1 General information

2015/07 9939062x-mub-en – V10 3

Contents

1General information ............................................................................................................. 4

1.1Scope of these instructions ............................................................................................ 4

1.2Designated use .............................................................................................................. 4

2Safety instructions ............................................................................................................... 5

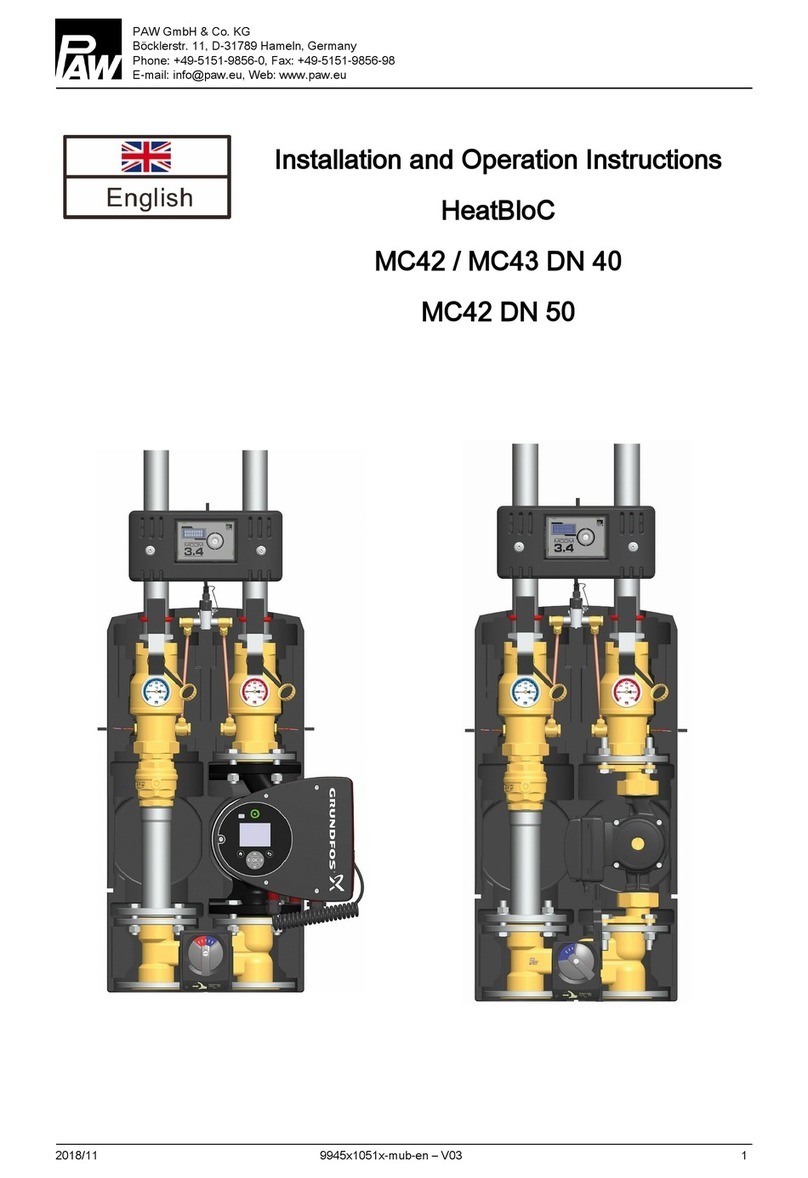

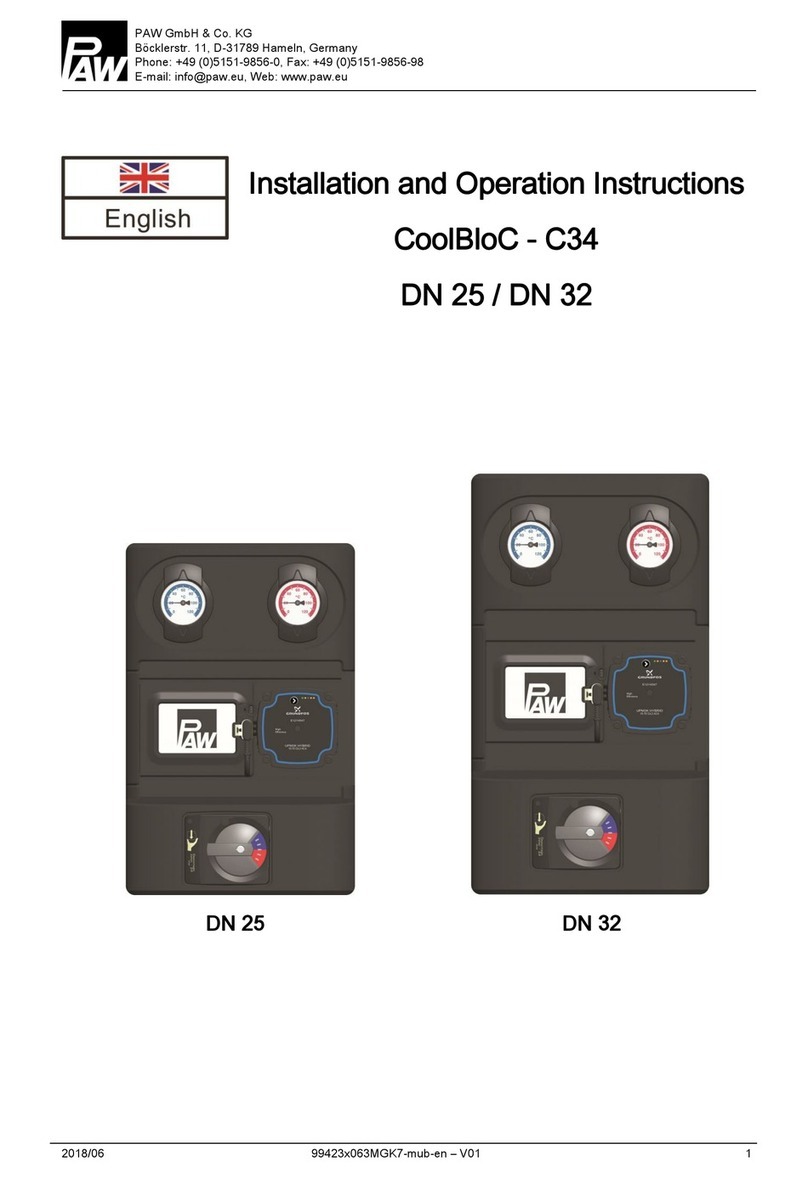

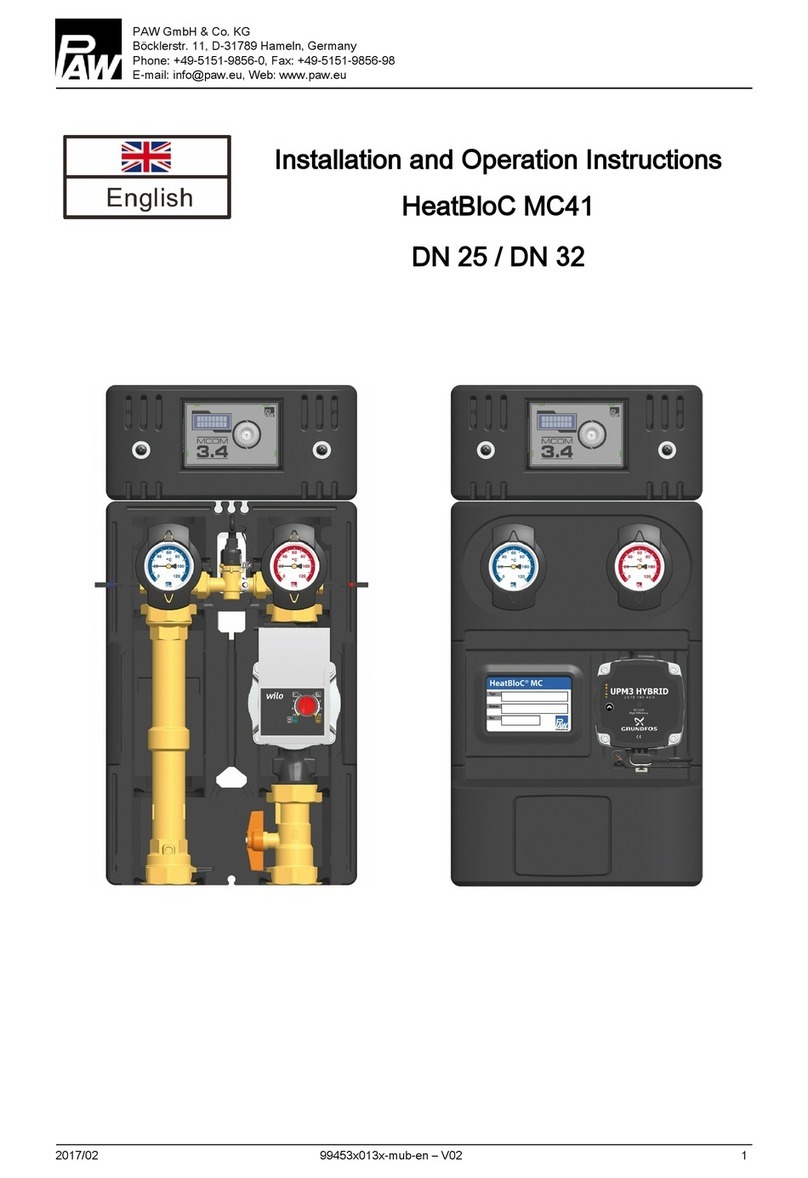

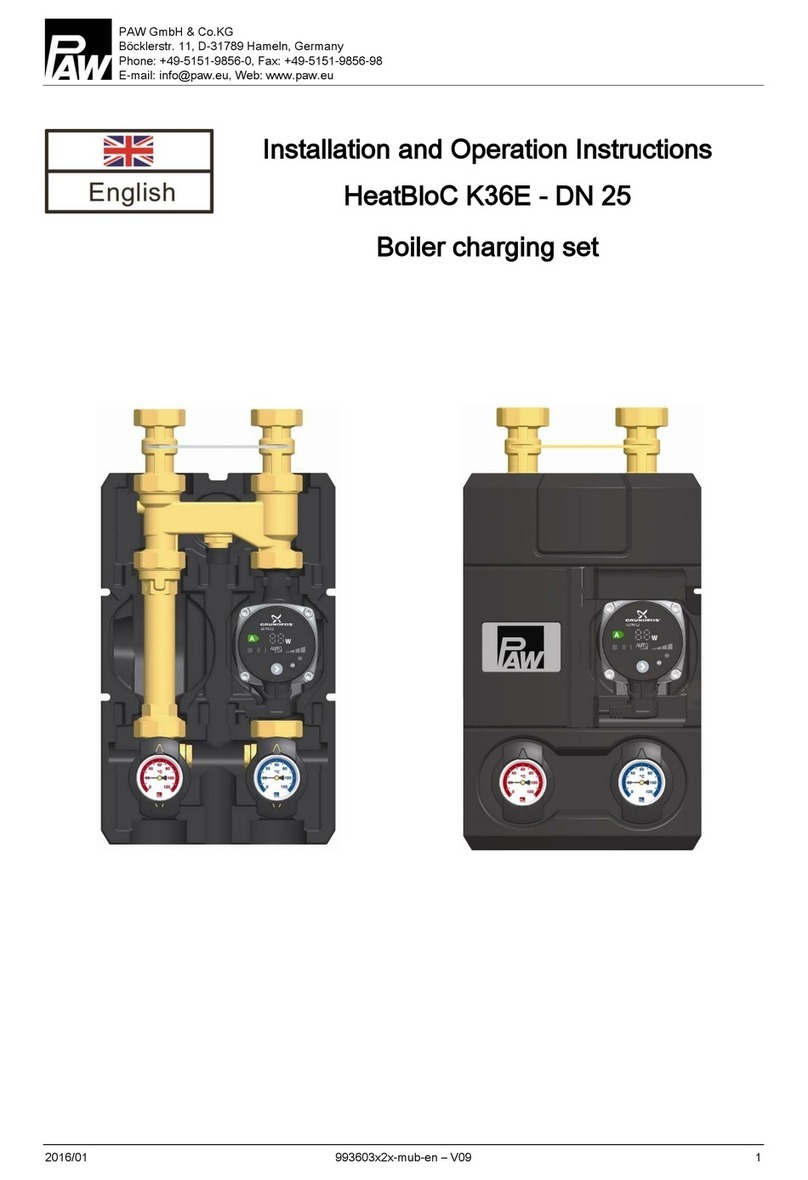

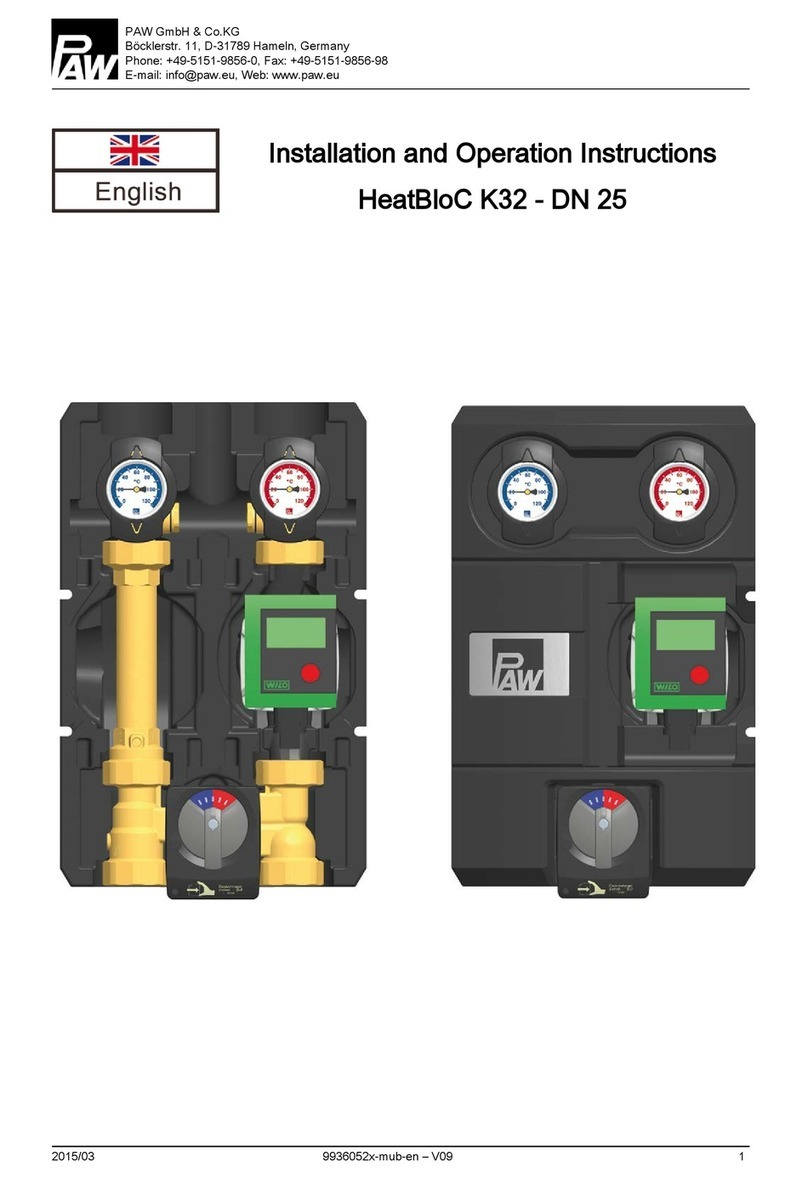

3Product description.............................................................................................................. 6

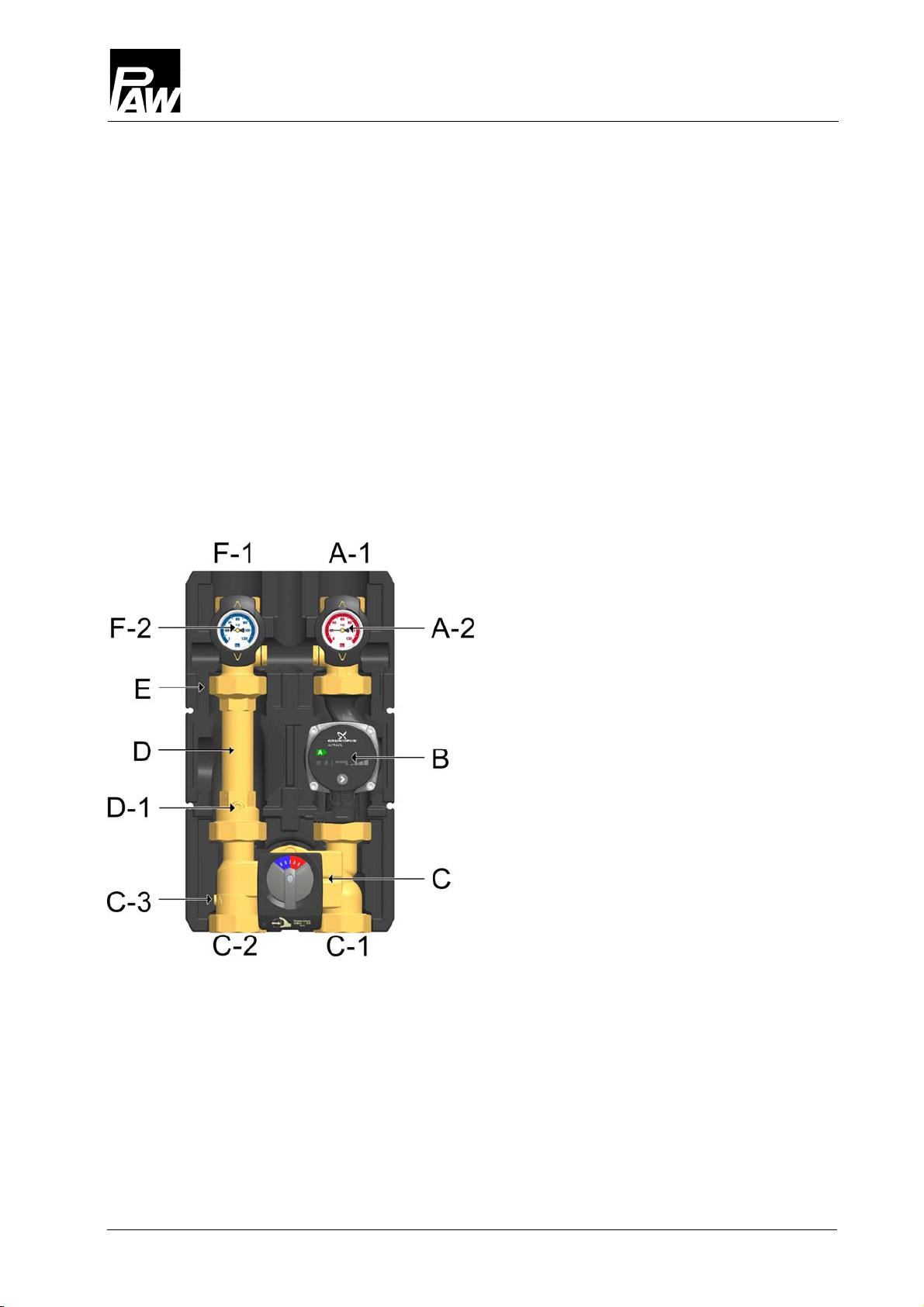

3.1Equipment ...................................................................................................................... 6

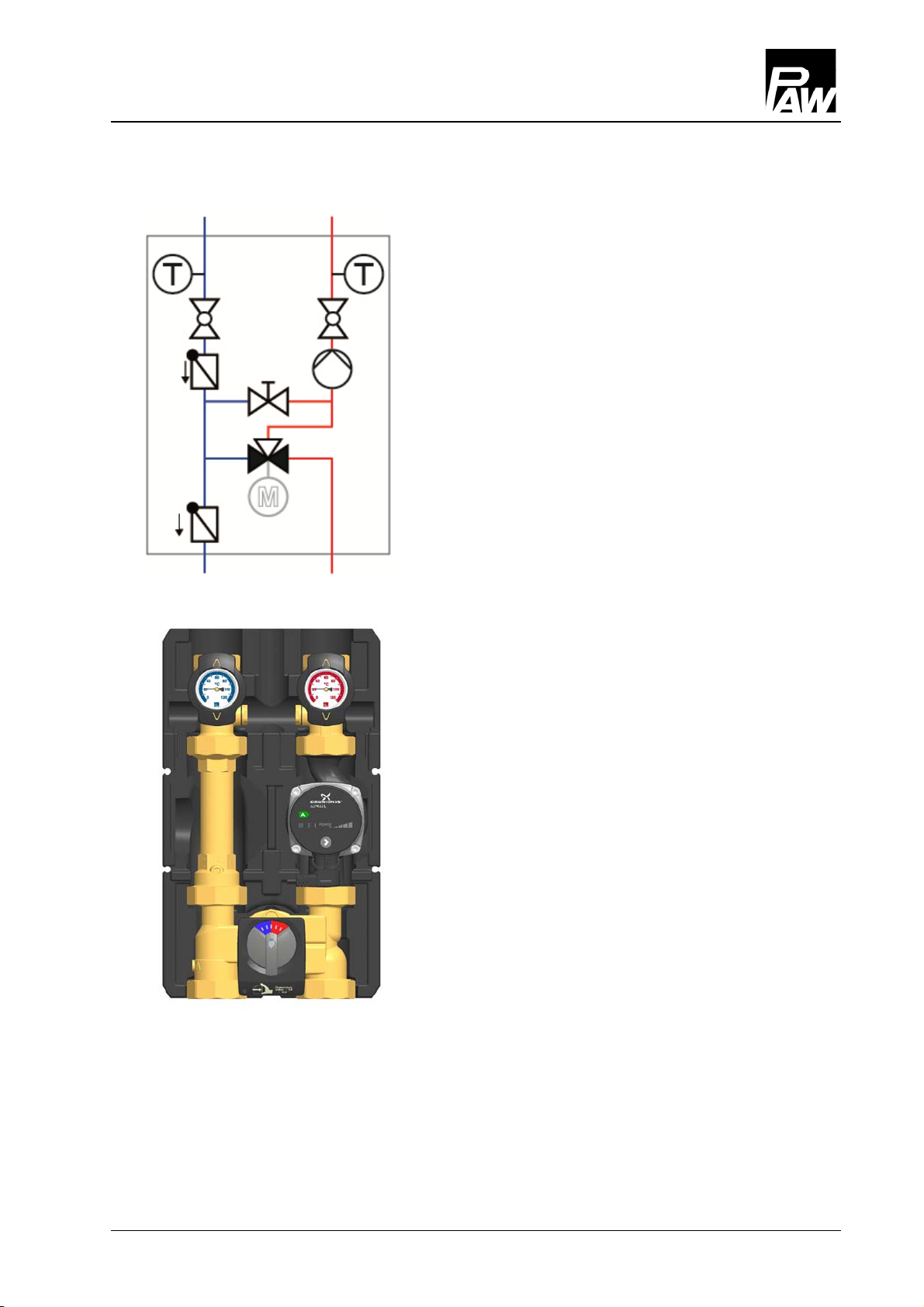

3.2Function ......................................................................................................................... 7

3.2.1Check valve and non return valve .......................................................................... 8

3.2.2Pump [specialist] ..................................................................................................... 9

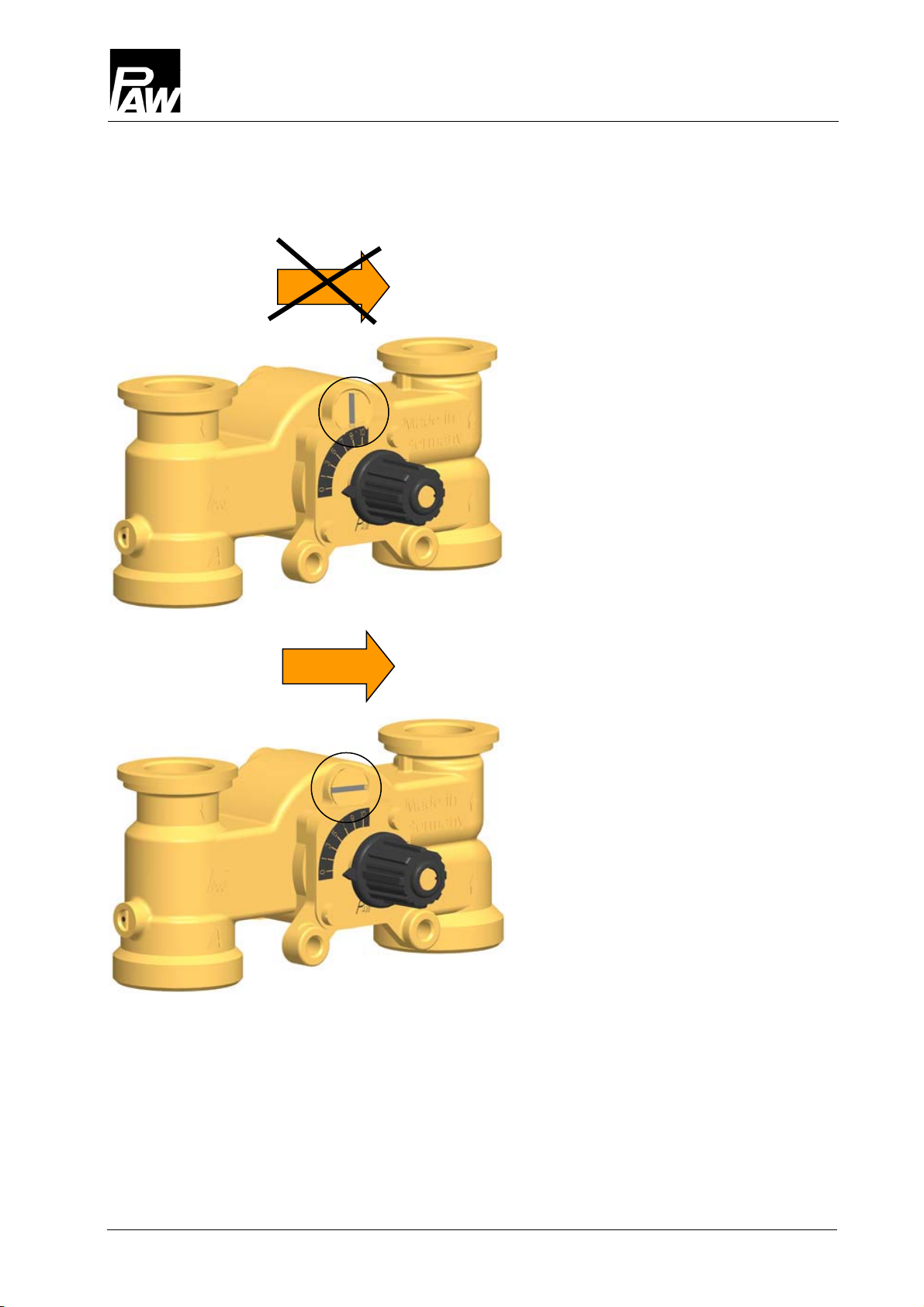

3.2.33-way mixing valve [specialist] ................................................................................ 9

3.2.4Accessories: actuator (not included in delivery) ................................................... 13

4Assembly and installation [specialist] ................................................................................ 14

4.1Installation of the modular distribution manifold / wall bracket with mounting plate ..... 14

4.2Installation of the HeatBloC and commissioning .......................................................... 15

5Scope of delivery [specialist] ............................................................................................. 17

6Technical data ................................................................................................................... 18

6.1Pump and pressure drop characteristics ..................................................................... 19