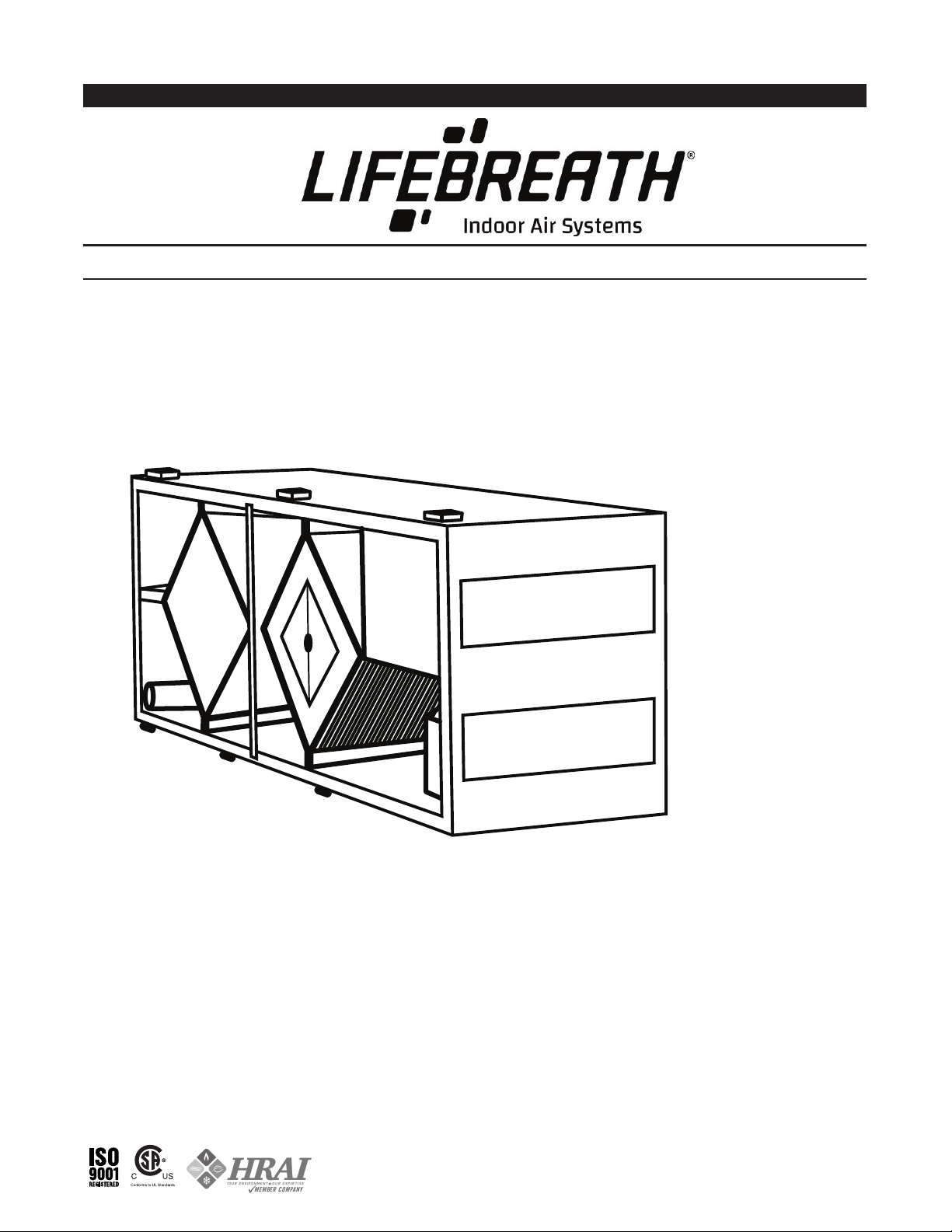

3

49"

(1245 mm)

8"

(200 mm)

FRONT VIEW

18 3/4"

(475 mm)

28 1/4"

(717 mm)

14"

(356 mm)

5 7/8"

(150 mm)

1 1/4"

(32 mm

)

INTERIOR DUCT

CONNECTION SIDE

18 3/4"

(475 mm)

8"

(200 mm)

28 1/4"

(717 mm)

14"

(356 mm)

5 7/8"

(150 mm)

1 3/8"

(35 mm)

EXTERIOR DUCT

CONNECTION

SIDE

MOUNTING POINTS

EXHAUST AIR

TO OUTSIDE

EXHAUST AIR

FROM BUILDING

SUPPLY AIR

TO BUILDING

SUPPLY AIR

FROM OUTSIDE

NOTE:

Service

clearance

is

30

in.

(760

mm)

DRAIN CONNECTION

DEFROST

CORES

Two modular (two section) aluminum HRV cores arranged for high efficiency cross-flow ventilation.

MOTORS

Two PSC, 5 speed double shafted, 120 VAC, 3.15 A motors. (6.3 A total on high speed) with 1/10

hp at 1625 RPM. Total of 610 watts on High speed. MCA: 7.9 MOP:10

BLOWERS

Centrifugal-type rated at 530 cfm (250 L/s) free air delivery. Each air stream has two centrifugal

blowers driven by two PSC motors.

FILTERS

Washable air filters in exhaust and supply air streams.

DEFROST

Supply bypass damper routes indoor air to defrost cores.

WEIGHT 160 lbs. (70 kg) SHIPPING WEIGHT 240 lbs. (110 kg)

CONNECTION DUCT SIZES

Four 14”x 8” ( 356 mm x 200 mm)

MOUNTING

Unit to be set on support brackets hung by threaded rod-type apparatus (brackets and rods not

included).

CASE

Twenty gauge pre-painted galvanized steel (G60) for superior corrosion resistance. Insulated with

foil faced insulation duct liner where required to prevent exterior condensation. One drain

connection 1/2" (12 mm) OD.

ELECTRONICS

Integrated microprocessor circuit board. Built-in interlock contacts.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

PERFORMANCE

Net

supply

airflow

in

cfm

(L/s)

against

external

static

pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 450 (212)

@ 0.2” (50 Pa) 426 (201)

@ 0.3” (75 Pa) 400 (189)

@ 0.4” (100 Pa) 371 (175)

@ 0.5” (125 Pa) 337 (159)

@ 0.6” (150 Pa) 304 (143)

@ 0.7” (175 Pa) 269 (127)

@ 0.8” (200 Pa) 158 (75)

@ 0.9” (225 Pa) 107 (50)

VAC @ 60HZ 120

WATTS / Low speed 187

WATTS / High speed 610

Amp rating 6.3

AIRFLOWS (Each Air Stream)

250

200

150

100

50

0.1 0.2

100%

90%

80%

300

(143)

400

(190)

500

(235)

600

(282)

AIRFLOW IN CFM (L/s)

NOTE: Exhaust Relative Humidity (RH) at 40%

EFFECTIVENESS

200

(94)

300

5

1

2

3

4

*3 - Medium Speed

*1 - Low speed

*5

*4

-High Speed

-Medium High Speed

*2 - Medium Low speed

0

350

400

450

500

0.3 0.4 0.5 0.6 0.7

EXTERNAL STATIC PRESSURE (inches W.C.)

TEMPERATURE EFFECTIVENESS

0.8 0.9

Specifications 350DCS

AIRFLOW CFM

DIMENSIONS inches (mm)

All units conform to

CSA and UL

standards

NOTE: All

specifications are

subject to change

without notice.

WARRANTY

Units carry a 15 year warranty

on the HRV core and a 2 year

replacement parts warranty.

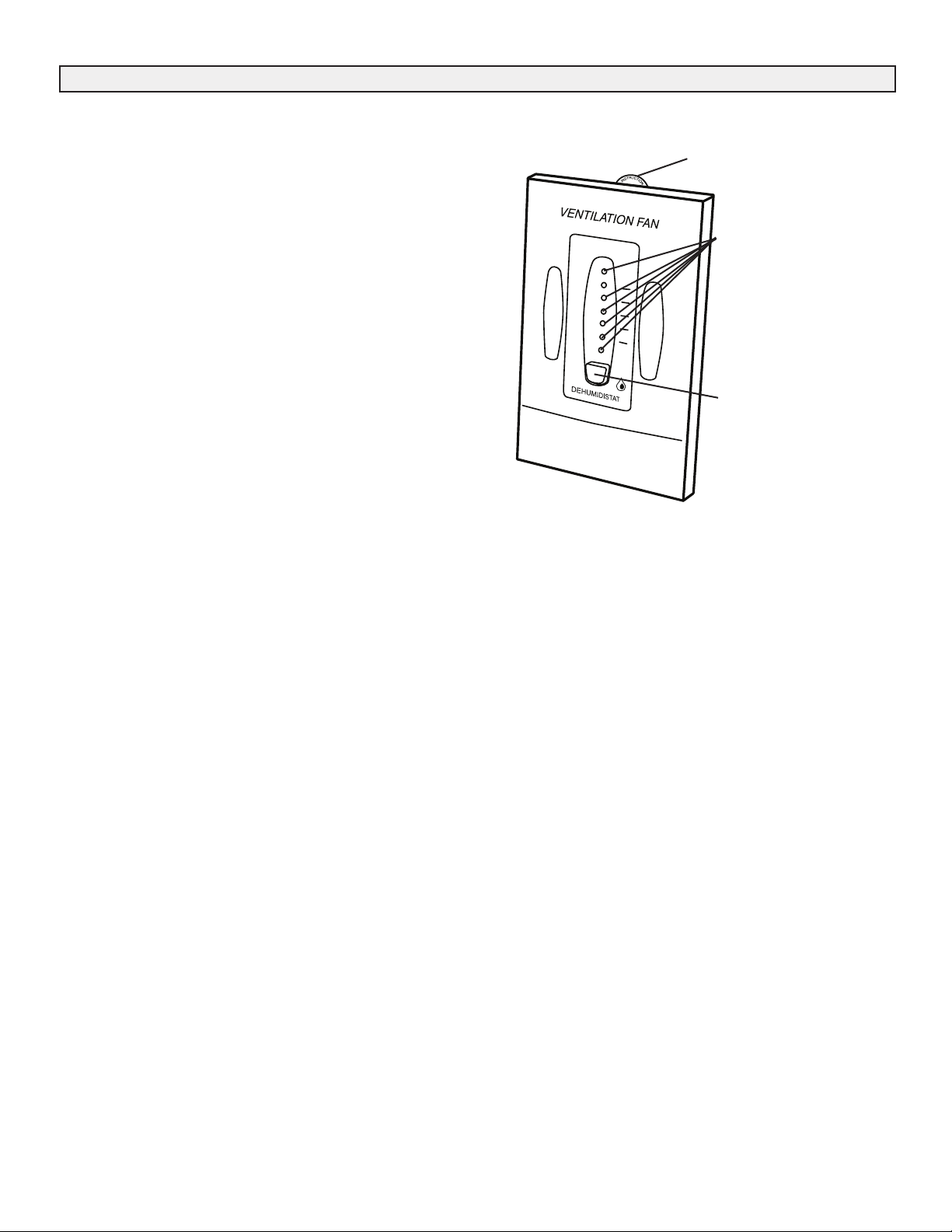

99-BC03 Lifebreath Ventilation Control

•

•

•

Continuous Low fan speed Humidity

control through adjustable

Dehumidistat

3 modes of operation: Ventilation,

Recirculation, 20/40

•

Compatible with 99-DET02 Wireless

Timers

•

3 wire connection

CONTROL OPTIONS

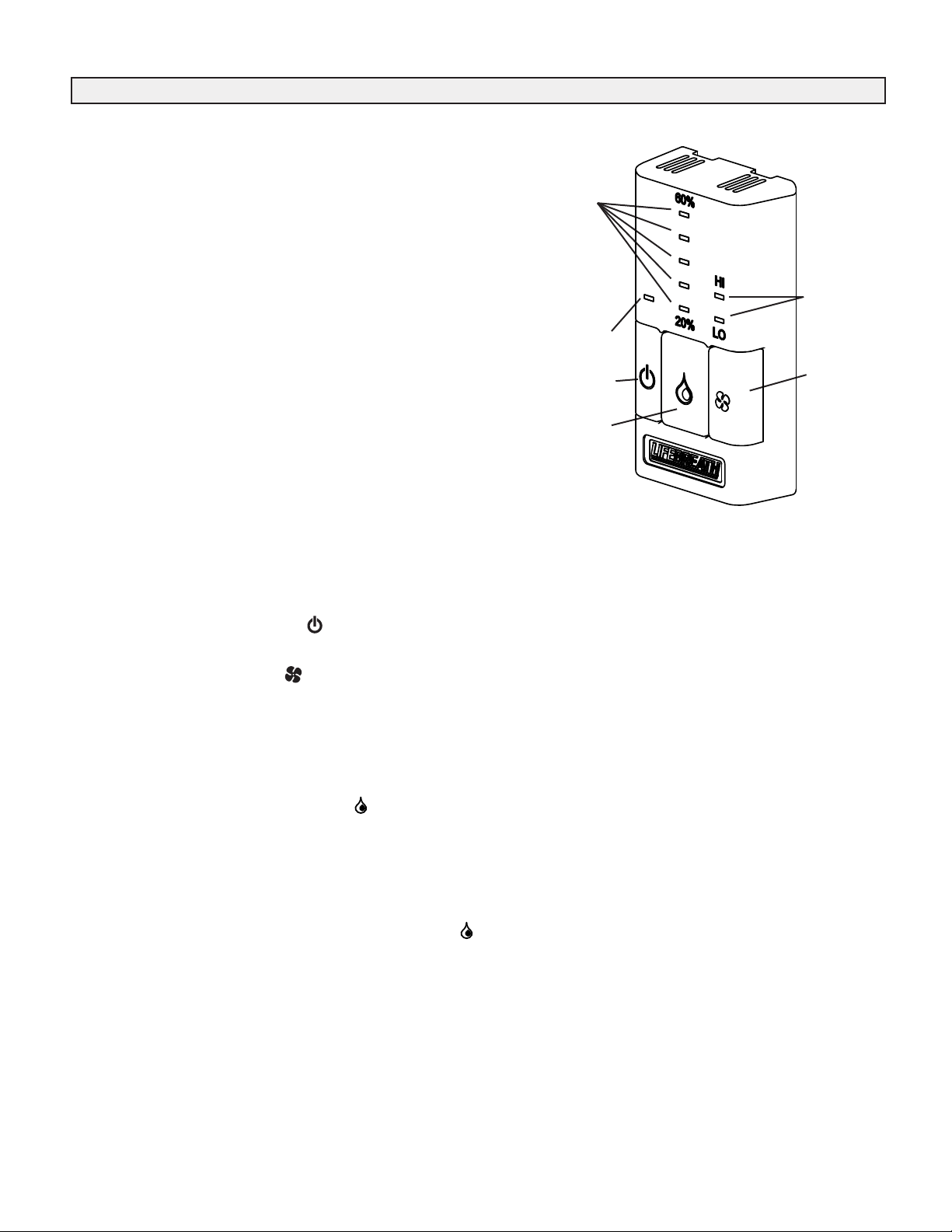

99-DXPL02 Lifebreath Digital Control

(Included)

•

•

5 speed operation on each mode

Humidity control through adjustable

Dehumidistat

•

5 user selectable operational modes: Continuous

Ventilation, Continuous Recirculation, 20 ON/40

OFF, 10 ON/50 OFF, 20 ON/40 Recirculation

•

20/40/60 min. High speed override

button

•

Compatible with 99-DET02 Wireless

Timers

•

3 wire connection

99-BC02 Lifebreath Ventilation Control

•

2 speed fan setting (Low/High)

•

Humidity control through adjustable

Dehumidistat

•

Compatible with 99-DET02 Wireless

Timers

•

3 wire connection

99-BC04 Lifebreath Ventilation Control

•

2 speed fan setting (Low/High)

•

2 modes of operation: Ventilation, 20/40

•

Compatible with 99-DET02 Wireless

Timers

•

3 wire connection

99-DH01 Lifebreath Dehumidistat

•

Humidity control through adjustable

Dehumidistat

•

3 wire connection

TIMER OPTIONS

99-DET01 Lifebreath 20/40/60 Minute Timer - Initiates High speed Ventilation for 20, 40 or 60 minutes. 3 wire connection.

99-DET02 Lifebreath WIRELESS 20/40/60 Minute Timer - Initiates High speed Ventilation for 20, 40 or 60 minutes.

Wirelessly connects to main control for ease of installation. 40' approximate range.

99-RX02 Lifebreath WIRELESS Repeater - Used to extend range of 99-DET02 Wireless Timers. Plugs into 120V power

outlet. Wirelessly connects to main control and 99-DET02. Install at halfway point between timer and main wall control

if timer is out of range.