Hi-Velocity HE Series User manual

TM

Includes:

Hi-Velocity Fan Coils

Heating Coils/Modules

Cooling Coils/Modules

Add-ons and Options

Product Specications

Small Duct Heating, Cooling and

Indoor Air Quality Systems

HE Series

Installation Manual

Table of Contents

Module

INT

Common Parts & Introduction (3 Pgs)

Components, Benets, Applications, Quality Assurance, Warranty Terms Pgs. 3-5

Module

OTL

Hi-Velocity Outlet Installation (2 Pgs)

Locating and Installing Vents, Installing Rough-In Boot, Pgs. 6-7

Module

FCP

Fan Coil Placement (2 Pgs)

Location, Clearances, Hanging Strap Kit Pgs. 8-9

Module

DUC

Installing Plenum and Branch Duct (9 Pgs)

Location, Connections, Duct Reductions, Flexible Duct Pgs. 10-18

Module RAI Return Air Installation (2 Pgs)

Duct Sizing, Return Air Cutout, Dimensions Pgs. 19-20

Module

WIR

Wiring and Dip Settings (11 Pgs)

Wiring, Extended Diagrams, Controls, Dip Settings and

Air Flow Data

Pgs. 21-31

Module

RPM

Refrigerant Module Installation (RPM-E) (4 Pgs)

Specications, Mounting, Drain Connections, Piping, Brazing,

Evacuating, Charging, Heat Pumps, Trouble Shooting

Pgs. 32-35

Module

WCM

Chilled Water Coil Installation (1 Pg)

Mounting, Piping, Specications Pg. 36

Module

HWC

Hot Water Coil Installation (1 Pg)

Installation, Piping, Specications Pg. 37

Module

ESH

Electric Strip Coil Installation (4 Pgs)

Placement, Conguration, Wiring Diagram Pg. 38-41

Module

TPA

Add-Ons and ird Party Options (2 Pgs)

Hi-Velocity Air Purication System, PWM Zone Controller, Turbo Meter,

Fresh Air Make-Up, Fire Stopping, Humidiers

Pgs. 42-43

Module

CTS

Checklist and Troubleshooting (4 Pg)

Installation Checklist, Troubleshooting: EPC Motor, Low Air Flow, 24V

Htg, 24V Clg. Outdoor Unit, Short Cycling,

Pgs. 44-47

Module

SPC

Specications and Sizing (2 Pg)

Standard, Metric, Quick Sizing Guide Pgs. 48-49

Module

SRV

Service and Performance Form (2 Pg)

Fill this Form out for Service Calls Pg. 50-51

Elbow

Joint Connector

End Cap

Rough-In Boot

Vent Plate

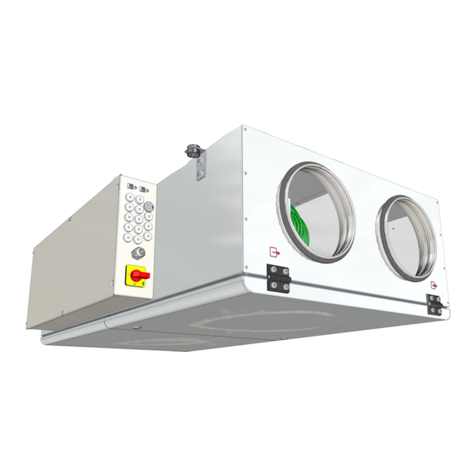

HE Fancoil

Branch Take-Off Plenum Duct

Flexible Duct

Common Parts*

RPM-E Pre-Piped

Cooling Module

Cooling Options Heating Options

Other Options

Hot Water Coil

Water Coil Module Electric Strip Coil

Hi-Velocity Air

Purication System

PWM Zoning

Controller

*Example

Conguration

Only

Connection Tee

Module INT

Common Parts & Introduction (1/3)

Module INT Introduction to Hi-Velocity (1/3)

We are condent that you will enjoy years of trouble-

free service from your Hi-Velocity System. As with any

product that requires installation and assembly, a good

understanding of ALL the components and the nal

product is necessary to achieve the optimum result.

This manual has been designed to be as concise and

straightforward as possible.

Module INT

Introduction to Hi-Velocity (2/3)

Module INT Introduction to Hi-Velocity (2/3)

The Hi-Velocity System is an energy efcient high

pressure air delivery system that can be designed

to provide heating, cooling, ltration, ventilation,

humidication and dehumidication.

With a pressurized small diameter duct we condition

the air differently than conventional forced air systems.

With the use of a high pressure area to low pressure

area, we continuously mix the room air, creating even

temperatures from oor to ceiling. Because the plenum

duct is pressurized, dust build-up within the duct work

is eliminated. With continuous air circulation from the

constant fan, airborne dust and other allergens can be

easily ltered out of the air, and conditions that promote

the growth of mold and mildew are reduced.

Please read the eNtIre

maNual before begINNINg

INstallatIoN as thIs wIll helP

avoId mIstakes that may cost

tIme aNd moNey.

Our innovative fan coil and unique cooling module

technology helps create a healthier and more enjoyable

indoor living environment for the end-user, while saving

money on monthly operating costs.

Powered by a variable-speed EPC motor, the Hi-

Velocity System can be used for heating, cooling, or a

combination of both. The EPC motor quietly drives the

system’s fan continuously, limiting wear and tear and

increasing the lifespan of the system.

To provide heating, the system can be used in

conjunction with any water source (hot water tank,

boiler or geothermal). Unlike traditional heating and air

conditioning systems, it does not depend on the natural

laws of convection. A network of smaller, exible ducts

operate under high pressure to continuously circulate

air and ensure even heat distribution. When using a

hot water tank, after going through the heating system,

the hot water is recycled for household use. With a

proper tank, the Hi-Velocity System can reduce energy

requirements by up to 50 per cent.

For air conditioning, a cooling module, condensing

unit, chiller, heat pump or geothermal sytem can all

be used. The high pressure distribution network cools

each level of the structure evenly. Use of a lower CFM

across the cooling coil

means that the Hi-Velocity System

can remove up to 30% more moisture from the air than

conventional systems, leaving a constant and comfortable

temperature on the skin surface.

The Hi-Velocity System can be installed in 25 per

cent less time than a traditional heating system and is

equally suitable for commercial and residential, in both

new construction and retrot applications. For residential

applications where every cubic foot of area is critical, the

Hi-Velocity System is the solution to your heating and

cooling needs. Being able to run duct work into places

where standard duct work would not t, allows heating,

cooling and ventilation to be installed in applications

where the options are very limited.

IAQ is integral to the comfort and health of a building’s

occupants. The optional Hi-Velocity Air Purication

System (HE PS) was designed to complement the

heating and cooling system. It contains three powerful

technologies. First, an electrostatic MERV-11 lter

removes allergens. Photo-catalytic oxidation is then

used to destroy toxic chemicals and eliminate odours.

Finally, Ultraviolet Light is used to kill germs on contact.

The result is clean, puried air, and unsurpassed Indoor

Air Quality for your home or ofce.

The Hi-Velocity System works on the principle of

pressure rather than air velocity. It is quite different than

a conventional furnace, the main difference being that

the supply duct work is all “small diameter” or “mini duct”.

For all of your heating, cooling, and Indoor Air Quality

needs, the Hi-Velocity System is the right choice for you!

Module INT

Introduction to Hi-Velocity (3/3)

Module INT Introduction to Hi-Velocity (3/3)

Fan coil units shall be a total indoor air quality system

complete with heating, cooling, air ltration, and possibility of

humidity control and fresh air make up. The fan coil must be

factory manufactured, assembled and tested.

Energy Saving Products Ltd. reserves the right to

discontinue, make changes to, and add improvements

upon its products at any time without public notice

or obligatiion. The descriptions and specications

contained in this manual were in effect at printing.

Some illustrations may not be applicable to your unit.

the hI-velocIty system Is Not to be

used as temPorary heatINg/coolINg

durINg the coNstructIoN of the

structure. If used IN thIs caPacIty all

warraNtIes wIll be Null aNd voId.

Refer to Module SPC - Specications and Sizing

for system specications, measurements, etc. For more

detailed specication pages please see our website,

www.hi-velocity.com.

Also available on our Website:

• Installation Videos

• Promotional Video

• Engineering Specications

• Applications

• Downloadable Installation Modules

• Performance Graphs

• Brochures and Marketing Tools

• Complete Parts List

• Complete list of Agents/Distributors

• News and Newsletters

• Case Studies

All equipment furnished under this specication shall

comply with the following standards:

ASHRAE

American Society of Heating,

Refrigerating and Air-Conditioning Engineers

AHRI Air-Conditioning, Heating, and

Refrigeration Institute

CSA Canadian Standards Association

CE European Conformity

DOE Department of Energy

UL Underwriters Laboratories

One year limited warranty. The heat exchanger and

blower are free from defects in workmanship for one year

from date of purchase.

Three year limited warranty. The EPC Motor, EPC

Controller, EPC Circuit Board and PWM Controller are free

from defects in workmanship for three years from date of

purchase.

Two year limited warranty. The electrical strip heater is

free from defects in workmanship for two years from date

of purchase.

This warranty applies only to the fan coil unit and does

not include connections, attachments, and other products

or materials furnished by the installer. This warranty applies

only to the rst purchaser at retail and excludes any

damages caused by changes, relocation to, or installation

in a new site. This warranty does not cover any defects

caused by failure to follow the installation and operating

instructions furnished with the fan coil, local building codes,

and good industry standards. Failure to correctly install

the fan coil, or material related to the unit, may result in

improper system performance and/or damages and will

void this warranty.

• Any repair performed under warranty must be

approved by Energy Saving Products Ltd. for this

warranty to be valid.

• The manufacturer is not liable for any other damages,

personal injury, or any other losses of any nature.

• The liability of the manufacturer is limited to and shall

not exceed the cost of replacement parts and shall

not include transportation to and from the factory,

and eld labour.

• Inoperative parts must be returned with serial

number, purchase date, and a detailed description of

the entire problem with an ESP RMA Form.

• This warranty replaces all other warranties expressed

or implied.

6/7”

6/7”

(152/178mm)

(152/178mm)

Constant circulation is very important to maintain

room comfort. Do not install vents under/beside/on-top

of objects that may hamper the cone of inuence from

circulating the room air.

Outlets do not have to be located on an outside wall. Due

to the venturi action of the Hi-Velocity System, the air in

the entire room is gently circulated at all times. The outlets

should be located six inches (152mm) on centre from any

possible obstruction, seven inches (178mm) for HE outlets.

(Fig. 02).

Proper location is critical to the operation of the Hi-Velocity

System for optimum home comfort. The outlets should be

located where it is considered to be a “low trafc area”.

Typical areas are in the corner of a room, or to the side of

a window or door. When the vents are properly located, the

home owner can expect to have a nearly draft free home.

Fig. 02 - Six/Seven inches (152mm/178mm) on center

Vent placement in outside walls of the structure

should be avoided. Flexible duct that is run in outside

walls may receive a substantial heat loss/gain. This can

result in a higher operating cost for the structure while

delivering an inferior air quality.

BEFORE YOU BEGIN INSTALLATION:

A heat load calculation and duct layout is required

before any installation can begin. See Module DES

- Designing the Hi-Velocity System, before you begin

installation. The layout is designed to provide you with

the maximum benet from your Hi-Velocity System.

Small deviations may be necessary due to existing

construction. However, please contact your system

designer before proceeding if large deviations must be

made such as:

Please Note: he flex duct

outlets CANNOT be used

for 2” x 4” (51mm x 102mm)

sIdewall aPPlIcatIoNs.

Module OTL

Hi-Velocity Outlet Installation (1/2)

Module OTL Hi-Velocity Outlet Installation (1/2)

Fig. 01 - Cone of Inuence

With the venturi effect of the Hi-Velocity system, you

have more options in vent placement. Each vent has an

effective throw of 18’ (5.49m) and causes the air to constantly

circulate. (Fig. 01) This allows for vent placement in oors,

ceilings, or walls.

• Elimination of a vent from a room

• Moving a vent more than 10 feet (3.05m) from its

specied location

• Re-routing the main plenum

4a 4b

4c

4d

By locating the vents in this position, there will now

be horizontal airow. Caution should be exercised when

locating vents in the horizontal position. Avoid placing

vents directly below sinks or other locations people will be

for extended periods of time.

Fig. 04 - Rough-In Cap Installation

4a - Rough-In Cap ts on Rough-In Boot

4b - Rough-In Boot installed with a Rough-In Cap

4c - Floor installed Rough-In Boot

4d - Wall installed Rough-In Boot

Fig. 05 - Trim the edges for kick spaces

Vent caps are used during construction to prevent

damage during construction from drywall dust, saw

dust, stipple ceiling, paint and other small particles

from clogging and damaging the and Rough-in Boot

and Fan coil unit.

In oor applications simply place the cap over the

boot before installing the boot. In ceilings or sidewall

applications it may be necessary to tape the cap on to

the Rough-in boot hold into place prior to installation.

To prevent damage during construction, do not cut out

the Rough-In Caps until the vent plates are ready to be

installed.

In kitchens and bathrooms, it is sometimes hard to nd

a “low trafc area”, so an alternative is to locate the vents

in the kick space under the counters. Our Vent plates

have a 4” (102mm) and 5” (127mm) diameter, which may not

t in all kick spaces without trimming. This can easily be

done by trimming the top and bottom of our vent plate so it

ts. HE outlets are not recommended for kick spaces.

The easiest way to install the round vent plates in the

kick space is to trim off two edges of the plate. (Fig. 05).

Module OTL

Hi-Velocity Outlet Installation (2/2)

Module OTL Hi-Velocity Outlet Installation (2/2)

Once a suitable unobstructed location has been

chosen for the vent placement, use a 3” (76mm) hole saw

to drill an opening large enough for the Rough-In Boot

with a Rough-In Cap (Fig. 03). For HE, use 3 3/4” (94mm)

hole saw.

Fig. 03 - Drill a 3”/3

3/4

” (76mm/95mm) hole

Before securing the Rough-In Boot, make sure to

use a Rough-In Cap (Fig. 04).

When placed in the Counter ow position, the supply air

delivery is from the bottom of the unit (Fig. 02).

Fig. 03 - Horizontal installation

Quite often, the best location for the fan coil unit is

suspended from the ceiling of the mechanical room, in the

horizontal position (Fig. 03). This will allow for more oor

space in the room, and will minimize the duct work needed

to connect to the fan coil unit.

Unit Inches

HE – 50/51/52 18” (457mm)

HE – 70/71 22” (559mm)

HE – 100/101 29”(737mm)

Add an additional 4” (102mm) for Electric Strip Coils

Clearance is only needed on the access side of the units.

However, ensure that there is a small space between the

unit and any other surface to prevent vibration transfer. In

order to maintain and service the fan coil unit, minimum

clearances are required on the access side (Table 01).

The Hi-Velocity System fan coil is manufactured with

a direct drive permanently lubricated EPC Motor that is

mounted within the blower. All HE fan coils are single

side access. The blower assembly can easily be slid out

by removing the three mounted bolts that attach it to the

center plate. In some instances, the electrical box may

need to be removed.

The fan coil unit is to be placed according to the layout

provided by the designer. As with vent placement, small

deviations can be made in fan coil placement. If the

fan coil has to be moved more than a few feet from

it’s pre-designed location, contact the designer before

proceeding.

When installing the fan coil keep these points in mind.

• Serviceability and access to the unit.

• Maximizing usable oor space.

• Location of heat/cool source to fan coil.

The fan coil can be installed in many different

congurations. The fan coil can be located in a Hi-Boy,

Counter ow, or Horizontal position. In the Hi-Boy

position, the supply air is delivered from the top of the

unit (Fig. 01).

Module FCP

Hi-Velocity Fan Coil Placement (1/2)

Module FCP Hi-Velocity Fan Coil Placement (1/2)

Fig. 02 - Counter ow

Fig. 01 - Hi-Boy

X8

X8 X16

X4

X8

04b

04a

X

The Hanging Strap Kits are designed to suspend a

horizontal or vertical fan coil. The nylon straps will absorb

most of the vibration generated by the fan coil system,

eliminating any sound transfer. Alternative hanging

methods may be used, e.g. Reddy Rod or Unistrut.

Attach the metal anges to the four facing corners of

the fan coil unit (Fig. 02).

Cut the nylon straps to the desired length (4”/102mm or

more) and drill a 3/8” (7mm) hole 1” (25mm) from the end of

each nylon strap. (Fig. 03)

Secure the nylon straps to the joist or support. It may be

necessary to install a support across the joists to properly

fasten the Nylon Straps (Fig. 05). The Nylon Straps are

always installed in a vertical position; they should never

be installed at an angle. It is acceptable to put a 90º twist

in the Nylon Straps (Fig. 05a), do not exceed 90º.

Fig. 05 - Install Support if Needed

Fig. 05a - 90° twist

Using the “L” brackets provided with the cooling coil,

attach the module to the return side of fan coil unit, using

two sided tape for air seal between units. Assure that

drain controls are on the bottom (Fig 06), and that no

screws puncture the drain pan or coil. The WCM and WM

chilled water coils are a horizontal airow with a vertical

position of the coil while the RPM-E is also a vertical coil

with multiple air ow capabilities. See the corresponding

manual included with the coil for detailed installation

instructions.

Fig. 02 - Attach anges to Unit

Slide the 11⁄4” (32mm) bolt into the hole of the metal

flange then into the nylon strap, secure with washer

and nut. Repeat this at each end of the nylon straps

(Fig. 04a,04b).

Fig. 03 - Cut Hole in Straps

Fig. 04 - Attach Flanges to all Straps

Lift the fancoil unit and slide the bolt into the metal

ange located on the unit through the nylon strap, and

nish with the washer and nut.

Fig. 01 - Hanging Strap Kit Components

BOLT 5/16”

WASHER

(7.9mm)

1/4” LOCK

NUT (6.4mm)

5/16” X 3/4”

SELF TAPPING

SCREW (12.7mm)

METAL

FLANGE

24” NYLON STRAP

X8

Fig. 06 Attach Cooling Coil to Fan Coil Unit

Attach the metal anges to the four facing corners

of the fan coil and cooling coil assembly.

After attaching the metal anges, follow the same

steps for hanging fan coil unit only.

Module FCP

Hi-Velocity Fan Coil Placement (2/2)

Module FCP Hi-Velocity Fan Coil Placement (2/2)

When locating the plenum duct, one of the main factors

to consider is the integration of the duct work into the

structure. The main supply duct can be located along the

main beam(s) in the basement (Fig. 01).

Fig. 01 - Basement installation

Min. 18” (457mm)

The main plenum can also be easily installed in the attic

space. (Fig. 02)

Fig. 02 - Attic Installation

18”

(457mm)

If the unit is installed in the attic, make sure that all ducts

in the attic are insulated with a vapour barrier (All A/C

systems main plenums need to be insulated and vapour

barriered, check with local codes for required R-Value).

This includes the Branch Take Off and the vent Rough-In

Boot. All main plenum and flex runs should be installed

under the attic insulation. If the duct work is run above

the attic insulation, an extra insulation sleeve may be

needed. Check your local building code for the ruling in

your area.

For any duct runs over 75% of the maximum allowable

plenum length (Module SPC - Specications and

Sizing Pgs. 1, 2), it is recommended to insulate the main

plenum. Insulating the main plenum will cut down on your

duct loss, and form a vapour barrier. The attic insulation

should be placed over all Hi-Velocity System ducts to

further reduce any duct losses.

There are ve types of connections that are possible

with the Hi-Velocity System.

All the connections are done as follows. Place the joint

connector, cap, tee, or elbow inside the plenum you intend

to connect. Push the plenum over the tting as tight as

possible. Use four screws on each side of the connector,

alternating the screw locations as indicated in Fig. 04.

Fig. 03 - Connectors

1. Tee Connection

2. Elbow Connection

3. Reducers

4. End Cap

5. Straight Connection

Fig. 04 - Alternating screw locations

Elbows and tees must not be placed any closer than 18”

from supply outlet on the air handling unit. A signicant

loss of airow can result if elbows or tees are installed

closer than 18” (457mm). Figs. 06 and Fig. 07 illustrate a

proper install with at least 18” of straight plenum after the

unit supply outlet. Fig. 05 shows the sigma velocity prole

of the rst 18” (457mm) of the main plenum and why it’s

important to allow the system to equalize air ow.

IF THE DUCT IS LOCATED IN AN UNCONDITIONED

AREA, INSULATING SLEEVE IS REQUIRED ON

THE MAIN PLENUM. IF USED FOR COOLING, IT IS

ALSO RECOMMENDED TO INSULATE AND VAPOR

BARRIER THE MAIN PLENUM AND FLEX DUCT

FITTINGS. INSULSLEEVES ARE AVAILABLE AS AN

ACCESSORY IN R4.2 FOR 6’ (1.83m), 8’ (2.44m) FOR 10’

(3.05m) PLENUMS IN 10’ (3.05m) LENGTHS.

Module DUC

Installing Plenum and Branch Duct (1/9)

Module DUC Installing Plenum and Branch Duct (1/9)

Insul-Sleeve

over plenum

If elbows, tees, or Branch-Take Off’s are placed closer

than 18” (457mm) you may lose up to 30% of your airow

as illustrated in Fig. 05.

Fig. 05 - Sigma velocity prole

Uniform

Velocity

Point

10% Loss

20% Loss

30% Loss

18”(457mm)

When branch tees are used, the plenum split is to be a

70/30 main/branch split (Fig. 06).

Fig. 06 - Branch Tee, 70/30 split

Fan Coil

30% FLOW

6 Vents

70%

FLOW

14 Vents

EXAMPLE

20 VENTS

18” Min.

Fig. 07 - Bullhead Tee, 50/50 split

Fan Coil EXAMPLE

20 VENTS

50% FLOW

(+/- 10%)

10 Vents

50% FLOW

(+/- 10%)

10 Vents

18” Min.

Bullhead tees are to be maintained as close to a 50/50

split as possible, with a maximum 60/40 split (Fig. 07). For

the best system performance, keep the number of elbows

and tees to a minimum.

After any connection is made, including the joints of

elbows and tees, foil duct tape or a duct sealant should be

used to eliminate any air leaks.

Fig. 08 - Seal all connections

When running the plenum duct between joists in

the basement, sheet metal strapping should be used

(supplied by the installer, not the factory) to secure the

plenum in place (Fig. 09).

Fig. 09 - Use metal strapping

When located in ceiling spaces, the duct may be laid

upon ceiling trusses. Run the duct work low so that it can

be covered with the house insulation (Fig. 02).

Any time the duct will be run in an unconditioned space

(attic or crawl space) it must be insulated with a vapour

barrier. It’s also recommended to vapour barrier runs

that exceed 75% of the total allowable distance (Module

SPC - Specifications and Sizing Pgs. 1, 2).

Module DUC

Installing Plenum and Branch Duct (2/9)

Module DUC Installing Plenum and Branch Duct (2/9)

(457mm)

(457mm)

Fig. 10 - Use an End Cap or Reducer

After the insulation sleeve is installed, cut an X through

the vapour barrier and insulation. Peel it back enough

to allow you to drill your hole without ripping all of the

insulation. Install the branch take-off as described in the

Branch Take-Off section.

To install the insulation sleeve over the main

plenum, either tape the end of the duct or use an

end cap. This will allow the sleeve to slide on easier,

and prevent the insulation from catching on the sharp

metal ends of the duct (Fig. 10).

Fig. 11 - BTO with insulation sleeve

After the main plenum duct and the fan coil unit

are in place, they can be fitted together. Do not

permanently fasten the two together yet, as the

plenum may need to be rotated in order to make

the branch take-off connections. Once rotated into

position, fasten and seal with duct sealant or foil

duct tape.

In some installations, it is necessary to reduce the

size of the main plenum. Caution must be used when

reducing plenum size, since smaller ducts can handle

less number of outlets. Also, when running the plenum

duct past 75% of max distance, it is best to keep full

size plenum duct to reduce restriction in the main

plenum. Keep in mind that once reduced, the main

plenum cannot be increased again. The Branch Take-

Offs form easily to ducts in the 6” (152mm) to 8” (203mm)

range; extra care must be taken with smaller sized

ducts to ensure a proper air seal. For tee reductions,

keep the tee to the full duct size, if reducing the plenum

duct, reduce only after the tee. Keep the length of the

smaller duct sizes to a minimum, since the friction loss

is much higher. If a hole saw will be used to drill the

Branch Take-Off holes, metal ducts are recommended

to be 28 gauge steel.

Duct

Size

# of 2”

(51mm)

Vents

# of Vents

(HE)

Max

Length

4” (102mm) 4 N/A 30’(9.14m)

5” (127mm) 6 3 40’(12.19m)

6” (152mm) 12 6 50’(15.24m)

7” (178mm) 19 9 60’(18.29m)

8” (203mm) 29 14 70’ (21.33m)

10” (254mm) 48 24 100’ (30.48m)

Module DUC

Installing Plenum and Branch Duct (3/9)

Module DUC Installing Plenum and Branch Duct (3/9)

With both the Main Plenum and Rough-In Boot installed,

there is now only the connection of the two. This is done with

the 2” (51mm) or HE Flexible Branch Duct. Keep in mind that

the minimum duct length is 10 feet, with a maximum length

of 25 feet (7.62m). Branch duct runs should be kept as short

as possible to maximize the airow through these runs.

Energy Saving Products supplies the both the 2” (51mm) and

the HE exible duct in three different congurations:

• 2” (51mm) x 10’ (3.05m) AFD (Assembled Flex Duct)

• 2” (51mm) x 15’ (4.57m) AFD (Assembled Flex Duct)

• 2” (51mm) x 25’ (7.62m) UFD (Unassembled Flex Duct)

• HE x 10’ (3.05m) AFD (Assembled Flex Duct)

• HE x 15’ (4.57m) AFD (Assembled Flex Duct)

• HE x 25’ (7.62m) UFD (Unassembled Flex Duct)

All congurations are available in both R4.2 and R8 R

Values.The 2” (51mm) and HE AFD come complete with the

necessary components for one complete ten foot or fteen

foot branch run. The 25’ (7.62m) UFD is to be used only to

extend these runs if needed.

If extending branch runs longer than the minimum,

contact the system designer, or reference Table 03 for

branch duct losses on extended runs.

HE Duct is designed as a direct alternative for two 2”

(51mm) ex duct of the same length used in Hi-Velocity

Systems. No changes are required to fancoil selection and

main plenum duct sizing.

HE Duct utilizes the same selecting process as the

standard 2” (51mm) ex duct, a complete and comprehensive

heat loss/gain must be completed in order to select fancoil,

plenum size, and outlet quantities. The HE Duct is designed

to directly replace two (2) standard 2” (51mm) outlets,

therefore when an area requires multiple outlets, a

single HE outlet can replace two of the standard 2”

(51mm) ducts. Any combination of 2” (51mm) ducting, HE

ducting, and drilled outlets can be used, following the

minimum and maximum outlets as per unit selection.

Fig. 12 - Drill hole

The locations for the Branch Take-Offs should be

determined before any drilling is done. Holes need to be

drilled a minimum of 6” apart on center (152mm) for 2” ex,

and 7” (178mm) apart on center for HE ex. Once all spots

are marked for the Branch Take-Offs, a hole saw is used

to drill the outlets - 2 1/4” (57mm) for 2” (51mm) Branch Take-

Offs and 3” (76mm) for HE Branch Take-Offs. (Fig. 12).

Example: If a 3 Ton Unit has 24 outlets of the normal 2”

X 10’ (51mm) ex duct, you can change to 12 HE X 10’ Duct

outlets, or 8 HE Duct and 8 2” (51mm) Duct outlets, or any

combination to give you the equivalent. See Specication

& Sizing Pgs 1,2 for Air Flow data.

Duct Size CFM Output

TWO 2” (51mm) Flex Duct 32 CFM X 2 (15 L/s X 2)

ONE HE Duct 65 CFM (31 L/s)

After all the holes have been drilled in the main plenum,

the Branch Take-Offs are then installed. The Branch Take-

Off is placed over the hole with the gasket in between

(Fig. 13a). The curvature of Branch Take-Off is aligned

so it matches the shape of the plenum. With the opening

fully over the hole push the BTO tight against the main

plenum and secure with four ¼” (7mm) self tapping screws

(Fig. 13b).

It is NOT recommended to connect any Branch Take-Offs

until all holes have been drilled, as it may be necessary to

rotate the plenum to drill the outlets.

Fig. 13a - Branch Take-Off

Fig. 13b - Securing

Module DUC

Installing Plenum and Branch Duct (4/9)

Module DUC Installing Plenum and Branch Duct (4/9)

Table 03: De-rating Values

HE Series

Tubing Length

Adjustment Factor

10’

0%

15’

10%

20’

20%

25’

35%

Outside Diameters of Flexible Duct:

2” - R4 = 4.5” (114mm)

2” - R8 = 6.5” (165mm)

HE - R4 = 5.5” (140mm)

HE - R8 = 7.5” (191mm)

MIN.

6” or

152mm

BEND

RADIUS (7”

or 178mm

for HE)

After the all the Branch Take-Offs have been installed,

the exible duct can then be fastened to the joist with

strapping material. Staples may be used, as long as the

insulation sleeve isn’t damaged or torn.

Only use staples if local code allows. If the

insulation sleeve is damaged use foil duct tape to seal

the sleeve, do not use cloth style tapes as they will not

create a proper seal. Try to run the exible duct parallel

to the joists whenever possible as this takes less space

(Fig. 14).

Fig. 14 - Use strapping to hold the Flexible duct

Fig. 15 - Through or under joists

When larger holes (4”/102mm) can be drilled, then the

insulated ex duct may be pulled through whole. If code

or the designer only allow for a 2 ¼” (57mm) or 3” (76mm)

hole, the insulation must rst be removed from the exible

duct (Fig. 16a). The insulation is then cut into lengths that

correspond to the joist spacing. As the inner soft core of

the exible duct is fed into each hole the insulation is slid

over the core (Fig. 16b).

Fig. 16a - 2 1⁄4” holes (57mm)

Fig. 16b - Add insulation at each joist

When installing the flexible duct in areas in which

you must run opposite to the direction of solid joists,

some drilling may be required. It is recommended

to drill the smallest hole possible (Fig. 15) in order

to maintain structural integrity. Check with local code

laws and ensure that it is allowable to drill holes

through the joists before proceeding. If possible, run

the flex duct under the joists and avoid drilling any

holes.

The exible duct should never be cut shorter than 10’

(3.05m) in length. If the run to the outlet is less than 10’

(3.05m) the exible duct can be coiled up. The bends in the

exible duct shall have a minimum radius of 6” or 152mm

(7” or 178mm for HE Duct) (Fig. 17). Sharp bends in the

Flexible Duct will reduce airow to that vent.

Fig. 17 - 6” (152mm) minimum radius on bends

If a T-Bar ceiling is going to be installed, it is far easier

to run the exible duct in that space, rather than drilling

through several joists.

Module DUC

Installing Plenum and Branch Duct (5/9)

Module DUC Installing Plenum and Branch Duct (5/9)

The Flexible Duct coupling is connected to the branch

Take-Off, then mechanically fastened with at least one ¼”

(6.7mm) self tapping screw. The connection then should be

sealed with foil duct tape or an approved sealant.

Fig. 18 - Secure to plenum with gentle bends

SLIGHT

ANGLE

SLIGHT ANGLE

The Flexible Duct coupling is connected to the Rough-

In Boot, then mechanically fastened with at least one ¼”

(6.7mm) self tapping screw (Fig. 19). The connection then

should be sealed with foil duct tape or an approved sealant.

Hard angles should never be used when connecting

to the main plenum or Rough-In Boot, keep the bends as

gentle as possible (Fig. 18). A hard bend should never be

created in the exible duct as this will restrict airow to the

outlet.

Fig. 19 - Mechanically Fasten

When connecting the UFD to the AFD, attach the

branch coupling into the inner core of the UFD with foil

duct tape, connect the two branch couplings with the

branch connector tube (Fig. 20). Now pull the insulation

and vapour barrier over the inner core and secure around

the outside of the vapour barrier with a cable tie. Tighten

the cable tie securely around the branch connector, inner

core, insulation, and vapour barrier.

Fig. 20 - Fasten with tie straps

To complete the installation, cut out the Rough-In Cap

(Fig. 21) and install the vent plate by sliding the vent plate

into the end of the damper tube (Fig. 22). Ensure the vent

is in the fully open position.

If the exible duct is in an unconditioned space, then all

connections must be taped to ensure a continuous vapour

seal. This includes the Branch Take-Off and the vent

Rough-In Boot. Try not to damage the vapour barrier on

the exible duct. If it is damaged, holes must be taped. If

possible, try to run the exible duct between the insulation

and the vapour barrier.

Flexible duct is not to be used in concrete applications.

Caution should be used when running metal or PVC pipe

under concrete, to ensure pipe is not crushed. For certain

applications in which hard pipe is needed, certain guidelines

must be followed. All metal ducts run in a concrete slab

must be sealed with an approved duct sealer. For vertical

runs out of the oor, it may be necessary to extend the

damper tube or vent plate collar (Fig. 23), to connect to

the AFD Kit.

Fig. 21 Fig. 22

When the sub oor and oor nishing is too thick for

the connection of the vent plate, it may be necessary to

use an extension kit. Connect the vent plate extension

to the branch connector tube and vent plate. The branch

connector tube can be cut at different lengths so the vent

plate sits ush with the oor nishing.

Fig. 23 - Extension kit

Module DUC

Installing Plenum and Branch Duct (6/9)

Module DUC Installing Plenum and Branch Duct (6/9)

TEST SYSTEM FOR LEAKS BEFORE

INSTALLATION OF DRYWALL.

The Rough-in Boot can be insulated and vapor barriered

using the insulation and vapor barrier that is around the

ex duct. Cut the cable tie on the ex duct and pull the

insulation and vapor barrier over the ange of the Rough-in

Boot and replace cable tie. Tighten the cable tie securely

around the boot, insulation and vapor barrier.

Fig. 25 - Run ex through opening

3” (76mm)

3

1/2

” (89mm)

2 1⁄4” (57mm)

Fig. 24 - Dimensions

Using a 3” (76mm)

hole saw, drill a hole

where the vent outlet is

to be placed (Fig. 24).

The hole needs to be

enlarged in the direction

of the incoming exible

duct. This is done by

creating a 2 1⁄4” (57mm)

x 1⁄2” (13mm) rectangle,

which will allow the

Rough-In Boot to slide

easily into the wall.

For ease of installation, it is recommended to use the

2” (51mm) exible duct and vents for retrot applications.

With the proper preparations, installing vents into nished

walls and ceilings is quick and simple.

Once the hole is nished, run the exible duct

through the wall/ceiling to the vent outlet. If installed

in drywall, care must be taken when pulling the ex out

of the opening (Fig. 25). Too much force can result in

damage to the dry wall.

The Rough-In Boot needs a little preparation before it

can be mounted to the exible duct. The corners need to

be trimmed along the score lines of each corner (Fig. 26).

This will allow the Rough-In Boot to be completely hidden

with a beauty ring (Fig. 32).

Fig. 26 - Trim off the 4 corners

The Rough-In Boot is then connected to exible duct and

mechanically attached with a self tapping screw (Fig. 27).

Fig. 27 - Secure ex to Rough-In Boot

Next the ex is fed back into the wall and Rough-In Boot

slid into the hole (Fig. 28).

Fig. 28 - Feed the ex back into the wall

If being installed in drywall, with the boot seated rmly

against the top, 3 pilot holes need to be drilled for 1/4”

(6.7mm) drywall anchors (Fig. 30).

In drywall applications, 3 drywall anchors (1/4” or 6.7mm)

should be used to secure the Rough-In Boot to the wall (Fig.

31).

The Rough-In Boot is

placed at the top of the

hole; top is the opposite

side of the cut out

rectangle (Fig. 41).

Fig. 29 - The Top

Fig. 30 - Pre-drill for anchors

Fig. 31 - Anchors

The hole and Rough-In Boot can be completely hidden if a

beauty ring is used in conjunction with a vent plate (Fig. 32).

Fig. 32 - Beauty ring with Vent Plate

Once drywall anchors are installed, screw down the

Rough-In Boot and secure it in place.

Module DUC

Installing Plenum and Branch Duct (7/9)

Module DUC Installing Plenum and Branch Duct (7/9)

Installations in areas that have a high heat loss/gain

require multiple vents. Multiple vents can be installed

into linear grills for a more esthetically pleasing look.

Installing in a high sidewall/ceiling or oor makes little

difference (Fig. 33). A Straight Vane vent grill is the only

type of linear grill that can be used with the Hi-Velocity

System (Fig. 34). Linear grills must be purchased from

a third party vendor.

Fig. 33 - Linear Grills

Fig. 34 - Straight vanes only

When installing multiple vents into linear grills, the 2”

(51mm) vents must be a minimum of 6” (152.4mm) on center

from each other, 7” (178mm) for HE vents. (Fig. 35). Same

rules apply for vents in linear grills as a single outlet

installation; see Module OTL - Outlet Installation for

more information on vent placement.

Fig. 36 - Outlet no more than 2” (51mm) from grill

6”/7”

2”

The outlet of the Rough-In Boot must be no more than

2” (51mm) away from the grill (Fig. 36).

Installing the vents around the room will allow for the room

air to mix. This will give the room a more even air tempera-

ture and better distribution.

Fig. 35 - 6”/7” Apart on Center (152mm/178mm)

Module DUC

Installing Plenum and Branch Duct (8/9)

Module DUC Installing Plenum and Branch Duct (8/9)

6”/7”

6”/7” (152mm/177mm)

(152mm/177mm)

(152mm/177mm)

(51mm)

Caution must to be used when not using the exible duct,

the air velocity from the drilled outlet may create noise.

Drilled Outlets CANNOT be installed in a residential

structure; too much noise may be generated from the

outlets. In commercial areas with large ceilings the

sound can be absorbed by the room or is not a concern

because of the ambient noises.

Drilled outlets are commonly used to supply a large

area with heating and cooling. Drilled outlets can also be

used to create a pressurized air curtain for bay doors, or

large openings to the outside environment. When drilled

outlets are used with the Hi-Velocity System a few points

to remember:

• When multiple 11⁄4” (32mm) or 2” (51mm) holes are used,

they need to be a minimum of 6” (152mm) apart on

center (Fig. 37).

• One 11⁄4” (32mm) drilled hole is equivalent to a single

2”x10’ AFD kit (2”/51mm Rough-In Boot attached to a

10’/3.05m piece of ex duct). With the 11⁄4” (32mm) drilled

outlet the throw from the outlet is up to 18’ (5.49m).

• One 2” (51mm) drilled outlet is equivalent to two - 2”x10’

AFD kits (2”/51mm Rough-In Boot attached to a

10’/3.05m piece of ex duct). With the 2” (51mm) drilled

outlet the throw from the outlet is up to 30’ (9.14m) in

distance.

• Using drilled outlets larger than 2” (51mm) is not

recommended; with too large of an opening in the

main plenum the static pressure may drop to an

unacceptable level.

Fig. 37 - 6” (152mm) Apart on center

When drilled outlets are used in a ceiling install, drill the

outlets at a 45° angle to properly circulate the room air (Fig.

38).

Fig. 38 - Airow 45° angle to oor

Fig. 39 - 6” (152mm) Airow parallel to oor

If there is an air velocity noise coming from the drilled

outlets, a static pressure reading from the plenum duct

should be taken. This reading is to be taken no closer than

18” (457mm) from supply air outlet of fan coil. Static pressure

readings are taken from the inside edge of the plenum; do

not insert pitot tube deeper than 1⁄4”(6.7mm) from the inside

surface of the plenum.

If the static pressure is high, drilling more holes into the

main plenum will lower the static pressure and the noise

level of the system. The standard supply pressures for the

Hi-Velocity System runs between 0.7 H2O (174 pa) and 1.2

H2O (299 pa). Do not allow the static pressure to drop below

0.7 H2O (174 pa) as this can cause a low airow.

For sidewall installations the outlets are drilled parallel

to the oor (Horizontal airow). When the vents are in this

conguration, they can be used to create a pressurized air

curtain.

Module DUC

Installing Plenum and Branch Duct (9/9)

Module DUC Installing Plenum and Branch Duct (9/9)

The return air duct is not supplied with the Hi-Velocity

System. It is to be supplied and installed by the contractor.

The return air and fresh air make-up ducts are to be

installed according to local building code.

The return air duct from the air handling units is to be

acoustically lined for sound absorption, for the rst ve

feet, or for the line of sight. This only applies on short return

air duct work of less than 10 feet (3.05m).

The return air is to be sized on a 0.15 static pressure

(37 pa) as compared to 0.10 static pressure (25 pa) for

conventional forced air systems. The maximum length for

an individual return air duct is fty feet (15.24m).

Table 01 has recommended return air sizes for

round and rectangular ducts. A variance of plus 20% is

allowable for sizing return ducts that connect to the

Hi-Velocity Systems unit.

It is recommended to install a grill that is 10 - 20% larger

than specications require, this will ensure that there is no

air velocity noise at the grill. Where allowed by local codes,

a single return air grill may be used.

Unit Round

Duct

Rect. Duct Equiv. in

Sq. Inches (Sq. cm)

HE-50/51/52 12”

(305mm)

120

(774cm)

HE-70/71 12”

(305mm)

120

(774cm)

HE-100/101 14”

(356mm)

168

(1084cm)

Module RAI

Return Air Installation (1/2)

Module RAI Return Air Installation (1/2)

When designing the return air for a Hi-Velocity System,

there are a few things to consider. It is common to use

centralized return air with systems that have rooms that

are within a common area. Separate oors or rooms that

have high loads and require a large amount of supply air

ow should have their own return air, or be tied into the

centralized return air to allow the air to return back to the

fan coil. Rooms or areas that cannot be tied into the return

air should have an air transfer grill to allow the air to escape

the room and ow back to a centralized return air.

The Hi-Velocity System is a pressure supply duct system

that forces the air into rooms through supply outlets. A

closed room will pressurize, and air will escape through

the undercut of a door back to a centralized return air. (i.e.

a typical bedroom with two outlets will deliver 64 cfm into

the space, a 1/2” undercut door will provide 15 square

inches of r/a from the space at a transfer velocity of 4 fpm,

sufcient to provide comfortable r/a.) If more than four 2”

or two HE vents are installed in a room, or if there is a

sealed door in the room, an air transfer grill or return air

should be installed to allow the air back to the fan coil.

Once the placement of the return has been decided,

the return air knockout(s) can be cut. (Fig. 01) The pre-

measured guide cuts supplied with the fan coil should

always be used; this will guarantee maximum airow

across the coil.

Fig. 01 - Return air cutout

Table 02 – Return Air Cutout Dimensions

Model Dimensions

HE-50/51 H/BU 91/2” X 131/2” (241mm X 343mm)

HE-70/71 H/BU 14” X 131/2” (356mm X 343mm)

HE-100/101 H/BU 20” X 14” (508mm X 356mm)

Module RAI

Return Air Installation (2/2)

Module RAI Return Air Installation (2/2)

The return air base comes complete with a one-inch

(25mm) lter and one-inch (25mm) lter rack. The lter is

a 3 medium lter approximately 14% efcient, and can

be replaced with any aftermarket lter. All the Return

Air bases come acoustically lined with half-inch sound

absorbing insulation.

A B C D E

HE-50/51/52 24”

(610mm)

181⁄2”

(470mm)

141⁄2”

(368mm)

11⁄8”

(28.6mm)

213⁄4”

(552mm)

HE-70/71 24”

(610mm)

181⁄2”

(470mm)

191⁄2”

(495mm)

11⁄8”

(28.6mm)

213⁄4”

(552mm)

HE-100/101 24”

(610mm)

181⁄2”

(470mm)

251⁄2”

(648mm)

11⁄8”

(28.6mm)

213⁄4”

(552mm)

Energy Saving Products manufactures a return air

base with a built in lter rack that matches up to the fan

coil units.

For installation of Heating and Cooling Add-Ons, Refer

to:

• Module RPM - Refrigerant Module Installation

• Module HWC - Hot Water Coil Installation

• Module WCM - Chilled Water Coil Installation

• Module ESH - Electric Strip Coil Installation

These manuals are included with the coils, and are also

available online at www.hi-velocity.com.

11⁄8” Opening

Two 11⁄8” (28.58mm) Rails (D) for fan coil

placement and Filter Holder

A

E

C

B

D

Fig. 03 - Return Air Design

(28.58mm)

For lter options and other Add-Ons available from

Energy Saving Products, see Module OPT - Options

and Add-Ons.

Once the return air has been cut out, a transition will be

needed to attach the return air duct to the fan coil (Fig. 03).

Fig. 02 – Return Air using a transition

A round or square return air duct can be used; they must

be sized for the Hi-Velocity Systems according to Table

01. Before the return air can be attached to the transition,

the rst ve feet (from the fan coil) is to be acoustically

lined for sound absorption.

When mounting additional components onto the back of

the unit, (Filter Rack, Return Air Base etc.) the hex head (a)

screws (4 or 6 depending on unit size) can be replaced with

at head (b) screws for a ush t.

Table of contents

Popular Heating System manuals by other brands

Thermrup

Thermrup HI616 instruction manual

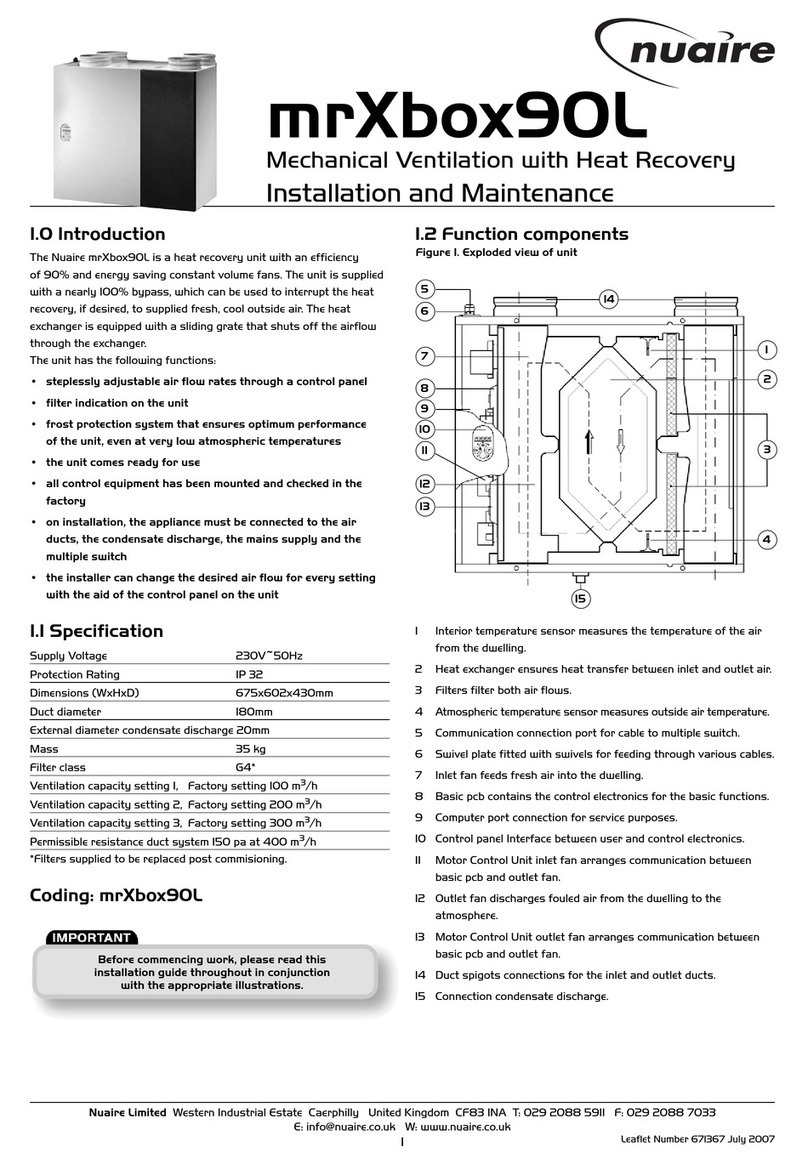

Honeywell

Honeywell S8700 Series installation instructions

Energotech

Energotech EnergoCassette ENC360 Mounting and installation

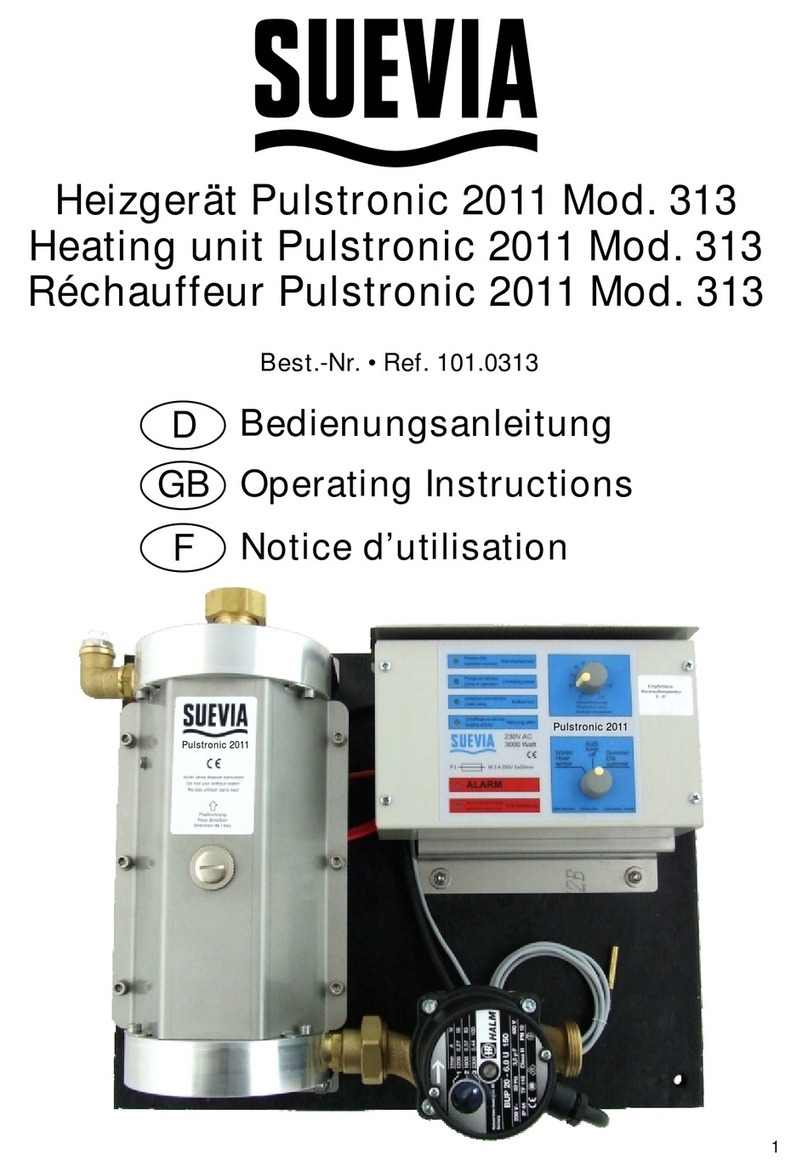

Suevia

Suevia Pulstronic 2011 Mod. 313 operating instructions

Salda

Salda RIRS 3500HE EKO 3.0 Technical manual

aerauliqa

aerauliqa QR180M Installation, use and maintenance manual

Lifebreath

Lifebreath 350DCS Operation and installation manual

Vaillant

Vaillant allSTOR plus VPS 800/4-5 operating instructions

Vortice

Vortice VORT HRW 20 MONO Instructions for the installer

Kabola

Kabola Ecoline series user manual

LK Systems

LK Systems PE-X Assembly instructions

Valeo

Valeo Thermo E+ 120 Workshop manual