Physical Data

Length (mm)Model Width (mm) High (mm) Colour Material Weight (kgs)

338HP1000E Control 166 96 Black Aluminium 4.0

WARNING: This manual contains important safety that should be followed

during the installation and maintenance of the product. Please read this manual

thoroughly before attempting to install or operate this product.

1. Before any assembly or maintenance, make sure the power supply is turned o.

2. To ensure safe system operation, only use certied light shades, cords, and

lamp sockets which match a national or international safety standard.

3. Lamp must be operated a distance away from any ammable substance.

4. Do not cover the digital ballast without proper heat sinking; doing so may aect

the normal case temperature (tc) of the digital ballast. Improper heat dissipation

may shorten ballast life and void the warranty. tc=70oC/158oF.

5. Product is for indoor/enclosed use only; it must be protected from water/liquids.

6. Ensure proper mounting and installation of the digital ballast; it must be securely

fastened to a xed substrate to protect it from detachment, impact and excessive

vibrations. If not secured, damage to the unit or persons may result.

7. Please ensure the input power matches with the specications of the digital

Ballast. If you are not clear about the electrical source, please contact your power

utility company, an electrician or your local distributor.

8. Install the power cord so it can not be pinched, stepped on or tripped over;

secure cord and digital ballast properly to avoid lighting interruptions/hazards.

9. If the power cord needs to be extended, please make sure it meets the standard

electrical safety requirement; the wire diameter should be at least 1.5mm² or 16AWG. Not

following electrical code may result in re or other accidents.

10. To avoid the risk of shock or re, and as to not void the Warranty, do

not open or disassemble the digital ballast.

11. If you have any questions on the installation of the digital ballast, or should you

experience any trouble please contact your local authorised HI-PAR dealer.

Connecting the Ballast

- Please refer to the included wiring diagram for proper wiring connection.

- Only use the provided cables to connect the ballast to the power supply/socket.

- Insert recommended HPS/MH lamp into lamp socket.

- Ensure lamp type is correct orientation.

- Do not use an external ignitor.

- Lamps with auto-ignitor will not work with the digital ballast.

- Connect the ballast into the Hi-PAR Control Station.

Ignitor Safe Protection

The Digital Ballast will ignite automatically. During this period, the ballast can protect

itself without manual intervention. If HPS lamp does not work after 5 minutes (For MH, at

most 15 min), please check the connection or change the lamp.

User Guide

This product must be equipped with the right High Pressure Sodium

lamp (HPS) or Metal Halide lamp (MH) to get the highest eciency,

safety, and luminance output from the lamp.

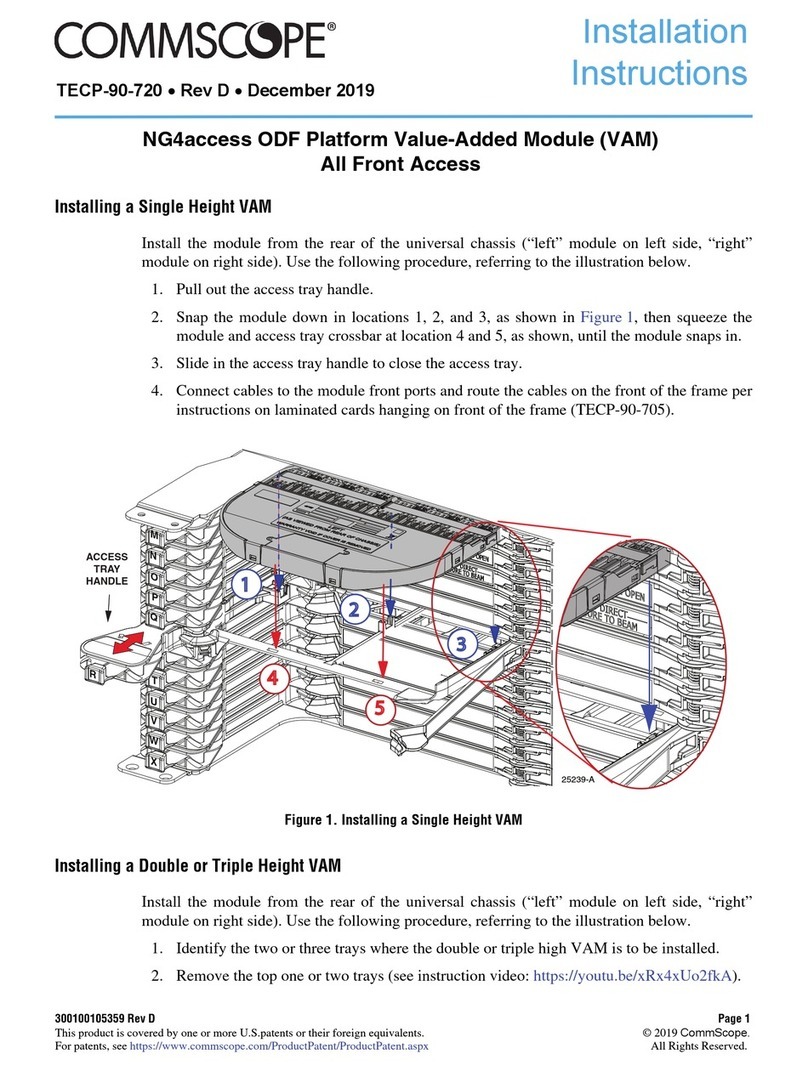

Connecting the Ballast to the HI-PAR ‘Control Station’ (controller - sold separately)

- Control Station communicates with ballast via TRS (Stereo) cable

- Multiple ballasts can be installed in‘daisy-chain’ arrangement

- Up to 200 Ballasts per zone, two zones per Control Station

- Control Station and Thermo Sensors regulate timing and dimming control

CONTROL STATION Compatible - Plug and Play Linkable 400 Fixture - 200 Ballast on each channel

ZONE A

THERMO SENSOR

POWER

THERMO SENSOR

UP TO

200

BALLASTS

UP TO

200

BALLASTS ZONE B

www.hi-par-horticulture.comwww.hi-par-horticulture.com