATION

2.1. Installation

1. Unpack the diptank.

2. Level the machine on a flat firm surface.

3. Apply the brakes of the wheels

4. Have a qualified electrician connect a suitable plug to

the connection cable.

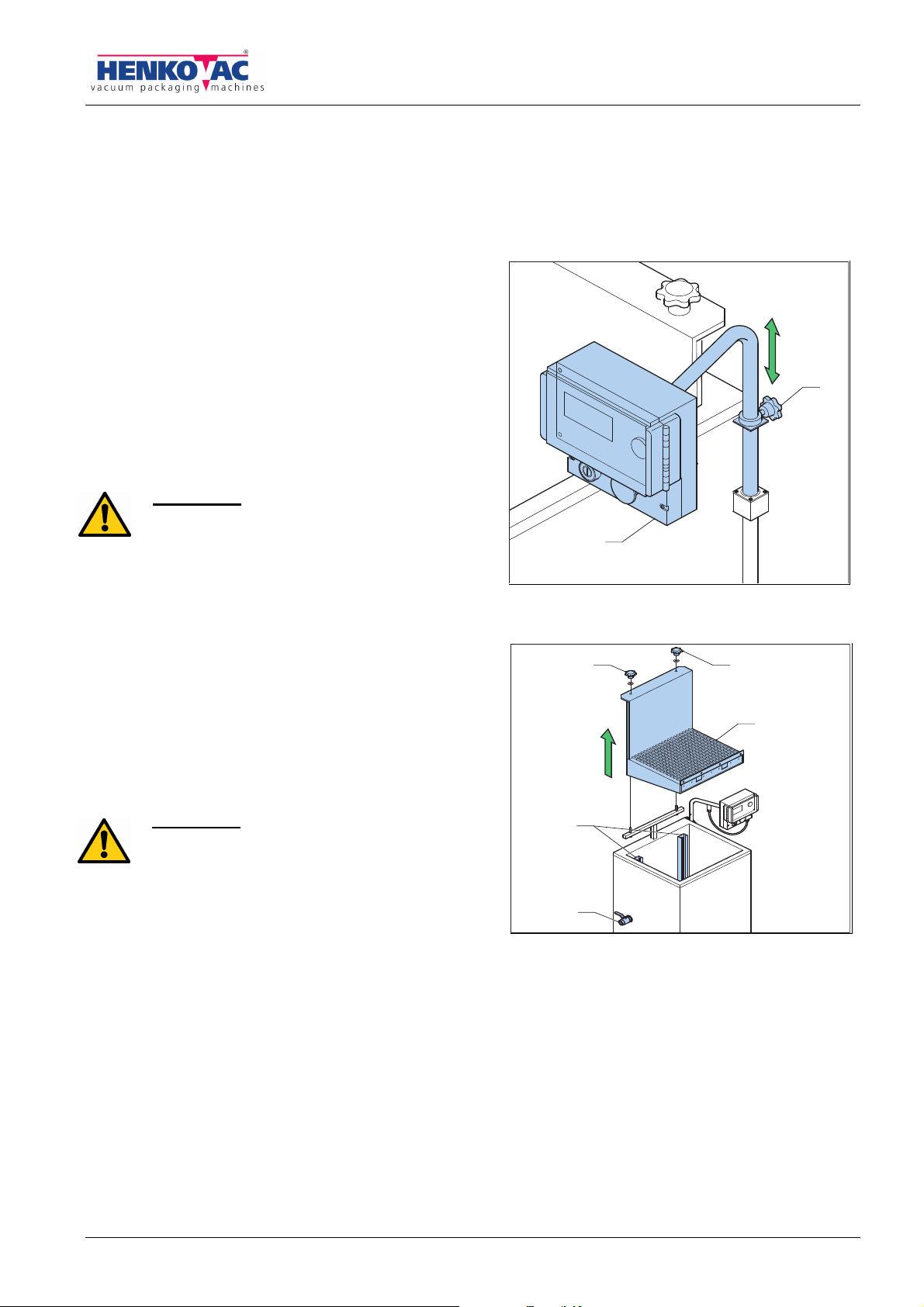

5. Adjust the height of control panel:

Loosen the star button (A) and position the control

panel (B) at a suitable height and angle, in order to

work easier with the diptank.

ATTENTION

Never place the diptank before an entrance, exit

or emergency exits that are meant for

emergency services.

2.2. Prepare for use

1. Make sure that the draw-off tap (C) is closed.

2. Fill the tank with water, until about 4 to 6 cm. under

the platform (B), if the platform is positioned in the

upper level.

3. Connect the diptank to a socket.

ATTENTION

Pay attention to the dimensions of the vacuum

packed products. If the packed product will go

completely under water, no water may flow over

of the tank.

B

A

D

B

AA

C

CONTROL

12 96.06.5.0805-IM-GB/11.06

3. CONTROL

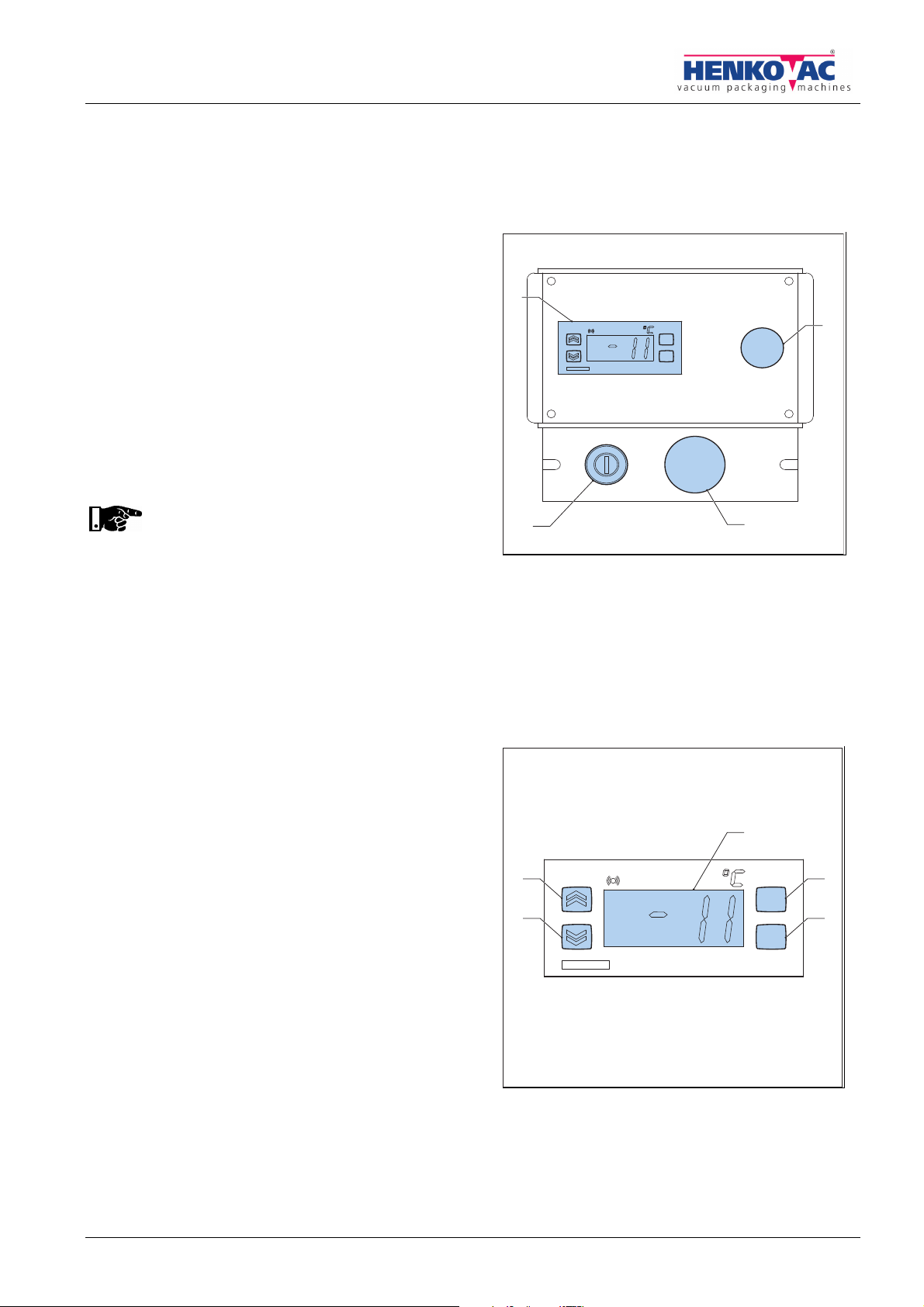

3.1. Control panel

A. Temperature control

B. Control lamp

C. Pulse button in order to have the diptank make one

cycle.

D. Start button for the heating

3.2. Switching on

1. Press the start button (D): the heating will be

switched on. The control lamp (B) will burn.

The heating of the water takes 45-60 minutes.

2. Press the pulse button (C): the platform makes one

cycle and stops in the upper position. Check the water level, see § 2.2.

3. Open the transparent cover.

4. Adjust the required water temperature.

3.3. Thermostat

A. Display

B. Function button “fnc”

C. Function “set”

D. Function “down”

E. Function “up”

3.3.1.Adjust working temperature

1. Press the button “set” (C) for 1 second.

The display (A) will show “SET”.

2. Press “set” again. The display shows the adjusted

value.

3. Adjust the temperature to 90°C by pressing the

button “op” (E) or button “down” (D).

4. Press twice on “fnc” (B) to store the adjusted value.

This ends the adjustments.

fnc

set

out

D

A

B

C

out

set

fnc

B

A

C

E

D

CONTROL

96.06.5.0805-IM-GB/11.06 13

Remarks

•The display shows the measured temperature. This is the actual temperature, not the adjusted temperature.

•If you have not pushed a button during 15 seconds, the display automatically returns, without storing the

value.

3.3.2.Control working temperature

1. Press two times on “set”. In the display the adjusted temperature will be shown.

3.3.3.Control working thermostat

1. Adjust the working temperature at about 3°C above the surroundings temperature.

In the display a point will lighten, that shows that the relays of the controller will be changed over.

2. Adjust the working temperature at about 3°C below the surroundings temperature.

If the point extinguishes, the working of the thermostat is okay.

3. Adjust the correct working temperature again, see § 3.3.1.

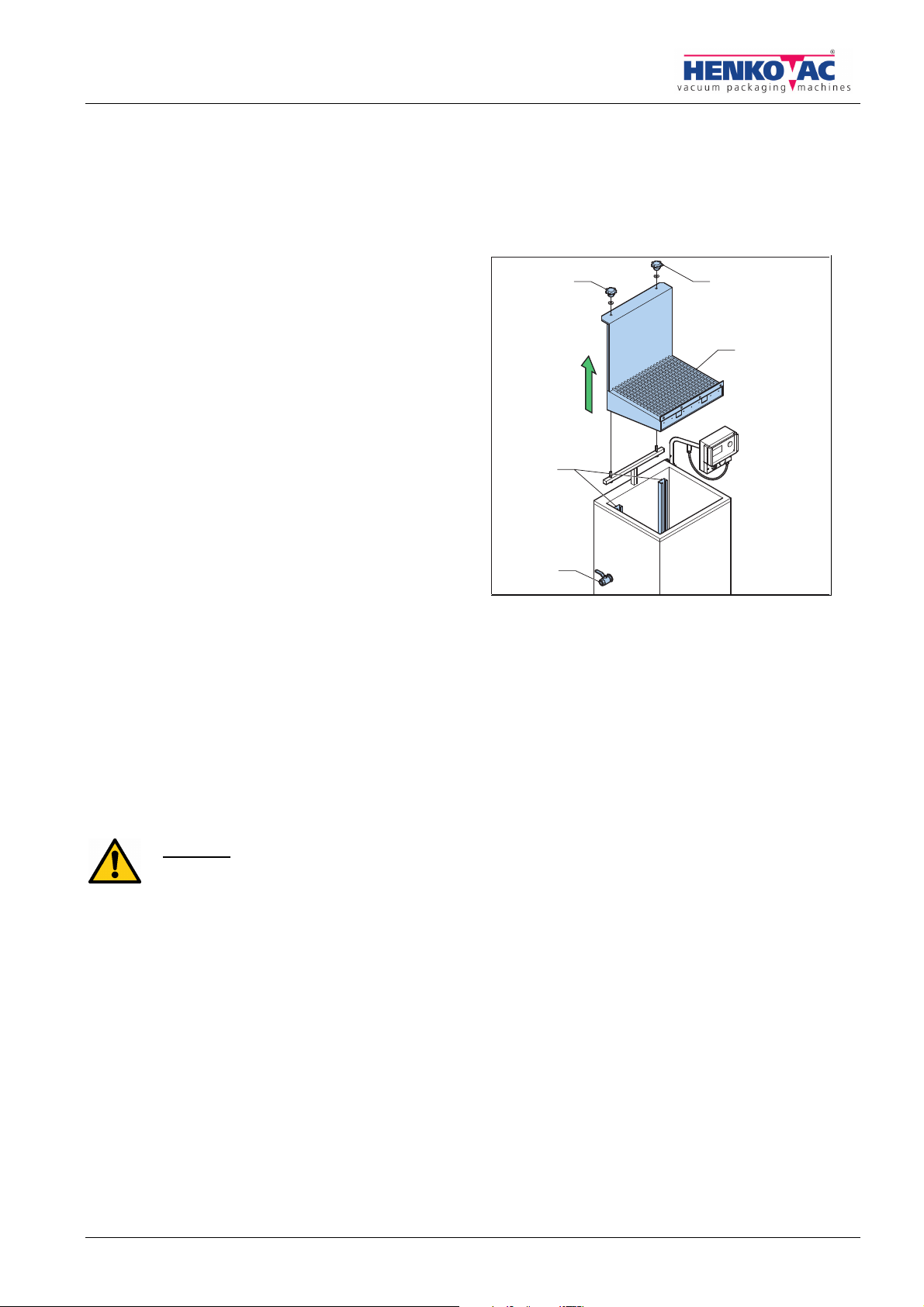

3.4. Use

If the water is on temperature is, the diptank can be

used.

1. Place the to be final processed vacuum packed

product (A) on the platform (B).

2. Push the pulse button (C). The platform makes one

cycle: one down and one up. In this upper position

the platform will stop.

3. Remove the final processed product from the

platform.

A new to be final processed vacuum packed product

can be placed on the platform.

DANGER

During the cycle the platform moves down

and up. Keep away from moving parts in

order to prevent oppressing.

B

C

A

MAINTENANCE

14 96.06.5.0805-IM-GB/11.06

4. MAINTENANCE

4.1. Cleaning of the tank

Daily maintenance in order to work hygienically it is

necessary to:

•Clean the tank

•Refresh the water

1. Remove the plug from the socket. Because of this

the diptank, so including the heating, will be

switched off.

2. Loosen the star buttons (A).

3. Take the platform (B) out of tank.

4. Clean the platform.

5. Draw off the water in the tank, by opening the

draw-off tap (C). Make sure of a good discharge of

the water.

6. Close the draw-off tap.

7. Attach the platform: the guide rollers have to slide

in the rails (D).

8. Tighten the platform with the star buttons.

9. Fill the diptank with clean water before starting the new production, see § 2.2.

4.2. Connection cable

1. Check the connection cable regularly for damages.

DANGER

Have the dealer replace a damaged connection cable immediately.

D

B

AA

C

FAULTS

96.06.5.0805-IM-GB/11.06 15

5. FAULTS

Faults Cause Remedy

The plug is not in the socket. Plug the plug into the socket.

(Earth leaking) protection in the

electric cabinet has tripped.

Check the electric cabinet.

A fuse(s) in the electric cabinet is

defective.

Check the electric cabinet.

A fuse(s) in the machine is defective. Consult your dealer.

The motor protection of the machine

is switched off.

Consult your dealer.

The diptank does not

work.

There is a break in the connection

cable.

Have the connection cable been replaced

by authorized electrician.

TECHNICAL DETAILS

16 96.06.5.0805-IM-GB/11.06

6. TECHNICAL DETAILS

Type HV-40/60 HV-55/75

Dimensions and weight

Depth 675 mm 800 mm

Width 860 mm 1020 mm

Height 1350 mm 1350 mm

Weight 106 kG 130 kG

Dimensions and weight of the packed machine

Depth 960 mm 1035 mm

Width 950 mm 1180 mm

Height 1260 mm 1375 mm

Weight 157 kG 190 kG

General information

Platform Length 580 mm 730

Width 410 mm 530

Contents diptank 110 ltr 180 ltr

Maximum water volume 75 – 80 ltr 100 – 140 ltr

Connection draw-off tap 1" female

Electrical connections

Voltage, Current, Frequency See the identification plate, see “identification of the machine”.

Capacity 9 kW 15 KW

Phases 200V – 240V 3 phases

Phases 380V – 415V 3 phases + neutral

Frequency 50/60 Hz

Voltage tolerance ± 10 %

Voltage date was not included in this summary, because these are dependent on the electricity

supply of the country that the machine is intended for. The voltage dates are given on the machine

identification plate (see “identification of the machine”),

Dimensions and weights are for the standard model machines.

96.06.5.0805-IM-GB/11.06 17

7. CE-DECLARATION

CE-VERKLARING VAN OVEREENSTEMMING

CE-DECLARATION OF CONFORMITY

CE-KONFORMITÄTSERKLÄRUNG

DECLARATION DE CONFORMITÉ CE

DICHIARAZIONE DI CONFORMITA'CE

Wij,

We, HFE vacuum systems bv.

Wir, Het Sterrenbeeld 36, 's-Hertogenbosch

Nous, The Netherlands

Noi,

verklaren geheel onder eigen verantwoordelijkheid dat de produkten,

declare under our sole responsibility that the products,

erklären in alleiniger Verantwortung, daß die Produkte,

déclarons sous notre responsabilité, que les produits,

Dichiariamo sotto la nostra responsabilità che las macchinas

Henkovac vacuum packing machines

waarop deze verklaring betrekking heeft, in overeenstemming is met de volgende Europese Richtlijnen:

to which this declaration relates, complies with the requirements of the following European Directives:

auf die sich diese Erklärung bezieht, folgende Europäischer Richtlinie entspricht:

auquel se réfère cette déclaration, est conforme aux Directives Européennes:

alla quale si riferisce questa dichiarazione, è conforme alle Direttive Europee:

•the machine guideline: 2006/42/EG

•the EMC-guideline: 2004/108/EG

Conformiteit is aangetoond door overeenstemming met de volgende normen:

Conformity is testified by complete adherence to the following standards:

Die Übereinstimmung wird nachgewiesen durch die vollständige Einhaltung folgender Normen:

La conformité est demonstrée par la conformité intégrale avec les normes suivantes:

La conformità è dimostrata dalla conformità alle sequenti norme:

NEN-EN-ISO 12100-1

NEN-EN-ISO 12100-2

NEN-EN-ISO 14121-1

NEN-EN-ISO 13857

NEN-EN 60204-1

E.H. Goudsmid

Managing Director

The Netherlands, 's-Hertogenbosch, June 2011

This manual suits for next models

1

Table of contents