HG SUPER SKUB E-700 User manual

HG Super Skub - an alternative to the traditional wheelbarrow

USER MANUAL

SUPER SKUB E-700

2

CONTENTS

HG Super Skub - an alternative to the traditional wheelbarrow

Super Skub E-700

Subject Page

Introduction......................................................................... 3

1Safety instructions....................................................... 4

1.1 Training .............................................................. 5

1.2 Preparation........................................................ 5

1.3 Noise and vibration levels ............................... 5

1.4 Operation........................................................... 7

1.5 Maintenance...................................................... 8

1.6 Transporting/Towing........................................ 9

1.7 Disposal/Dismantling....................................... 9

2Functional description.............................................. 10

3Driving ........................................................................16

5Maintenance.............................................................. 18

5.1. Maintenance overview ...................................18

5.2. Towing and tipping in case of motor failure,

hydraulic failure or power failure.................. 19

5.3. Maintenance points........................................21

6FAQ .............................................................................24

7Hydraulic diagram and electrical diagram............. 25

8Technical specifications............................................26

9Warranty provisions.................................................. 28

10 EU Declaration of Conformity .................................29

Model:

280200

280205

280210

dcontent

INTRODUCTION

3

HG Super Skub - an alternative to the traditional wheelbarrow

Introduction

HG Super Skub E is an electrically motorised wheelbarrow

used for transporting materials on solid surfaces.

The power barrow can load up to 700 kg at a time, e.g. 550

litres of sand, meaning that it can hold 8 times more than an

ordinary wheelbarrow.

With pendulum suspension, fully electric transmission and

hydraulic tipping, the machine is easy to handle and the

ergonomically correct control panel provides a good

working position.

The strong construction of the power barrow provides a

long service life and requires minimal service.

Manufacturer:

Vejlevej 15

DK-8722 Hedensted

Tel. (+45) 75 89 12 44

Email: [email protected]

www.superskub.dk

4

HG Super Skub - an alternative to the traditional wheelbarrow

SAFETY

1Safety instructions

Read the manual

Read the manual carefully and make sure that other potential

users of the machine read it as well. If the user is unaware of

certain details about the machine, this could lead to hazards.

If one of the warning labels is loose, worn or damaged so that

the symbol is illegible, the label must be replaced.

WARNING! next to a text in the manual highlights a risk

of injury if users do not follow the instructions.

Do not touch the electric motor

during operation or when the motor

has just stopped. Hot parts can cause

severe burns.

We recommend the use of qualified

service staff/workshop for servicing

or troubleshooting, as there is a risk

of electric shock. Electric shock can

cause fire damage, death and/or

long-term injuries.

Manuals, spare parts lists

and instructional videos are

available on

www.superskub.com or by

scanning the QR code

located by the machine's

controls.

Setup, manual and

programming of the

Victron BMV 712 are

available on

www.victronenergy.dk

/support-and-

downloads/manuals#it

em=manuals-bmv-

712-smart

Avoid contact with moving machine

parts. This applies to both fingers and

clothing, as this can lead to mutilation.

When servicing and parking the machine, the motor must be

switched off, the ignition key removed and the main switch

turned off.

At HG, we always recommend qualified staff/workshops for

servicing and troubleshooting.

We recommend the use of

hearing protection.

Prolonged exposure to

noise damages hearing.

WARNING!

Hot parts

WARNING!

Electric shock

WARNING!

Danger of crushing

WARNING!

Danger

WARNING!

NOISE

dcontent

SAFETY

5

HG Super Skub - an alternative to the traditional wheelbarrow

1.1 Training

◆Read the instructions carefully. You should be familiar

with all controls, switches etc. and with how to use the

equipment correctly.

◆To use the motor barrow, the operator must be over 18

years of age and have normal mental condition and

mobility. Relevant legislation may mandate a different

age limit for operators of the motor barrow in specific

situations.

◆Remember that the operator is responsible for any

accidents or hazardous situations that may occur

involving other people or their property.

◆The operator should be given adequate instructions for

using the motor barrow. These instructions should focus

on:

1) The need to be careful and focused when working

with self-propelled machines.

2) The fact that the operator must have a good

overview of what is happening in front of/behind the

vehicle - especially where other people may be

present.

The most common causes of accidents are:

1) Lack of overview;

2) The operator's knowledge of the vehicle is

insufficient;

3) Overly steep terrain conditions;

4) Insufficiently stable terrain;

5) The vehicle being used in conditions with insufficient

space.

1.2 Preparation

◆Be sure not to wear loose clothing when driving.

◆Ensure that he machine is adequately charged. HG does

not recommend driving with less than 15% battery

capacity

◆Ensure that the machine holds sufficient hydraulic oil for

the tipping function.

◆Top up hydraulic oil if required, before activating the

main switch and ignition key to ON position. Never

remove the hydraulic tank cap or top up the hydraulic oil

while the motor is running or hot.

◆In case of spilling hydraulic oil, do not attempt to turn on

the machine until the hydraulic oil spilled on the machine

has been removed. Hydraulic oil can create very slippery

surfaces and can thus increase the risk of accidents while

driving.

◆If you get hydraulic oil on your skin, you should wash your

skin thoroughly with soap. If irritation persists, consult a

physician

◆Ingestion of hydraulic oil is potentially fatal.

1.3 Noise and vibration levels

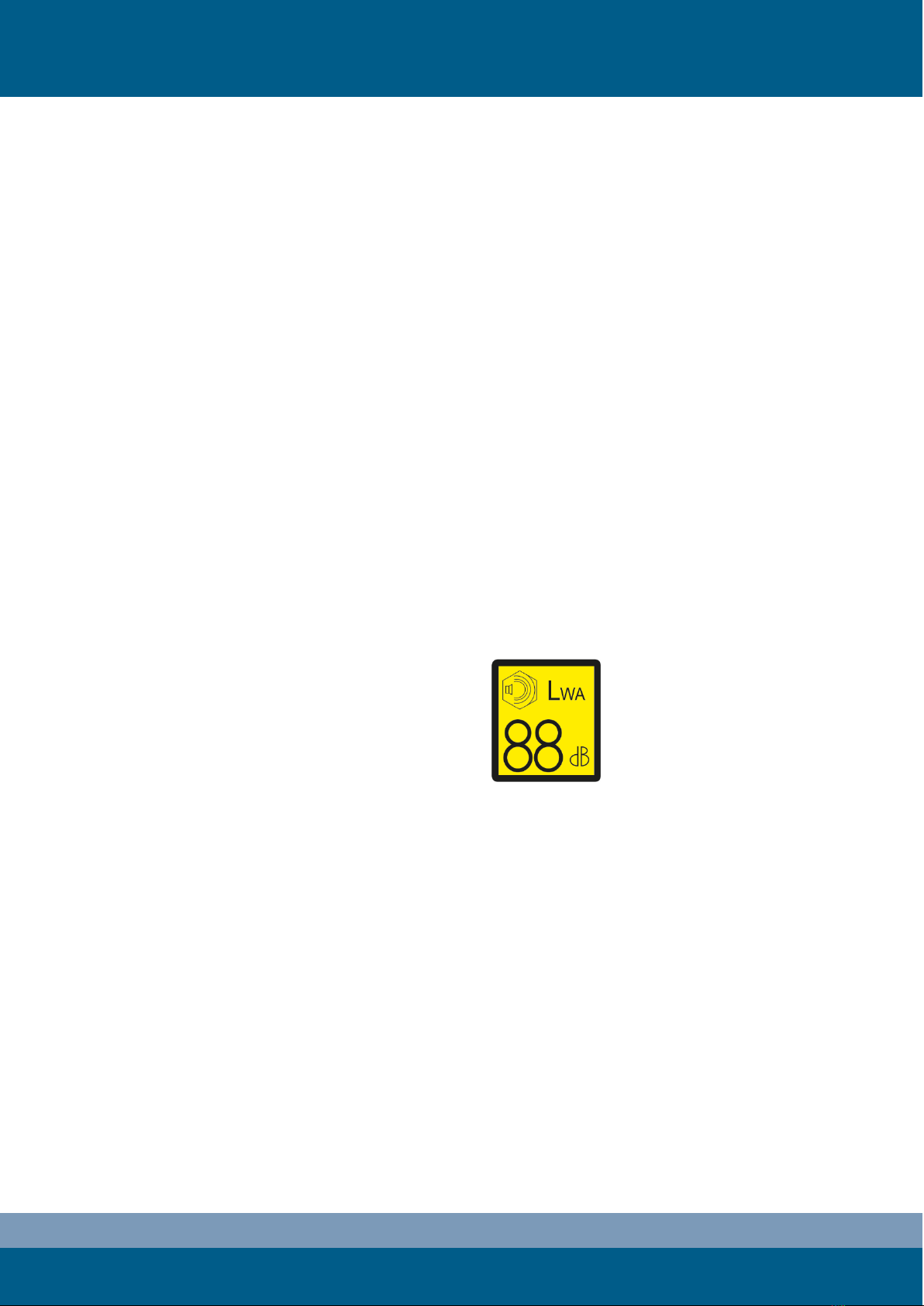

1.3.1 Noise level

According to ISO 6396, the max.

energy equivalent sound pressure

level is 88 dB (A) at the operator

location, measured during tipping

with an empty skip and at maximum

motor speed.

According to ISO 6396, the highest energy equivalent sound

pressure level is 87 dB (A) at the operator location, measured

during simulated operating conditions between driving and

tipping.

The uncertainty of the above measurements is ± 2 dB.

HG recommends the use of hearing protection, even if the noise

is below the statutory limit.

1.3.2 Vibration level

According to ISO 1032, the maximum weighted arm/hand

vibration level at the operator location, measured at empty skip

tipping and maximum motor speed, is:

ahv = 5.0 m/s2.

This manual suits for next models

3

Table of contents

Other HG Construction Equipment manuals