Hi-Force HTWP21 Series User manual

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 1of 8

Hi-Force HTWP21 series air driven pumps are designed to operate high pressure hydraulic double

acting torque wrenches with an operating pressure of 700 bar (10 000 psi). These instructions cover the

following models:

HTWP2140P – Air driven unit with 7.0 bar supply

Refer to nameplate on the pump for identification.

SAFETY

●Ensure that all equipment connected to the pump is in good condition and is all rated for 700 bar

operating pressure.

READ THIS MANUAL BEFORE OPERATING THE TOOL. FAILURE TO OBSERVE THE

FOLLOWING WARNINGS COULD RESULT IN SERIOUS BODILY INJURY.

●Always stand the pump on a stable level surface during operation.

●Never invert the pump or lay it on its side either in use, transport or in storage.

●Inspect hoses regularly for damage and wear. Do not use hoses that are frayed, abraded or

leaking.

●Never move the pump by pulling the hoses.

●Do not work with hoses sharply bent or kinked.

●Do not handle hoses that are pressurised. Oil escaping under pressure can penetrate the skin

causing serious injury. If oil is injected under the skin see a doctor immediately.

●Never pressurise disconnected couplers.

●Always use eye, ear and hand protective equipment when using this pump and associated

equipment.

●Isolate the pump from the air supply when carrying out maintenance or adjustments (except

pressure relief valve adjustments).

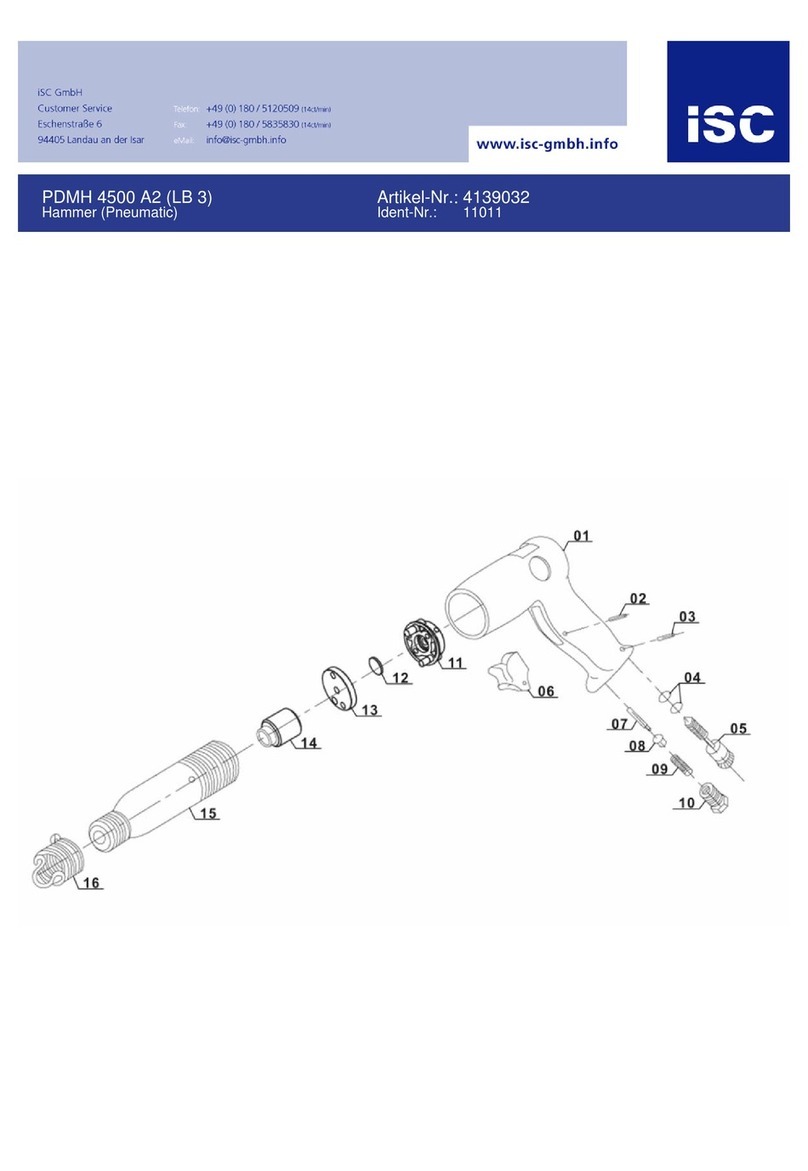

1. Oil reservoir.

IDENTIFICATION OF COMPONENTS

Refer to diagrams on following pages:-

2. Oil temperature/ level gauge

3. Oil filler breather cap.

4. Motor.

5. Oil pressure gauge.

6. Adjustable pressure relief valve.

7. Tool advance coupler (700 bar maximum)

8. Tool retract coupler (120 bar maximum)

9. Drain plug.

10. Air pressure gauge.

11. Pendant signal connections.

12. Pendant air supply connection.

13. Air pressure regulator.

14. Air lubricator control.

15. Air lubricator bowl.

16. Pendant hoses

17. Control pendant

18. Exhaust muffler.

19. Air inlet port G3/8” (3/8” BSP)

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 2of 8

PREPARING THE PUMP FOR FIRST USE

Immediately after unpacking, examine the pump for signs of transit damage and if found contact the shipping

company.

Establish the oil level in the oil reservoir using the level gauge on the end of the tank. Depending on the shipping

method used, the reservoir may either be supplied full or empty. If the reservoir is empty it must be correctly filled

before use. Running the pump without oil will result in damage.

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 3of 8

FILLING OF PUMP WITH OIL

Remove the cap (3) from the oil filler.

Stand the pump on a level surface and fill the tank via the filler breather (3) with Hi-force HFO46 oil until the oil

level is at the maximum level as shown on the level gauge. N.B more oil can be added if desired to assist cooling

but never to more than 25mm below the tank lid.

If the pump was supplied full of oil then no further action is necessary.

CONNECTION OF AIR CONTROL PENDANT

The air control pendant has three self sealing quick release connections, one male and two female. The male

connection should be connected to the pendant air supply connection (12) on the pump gauge panel. The female

connectors should be connected to the pendant signal connections (11). One connection controls tool advance and

the other controls tool retract. If the pendant button functions are later found to be incorrect simply swap the

connections.

AIR SUPPLY

An air supply up to a maximum of 10 bar must be connected to the air inlet port (19). However the air regulator (13)

should be adjusted so that the reading on the air pressure gauge (10) is a maximum of 7 bar (100psi). Operating

the pump at above this pressure may result in damage to the motor. The maximum air consumption of the pump is

up to 132m³/h (78 cfm) at maximum pressure and power output. Satisfactory operation can be achieved with lower

flow rates but tool operation will be slower. Add viscosity grade 22 air line lubrication oil, to reservoir (15), via filler

plug adjacent to air lubricator control (14). Do not use hydraulic oil. Adjust the flow of oil using the air lubricator

control to give a drop of oil approx every minute.

CONNECTION OF TORQUE TOOL TO PUMP

Connect the torque tool to the pump using Hi-Force hoses type HTWH. Ensure both halves of the couplers are

clean before connecting.

Connect the female coupler on the red hose to the male tool advance coupler (7). Connect the male end of the

black hose to the female tool retract coupler (8). Connect the other ends of the hoses to the torque tool. N.B. If

using torque tools other than Hi-Force or tools that have been modified, check that the tool is connected correctly

so that the advance pump port is connected to the advance port on the tool. Failure to do this may result in tool

damage or personal injury.

INITIAL OPERATION

Torque wrenches and hoses are not always completely filled with oil when new. For safe and efficient operation the

air must be removed from the system. The following should be carried out with a torque wrench connected to the

pump, but not fitted on a bolt. The torque wrench must be located at a lower level than the pump.

Connect the pump to an air supply. (The motor will not start until a pendant button is pressed.) Adjust the air

regulator control (13) to between 5 and 7 bar, as shown on the air pressure gauge (10).

Press and hold the advance button on the control pendant. The motor will start and the torque wrench should

advance until it reaches the end of its stroke and then the pressure on gauge (5) should start to build up. If the

torque wrench does not advance and pressure is shown on the gauge then it may already be fully advanced. If

there is no pressure registering on the gauge, turn the adjustable pressure relief valve knob (6) clockwise until

pressure shows on the gauge. If the tool retracts, then swap the pendant signal hoses (11).

Press and hold the retract button on the control pendant. The torque wrench should retract until it reaches the end

of its stroke and the pressure should build up to a maximum of 120 bar. If the pressure goes above 120 bar then

the tool is connected the wrong way round. This must be corrected before proceeding otherwise tool damage or

personal injury may result.

Repeat this advance and retract cycle at least 10 times to purge air from the system.

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 4of 8

NB if very long hoses are employed (greater than 5 m) then this method will not be totally effective. Consult your

Hi-Force distributor for advice on pre-filling hoses.

Press and hold the advance button again and whilst doing so adjust the relief valve by turning the knob clockwise

until maximum working pressure (700 bar) is reached. Reduce the pressure by turning the knob anticlockwise. The

pressure setting can be locked at the desired value by tightening the wing nut under the adjusting knob clockwise.

The pump is now ready for use

Refer to torque wrench operating instructions for detailed information on the correct operation of these tools.

●The oil level in the reservoir should not be allowed to fall below the minimum level during use. Keep the

reservoir topped up with Hi-Force HFO46 oil. If the oil level does fall below the minimum level then air may

be drawn into the system and cause erratic operation.

MAINTENANCE

●Regularly inspect the air hoses for damage.

●Oil should be replaced after approximately 500 working hours. Drain oil via drain plug (9)

●Add viscosity grade 22 air line lubrication oil to reservoir (15) as required. Do not use hydraulic oil.

Drain water from air regulator filter bowl as required by depressing the valve on the bottom of the bowl.

PROBLEM

TROUBLE SHOOTING

These pumps should be repaired only by authorised Hi-Force repair centres. The following table gives possible

causes and remedies for common problems.

POSSIBLE CAUSE

Tool will only reach 120bar in advance

mode, but higher in retract mode.

Tool incorrectly connected. Swap hose

connections at tool.

Tool advances when retract button is

pressed and vice versa.

Pendant signal hoses wrongly connected –

swap hoses at connections (11)

Motor stalls before 700 bar is reached.

Low supply pressure or insufficient air flow.

Motor runs slowly

Low supply pressure or insufficient air flow.

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 5of 8

NOTE:-

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 6of 8

NOTE:-

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 7of 8

NOTE:-

OPERATING INSTRUCTIONS FOR HTWP21 SERIES

AIR DRIVEN TORQUE PUMPS

TDS:-

1319

Prepared by:-

Mark Dalley

Approved by:-

Matthew Hughes

Date: 19/10/12

REV NO:- 002

ECO:- 3942

Page 8of 8

UK Head Office:

GLOBAL BRAND.LOCAL SERVICE. www.hi-force.com

Hi-Force Regional Offices:

Hi-Force Limited

Prospect Way,

Daventry,

Northants,

NN11 8PL, United

Kingdom, ..Tel: +44 1327

301 000 ..Fax: +44 1327

706 555 Email:

daventry@hi-force.com

Hi-Force Regional Offices:

Hi-Force Hydraulics (Asia) S.B

Selangor

Malaysia

Tel: +603 5569 4209

Email: malaysia@hi-force.com

Hi-Force Hydraulic Equipment

(Shanghai) Ltd. Co.

Shanghai, China

Tel: +86 21 6697 3010

Email: china@hi-force.com

Hi-Force Nederland BV

Strijen

Netherlands

Tel: +31 78 6745488

Email: holland@hi-force.com

Hi-Force Hydraulics (Pty) Ltd

Midrand

South Africa

Tel: +27 11 314 0555

Email: south.africa@hi-force.com

Hi-

Force Hydraulics

Abu Dhabi

United Arab Emirates

Tel: +971 2 551 3100

Email: abu.dhabi@hi-force.com

Hi-

Force FZCO

Dubai

Unit

ed Arab Emirates

Tel: +971 4 815 0600

Email: dubai@hi-force.com

Hi-Force Australia Pty. Ltd

Rockingham

Australia

Tel: +61 8 9591 1288

Email: australia@hi-force.com

Hi-

Force Caspian

Baku

Azerbaijan

Tel: +994 12 447 4100

Email: baku@hi-force.com

This manual suits for next models

1

Table of contents

Other Hi-Force Tools manuals

Popular Tools manuals by other brands

Tyco Electronics

Tyco Electronics 1372039-1 operating instructions

Pattfield Ergo Tools

Pattfield Ergo Tools PE-500PF Original instructions

Harbor Freight Tools

Harbor Freight Tools DOYLE Owner's manual & safety instructions

Napa

Napa 791-6425A operating manual

Suncast

Suncast MWM125 Operation instructions

Matco Tools

Matco Tools MT1811 operating instructions