Hi-P PT2020 Series Operation manual

Instructions-Parts

C

PT2020 Programmable

Pneumatic Pump Controller

For controlling pneumatic intensifier pumps used for proof pressure testing. For

professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 4 for model information.

Important Safety Instructions

Read all warnings and instructions in this manual,

and other related manuals on page 3, before using

the equipment. Save all instructions.

3A6828B

EN

23A6828B

Contents

Models and Approvals . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Enclosure . . . . . . . . . . . . . . . . . . . 6

Connecting the Transducer . . . . . . . . . . . . . . . . . 6

Updating the Software . . . . . . . . . . . . . . . . . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Procedure . . . . . . . . . . . . . . . . 11

Controller Operation . . . . . . . . . . . . . . . . . . . . . . . 12

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Logging In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Logging Out . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting Pressure Units . . . . . . . . . . . . . . . . . . . 14

Setting Up the Transducer . . . . . . . . . . . . . . . . 15

Setting Up the Pump . . . . . . . . . . . . . . . . . . . . . 17

Setting Up Pressure Tests . . . . . . . . . . . . . . . . 18

Setting Up the System . . . . . . . . . . . . . . . . . . . 20

Run Screen Operations . . . . . . . . . . . . . . . . . . . . . 23

Running a Test . . . . . . . . . . . . . . . . . . . . . . . . . 23

File Management . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Managing Pressure Test Results . . . . . . . . . . . 24

Transferring System Settings . . . . . . . . . . . . . . 24

Transferring Pressure Tests . . . . . . . . . . . . . . . 25

Locating Test Data via FTP Client . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Optimizing Performance . . . . . . . . . . . . . . . . . . 27

Viewing Alarm Events . . . . . . . . . . . . . . . . . . . . 27

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing the Transducer . . . . . . . . . . . . . . . . . 28

Replacing the Electronic Air Regulator . . . . . . . 28

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PT2020 Enclosure . . . . . . . . . . . . . . . . . . . . . . 29

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PT2020 Controller . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Specifications . . . . . . . . . . . . . . . . . . . . 33

Graco High Pressure Equipment Company

Standard Warranty . . . . . . . . . . . . . . . . . . . . . 34

3A6828B 3

Models and Approvals

PT2020 Controller Models

(Part number includes enclosure,

transducer, and cord set)

Transducer Pressure,

in ksi (kilopound/in2)

Cord

Set

Controller

with Cord Set

& Transducer

Only

Approvals

Enclosure (PN 26C600) Only

Approvals

25N950 10 US

N/A

25N951 25 US

25N952 40 US

25N953 60 US

25N954 75 US

25D815 10 UK

25D816 25 UK

25D817 40 UK

25D818 60 UK

25D819 75 UK

25D820 10 EU

25D821 25 EU

25D822 40 EU

25D823 60 EU

25D824 75 EU

25D825 10 AU

25D826 25 AU

25D827 40 AU

25D828 60 AU

25D829 75 AU

Conforms to UL STD 508A

Certified CSA STDS C22.2 No. 14

Warnings

43A6828B

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama-

tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

•Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

his equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

Warnings

3A6828B 5

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

Installation

63A6828B

Installation

Grounding

Enclosure, controller, and transducer: grounded

through the power cord. Do not modify the plug pro-

vided; if it does not fit the outlet, have the proper outlet

installed by a qualified electrician.

Pump: refer to your pump’s instruction manual.

Air and fluid hoses: use only electrically conductive

hoses.

Air compressor: follow manufacturer’s recommenda-

tions.

Fluid supply container: follow local code.

Mounting the Enclosure

1. See Typical Installation, on page 8, for location of

the enclosure relative to the pneumatic intensifier

pump.

2. See Dimensions, on page 31, to determine the size

of the flat surface needed for the enclosure.

3. Use the slots in the mounting feet (27) (see Parts,

on page 29) or the Dimensions, on page 31, to drill

holes in the mounting surface for customer-supplied

mounting screws.

Connecting the Transducer

1. Follow the Pressure Relief Procedure on page 11.

2. Turn the disconnect switch (8) to the OFF position.

(See FIG. 2 on page 9.)

3. Attach the transducer (S) close to the pump’s outlet

port (M). (See FIG. 1 on page 8.)

4. Connect the transducer cable (R) from the trans-

ducer connection (10) to the transducer (S).

5. Turn the disconnect switch (8) to the ON position.

All electrical wiring must be done by a qualified elec-

trician and comply with all local codes and regula-

tions.

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Installation

3A6828B 7

Updating the Software

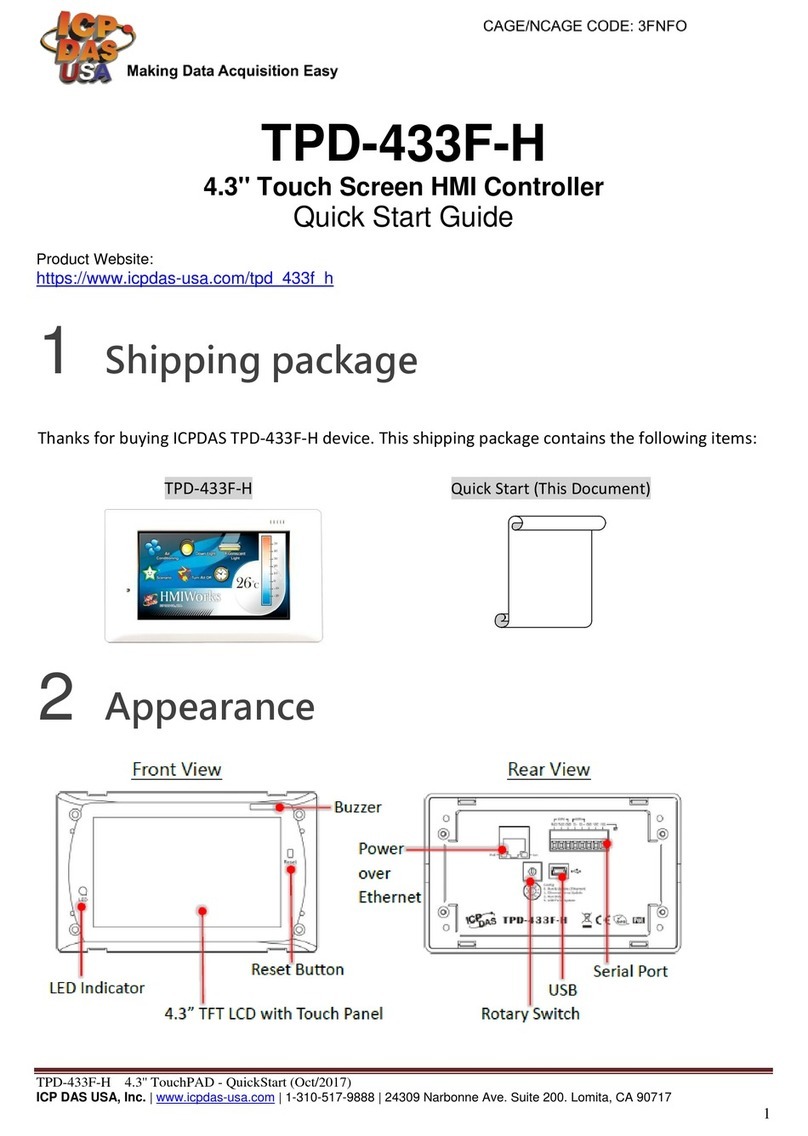

The PT2020 has a USB port on the front cover for

updating the software, and for importing and exporting

data.

NOTE: Settings and pressure test data may be lost

when updating software. See File Management, on

page 24, for saving and restoring settings and pressure

test data.

Getting the Software

1. Contact HiP customer assistance for the latest soft-

ware.

2. Move the “Default_PPC7x” folder and “arnbcfg.xml”

file to the root directory of a USB drive.

Installing the Software

1. Follow the Pressure Relief Procedure on page 11.

2. Turn the disconnect switch to the OFF position.

(See FIG. 1 on page 8.)

3. Insert the USB drive with the new software into the

USB port on the front cover of the enclosure. (See

FIG. 1 on page 8.)

4. Turn the disconnect switch to the ON position.

5. Wait for the PT2020 to update. Updates can take up

to five minutes. Do not turn the system off during the

update, as this can prevent the unit from operating.

The Home screen will appear once the update is

complete.

6. Turn the disconnect switch to the OFF position.

7. Remove the USB drive.

Installation

83A6828B

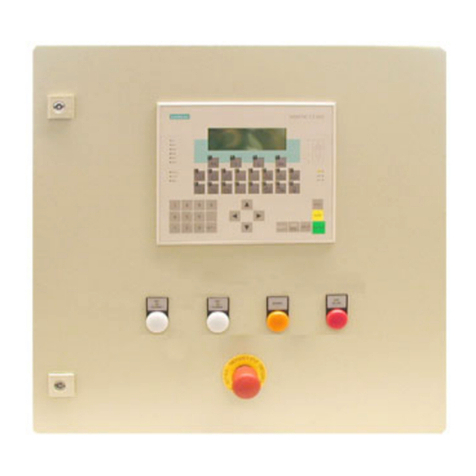

Typical Installation

FIG. 1 is an example of enclosure installation with a

pressure test system. Your installation may differ from

what is shown here.

Components Supplied by HiP

The following components, see FIG. 1, are supplied by

HiP:

Additional Modular System Components

The following components, see FIG. 1, are available

from HiP or supplied by the customer:

FIG. 1: System Layout

A*

B*

C*

D*

E*

Fluid Supply

Container

F

J*

K

P* L

M

N

R*

S*

T

Enclosure

panel display

USB &

Ethernet

Ports

G

H

BPneumatic Filter*

DPT2020 Controller*

RTransducer Cable*

STransducer*

TPower Cord*

*Required component

AMain Pneumatic Supply Line*

CBleed-type Master Pneumatic Valve*

EPump*

FStrainer (at the fluid supply container)

GIsolation Valve (PT2020-controlled)

HPressure Release Valve (PT2020-controlled)

JFluid Pressure Relief Valve*

KFluid Inlet Line

LInlet Port

MOutlet Port

NFluid Outlet Line to Hydraulic System

PSupply Fluid Shutoff Valve*

*Required component

Installation

3A6828B 9

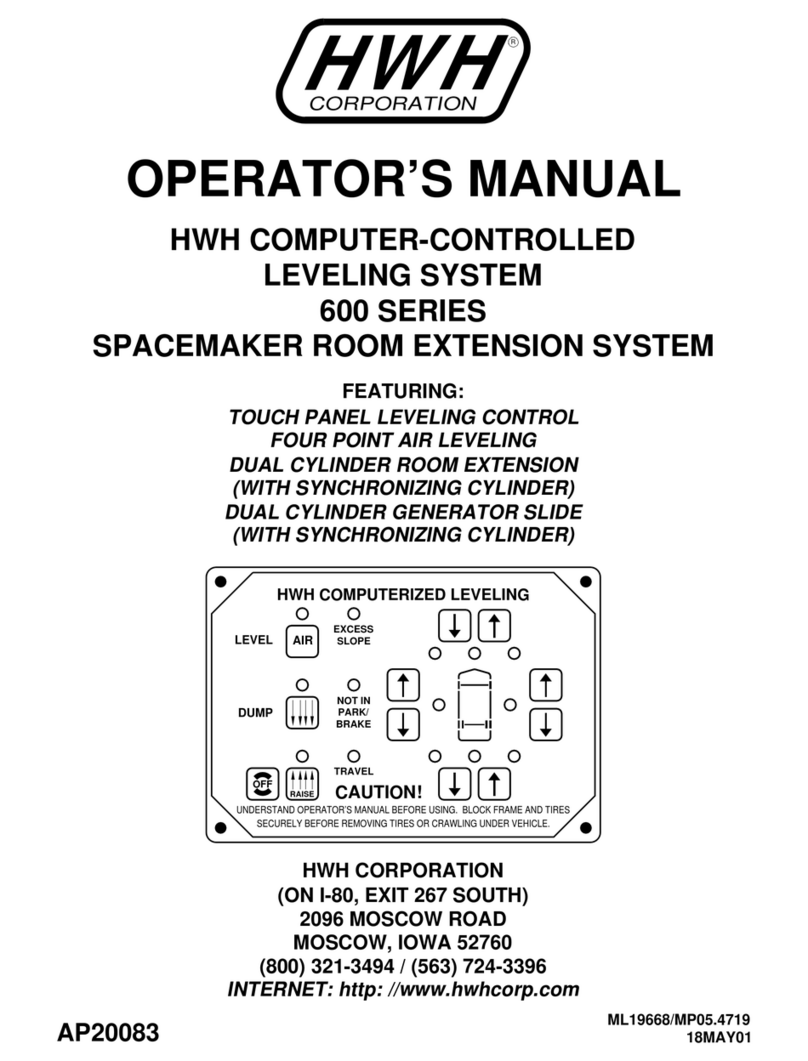

Enclosure Components

FIG. 2: Enclosure Components

6

9

8

7

3

2

1

4

5

10

11

12

Mounting holes

Mounting holes

1314

1Electronic regulator

2M12 cable connection

3Pneumatic hose connection

4Regulator base

5Base screws

6Backplate

7Filter

8Disconnect switch

9Power cable connection

10 Pressure transducer connection

11 I/O cards

12 Ethernet connections

13 Isolate valve air solenoid

14 Pressure release valve air solenoid

Installation

10 3A6828B

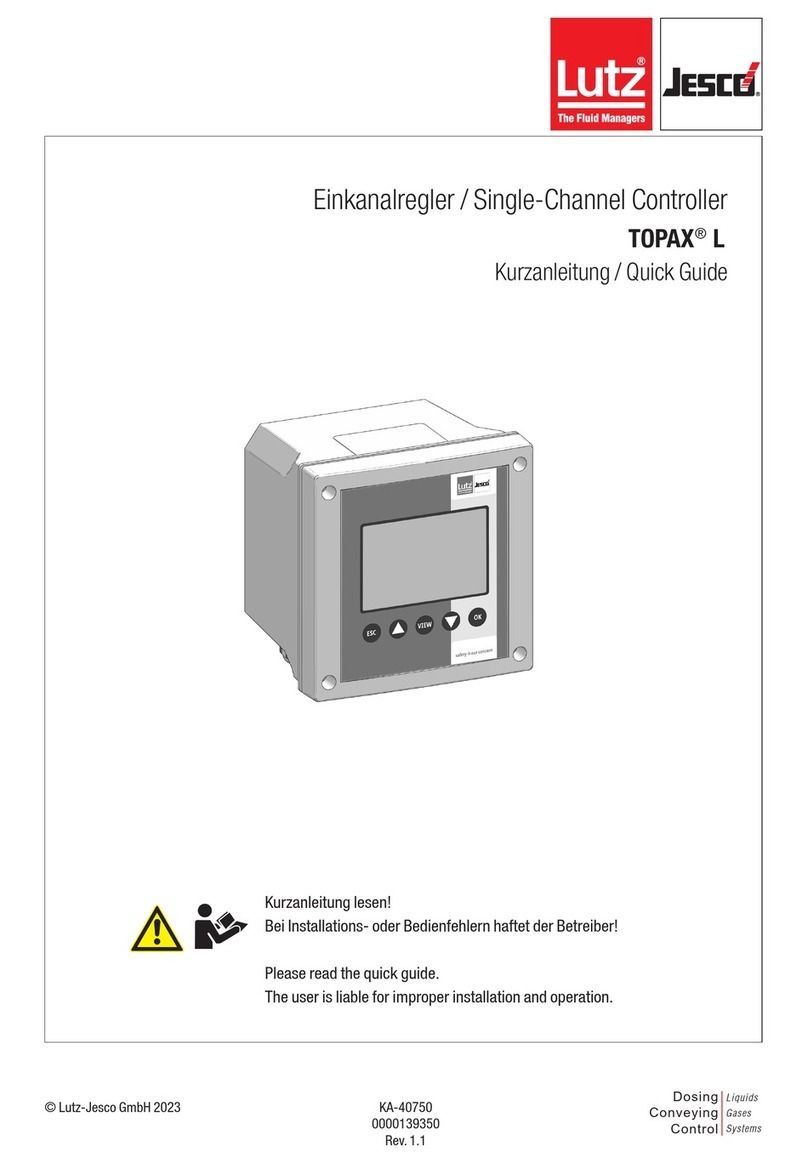

Wiring Diagram

FIG. 3: Wiring Diagram

0

A

B

C

D

E

F

G

H

I

J

K

L

123456789101112131415

E1

LNG

RD1

1

2

3

4

5

6

CB1

3A

1

2

3

4

PS1

L+

N-

GND

V-

V-

V+

V+

+24V

NEU

BC0083

IF1

IF2

PR1

1

2

3

4

11

12

13

14

15

16

21

22

23

24

25

26

CM8281

11

12

13

14

15

16

21

22

23

24

25

26

PS9400

CN1

1 +

2 N.C.

3 -

4 N.O.

5

W1\BLU

1 (+VDC)

2 (-VDC)

IF1

IF2

IF3

IF4

4 - SHIELD

3 - X2X DATA INV.

2 - X2X GND

1 - X2X DATA

1 - CAN H (IF7)

2 - GND (IF7)

3 - C AN L (IF7)

4 - CAN H (IF6)

5 - GND (IF6)

6 - CAN L (IF6)

PLC1

GND

13

1

14

14

10-9-B

10-6-K

+24V

+24V

NEU

NEU

W2\WHT

W2\WHT

13

10-14-I

10-14-G

W3\ETHERNET

W2\BRN

16

44

GND1

GND1

W1\GRY

W1\BRN

10-15-B

10-7-K

12

FB1

V1

V2

11, 15

11

CN2

CN3

W4\ETHERNET

W5\USB

11

20

Blue

15

20

Blue

16

20

Blue

2

22

Black

1

22

Black

9

20

Blue

12

20

Blue

7

20

Blue

3

20

Blue

1

18

Green

1

14

Green

2

20

Brown

13

20

Brown

14

20

Brown

4

18

Green

2

18

White

3

18

Black

4

14

White

5

14

Black

3

14

White

2

14

Black

Operation

3A6828B 11

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1. Press the Stop button on the controller display

to ensure the PT2020 controller is in an Off state.

2. Close the master pneumatic valve (C).

3. Close the fluid supply valve (P).

4. Bleed the pressure by opening the user-supplied

fluid pressure relief valve (J).

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you are finished operating the pump,

and before cleaning, checking, or servicing the

equipment.

Controller Operation

12 3A6828B

Controller Operation

Navigation

Screen Buttons

Screen buttons allow you to access any of the three pri-

mary screens from anywhere in the system. With the

exception of the Settings button, all screen buttons are

available from any screen.

Action Buttons

Entry Fields

Data Field Keypads

Selecting a data field will display either an alphanumeric

or numeric keypad, depending on whether the field is

primarily for text or numbers. Common features include

a backspace key (next to the entry display), a save key

(the check mark), and a cancel key (a circle with an “X”).

Home - Press from any other screen to

return to the Home screen.

Run - Press to display the Run screen (see

page 23), where you can select and run

any pre-configured tests (see page 14).

Settings - Press to display the Setup

screen (see page 16), where you can

select Transducer, Pump, Units, Pressure

Tests, and System Settings for configura-

tion. This is also where you can access the

Alarm Log and File Management.

This button will not be available while the

pump is running.

Stop - Press to stop the pump, bleed the

air pressure to the pump to 0 PSI.

Forward - This button is used on the Setup

screens and indicates another screen is

available for the corresponding selection.

Press this button to display related screen.

Back - Press to return to the previous

screen. Any changes to the current screen

will be saved.

Toggle - Press to toggle between Off

(white background) and On (green back-

ground).

Menu - Select to display a list of menu

options.

Field - Select to display an alphanumeric

or numeric keypad. See Data Field Key-

pads.

FIG. 4

Alphanumeric Keypad Numeric Keypad

Controller Operation

3A6828B 13

Logging In

The Startup screen is displayed when the PT2020 con-

troller is first turned on or when the Logout button is

pressed.

1. Select the blank Login field to display an alphanu-

meric keypad.

2. Enter the login code (up to three characters). The

login code is used to track who is running the pres-

sure tests. It appears in the Current User field at the

top of the screens.

3. Press the Login button to display the Home screen

without the Login dialog box.

Logging Out

Press the Logout button on the Home screen.

FIG. 5 Home Screen, before logging in

Login

field

FIG. 6 Home Screen, after logging in

Manual air

pressure

decrease

Manual air

pressure

increase

Home

button

Run

button

Settings

button

Stop

button

Current air

pressure as

a percent-

age of max-

imum air

pressure

Controller Operation

14 3A6828B

Setting Pressure Units

The pressure units (PSI, BAR, or MPa) set on the Units

screen are used throughout all of the PT2020 controller

screens, unless otherwise noted.

1. Press the Settings button to display the Setup

screen.

2. Select Units to display the Units screen.

3. Press the toggle button next to the appropriate pres-

sure unit.

FIG. 7 Setup Screen

FIG. 8 Units Screen

Controller Operation

3A6828B 15

Setting Up the Transducer

Selecting a Transducer

The following steps assume you have already installed

a Graco-supplied pressure transducer.

1. Press the Settings button to display the Setup

screen.

2. Select Transducer to display the Transducer

screen.

3. Press the toggle button next to the maximum pres-

sure (in PSI) rated for your transducer.

NOTE: For non-Graco-supplied transducers, or other

custom 4-20 mA transducers, select Custom to display

the Custom screen, and enter the Max Transducer

Pressure rated for the transducer.

FIG. 9 Transducer Screen

FIG. 10 Transducer Custom Screen

Controller Operation

16 3A6828B

Zeroing the Transducer

Graco-supplied pressure transducers will not be cali-

brated, and will need to be zeroed before running pres-

sure tests. Zeroing a non-calibrated transducer

effectively sets the low pressure setting of the trans-

ducer to 0 PSI within the system.

1. After Selecting a Transducer (on page 15), press

the Stop button and perform the Pressure Relief

Procedure on page 11.

2. With 0 PSI in the system, press the Zero button on

the Transducer screen.

Calibrating the Transducer

Calibrated pressure transducers do not need to be

zeroed, but their calibration parameters will need to be

entered the Calibration screen.

1. After Selecting a Transducer (on page 15), press

the Stop button and perform the Pressure Relief

Procedure on page 11.

2. With 0 PSI in the system, press the Calibrate button

on the Transducer screen after Selecting a Trans-

ducer to display the Calibration screen.

3. Select the Low Pressure and High Pressure fields,

in turn, and enter the calibration parameters (both

mA and PSI) from the transducer calibration sheet.

NOTE: The Reset button will reset all fields on the Cali-

bration screen to default values.

FIG. 11 Transducer Screen

FIG. 12 Transducer Calibration Screen

Controller Operation

3A6828B 17

Setting Up the Pump

The following steps assume you have already con-

nected a pump to the PT2020 controller. The parame-

ters on the Pump screen are used to calculate the pump

ratio, which is based on the Max Fluid Pressure Rating

and the Max Air Pressure Rating. The Pump Ratio can-

not be directly entered.

1. Press the Settings button to display the Setup

screen.

2. Select Pump to display the Pump screen.

3. Select the Max Fluid Pressure Rating field and use

the keypad to enter the maximum pressure of the

connected pump. This is typically noted in the

pump’s instruction manual as the maximum working

pressure.

4. Press the Save button on the keypad to save the

pump pressure.

5. Select the Max Air Pressure Rating field and use the

keypad to enter the maximum air pressure for the

connected pump. This is the maximum air pressure

that the pump can handle, and is typically noted on

the pump or in the pump’s instruction manual.

6. Press the Save button on the keypad to save the air

supply pressure.

To reduce the risk of skin injection and damage to the

pump, ensure the user-supplied pressure relief valve

(J) is set at or below the maximum working pressure

of the pump. Refer to your pump’s instruction manual

for specifics.

FIG. 13 Pump Screen

Controller Operation

18 3A6828B

Setting Up Pressure Tests

Creating a New Test

1. Press the Settings button to display the Setup

screen.

2. Select Pressure Tests to display the Tests screen.

3. Press the New Test button to display a Pressure

Test Setpoint Overview screen with a blank Name

field. Each pressure test has it’s own Overview

screen.

4. Select the Name field and use the keypad to enter

the name of the new pressure test. Press the Save

button next to the Name field. The Tests screen

reappears with the name of the new test added to

the list of tests.

5. Select the desired test from the test list to redisplay

the Pressure Test Setpoint Overview screen for that

test.

FIG. 14 Tests Screen

FIG. 15 Test Setpoint Overview Screen

Controller Operation

3A6828B 19

6. Press the New Setpoint button to display the Set-

point screen. You can set up to 30 setpoints for

each pressure test.

7. Enter the pressure for the setpoint in the Pressure

field.

8. In the Time field, enter the time for the setpoint to be

held or monitored before moving on to the next set-

point or ending the pressure test.

9. Select one of the following Setpoint Types from the

menu list:

•Hold - This maintains the setpoint pressure for

the duration entered in the Time field. Air pres-

sure is maintained on the pump.

•Decay - This builds pressure up to the setpoint

pressure before starting a pressure decay test.

The pressure will overshoot the setpoint during

buildup to ensure the decay starts at the actual

setpoint. The pressure decay will be measured

over the duration entered in the Time field.

Once the decay is started, air pressure is

removed from the pump.

The Decay Allowed field is the maximum pres-

sure decay allowed below the setpoint. An

alarmed is tripped if the actual decay exceeds

the entered value. The percent value will auto-

matically change with the amount entered, and

vice versa.

•Interact - This builds pressure up to the set-

point pressure and holds for interaction by the

operator. A popup window reminds the operator

that manual interaction is required for the test to

continue. Examples include actuating a valve or

checking for leaks.

The Interaction Type menu list includes two

popup window options: Visual Check and Man-

ual Operation.

10. In the Stabilize Time field, enter the duration for the

system to wait and “settle” at the setpoint pressure

before starting the actual test.

NOTE: The Delete Setpoint button will delete the cur-

rent setpoint from the test.

FIG. 16 Setpoint Screen

FIG. 17 Decay Fields

FIG. 18 Interaction Fields

Controller Operation

20 3A6828B

Setting Up the System

1. Press the Settings button to display the Setup

screen.

2. Select System Settings to display the System

screen.

Setting Date and Time

1. Select Date/Time on the System screen to display

the System Date/Time screen.

2. Enter the current date in the Date fields.

3. Enter the current time (in 24-hr format) in the Time

fields.

4. Press the Back button to return to the System

screen.

FIG. 19 System Screen

FIG. 20 System Date/Time Screen

This manual suits for next models

20

Table of contents