4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.7G-9/01

Page 3 of 25

Installation Tips

a. When installingtheseunits,itisimportantto comply with the most recently established

rulesandregulationsas deemed pertinent by thelocalandnational electrical, gas, ventilation,

sanitation,andfire codes. These units are classifiedbyUnderwriters Laboratories, Inc. as

Gas-FiredFoodService Equipment in accordancewith American National StandardsInstitute

ANSIZ83.11b-1991, Gas Food Service Equipment - Ranges andUnit Boilers.

b. Thesegasunitsmaynotbe directly connected to a gas flueorexhaust. However, the

unitsmayonlybeoperatedinconjunctionwithacanopytypeexhausthood.

c. Theroomwhere the units arebeinginstalled must be ventilatedinaccordance to the

validcodes and regulations.

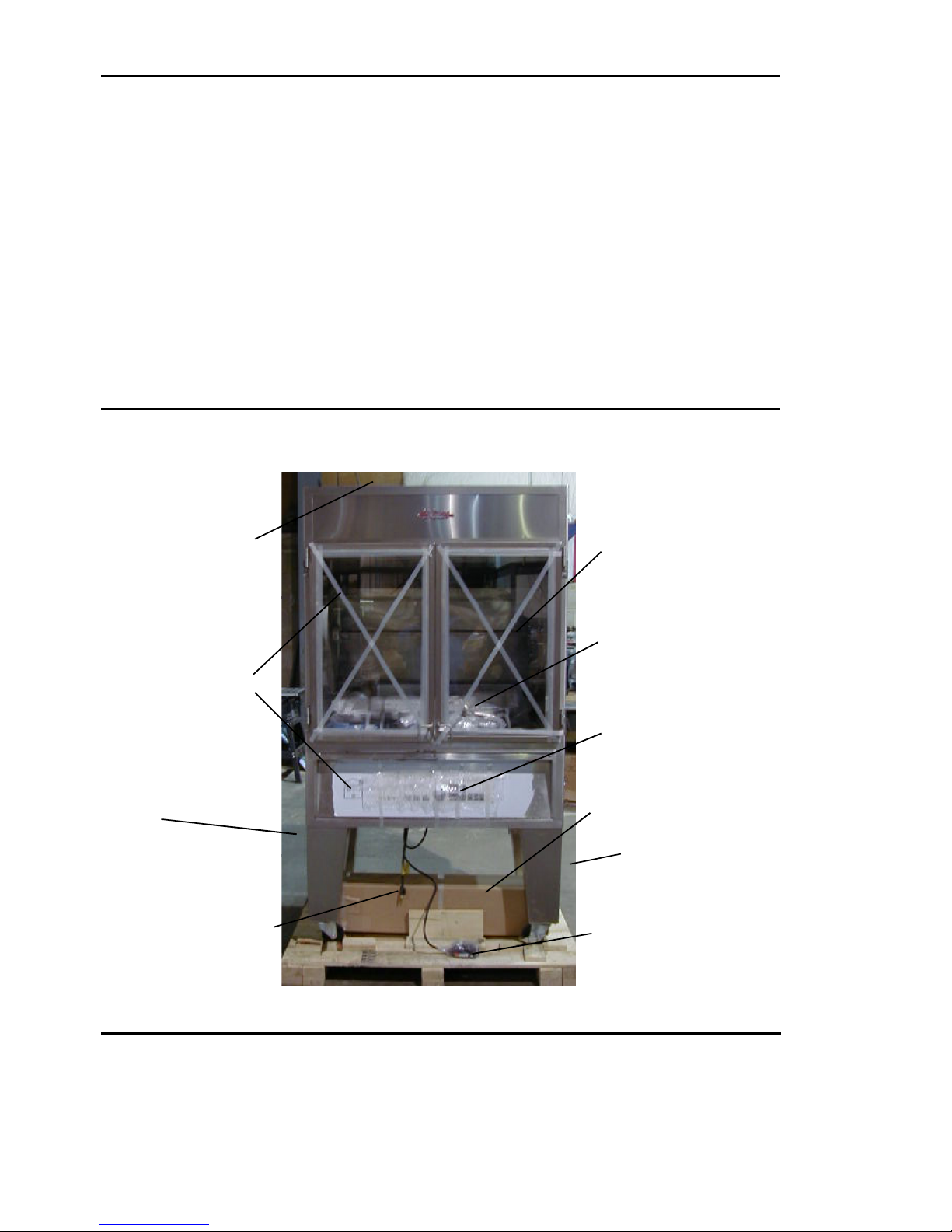

d. Theunitsaretobe installed securely and horizontally. The unitsmay be installed on

combustiblefloors.

e. Theminimum clearance to the rear or side walls must be 3 inches. It isalso important

toinsure that the bottomof the units iskept clear so thatproper ventilation or airexchange can

occur.

f. Normally,theunitswillbesent to the operator already setupfortheparticulartypeof

gasavailable at their location. However,unless otherwise specified, theunits will be setup for

naturalgasuse. Before installing and usingtheunits for the firsttime,it is important tomake

surethat the gastype and pressure indicated on the data plate matches the type of gas avail-

ablein the location. Should thisnot be the case,it is imperative tochange or convertthe units

tothe needed gastype.

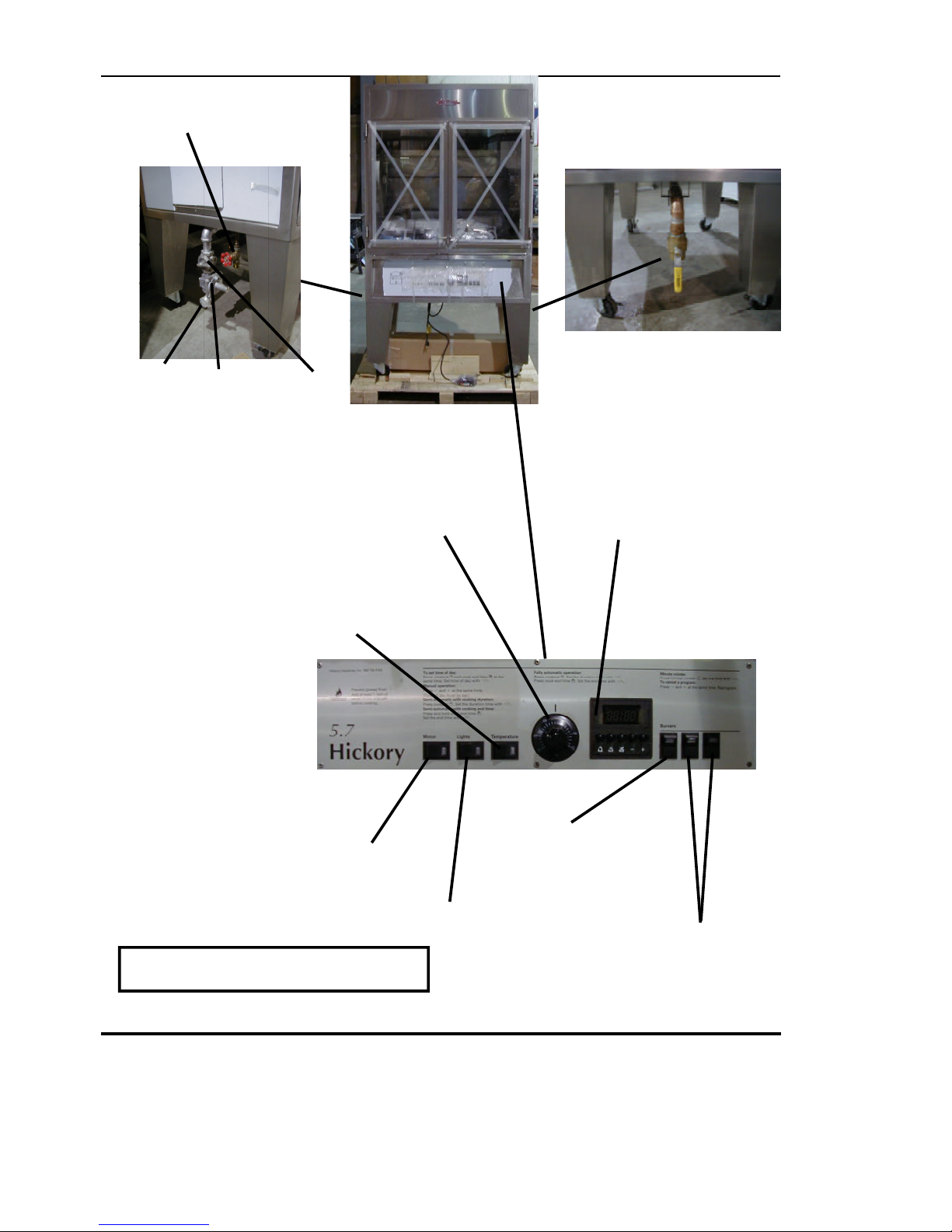

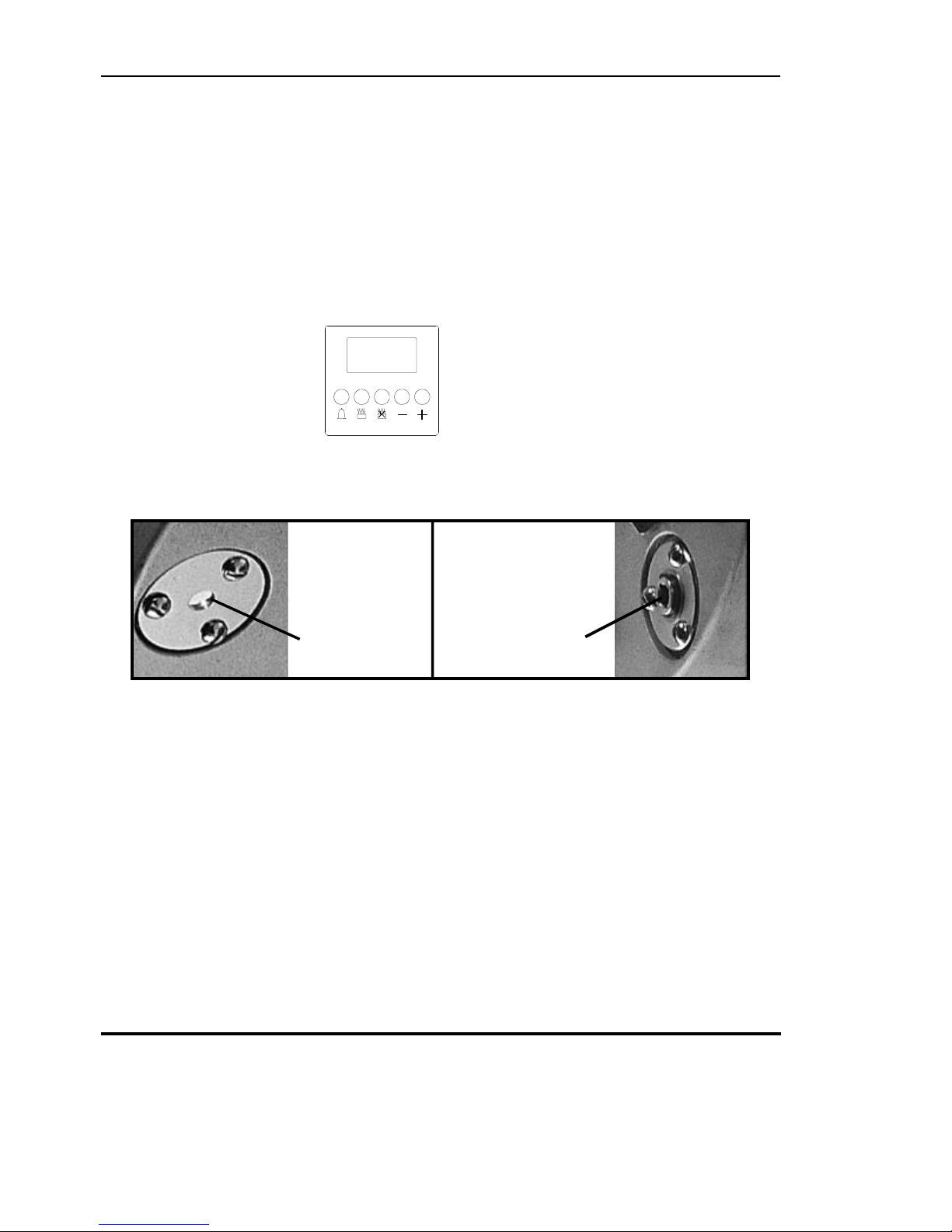

g. Theunitsmustbefittedwiththemanualshut-offgascock(valve)suppliedwiththe

machine. Thismanualvalve is needed to shutoffthe gas to the machineduringmaintenance

work,repairs, pressure testingand if the unit needs to be disconnectedfor any reason. DO

NOT REMOVE otherwise warranty will be voided.

h. Agas regulator is alsosupplied with the machine. This component is neededso that

theappropriategas pressure can beset and insure anoptimum operation of theunit. DO

NOT REMOVE otherwise warranty will be voided.

i. Wheninstallingthis unit with agasquick disconnect, a tetheringdevicemust be used.

j. Depending on local codes or if deemed necessary, a gas filter may also be required.

k. Doconnect the unit toa 1" gasline. Connecting the unit to a lesser linecan reduce the

unitseffectiveness or cause improperoperation.