Hickory Industries N/7.5E User manual

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 1 of 24

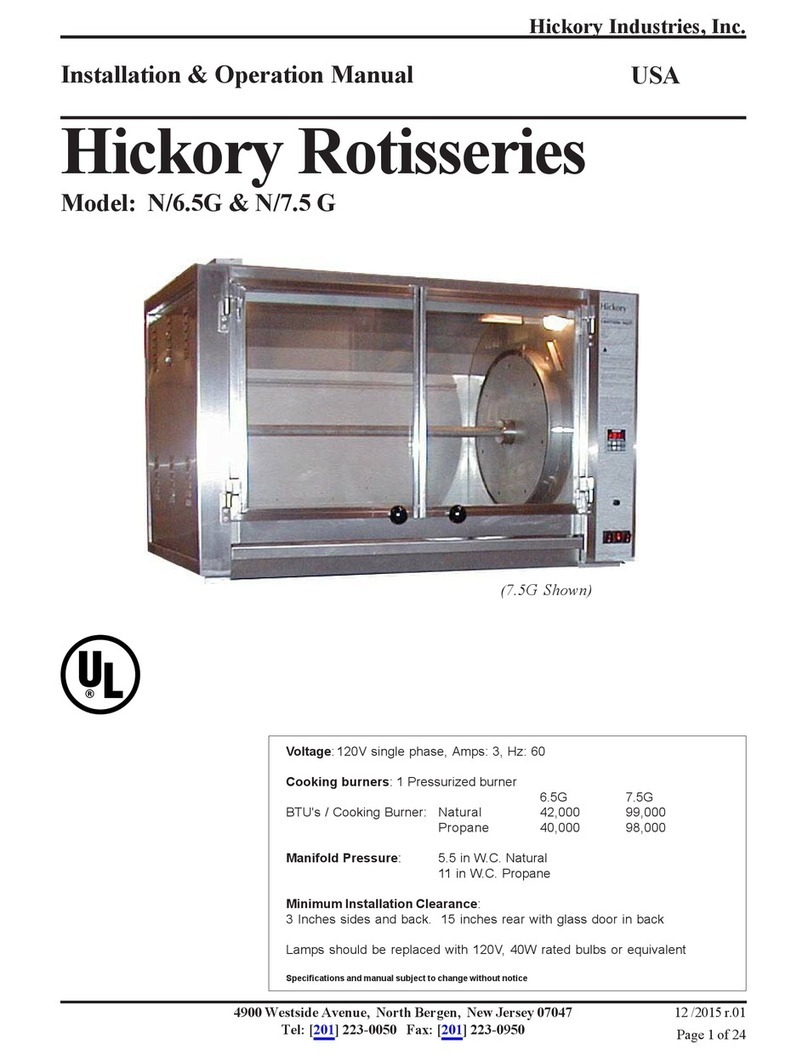

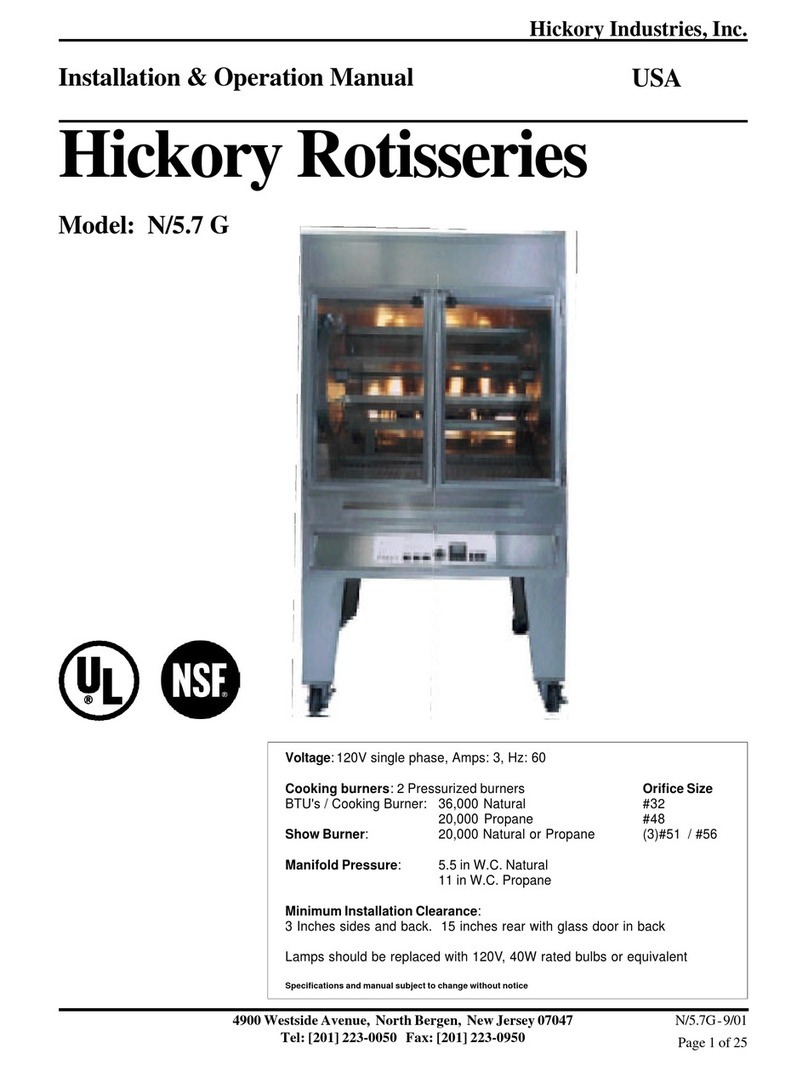

Hickory Rotisseries

USA

Installation & Operation Manual

Models: N/7.5E

N/14.5E (Shown)

Voltage: 208V, 3 phase, 5 Wire

Amperage Draw: Line 1 , Line 2 , Line 3 , Nueltral .

N/7.5E N/14.5E

Elements: 612

Watts Per Element: 2000 2000

Total Cooking Wattage: 12,000 24,000

Lighting: (2)25W (4)W

Lamps should be replaced with 120V, 25W, 300°C rated bulbs or equivalent

only.

Minimum Installation Clearance:

3 Inches sides, 6 inches rear.

Specifications and manual subject to change without notice

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 2 of 24

Table of Contents

Installation Tips .................................................. 3

Overview Of The Unit ......................................... 4

Unpacking The Unit ............................................ 5

Setting Up The Rotisserie .................................. 5

Control Panel Overview ...................................... 5

Spit Preparation Using Angle Spits .................... 6

Spit Preparation Using Spits & Skewers ............ 13

Daily Operation .................................................. 18

Cleaning ............................................................ 19

Thermometer Guidelines .................................... 20

Temperature Chart ............................................. 21

Do's and Don'ts ................................................. 22

Parts Diagram ................................................... 23

Electrical Diagram ............................................. 24

Warranty ............................................................ 25

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 3 of 24

Installation Tips

a. When installing these units, it is important to comply with

the most recently established rules and regulations as

deemed pertinent by the local and national electrical, ventila-

tion, sanitation, and fire codes. The Model 14.5E was tested

for safety by Intertek Testing Services ETL Semko.

b. Electric units normally do not require venting. The room

where the units are being installed must be ventilated in ac-

cordance to the valid codes and regulations.

c. The units are to be installed securely and horizontally.

The units may be installed on combustible floors.

d. The minimum clearance to the side walls must be 3

inches and 6" to the rear wall. It is also important to insure

that the bottom of the units is kept clear so that proper venti-

lation or air exchange can occur.

e. When installing the unit, ensure that a qualified

electricain performs the electrical connection. The unit re-

quires 208V three phase power with a nueltral and a ground.

f. After the unit is installed, ensure that the operator and or

installer reads the operating manual for proper operation.

g. After installation, when the unit is turned on, it may

smoke slightly. This is due to cleaning oils sprayed on the

unit prior to shipping. This is normal.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 4 of 24

Unpacking the unit:

a. After the unit is un-crated, roll the unit and all accessories into place.

b. Remove all vinyl paper from the stainless steel surfaces

c. Remove all tape from glass surfaces and metal surfaces

d. Carefully remove and inspect parts that are inside the unit. Ensure that all materials

sent with the crate are inspected:

Items that are sent with the unit are:

(extra parts vary from customer to customer)

Cooking Spits (7) Spits and skewers, Angle spits or thermowave spits.

Removable rear cleaning panel (2)

Ball Knobs (4)

Log Carrier (1) Installed on the rear burner

Thumbscrew Key (1) If sent with spits and skewers

Setting Up The Rotisserie

a. Clean, rinse and sanitize the spits. If baskets and accessories are ordered, clean and

sanitize as well.

b. Place the ball knobs on the doors.

Tighten firmly.

c. Place the removable rear panel on the rear of the unit.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 5 of 24

Motor Switch:

Turns motor ON / OFF

Light Switch:

Turns lights ON / OFF

Temperature Switch:

Turns heat ON / OFF Indicator is illuminated when the

thermostat calls for heat.

Thermostat:

Cycles heat ON and OFF during cooking.

Product that has marinades, citrus, rubs etc., may burn which can be

remedied by turning the thermostat at a lower temperature.

Timer:

Displays the time of day.

Allows the unit to cook and can

be used to shut the heat OFF

at the end of a cook.

TIMER NEEDS TO ON FOR

THE UNIT TO COOK

Timer (Upper)

Thermostat (Upper)

Switches

Fuse .5A (Protects

Lights and motors)

Control Panel Overview

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 6 of 24

Spitting Chickens

The most important part in getting started with a rotisserie is knowing how to properly spit the product.

This is quite easy, but it must be learned! As an operator, you will become an expert in spitting chickens

within half an hour! There are two types of commonly used spits: the angle spit and the regular spit. The

following pages describe and show how spitting is done with both these types of spits.

Figure 1. Chickens Ties

When using a “V” or angle spit, it is very important to tie

or truss the product being cooked. This prevents the

product from moving around the spit and also prevents

damage by preventing the legs and wings from flopping.

In this section, we will show how to properly truss a

chicken. It is important to use a tie to fit the size of the

product. In this case, we are tieing a 2 3/4lb. chicken

with a 6” tie.

Figure 2. Trussing Wings

With the back of the chicken facing up, take the tie and

wrap it around the breast, making sure to tuck the wings

against the breast. Pull on the tie as pictured. You will

also need to hold the chicken with your other hand.

Figure 3. Trussing Across Back

While pulling on the tie, cross the strings so that you

make an “X” across the back of the chicken. With the

“loop” in your hand, you will now need to tie the legs of

the chicken.

A. Using Angle Spits

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 7 of 24

Figure 4. Trussing Legs

While pulling on the tie, loop the strings over the legs of

the chicken.

Figure 5. Trussed Legs

Make sure that both legs are securely held by the tie.

Figure 6. Trussed wings

Make sure that both wings are securely held by the tie

against the breast of the chicken.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 8 of 24

Figure 7. Pop-up Thermometer

The only way to tell if a chicken is done is take

the internal temperature. Since it can be difficult

to probe the chickens while they are in the rotis-

serie, we recommend the use of pop-up ther-

mometer. These inexpensive items should be

place in the thickest part of the chicken, which is

the breast. The thermostat will “pop-out” when

the internal temperature reaches 185º F.

Figure 8. Chicken Ready to Spit

With the chicken trussed and the pop-up thermometer in

place, the chicken is ready to be spitted with an angle

spit.

Figure 9. Spitting Accessories

In order to make the use of the angle spits fast

and easy, we offer an accessory called a Spit

Holder (Hickory Part 195). This aluminum plate

offers six holes where the base (square-end) of

the angle spit can be inserted.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 9 of 24

Figure 10. Using the Angle Spit

Insert the bottom (square-end) of the spit into one of the

holes in the Spit Holder.

Figure 12. Chicken Position on Spit

When spitting the chicken, make sure that the breast is

sitting on the flat, exterior side of the spit. Notice on the

picture how the breast is not directly on the rounded

corner of the spit, but above one of the flat parts of the

“V”. It is also important to note that the legs (and the

tie) must sit on the same flat side of the spit. This picture

shows exactly how the chicken should look when

spitted.

Figure 11. Spitting a Chicken

Spit the chicken through the cavity. The chicken should

be inserted through the “head” (or at least where the

head used to be) first.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 10 of 24

Figure 13. Incorrectly Spitted Chicken

This picture shows a chicken with the legs improperly

placed. Note how the chicken seems to hang to one

side. When spitted this way, the chickens will tend to

“bounce” up and down causing the chicken to breakup.

Figure 14. Complete Spit

After inserting the first chicken, push it all the way to the

bottom of the spit and add the next chicken. Depending

on the size of the birds and on the rotisserie model, each

spit will accommodate three to four 2 3/4lb. chickens.

Once completed, the spit is ready to be placed in the

rotisserie.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 11 of 24

Figure 15. Inserting Single Bottom Skewer

Attach a single skewer with a thumb screw at least 1/2"

fromthesquareendofthespit. Theskewermustbeonthe

round section of the spit.

Figure 16. Fastening Bottom Skewer

Usethe"T" shapedtoolsuppliedwith theunittotighten the

thumb screw. This will prevent the bottom skewer from

slidingoffthescrew.

Figure 17. Using the Spit Holder

Even though the chickens can be spitted on a work table,

theuseofthe Spit Holder (HickoryPart195)willmakethe

spittingprocessmucheasier.

B. Using Regular Spits

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 12 of 24

Figure 19. Tucking the Legs

The legs must be tucked between the skewer prongs

and the center spit. Note that the bottom of the drum-

stick is what is being locked in place.

Figure 20. Pressing Chicken Towards Skewer

When viewed from the breast side of the chicken, the

bottom of the drumstick is being pushed back while the

meaty part of the leg is “puffed up” for better presenta-

tion. Note that the skewer is not going straight through

the drumstick!

Figure 18. Inserting Chicken

Takethechicken,withthedrumsticksinthedirectionofthe

attachedskewer,andslide thespitthroughthe cavity ofthe

chicken.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 13 of 24

Figure 21. Locking Wings

The wings must be locked or tucked in place. When

using the models N/5.5 and N/10.10, the locking

method (pictured here) is only recommended with

birds up to 2¾lbs! With larger birds, the wings must

be tucked under the breast, with elastic ties or “wing

tuckers”. If the wings are locked on large birds, the

wings on the adjacent spits will rub or catch, preventing

the spits from rotating freely. This will cause the wings

to break off or the gear mechanism to jam.

Figure 22. Tucking Wings

With larger birds, the wings must be tucked under the

breast, with elastic ties or “wing tuckers”.

Figure 23. Tucked Wings

Notice how the wings are tucked against the breast. By

“tucking” instead of “locking” the wings, the working or

rotating diameter of the chicken has been reduced.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 14 of 24

Figure 24. Inserting Double Skewers

With the first chicken in place, insert a double skewer

down the length of the spit into the shoulders of the first

chicken. No thumb screw is required for the double

skewers!

WARNING! When driving the double skewer

into the chicken, do not exert pressure from the

end of the prongs! These are sharp and will pierce

a finger or hand if not careful. Only apply

pressure at the bottom of the "U" shaped half of

the skewer!

Figure 25. Double Skewer in Place

With the double skewer in place, insert the next chicken

down the length of the spit and position the chicken as

previouslydescribed.

Figure 26. Loaded Spit

When the loading of the chickens is complete, the end

of the spit must be locked in place with another single

skewer.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 15 of 24

Figure 13. Completing the Load

Slide a single skewer with a thumb screw into place

from the top,

Figure 14. Tightening Final Skewer

Compress the chickens by exerting pressure on this last

skewer, and tighten the thumb screw securely.

Figure 15. Securing the Load

Tighten the thumb screws with Hickory's thumbscrew

tightening tool. This will prevent the chickens from

coming loose.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 16 of 24

Hickory Timer Tips

Timer

Setting / Resetting the Time of Day

In the event of a power failure the timer display will be flashing. To reset the Time of Day,

press both buttons "B" & "C" simultaneously and while holding these buttons depressed;

toggle the plus and minus buttons "D" & "E" to set the time of day.

Entering Manual Mode

To insure that the timer does not interrupt the cooking cycle(s), you must make sure that the

cook pot symbol is always illuminated on the timer. No other icons should be illuminate i.e.

a steady or flashing "A". To enter this manual mode; press both buttons "B" & "C"

simultaneously. This will clear any accidental programming stored in the timer and place

the timer into the manual cooking mode.

Bell/Time Function

To use the timer as a count down timer; press and release the bell button "A". Immediately

press the plus (+) button "E" and set the cook time desired. (i.e. 1hr 30 minutes). After the

time has elapsed, the timer will beep. You can add additional time by repeating the above-

mentioned process. You can also decrease the cooking time by pressing the minus (-)

button "D" instead of the plus button "E".

Louder Beep/Buzzer

Occasionally, if the wrong button is depressed it will quiet the beep/buzzer. The audible

tone may change to a much lower tone. To get the loudest tone available; press both the

plus (+) and minus (-) buttons "D" & "E" simultaneously. Continue to press and release

both buttons until you have reached the desired tone. The unit is programmed with one

loud and two low tones.

Silencing the Beep/Buzzer

Press the bell button "A".

9: 00

A B C D E

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 17 of 24

Cooking Preparations

Morning Preparation:

1. Cover the center shaft with aluminum foil.

2. Add water into upper and lower drip pans (approximately one inch of water should be

sufficient. If the unit will be in operation all day, you may need to add more water

accordingly.).

3. Be sure to spray the non-cooking components of the oven with Kote™. (Spray the

interior walls; drums and the rear wall with USDA and FDA approved KOTE™.

4. Preheat the oven to desired temperature.

Cooking Preparations:

9: 00

A B C D E

1. Be sure that the rotisserie has been preheated.

2. Using the motor switch, stop the rotation of the drums, open the glass doors and place the

spitted product in the rotisserie. The pointy end of the spit goes to the right and the

square end of the spit goes towards the left.

Left side Right side

Square hole Round

3. Advance the drum until the unit is loaded.

4. Close the glass doors.

5. Be sure that the timer is set to cook. By pressing both the cook pot ("B") and cook pot off

("C") buttons simultaneously you will place the unit into the manual-cooking mode. The cook

pot symbol on the timer will illuminate.

6. Turn your temperature switch on and verify the thermostat setting. If the timer is set

properly, the temperature switch will be illuminated. This indicator will only glow when the

unit calls for heat.

7. Press the bell/chime button ("A") and then press the + button ("E") to set the desired cooking

time in hours and minutes.

8. After the programmed time has elapsed, the timer will beep, but the cooking process will

continue. Always check the product’s internal temperature and ensure that they are at least

180°F. If the product needs additional time to cook, you can do so by pressing the cook pot

symbol ("B") and then pressing the + button ("E").

9. If product is fully cooked, shut off the temperature switch, remove the product from the oven

and package accordingly. Take care not to allow the product temperatures to fall below

critical temperatures.

10. To start a new load, follow step #1 through #7. REMINDER: If possible, wipe the glass

down with approved glass cleaner between cooking loads. This will facilitate end of

day cleaning.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 18 of 24

Cleaning:

1. Shut off all switches.

2. Allow oven cool down. Please note - if the lights are not shut off, the lamp guards may break

when spraying the oven with cool water.

3. Remove the aluminum foil from the center shaft.

4. Pull the upper drip pan and drain drain the contents of the drip pan by removing the drip pan plug.

Repeat with the lowerdrip pan. DO NOT drain grease into the sink. We recommend that the

drippings are placed in a bucket, cooled down and then skimmed off and placed in fat rendering

tanks.

5. Pour some warm water into the drip pan and wipe the oven surfaces with a rag using the soapy

solution; the Kote coating and the fat that has adhered to the Kote will remove very easily. If the

unit was not sprayed with Kote, appropriate degreasers / cleaner will be required. Take care not

to spray aggresive cleaners on the elements and lamp guards.

6. When finished cleaning the oven, drain the soapy solution from the drip pan and wipe the drip

pan clean.

7. Wipe the glass with a glass cleaning solution. DO NOT USE RAZOR BLADES, SCOURING

PADS OR ANYTHING ABRASIVE TO CLEAN THE GLASS. To minimize grease from baking

on the glass, during the day should wipe the glass before loading product in the unit.

8. Place the spits and skewers and/or baskets in a hot soapy solution. Soak for 15 - 20 minutes –

this will loosen the baked on residue. If you have basket spits, brush the baskets clean with a

scrubbing brush. Follow guidelines for rinsing and sanitizing.

9. Recommendation – Place aluminum foil on the the center shaft, spray the oven down with

KOTE™and fill the drip pan with water in preperation for tomorrow’s cooking cycle. Kote can be

ordered thru Kay Chemicals @ 800-333-4300

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 19 of 24

Thermometer Guidelines

When checking product temperature, ensure that you have a calibrated thermometer. A good

thermometer should be 1/8" thick and about 6 inches long. The thermometer should not have a

dimple. If it does, this is where the thermometer actually measures temperature. This dimple must

be placed in the thigh area.

Dimple Thermometer Dimpleless Thermometer

The thermometer should have an easily readable scale. It also should be calibrated using

manufacturers recommendation.

Readable scale 0-500 recommended Calibrating nut

When checking for product temperature, insert your thermometer into the meatiest part of the

product. When testing chickens, the thermometer should be inserted into the leg and thigh area and

it should read 180 to 185 degrees F.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/14.5E - 6/15/04

Page 20 of 24

Temperature Chart

Product Internal Temperature

Poultry 185F

Beef 135-140F Rare

150F Medium

160F Well

Lamb 140F Rare

150F Medium

160F Well

Pork 160F Medium

170F Well

This manual suits for next models

1

Table of contents

Other Hickory Industries Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use