7. If petrol or oil comes into contact with

your skin, wash your skin thoroughly with

soap.

8. Inhalation of fuel vapors or oil mists is

harmful to health.

9. Ingestion of fuel or oil is life-threatening.

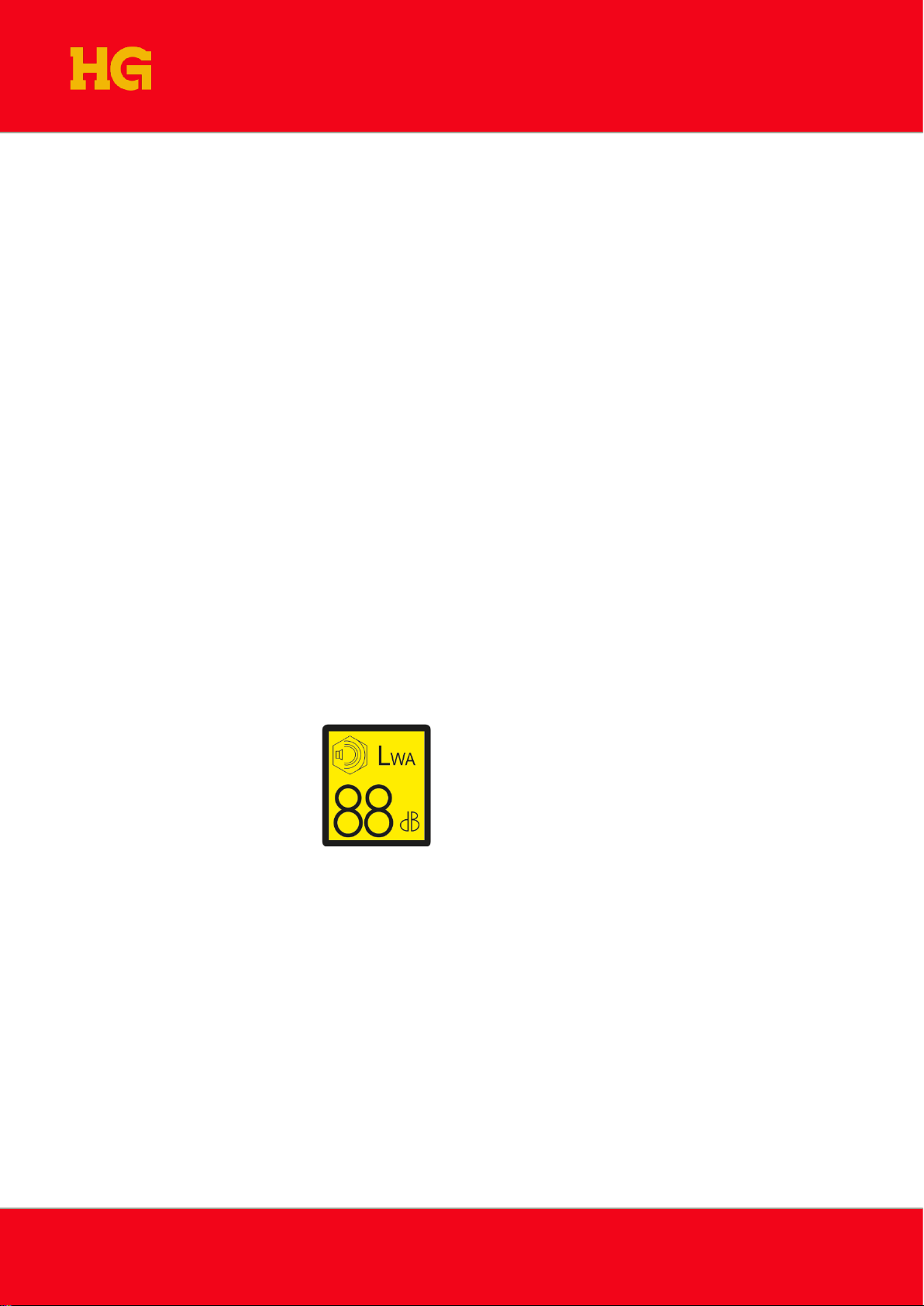

1.5 Noise and vibration level

When tipping with an empty tray and maximum

revolutions, the highest energy-equivalent sound

pressure level at the operator's position has

been measured at 88 dB (A) in accordance with

ISO 6396.

Under simulated operating conditions involving

combined driving and tipping,

the highest energy-equivalent

sound pressure level at the

operator's position has been

measured at 87 dB (A) in

accordance with ISO 6396.

The uncertainty of the measurements stated

above is ±2 dB. HG recommends the use of

hearing protectors, even though the noise level

is below the limit where hearing protection is

required.

1.5.1 Vibration level

When tipping with an empty tray and maximum

revolutions, the maximum weighted arm-hand

vibration level at the operator's position has

been measured in accordance with ISO 1032 at:

ahv = 5.0 m/s2.

Under simulated operating conditions involving

combined driving and tipping, the maximum

weighted arm-hand vibration level at the

operator's position has been measured in

accordance with ISO 1032 at:

ahv = 3.0 m/s2.

The uncertainty of the measurements stated

above is ±25%.

1.6 Operation

WARNING!

Failure to observe the following operating

instructions may result in personal injury:

•When operating the machine indoors,

make sure there is an effective extraction

system in place in accordance with the

applicable on-site rules and instructions.

•Do not let the engine run in small

confined spaces where dangerous

carbon monoxide may accumulate.

•Inhalation of carbon monoxide may

cause poisoning and death.

•Do not use the machine in areas with

combustible dust or explosive gases, or