Hi-Velocity HE-Z User manual

The Hi-Velocity Systems Zoning Fan Coil features a superior design with simple setup options.

Pre-wired multi-zone controls with adjustable power open and power closed actuators make it easy to

understand and set up our zoning system. The fan coil can also be used with any off-the-shelf 24v

thermostats.

The HE-Z Zoning Package is designed for continuous air circulation when the thermostat is satisfied,

allowing for increased filtration more even air temperatures and fresh-air make-up at all times. Hi-

Velocity Systems sets another high standard and energy efficiency in the residential & light

commercial Forced Air Zoning Industry.

Zoning Controls Features

Adjustable Zone Dampers - Power Open and Power

Closed zone dampers are pre-wired and installed on

the fan coil.

Zone Capacity - The main module controls three

zones using motorized dampers and may be

expanded to 4 or 5 zones.

Compatible Controls - Controls single or two-stage

hydronic heating systems, with single or two stage air

conditioning.

Thermostats - Compatible with off the shelf 24v

Heat/Cool Thermostats. Example (1heat/1cool) or

(2heat/1cool).

Automatic Heat/Cool Changeover - Automatic

changeover from any thermostat allowing for individual

zone comfort.

Status LED - A green STATUS LED pulses as a

steady heart beat to indicate Micro- processor activity

and 24v power is present

System LEDs - Function specific colored LED’s

illuminate to indicate the HVAC system mode of

operation and active zone identification.

Damper LEDs - Green LEDs labelled Zone 1 thru

Zone 5 indicate which dampers are energized to the

open position.

See Page 3

for details.

Constant Fan Control - Any zone can activate the

indoor fan and only the dampers in zones calling for

continuous fan operation will open. Continuous fan

operation will only occur when there are no active or

pending, heat or cool demands.

Internal Fuse (F1)- CAUTION: When the Internal

Fuse is tripped it will get quite hot. To reset the Fuse:

Shut off power to the fan coil and find and repair the

short. Restore the 24VAC power.

Page Breakdown

1. Introduction

2. Dip settings and Timer Breakdown

3. Zone LED Indications

4. Zone Control Breakdown

5. Zone Dampers and take-offs

6. Damper Actuator, Constant Fan

7. Zone Control Wiring

8. 120v Wiring

9. 220v Wiring

10. 120v and 240v Wiring Continuation

1

12615-124 STREET

EDMONTON, ALBERTA, T5L-0N8

PHONE: 1-(888) 652-2219

HE-Z ZONING FAN COIL

(2 - 4) ZONES

Pre-Release 052917

Selecting the Options Using the DIP Switches

Select OAS, if you

want to delay auxiliary heat based on the

outside air temperature sensor. Select TIMER, if

you want to delay staging heat & cool based on

the adjustable on-board timer. NOTE: ‘Y2’ output

defaults to a 30 minute delay, when OAS is

chosen. An optional Outside Air Sensor (OAS) is

required to use the OAS feature.

Select OFF, if you do

not want to inhibit Y2 and/or auxiliary heat

based on the total number of zones calling.

Select ON, if you want to inhibit Y2 and/or

auxiliary heat based on the total number of

zones calling. More than half the total zones

must be calling for the same mode of operation

(heat or cool), or the zone panel will not stage

up. The 50% rule will always dominate the

staging timer and thermostat demands unless

Emergency mode is active.

Select OFF, if you do not

want to use the supply air sensor for the Zone

Control system. Select ON, if you intend to use

an optional supply air sensor (SAS).

NOTE: The indoor

fan mode is automatically set for you. There is

no need to move this switch when setting up for

operations.

OAS < STAGING > TIMER -

OFF < 50% RULE > ON -

Seven Built-in Timers for Safe & Reliable

Operation

** During set-up momentarily pressing the

RESET Button clears the built-in timers.

Pressing the RESET Button for 7 seconds will

reset the CPU.

Startup Delay Timer - The panel will not

activate any cooling or heating operation until

the startup delay has expired.Momentarily

pressing the RESET Button clears the built-in

OFF < SAS > ON -

GAS < FAN > HYDRONIC -

* Start-up Delay Timer = 3 minutes-fixed

* Short Cycle Timer = 3 minutes-fixed

* Change Over Timer = 4 minutes-fixed

* Opposing Call Timer = 20 minutes-fixed

* Staging Timer = OFF or 7-42 min.-Adj.

* Supply Air Limit Timer = 3 minutes-fixed

* Purge Delay Timer = 90 seconds-fixed

Programming and Setting up your HVAC

System

Review each pin setting explanation of each dip

switch function and choose your settings for

correct operations. Some functions may not

apply to your application.

** Push the reset button for 7 seconds whenever

there is a change the dip settings to reset the

CPU.

O < RV > B -

HP < SYSTEM > OTHER -

DF < HP > CONV -

HC < TSTATS > HP -

IMPORTANT NOTE: True thermostatic

staging is not available when using 2 Stage

compressors, it is advisable to use single stage

Heat/Cool or HP thermostats and allow the zone

panel to stage via the on-board timer.

Type of HVAC

system you want to control. Select HP, if your

system is any type of Heat Pump. Select

OTHER, if your system is Hydronic/Electric

and/or Standard Cooling.

If HP is selected type of

Heat Pump you want to control. Select DF

(Restricted Mode) locks out the compressor

during auxiliary heat operation. Select CONV

(Unrestricted Mode) if you wish to have the

compressor run during auxiliary heat operations.

Select HC for regular

Heat/Cool thermostats, select HP for Heat

Pumps.

Select the correct Reversing

Valve signal for your particular Heat Pump.

Choose “O” for any Heat Pump that energizes

the RV in the cooling mode. Choose “B” for any

Heat Pump that energizes the RV in heating

mode.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

ON

HP < SYSTEM > OTHER

DF < HP > CONV

HC < TSTATS > HP

O < RV > B

OAS < STAGING > TIMER

OFF < 50% RULE > ON

OFF < SAS > ON

GAS < FAN > HYDRONIC

DEFAULT

OTHER

CONV

HC

O

TIMER

OFF

OFF

GAS

2

052917Pre-Release 052917

Zoning Panel LED’s

The 11 function specific LED’s that indicate HVAC system operation and zone damper status.

Familiarize yourself with the LED functions and definitions, in order to accurately determine the Zoned

HVAC system status and mode of operation.

3

Continue: Seven Built-in Timers

timers This occurs after any initial power up or

power failure. Press the Reset button for 1

second to override.

Short Cycle Timer - When all zone demands

are satisfied, the panel will not resume the same

mode of operation for a minimum of 3 minutes.

Changeover Timer - Prevents the system from

rapidly switching between heating and cooling

modes. At the end of a call, a 4 minute timer is

started and the panel will not switch to the

opposing mode until the timer has expired.

Opposing Call Delay - A 20 minute delay must

expire, or the active zone(s) must satisfy, before

the panel will honor a demand to changeover to

the opposite mode of system operation.

Staging Timer/OAS - The STAGING TIMER

sets the amount of continuous call time in 1st

stage, before second stage heat or cool is

energized. NOTE: The potentiometer also

serves as the Outside Air Changeover Setting.

Purge Delay - The STAGING TIMER sets the

amount of continuous call time in 1st stage,

before second stage heat or cool is energized.

NOTE: The potentiometer also serves as the

Outside Air Changeover Setting

The STATUS LED pulses as a steady

heart beat to indicate proper Micro-

processor system status.

The OAS LED illuminates solid to

indicate that the Outdoor Temperature

has fallen below the chosen set point.

The OAS LED will blink rapidly to

indicate a shorted or open Outdoor Air

Sensor circuit.

The SAS LED illuminates solid to

indicate that the Supply Temperature

has exceeded the chosen set point on

either the HIGH TEMP LIMIT or the

LOW TEMP LIMIT. The SAS LED will

blink rapidly to indicate a shorted or

open Supply Air Sensor circuit.

The ZONE 3 LED: Indicates that

damper(s) is energized open, and the

Zone is active.

The ZONE 2 LED: Indicates that

damper(s) is energized open, and the

Zone is active.

The ZONE 1 LED: Indicates that

damper(s) is energized open, and the

Zone is active.

STATUS

GREEN

ZONE 1

GREEN

ZONE 2

GREEN

ZONE 3

GREEN

SAS

RED

OAS

RED

The FAN LED: Indicates a demand for

fan operation, during COOLING,

HEATING, PURGE, or CONTINUOUS

FAN operations.

The Y2 LED: Indicates the 2nd stage of

DX COOLING or DX HEATING is

energized.

The Y1 LED: Indicates the 1ST stage of

DX COOLING or DX HEATING is

energized.

The W1/B LED: Indicates that the 1st

stage of HEATING is energized in

Gas/Hydronic mode. The W1/B LED

also ‘B’ reversing

valve is energized in HEAT PUMP

operation. NOTE: In Heat Pump Operation,

this LED will stay illuminated after the call for

heat is completed.

The W2/E LED: Indicates 2nd or 3rd

stage of HEATING is energized in

GAS/HYDRONIC or HEAT PUMP

mode. The W2/E LED also

EMERGENCY HEAT is energized

in HEAT PUMP mode.

illuminates when

illuminates

when

W1/B

RED

FAN

GREEN

Y1

YELLOW

Y2

YELLOW

W2/E

RED

052917Pre-Release 052917

Zone Controller Breakdown

4

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

M1

M4

M6

M2

D

A

M

P

E

R

M1

M4

M6

M2

D

A

M

P

E

R

STATUS

J1

XM2

rev B

M1

M4

M6

M2

D

A

M

P

E

R

M1

M4

M6

M2

D

A

M

P

E

R

J1

A [ 0 - 1 ]

A [ 0 - 2 ]

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

Z

O

N

E

5

Z

O

N

E

4

RESET

+

+

F1

OAS

SAS

SAS

OAS

M1

M4

M6

M2

ZONE 3

MOTOR

M1

M4

M6

M2

ZONE 2

MOTOR

M1

M4

M6

M2

ZONE 1

MOTOR

C

R

24 VAC

T’FORMER

C

R

SYSTEM

W2/E

Y1

Y2

RH

RC

G

W1/B

C

O

RC / RH

LINK

OAS

LED 2

Y

C

W

R

G

O/B

ONE

ZONE

Y

C

W

R

G

O/B

ZONE 2

T’STAT

ZONE1

T’STAT

Y

C

W

R

G

O/B

ZONE 3

T’STAT

STATUS

LED 1

SAS

LED 3

ZONE 3

LED 4

FAN

LED 7

Y2

LED 8

ZONE 1

LED 6

ZONE 2

LED 5

W1 / B

LED 10

Y1

LED 9

W2 / EM

LED 11

2

R

3

R

4

R

2ND STAGE HEAT

DIFFERENTIAL

47

5

40

33

26

19

12

HIGH TEMP

LIMIT

110

120

130 140 150

160

170

LOW TEMP

LIMIT

52

49

46

43

40

37

34

FUTURE USAGE

J1

TIMER OAS

STAGING

42

35

28

21

14

7

OFF

R

1

NORM

EM

Y

C

W

R

G

O/B

ONE

ZONE

EMERGENCY

HEAT SWITCH

GAS < FAN > HYDRONIC

OFF < SAS > ON

OFF < 50% RULE > ON

OAS < STAGING > TIMER

HC < TSTATS > HP

HP < SYSTEM > OTHER

DF < SYSTEM > CONV

TIMER OAS

STAGING

42

35

28

21

14

7

OFF

R

1

OFF, 7 - 42 minutes or

7 - 42 degrees F.

Any Setting below 7 is OFF!

OFF,

DO NOT set to - OFF - when using OAS

Emergency

Heat Switch

Isolated

HVAC System

Terminal Block

Future Supply Air and

Outdoor Air Sensor

Connections

24v 4.0 amp

Fuse

STAGING TIMER (W2/E AND Y2 OUTPUT)

DIP switch settings for

1st Expansion panel.

Zones 4 & 5

To Line

Voltage

Optional 24 VAC

Transformer

Pressing the RESET Button for 7 seconds

will reset the CPU for the entire zone system

Reset the CPU anytime you change the dip

switch settings.

Momentarily pressing the RESET Button

clears the built-in timers, this enables you to

test the installation faster. The built-in timers

controls the:

- Start-up delay timer

- Short cycle timer

- W2 timer

- Staging timer

- Changeover timer.

** Caution should be observed when using

this button.

Expansion Zone

Control for 4 - 5

Zones **

Main Zone

Controller

** Expansion Zone Control is installed in 4

zones unit only

Power and data

polarized Bus

Cable

052917Pre-Release 052917

O < RV > B

FRONT

2 - 8"

Zone

1

Zone

2

FRONT

2 - 8", 1 - 6"

Zone

1

Zone

2

Zone

3

FRONT

4 - 6"

Zone

1

Zone

2

Zone

3

Zone

4

FRONT

3 - 8"

Zone

1

Zone

2

Zone

3

FRONT

4 - 8"

Zone

1

Zone

2

Zone

3

Zone

4

FRONT

2 - 8"

Zone

1

Zone

2

FRONT

4 - 6"

Zone

1

Zone

2

Zone

3

Zone

4

FRONT

2 - 8", 1 - 6"

Zone

1

Zone

2

Zone

3

Zone

2Zone

1

Zone

4

Zone

3

FRONT

ZONE DAMPER LOCATIONS AND PLENUM TAKE-OFF SIZES

5

HE-Z-100-(**)-(***V)

c/w

** = BU (Blower Unit or

H c/w Hot Water Coil)

*** = 110v or 220v

HE-Z-100-Z4

10"

6"

8"

Zone Plenum Sizes

052917

HE-Z Zone Package Add-Ons - 2, 3 or 4 Collars

The Zoning Add-On package includes pre-wired zone panel and 2, 3 or 4 collars, each w/ power

open/close dampers and actuators installed. These are currently available pre-installed on our HE-Z

Series Fan Coils. Order HE-Z fan coil unit from our Standard Price List and add these multi-outlet

tops to your order as a separate part.

The plenum take-off outlets are 7" in height and adds to the height of the 32" fan coil. The fan coil can

be installed in the high boy, counter flow or horizontal position. When you are designing the individual

zones try to design each zone to have equal amount of vents and load.

Pre-Release 052917

HE-Z-50-Z2 HE-Z-50-Z4HE-Z-50-Z3

HE-Z-70-Z2

FRONT

2 - 10"

Zone

1

Zone

2

HE-Z-100-Z2

HE-Z-70-Z3 HE-Z-70-Z4

HE-Z-100-Z3 HE-Z-100-Z4

F.000

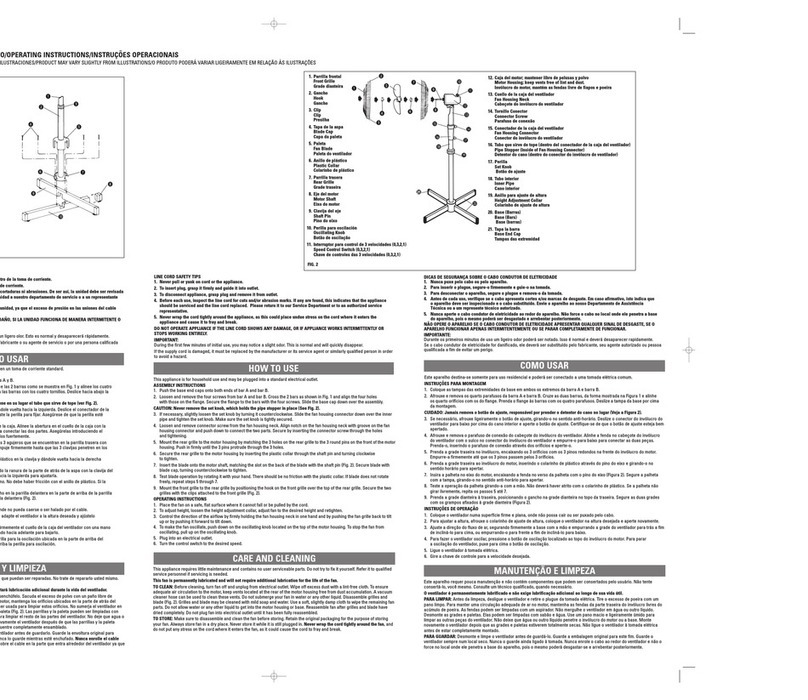

Open and Closed Adjustment Stops

The Adjustment Stops can be

adjusted to stop rotating before it

reaches its stops. These can be

moved to any position without harm.

1. Loosen the end stops. Caution: be

cautious not to unscrew from the

captive nut under the slot.

2. Move the stops (2.5° steps) to the

desired position and re-tighten the

screw.

Manual Override Button

Press the Manual Override Button

and the gear train is dis-engaged so

the damper shaft can be moved

manually. Release the button and the

gear train is re-engaged.

To lock in manual mode press down

the Manual Override Button and push

in the side locking tab. To release,

push down the Manual Override

Button and release this will disengage

lock.

0 1

0

1

Manual Override

Button

1

-~

+

2~

3+

Closing and Opening

Adjustment Stops

M6 - 24vac Closes damper

M4 - 24vac Opens damper

M2 - Constant 24 vac HOT

M1 - Common 24 vac

ZONE DAMPER WIRING

M6

M4

M2

M1

3

2

1

Constant Fan Comfort

Having the fan switch at the thermostat to the

“ON” position is strongly recommended. This

utilizes continuous air circulation for optimal

Indoor Air Quality (IAQ) and Energy Efficiency.

Independent testing has shown that utilizing the

recirculating fan with the Hi-Velocity Systems

VFD motor reduces total energy usage. This is

due to less on/off cycling of AC and Heating

equipment by constant de-stratification of the air.

The zone controller board will default the

actuators in the open position when there is no

call for constant fan, heat or cooling. If one of the

zones is calling for constant fan and the others

are not, the zones that are not calling will close.

In the event of a zone calling for heat or cooling

the zone dampers (regardless if a zone is calling

for constant fan) will close the non-calling

heat/cool zones. The actuators have been pre-

adjusted with approximately 10% bleed through,

this allows for air to circulate in a non-calling

zone. With the 10% by-pass it will not over heat

or cool a non-calling zone if the other zones are

calling heat or cooling but will add comfort as the

air will not be stagnate in the non-calling zone

and will supply more even air temperatures

throughout.

Zone Dampers Adjustment Stops

The Adjustment Stops on the

actuators have been preadjusted with

approximately 10% bleed through.

This allows for air to circulate in a

non-calling zone. This can be

adjusted by adjusting the “0" stop

limit.

Balancing Zones

In the case that there is too much

pressure through a calling zone

(usually a smaller zone on the

system) the damper can be adjusted

partially closed. Partially closing a

damper will cause back pressure on

the blowers pressure control and the

fan coil will slow down the motor.

Adjust the “1" stop to limit the

actuators opening to the level of

pressure/air required for the air flow

desired for the smaller zone.

Zone damper Wiring

The zone dampers on the HE-Z

Zoning Fan Coil comes pre-wired.

There are Seven Built-in Timers that

over ride the operation of the zone

dampers and output signals of the

zone board these are shown on

pages 2 and 3.

Damper Adjustment

6

052917Pre-Release 052917

Damper Wiring and Configuration

Y1

W1

C

G

W2

O/B

D

R

Y2

ZONE 3

THERMOSTAT

G

R

O/B

Y

W/E

C

C

W

Y

R

G

O/B

ZONE 3 THERMOSTAT INPUT

ZONE 2

THERMOSTAT

G

R

O/B

Y

W/E

C

C

W

Y

R

G

O/B

ZONE 2 THERMOSTAT INPUT

32 1

M6

M4

M2

M1

ZONE 2

DAMPER

32 1

M6

M4

M2

M1

ZONE 3

DAMPER

32 1

M6

M4

M2

M1

ZONE 1

DAMPER

24V INPUT - 4.0A

PROTECTED

R

C

G

Y2

Y1

O

W1/B

W2/E

RH

RC

C

ZONE 1

THERMOSTAT

C

W

Y

R

G

O/B

ZONE 1 THERMOSTAT INPUT

G

R

O/B

Y

W/E

C

ONE

ZONE

Y1

1

RH

RC

R

C

1OPTIONAL EXTERNAL 24V

1. REMOVE THE R AND C JUMPER

AND REPLACE WITH THE OPTIONAL

EXTERNAL 24V TRANSFORMER

HVAC

SYSTEM

HI-VELOCITY

PSB CIRCUIT BOARD

7

052917

SINGLE STAGE CONDENSING UNIT

TWO STAGE OR VARIABLE SPEED CONDENSING UNIT

Y1

W1

C

G

W2

O/B

D

R

Y2

ZONE 3

THERMOSTAT

G

R

O/B

Y

W/E

C

C

W

Y

R

G

O/B

ZONE 3 THERMOSTAT INPUT

ZONE 2

THERMOSTAT

G

R

O/B

Y

W/E

C

C

W

Y

R

G

O/B

ZONE 2 THERMOSTAT INPUT

32 1

M6

M4

M2

M1

ZONE 2

DAMPER

32 1

M6

M4

M2

M1

ZONE 3

DAMPER

32 1

M6

M4

M2

M1

ZONE 1

DAMPER

24V INPUT - 4.0A

PROTECTED

R

C

R

C

G

Y2

Y1

O

W1/B

W2/E

RH

RC

C

ZONE 1

THERMOSTAT

C

W

Y

R

G

O/B

ZONE 1 THERMOSTAT INPUT

G

R

O/B

Y

W/E

C

ONE

ZONE

HVAC

SYSTEM

HI-VELOCITY

PSB CIRCUIT BOARD

Dampers default to the "OPEN" position

- After a purge delay

- During change over

- Short cycle delays

- When all zone demands are satisfied with

no signals from the thermostats.

From factory the fan coil is pre-wired for two

stage cooling. If single stage cooling is desired

the fan coils controls will need to be re-wired.

Below are the required changes.

Follow the HE-Z Fan coils main Installation

Manual for wiring the PSB to the system.

RH and RC is

internally jumpered.

1OPTIONAL EXTERNAL 24V

1. REMOVE THE R AND C JUMPER

AND REPLACE WITH THE OPTIONAL

EXTERNAL 24V TRANSFORMER

RH and RC is

internally jumpered.

1

Pre-Release 052917

8

052917Pre-Release 052917

PSB / VFD POWER INPUT: 110-127/1/50-60

052917

HE-Z ZONING

120V

RESET

+

+

F1

OAS

SAS

SAS

OAS

M1

M4

M6

M2

ZONE 3

MOTOR

M1

M4

M6

M2

ZONE 2

MOTOR

M1

M4

M6

M2

ZONE 1

MOTOR

C

R

24 VAC

T’FORMER

C

R

SYSTEM

W2/E

Y1

Y2

RH

RC

G

W1/B

C

O

RC / RH

LINK

OAS

LED 2

Y

C

W

R

G

O/B

ONE

ZONE

Y

C

W

R

G

O/B

ZONE 2

T’STAT

ZONE1

T’STAT

Y

C

W

R

G

O/B

ZONE 3

T’STAT

STATUS

LED 1

SAS

LED 3

ZONE 3

LED 4

FAN

LED 7

Y2

LED 8

ZONE 1

LED 6

ZONE 2

LED 5

W1 / B

LED 10

Y1

LED 9

W2 / EM

LED 11

2

R

3

R

4

R

2ND STAGE HEAT

DIFFERENTIAL

47

5

40

33

26

19

12

HIGH TEMP

LIMIT

110

120

130 140 150

160

170

LOW TEMP

LIMIT

52

49

46

43

40

37

34

FUTURE USAGE

J1

TIMER OAS

STAGING

42

35

28

21

14

7

OFF

R

1

NORM

EM

Y

C

W

R

G

O/B

ONE

ZONE

EMERGENCY

HEAT SWITCH

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

M1

M4

M6

M2

M1

M4

M6

M2

D

A

M

P

STATUS

J1J1

A [ 0 - 1 ]

A [ 0 - 2 ]

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

Z

O

N

E

5

Z

O

N

E

4

D

A

M

P

4

D

A

M

P

4

4

3

2

1

3

2

1

3

2

1

3

2

1

Expansion Zone Control

SUPPLIED WITH 4 ZONE OPTION ONLY

Zone Control

ZONE 4

DAMPER

ZONE 2

DAMPER

3

2

1

3

2

1

ZONE 3

DAMPER

ZONE 1

DAMPER

ZONE 4

MOTOR

O < RV > B

GAS < FAN > HYDRONIC

OFF < SAS > ON

OFF < 50% RULE > ON

OAS < STAGING > TIMER

HC < TSTATS > HP

HP < SYSTEM > OTHER

DF < SYSTEM > CONV

1 2 3 4 5 6 7 8 9 10 11 12

L/L1 N/L2 U V W PE

P

0

I

Parameter

Value

WEG CONTROLLER

VFD

110-120 VAC

W1

W2

CRY2 Y1 DO/B

G

R

Y1 W2 W1 FZ FZ

Y2

C

F1

AUXILIARY RELAY

(HEATING)

L L

L2L2 NL1 L1

A3 A2 A1

LN

COOL HEAT FAN

LED

L1

J8

ON

OFF

H2

TIMER

AUTO

MAN

H3

MODE

ON

OFF

H4

DELAY

J5

J7

J4

U2

J3

R8

R7

R6

G C H F

318.29 Pcbw-001sep-040

J2

N

C

Ri

Ro

H1

J9

J1

LED

L2

PSB CIRCUIT BOARD

24v OUTPUTEMERGENCY DISCONNECT

C

110-127 VAC

110-127/1/50-60

110-127v POWER CABLE

L

N

Ground

WH

BK

G

LINE IN

EMERGENCY DISCONNECT

C - 24 VAC COMMON

C - 24 VAC COMMON

Ro - 24 VAC OUTPUT

Ri - 24 VAC INPUT

AUXILIARY HEATING RELAY

N - NEUTRAL

L - LINE VOLTAGE

A1 - AUXILIARY NORMALLY OPEN

A2 - AUXILIARY NORMALLY CLOSED

A3 - AUXILIARY COMMON

24 VAC OUTPUT CONNECTIONS

FZ - FREEZE STAT

FZ - FREEZE STAT

W1 - HEATING (W1) 24 VAC OUTPUT

W2 - HEATING (W2) 24 VAC OUTPUT

Y2 - CONDENSING UNIT 24 VAC OUTPUT

Y1 - CONDENSING UNIT 24 VAC OUTPUT

C - 24 VAC COMMON

R - 24 VAC OUTPUT

THERMOSTAT CONNECTIONS

R - 24 VAC OUTPUT

W1 - FIRST STAGE HEAT

W2 - SECOND STAGE HEAT

(OR SINGLE STAGE)

Y1 - FIRST STAGE COOLING

Y2 - SECOND STAGE COOLING

(OR SINGLE STAGE)

C - 24 VAC COMMON

G - THERMOSTAT FAN SWITCH

D - PRIORITY (RUNS AT W SPEED)

O/B - HEATPUMP REVERSING

MOTOR LEADS PLUG

(3 PHASE)

CAUTION

FOR SINGLE STAGE

COOLING OPERATION

USE Y2 OTHERWISE THE

FREEZE STAT WILL BE

BYPASSED

CAUTION

FOR SINGLE STAGE

COOLING OPERATION

USE Y2 OTHERWISE THE

FREEZE STAT WILL BE

BYPASSED

Equipment

Ground

TRIM POTS (COOLING, HEATING, CONSTANT FAN)

- ATMOSPHERIC PRESSURE

+ DUCT PRESSURE

TRIM POTS (COOLING, HEATING, CONSTANT FAN)

- ATMOSPHERIC PRESSURE

+ DUCT PRESSURE

24v / 20va

TRANSFORMER

Black

White

Orange

Black

Orange

White

Red

Red

Black

Black Wire (-)

+

-

Red Wire (+)

0-10 VDC

Equipment

Ground

RESET

+

+

F1

OAS

SAS

SAS

OAS

M1

M4

M6

M2

ZONE 3

MOTOR

M1

M4

M6

M2

ZONE 2

MOTOR

M1

M4

M6

M2

ZONE 1

MOTOR

C

R

24 VAC

T’FORMER

C

R

SYSTEM

W2/E

Y1

Y2

RH

RC

G

W1/B

C

O

RC / RH

LINK

OAS

LED 2

Y

C

W

R

G

O/B

ONE

ZONE

Y

C

W

R

G

O/B

ZONE 2

T’STAT

ZONE1

T’STAT

Y

C

W

R

G

O/B

ZONE 3

T’STAT

STATUS

LED 1

SAS

LED 3

ZONE 3

LED 4

FAN

LED 7

Y2

LED 8

ZONE 1

LED 6

ZONE 2

LED 5

W1 / B

LED 10

Y1

LED 9

W2 / EM

LED 11

2

R

3

R

4

R

2ND STAGE HEAT

DIFFERENTIAL

47

5

40

33

26

19

12

HIGH TEMP

LIMIT

110

120

130 140 150

160

170

LOW TEMP

LIMIT

52

49

46

43

40

37

34

FUTURE USAGE

J1

TIMER OAS

STAGING

42

35

28

21

14

7

OFF

R

1

NORM

EM

Y

C

W

R

G

O/B

ONE

ZONE

EMERGENCY

HEAT SWITCH

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

M1

M4

M6

M2

M1

M4

M6

M2

D

A

M

P

STATUS

J1J1

A [ 0 - 1 ]

A [ 0 - 2 ]

R

G

Y

O/B

W/E

C

R

G

Y

O/B

W/E

C

T’

S

T

A

T

T’

S

T

A

T

Z

O

N

E

5

Z

O

N

E

4

D

A

M

P

4

D

A

M

P

4

4

3

2

1

3

2

1

3

2

1

3

2

1

Expansion Zone Control

SUPPLIED WITH 4 ZONE OPTION ONLY

Zone Control

ZONE 4

DAMPER

ZONE 2

DAMPER

3

2

1

3

2

1

ZONE 3

DAMPER

ZONE 1

DAMPER

ZONE 4

MOTOR

O < RV > B

GAS < FAN > HYDRONIC

OFF < SAS > ON

OFF < 50% RULE > ON

OAS < STAGING > TIMER

HC < TSTATS > HP

HP < SYSTEM > OTHER

DF < SYSTEM > CONV

9Pre-Release 052917

W1

W2

CRY2 Y1 DO/B

G

R

Y1 W2 W1 FZ FZ

Y2

C

F1

AUXILIARY RELAY

(HEATING)

L L

L2L2 NL1 L1

A3 A2 A1

LN

COOL HEAT FAN

LED

L1

J8

ON

OFF

H2

TIMER

AUTO

MAN

H3

MODE

ON

OFF

H4

DELAY

J5

J7

J4

U2

J3

R8

R7

R6

G C H F

318.29 Pcbw-001sep-040

J2

N

C

Ri

Ro

H1

J9

J1

LED

L2

PSB CIRCUIT BOARD

24v OUTPUTEMERGENCY DISCONNECT

C

1 2 3 4 5 6 7 8 9 10 11 12

L/L1 N/L2 U V W PE

P

0

I

Parameter

Value

WEG CONTROLLER

VFD

200-240 VAC

MOTOR LEADS PLUG

(3 PHASE)

CAUTION

FOR SINGLE STAGE

COOLING OPERATION

USE Y2 OTHERWISE THE

FREEZE STAT WILL BE

BYPASSED

CAUTION

FOR SINGLE STAGE

COOLING OPERATION

USE Y2 OTHERWISE THE

FREEZE STAT WILL BE

BYPASSED

Equipment

Ground

TRIM POTS (COOLING, HEATING, CONSTANT FAN)

- ATMOSPHERIC PRESSURE

+ DUCT PRESSURE

TRIM POTS (COOLING, HEATING, CONSTANT FAN)

- ATMOSPHERIC PRESSURE

+ DUCT PRESSURE

110-127 VAC

L1

N

Ground

WH

BK

G

LINE IN

L2

R

200-240/1/50-60

24v / 20va

TRANSFORMER

200-240v POWER CABLE

White

OrangeOrange

White

Red

Red

Black

Black Wire (-)

+

-

Red Wire (+)

0-10 VDC

Black

052917

HE-Z ZONING

220V

THERMOSTAT CONNECTIONS

R - 24 VAC OUTPUT

W1 - FIRST STAGE HEAT

W2 - SECOND STAGE HEAT

(OR SINGLE STAGE)

Y1 - FIRST STAGE COOLING

Y2 - SECOND STAGE COOLING

(OR SINGLE STAGE)

C - 24 VAC COMMON

G - THERMOSTAT FAN SWITCH

D - PRIORITY (RUNS AT W SPEED)

O/B - HEATPUMP REVERSING

EMERGENCY DISCONNECT

C - 24 VAC COMMON

C - 24 VAC COMMON

Ro - 24 VAC OUTPUT

Ri - 24 VAC INPUT

AUXILIARY HEATING RELAY

N - NEUTRAL

L - LINE VOLTAGE

A1 - AUXILIARY NORMALLY OPEN

A2 - AUXILIARY NORMALLY CLOSED

A3 - AUXILIARY COMMON

24 VAC OUTPUT CONNECTIONS

FZ - FREEZE STAT

FZ - FREEZE STAT

W1 - HEATING (W1) 24 VAC OUTPUT

W2 - HEATING (W2) 24 VAC OUTPUT

Y2 - CONDENSING UNIT 24 VAC OUTPUT

Y1 - CONDENSING UNIT 24 VAC OUTPUT

C - 24 VAC COMMON

R - 24 VAC OUTPUT

PSB / VFD POWER INPUT: 200-240/1/50-60

Wiring and Configuration

Pre-Release 052917

JUMPER PIN SETTINGS

AUXILIARY RELAY TIMER (SEE

NOTES).

H3

LED LIGHT INDICATORS

LED 1 - GREEN LIGHT, PUMP TIMER AND

OPERATION MODE INDICATOR.

LED 2 - BLUE LIGHT, PRESSURE SENSOR.

H1 EMERGENCY DISCONNECT: REMOVE PIN IF

WIRED TO EMERGENCY DISCONNECT.

H2 TIMER:

MODE:

AUTO - FAN SPEED MODULATES

DEPENDING UPON STATIC PRESSURE.

MANUAL - FAN SPEED OPERATES AT TRIM

POTS SET AIR FLOW.

H4 DELAY: Y/20 AND W/30 SECOND FAN DELAY.

Y AND W 30 SECOND POST PURGE.

ZONE BOARD SEVEN BUILT-IN TIMERS FOR

SAFE & RELIABLE OPERATION

** DURING SET-UP MOMENTARILY PRESSING

THE RESET BUTTON CLEARS THE BUILT-IN

TIMERS. PRESSING THE RESET BUTTON FOR 7

SECONDS WILL RESET THE CPU.

MOMENTARILY PRESSING THE

RESET BUTTON CLEARS THE BUILT-IN TIMERS.

THIS OCCURS AFTER ANY INITIAL POWER UP

OR POWER FAILURE. PRESS THE RESET

BUTTON FOR 1 SECOND TO OVERRIDE.

STARTUP DELAY TIMER -

THE PANEL WILL NOT

ACTIVATE ANY COOLING OR HEATING

OPERATION UNTIL THE STARTUP DELAY HAS

EXPIRED.

* START-UP DELAY TIMER = 3 MINUTES-FIXED

* SHORT CYCLE TIMER = 3 MINUTES-FIXED

* CHANGE OVER TIMER = 4 MINUTES-FIXED

* OPPOSING CALL TIMER = 20 MINUTES-FIXED

* STAGING TIMER = OFF OR 7-42 MIN.-ADJ.

* SUPPLY AIR LIMIT TIMER = 3 MINUTES-FIXED

* PURGE DELAY TIMER = 90 SECONDS-FIXED

ZONE CONTROLLER

PRE-WIRED TO 2 ZONES, 3 AND 4 IF APPLICABLE

M6 - 24VAC TO CLOSE DAMPER

M4 - 24VAC TO OPEN DAMPER

M2 - CONSTANT 24 VAC HOT

M1 - COMMON 24 VAC

NOTES:

1) USE THERMOSTAT FAN SWITCH TO DISABLE/ENABLE CONTINUOUS FAN.

2) ‘C’ TERMINAL ON THERMOSTAT (COMMON) IS NOT NEEDED FOR SOME

THERMOSTATS CONSULT THERMOSTAT INSTRUCTIONS FOR DETAILS.

3) W1 AND W2 ACTIVATES AUXILIARY RELAY (A3) ON CALL AND CAN BE USED

WITH A1 AND/OR A2 AS DRY CONTACTS, ARMED 24VAC FROM THE ‘R’

TERMINAL, OR ARMED 110v FROM THE ‘L’ TERMINAL.

4) AUXILIARY HEATING RELAY TIMER ACTIVATES CIRCUIT FOR 5 MINUTES

EVERY 24 HOURS STARTING WHEN POWER IS APPLIED TO THE UNIT.

5) LED 1: INDICATOR LIGHT FOR FAN SPEED OPERATION AND AUXILIARY

RELAY OPERATION. SEE BELOW FOR LIGHT OPERATION SEQUENCE.

6) SEE INSTALLATION MANUAL FOR MORE DETAILED WIRING DIAGRAMS.

7)

8) FAILURE TO SET PROPER AIR FLOW AND/OR OPERATION OF THE SYSTEM

MAY RESULT IN DAMAGE TO EQUIPMENT.

9) FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION COULD CAUSE PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

10) ENSURE THAT THE FILTER IS KEPT CLEAN AT ALL TIMES.

11) MOTOR HAS PERMANENT LUBE BEARINGS AND DOES NOT REQUIRE

OILING.

12) WARRANTY VOID IF FAN COIL UNIT IS USED DURING CONSTRUCTION.

FOR SINGLE STAGE COOLING OPERATION USE Y2, OTHERWISE THE FREEZE

STAT WILL BE BYPASSED.

INCREASE AIR FLOW

(CLOCKWISE)

DECREASE AIR FLOW

(COUNTER CLOCKWISE)

FAN ADJUSTMENT TRIM POTS

ON: (ACTIVE)

PUMP TIMER STATUS

ON: (INACTIVE)

OFF:

FAN OPERATION MODE

NO LIGHT

D

W

Y

G

2 SECONDS 2 SECONDS 2 SECONDS

LED 1: (GREEN LIGHT)

PUMP TIMER/OPERATION MODE INDICATOR LIGHT SEQUENCE

LED 2: PRESSURE SENSING INDICATOR (BLUE LIGHT)

H3 JUMPER PIN: AUTO OR MANUAL MODE

AUTO MODE: LED 2 WILL SPORADICALLY FLICKER (ON/OFF)

TO SHOW THAT IT IS PROPERLY SENSING PRESSURE IN THE SYSTEM.

* NO LIGHT INDICATES TRIM POT IS ABOVE NORMAL OPERATING RANGE

(COUNTER CLOCKWISE DECREASE).

* SOLID LIGHT INDICATES TRIM POT IS BELOW NORMAL OPERATING

RANGE (CLOCKWISE, INCREASE).

MANUAL MODE: LED 2 WILL BE OFF, ADJUST EACH OF THE AIR FLOWS TO

DESIRED CFM/LPS OUTPUT.

ADJUSTING TRIM POTS: ON POWER START UP, ALLOW 45 SECONDS FOR

SYSTEM TO PRESSURIZE BEFORE MAKING ANY CHANGES.

DO NOT ADJUST MORE THAN A ½ TURN AT A TIME, ALLOW 30 SECONDS

BETWEEN ADJUSTMENTS FOR THE PSB TO REACH SET POINT.

REFER AND COMPLETE COMMISSIONING REPORT PRIOR TO NORMAL

OPERATION. FOR FULL DETAILS, REPORT IS AVAILABLE IN THE INSTALLATION

MANUAL OR ONLINE AT WWW.HI-VELOCITY.COM.

10

Table of contents

Other Hi-Velocity Fan manuals

Popular Fan manuals by other brands

UFESA

UFESA MONTREAL instruction manual

SEVERIN

SEVERIN VL 8630 - Instructions for use

Minka Group

Minka Group minkaAire Sundance F572-ORB instruction manual

UNITED

UNITED UIF-763 instruction manual

Suntec Wellness

Suntec Wellness CoolBreeze 12000 TV Operation manual

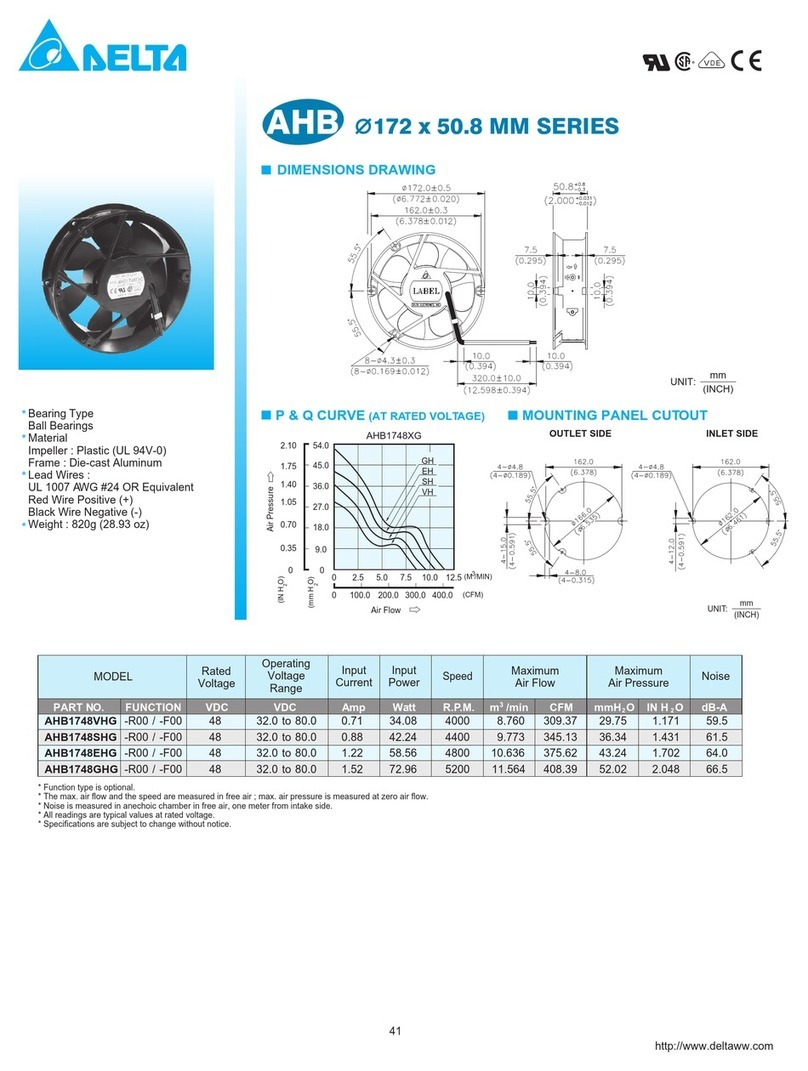

Delta Electronics

Delta Electronics AHB1748VHG Dimensions and installation information

SolarVenti

SolarVenti SV14 installation manual

Turn of the century

Turn of the century Elise Installation and operation instruction

MacroAir Technologies

MacroAir Technologies AirVolution-D 550 installation manual

Nordic Home

Nordic Home FT-775 user manual

Windmere

Windmere FN500 Use and care book

teko

teko BF-20B operating instructions