Blake Water Solutions Specialist Series Guide

XOWSEEAIO REV 06/2018

OPERATION AND INSTRUCTION MANUAL

SPECIALIST SERIES AERATION FILTER SYSTEM

For Residential Filter Systems with Clack WS1EE (4 Button) AIO Control Valve

www.blakeequip.com

Peak Performance Solutions

Integrity Excellence Teamwork Innovation

Index

Introduction / Installation Requirements

Page 1

Installation & Commissioning

Page 2

Filtration Media Loading

Page 3

Backwash / Regeneration Cycles

Page 4

Bypass Valve

Page 5

Controller

Page 6

Programming: Setting Time of Day / Installer Settings

Page 8

Programming: System Setup

Page 9

Replacement Parts

Page 10

Filtration Media Overview

Page 11

1 of 11

Integrity Excellence Teamwork Innovation

Introduction

Blake Water Solutions’ Specialist Series™ point-of-entry (POE) Aerating Iron Oxidizer (AIO) filter systems function as a

regenerable water treatment unit utilizing oxygen instead of potentially harmful chemicals to rejuvenate and enhance the

performance of the selective filtration media. The filtration media provided is specific to the water contaminant or contaminants

that your water treatment specialist has identified.

The AIO system utilizes the Clack WS1EE control valve equipped with air injection capability to remove ferrous (or clear water)

iron, manganese, and sulfur from the water by both oxidation and filtration. During the regeneration cycle, an air bubble is

established in the head space of the filter tank above the media. Then, during service, as untreated water enters the tank, it mixes

with the air. Oxygen present in the air oxidizes some of the iron and managese that are present in the water, causing them to

precipitate into particles which become trapped in the filter media. The remaining dissolved iron and manganese precipitate out in

the filter bed as they are oxidized by the catalytic reactions occurring on the media surface.

Unlike other iron filter alternatives, the Clack WS1EE AIO technology is designed for use in a single tank / valve system

configuration, reducing both installation and maintenance costs, yet delivering years of trouble-free service. No chemical additives

or air compressors are required for operation or regeneration with the Clack WS1EE AIO’s unique and advanced design.

Do not install this system if methane is present in the water - DANGEROUS DEADLY GAS CAN ACCUMULATE

This system is not intended to be used for treating water that is microbiologically

unsafe or of unknown quality without adequate disinfection before or after the system.

Installation Requirements

WATER PRESSURE: A least 30 psi of water pressure (2.7bar) is required for the injector to draw air and operate effectively.

CAUTION: Water pressure must not exceed 80psi (5.5 bars), water temperature is not to exceed 110°F (43°C), and the unit cannot

be subjected to freezing conditions.

NOTE: Due to the air pocket, exceeding 80PSI will adversely impact performance.

ELECTRICAL FACILITIES: An uninterrupted 120 VAC supply is required. The valve is supplied with a 12 VAC transformer.

Please make sure your voltage supply is compatible with your unit before installation.

EXISTING PLUMBING: Condition of existing plumbing should be free from scale and iron buildup. Piping that is built up heavily

with scale and/or iron should be replaced.

LOCATION OF FILTER AND DRAIN: The filter should be located close to a drain to prevent air breaks and back flow.

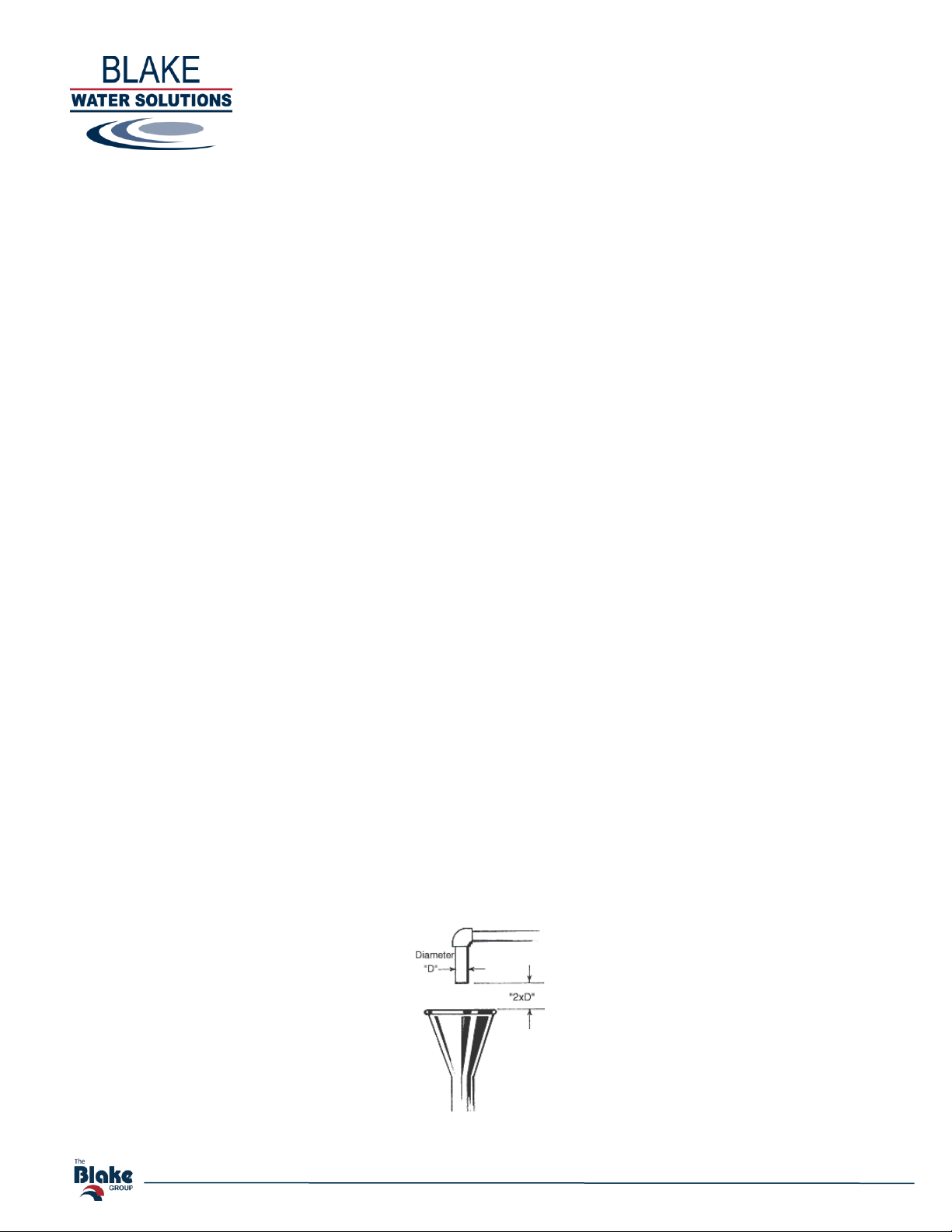

DRAIN AIR GAP: Always provide the proper air gap distance of two drain pipe diameters.

2 of 11

Integrity Excellence Teamwork Innovation

Installation & Commissioning

1. Note this system is supplied without media installed for ease of transportation and simplifying site location. Refer to the

section of this manual for Media Filtration Installation Guide/Commissioning.

2. Place the tank where you want to install the unit making sure the unit is level and on a firm base.

3. During cold weather, the installer should warm the valve to room temperature before operating.

4. All plumbing must be done in accordance with local plumbing codes. The pipe size for residential drain line should be a

minimum of 1/2” (13 mm). Backwash flow rates in excess of 7 gpm or length in excess of 20’ require 3/4” drain line.

Commercial drain lines should be the same size as the drain line flow control. Due to the release of the air during

regeneration, the drain line must be secured at the end, and anchored throughout the run.

5. Ensure that the check valve supplied with the AIO control valve is securely installed inside the control valve inlet. This is

required to prevent the pressurized air bubble inside the oxidizer tank from venting backwards up the feed water plumbing.

6. If not factory installed assemble the deflector to the distributor tube:

Put a thin layer of silicone lube around inside diameter of the deflector. Slowly slide the deflector over the distributor tube

down about 1”. When threading the AIO valve to the tank, the bottom of the threads will slide the deflector down. As

shown below.

7. Lubricate the distributor O-ring and tank O-ring. Place the main control valve on tank. Note: Only use silicone lubricant.

8. Solder joints near the inlet / outlet / drain must be done prior to making thoses connections. Leave at least 6” (15 cm)

between the inlet / outlet / drain fittings and solder joints when soldering pipes that are connected. Failure to do this could

cause interior damage to the fitting.

9. Teflon® tape is the only sealant to be used on the drain fitting. Do not use pipe dope or other compounds as they contain

petrochemical elements and will attack the drain housing and cause failure.

10. Place the bypass valve in the by-pass position (see page 6). Turn on the main water supply. Open a cold filtered water tap

nearby and let run a few minutes or until the system is free from foreign material (usually solder) that may have resulted

from the installation. Once clean, close the water tap.

11. Refer to Filtration Media Loading on page 12.

12. Plug unit transformer into an electrical outlet. Note: All electrical connections must be connected according to local codes.

Be certain the outlet is continually powered (unswitched/uninterrupted).

13. Connect Raw Water Inlet / Treated Water Outlet to control valve as indicated by the embossed direction arrows.

14. Set the current time on the UF Controller. Refer to Setting Time of Day on page 10.

3 of 11

Integrity Excellence Teamwork Innovation

Filtration Media Loading

Media filtration systems supplied by Blake Water Solutions are shipped without the media preloaded.

Aeration/Oxidation filtration media selected for Iron, Manganese, Hydrogen Sulfide removal or (other conditions your equipment

supplier has identified) are dependent on many factors and are carefully selected and applied based on reported water conditions at

the time of testing. Variables such as pH changes, changes in mineral concentration, unreported water contaminants as well as

increased flow and usage rates may affect the performance of this system.

1. With the bypass valve in the bypass position disconnect the control valve from the bypass valve and remove the control valve

from the mineral tank. Care should be exercised to avoid damage to the distribution tube and screen while loading the selected

media for the application.

2. Plug the open end of the riser tube to ensure that no filtration media or gravel falls down into the riser tube. The riser tube should

be firmly seated and centered in the tank and should be flush with the top of the tank opening (or tank top bushing if required).

Underbed support gravel if required should be pre-rinsed to remove fines and grit which could clog the screens and then carefully

loaded covering the distributor basket. Adding a sufficient amount of water (approximately 6” above the distributor) to the vessel

prior to adding the gravel will minimize the potential for damage and help to level the support bed.

3. Next load the required amount of media selected for the application. Again, adding additional water to the vessel will assist in

loading by minimizing dust and optimize leveling.

4. Unplug the riser tube, carefully position the valve over it and turn the valve into the threads in the fiberglass tank, tightening

securely into tank and secure to the existing piping bypass.

Note: Ensure that the internal O-ring in the valve fits securely over the riser tube.

Silicone lubricant should be applied to the O-ring to ease installation of the riser tube.

DO NOT use petroleum based lubricants as they will cause swelling of O-ring seals.

The bypass valve supplied with the equipment should still be in the bypass position and the filter tank can now be completely filled

with water by depressing REGEN on the control valve to initiate backwash and slowly opening the bypass to fill the tank with water

and purge any air. Once filled and purged of air the bypass should be returned to the bypass position. The valve controller can now

be cycled back to the service position. This step will allow the media to absorb water and will reduce the chance of backwashing

media out of the tank during the initial backwash on final start-up. Once the media is sufficiently hydrated the system regeneration

cycle should be initiated and the bypass valve slowly opened as the valve cycles into backwash. The backwash cycle should

continue unit the water runs clear. The valve can now be cycled to service and the bypass valve opened allowing treated water to

enter the household piping.

Caution: most Medias including, but not limited to, Carbon, Filter Ag, and Chemsorb require hydration prior to being put

into service as they are shipped dry. A minimum of 4 hours presoak, but preferably overnight saturation is recommended to

condition any newly installed media for service.

4 of 11

Integrity Excellence Teamwork Innovation

Backwash / Regeneration Cycle

The AIO filter is factory preset to backwash / regenerate every third day at 12:30 am. Only untreated water is available during

backwash / regeneration. A complete backwash / regeneration cycle lasts approximately 50 minutes, after which filtered water

service is restored. Homeowners with waters that contain very heavy iron / manganese loading may experience loss of pressure

and/or flow if too much water is filtered between backwash cycles. In this case, the backwash frequency may be reduced to every

other day (or every day in extreme cases). It is not recommend to operate more than 3 days between backwash cycles.

1. Backwash (10 minutes):

The valve piston will drive to the backwash position. Only unfiltered water is available during backwash.

Initially, what remains of the air bubble will be released to drain (the sound of air being released can be heard). Unfiltered raw water

will flow into the control valve through the inlet, down the riser tube, out the distribution basket, and up through the media. This

will fluidize and expand the media bed allowing oxidized iron and manganese and any other particles that were trapped during

service to be dislodged from the media and flushed to drain. The media is also de-compacted and readied for the the air injection

step. After the 10 minutes of flow to drain, the valve piston will drive to the draw position.

The Backwash step can be lengthened, if necessary, but it should never be shortened.

2. Air Recharge (40 minutes):

During this cycle, water flows to drain, creating a suction which allows air to be drawn into the filter. The air forces most of the

water out of the tank allowing the catalytic surface of the media to be recharged with oxygen from the air. The sound of air being

recharged will be heard. Air bubbles should go down to the drain before proceeding to the next step.

After the 40 minutes of air draw, the valve piston will drive back to the service position. As water begins to refill the tank, it will

compress the air and reestablish the air bubble in the top of the tank. Filtered water is available once again. The first draw of treated

water after regeneration may have a milky or cloudy appearance but this will dissipate quickly. It is just a bit of excess air in the

water.

The Air Recharge step can be lengthened, if necessary, but it should never be shortened.

3. Second Backwash (OFF)

4. Rinse (OFF)

Default is Off, but can be set to 1 or 2 minutes. Keep in mind that the longer the rinse cycle, the smaller the air bubble will be.

5. Fill (OFF)

5 of 11

Integrity Excellence Teamwork Innovation

Bypass Valve

The bypass valve can isolate the control valve from the plumbing system in order to perform repairs or maintenance. The bypass

consists of two interchangeable plug valves that are operated independently by red arrow-shaped handles. The handles identify the

flow direction of the water. The plug valves enable the bypass valve to operate in four positions.

1. Normal Operation: The inlet and outlet handles point in the direction of flow indicated by the engraved arrows on the

control valve. Water flows through the control valve during normal operation and this position also allows the control

valve to isolate the media bed during the backwash / regeneration cycle.

2. Bypass Operation: The inlet and outlet handles point to the center of the bypass, the control valve is isolated from the

water pressure contained in the plumbing system. Untreated water is supplied to the plumbing system.

3. Diagnostic Mode: The inlet handle points in the direction of flow and the outlet handle points to the center of bypass valve,

system water pressure is allowed to the control valve and the plumbing system while not allowing water to exit from the

control valve to the plumbing.

4. Shut Off Mode: The inlet handle points to the center of the bypass valve and the outlet handle points in the direction of

flow, the water is shut off to the plumbing system. If water is available on the outlet side of the softener it is an indication

of water bypass around the system (i.e. plumbing somewhere in the building bypasses the system).

6 of 11

Integrity Excellence Teamwork Innovation

Controller

Control Operation During Service

One of five displays is shown. Pressing NEXT alternates between displays.

User 1 - Displays gallons until backwash (not shown if set for time-clock operation).

User 2 - Displays number of days until next backwash.

User 3 - Displays present flow rate in gallons per minute (always reads 0 because no meter is installed).

User 4 - Displays total volume in gallons since last reset (always reads 0 because no meter is installed).

User 5 - Shows current time.

7 of 11

Integrity Excellence Teamwork Innovation

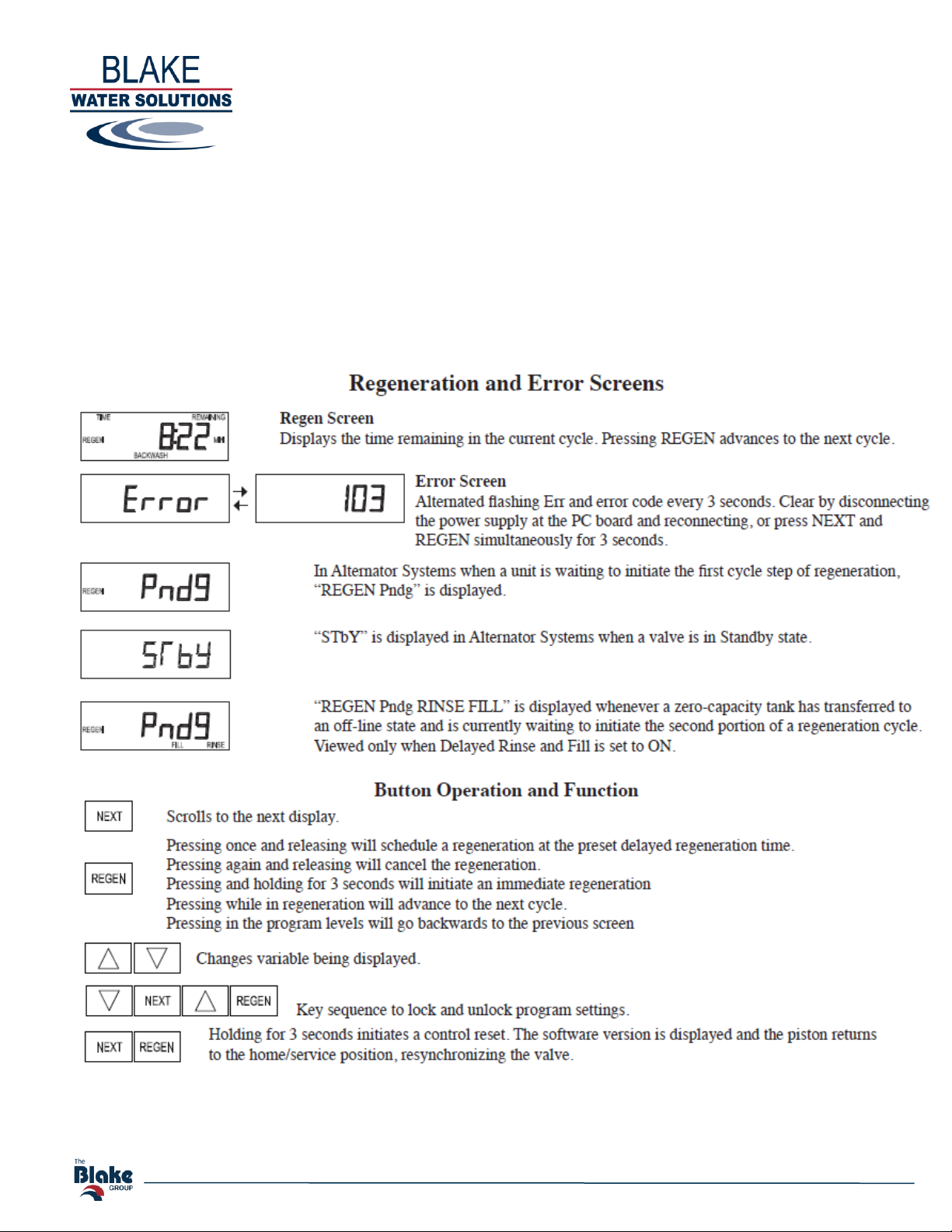

Control Operation during Backwash / Regeneration

During regeneration, the control displays the time remaining in the step that the valve is either advancing to, or has reached. The

step time flashes until the valve completes driving to that step. Once all steps are complete the valve returns to service / normal

operation. Pressing the REGEN button during regeneration advances the valve to the next step.

Control Operation during Programming

The control can only enter the Programming Mode with the valve in service. While in the Programming Mode, the control

continues to monitor water usage and time. Control programming settings are permanently stored in nonvolatile memory.

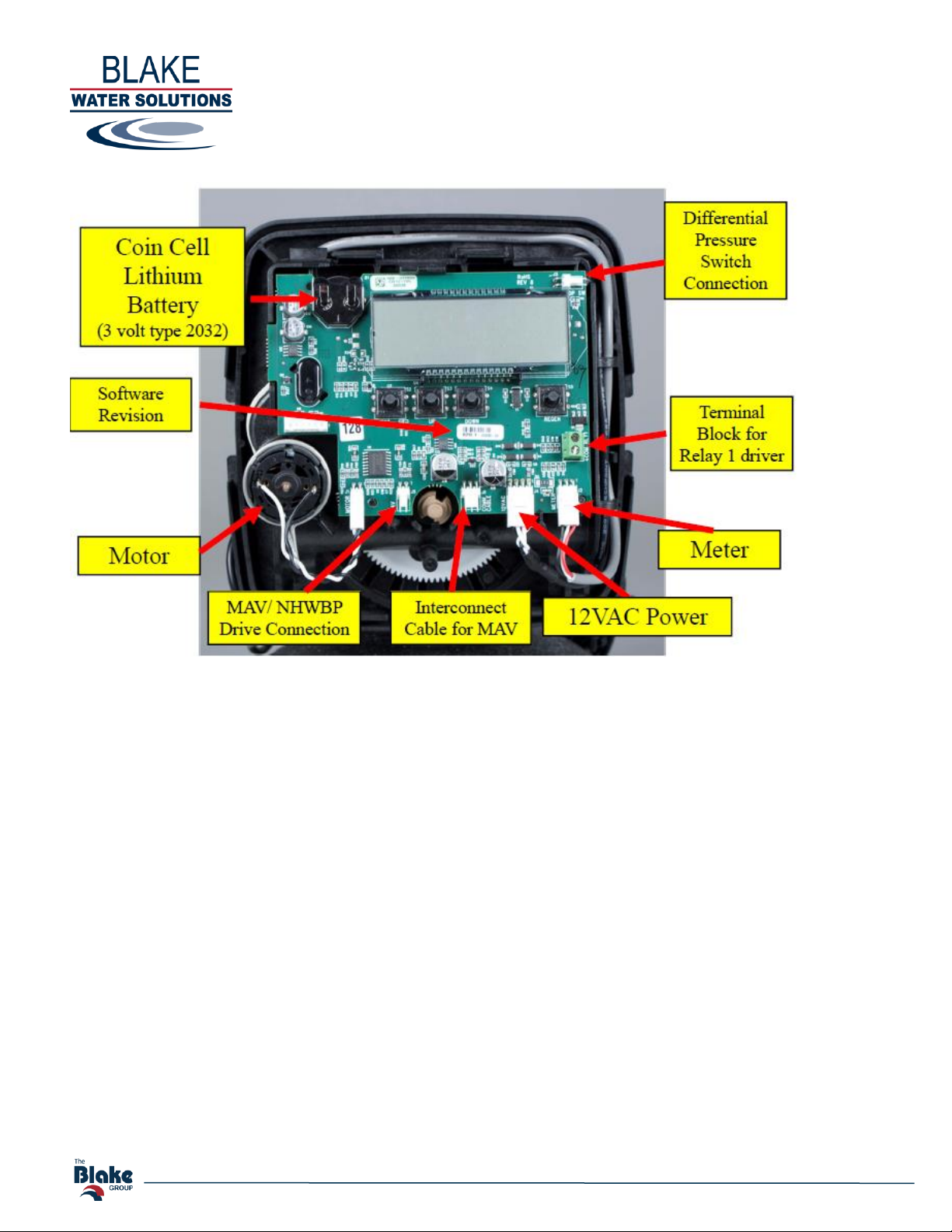

Control Operation during a Power Failure

The control valve includes a coin cell backup battery. In the event of power failure, the control shifts into power-saving mode and

stops monitoring water usage. The display and motor shut down, but the control continues to keep track of the time for

approximately 8 hours. System configuration settings are stored indefinitely in non-volatile memory. The Time of Day flashes

after a power failure. Press any button to stop the flashing. Reset time if necessary.

If power fails while the unit is in regeneration, the control will save the current valve position. When power is restored, the control

will resume the regen cycle from the point where power failed. The installation should include all required safety components to

prevent overflows resulting from a power failure during regeneration. The control will not start regeneration cycle without power.

8 of 11

Integrity Excellence Teamwork Innovation

Programming Screens

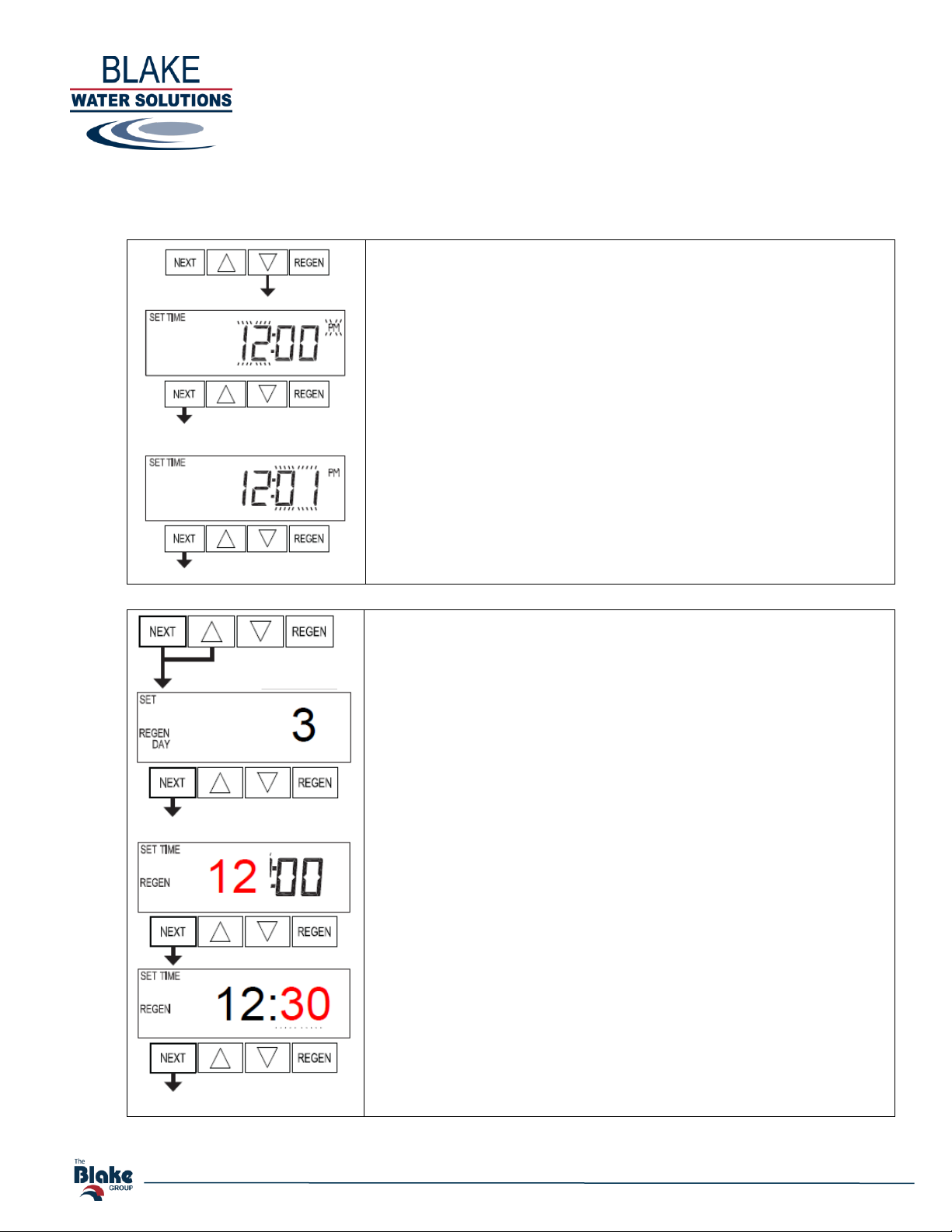

Setting Time of Day

Push NEXT until time of day screen is displayed.

Press and hold ▼ until SET TIME is displayed and the hour flashes.

Press ▲ or ▼ until the correct hour is displayed.

Then press NEXT. The minutes will flash. Press ▲ or ▼ until the

correct minute is displayed.

Press NEXT to return to the User Displays.

In the event of a power outage that is less than 8 hours, the control

valve will remember all settings and time of day.

After 8 hours, the only item that needs to be reset is the time of day

(indicated by the time of day flashing). All other settings are

permanently stored in the control valve’s nonvolatile memory.

If a power loss occurs that is less than 8 hours and the time of day

flashes, this indicates that the battery is depleted. The time of day

should be reset and the non-rechargeable battery should be replaced.

The battery is a 3 Volt Lithium Coin Cell type 2032. Time of day

should be reset when Daylight Savings Time starts / ends.

Installer Settings

To enter Installer Display press NEXT and ▲ simultaneously for

about 5 seconds and release.

Day Override: sets the number of days between regenerations. Set

Day Override using ▲or ▼(1 to 28). Default is 3 Days

Press NEXT to go to step 3I. Press REGEN to return to previous

step.

Regeneration Time (hour): Set the hour of day for regeneration

using ▲or ▼. The default time is 12:30 am.

Press NEXT to go to step 4I. Press REGEN to return to previous

step.

Regeneration Time (minutes): Set the minutes of day for

regeneration using ▲or ▼. The default time is 12:30 am.

Press NEXT to exit Installer Display Settings. Press REGEN to

return to previous step.

9 of 11

Integrity Excellence Teamwork Innovation

System Setup (for reference only –completed during assembly)

Step 1S - Press NEXT and ▼simultaneously for 5 seconds and release.

Step 2S –Leave as default setting = “SOFTENING”.

Press NEXT to go to Step 3S. Press REGEN to exit OEM Softener System Setup.

Step 3S –Leave as default Brining Direction = “dn”.

Press NEXT to go to Step 4S. Press REGEN to return to previous step.

Step 4S –Leave as default Fill = “Post”.

Press NEXT to go to Step 4S. Press REGEN to return to previous step.

Step 5S –Select the time for the first cycle (Backwash) using ▲or ▼.

Default = 10 minutes. INCREASE AS NECESSARY BUT DO NOT DECREASE.

Press NEXT to go to Step 6S. Press REGEN to return to previous step.

Step 6S –Select the time for the second cycle (Air Recharge) using ▲or ▼.

Default = 40 minutes. INCREASE AS NECESSARY BUT DO NOT DECREASE.

The display will flash between cycle number & time, & brine direction (UP or dn).

Press NEXT to go to Step 7S. Press REGEN to return to previous step.

Step 7S –Select the time for the third cycle using ▲or ▼.

Default = “oFF”. DO NOT CHANGE.

Press NEXT to go to Step 8S. Press REGEN to return to previous step.

Step 8S –Select the time for the fourth cycle using ▲or ▼.

Default = “oFF”. DO NOT EXCEED 1 MINUTE.

Press NEXT to go to Step 9S. Press REGEN to return to previous step.

Step 9S –Select the pounds for the fifth cycle using ▲or ▼.

Default = “oFF”. DO NOT CHANGE.

Press NEXT to go to Step 10S. Press REGEN to return to previous step.

Step 10S –Set System Capacity –Leave at Default.

Press NEXT to go to Step 11S. Press REGEN to return to previous step.

Step 11S –Set Volume Capacity –Leave at “oFF”

Regeneration will be triggered by the day override setting, or can be set to regenerate

on specific days of the week.

Press NEXT to go to Step 12S. Press REGEN to return to previous step.

Step 12S –Set Regeneration Trigger using ▲or ▼.

If Step 11S is set to OFF, Regeneration Trigger can be set to 28 day or 7 day.

Press NEXT to go to Step 13S. Press REGEN to return to previous

Step 13S –Not Shown

Step 14S –Set Relay Operation –“oFF”. If set to “oFF”, 15S & 16S are not shown.

Press NEXT to go to Step 15S. Press REGEN to return to previous step.

10 of 11

Integrity Excellence Teamwork Innovation

REPLACEMENT PARTS

Part #

Desc.

Photo (not to scale)

KT7704AIO

WS1EE AIO Valve

K74V3005

STACK

K74V3011

PISTON

K74V3174

REGENERANT PISTON

OV32

INLET CHECK VALVE

OV15HT

AIR DRAW CHECK VALVE

H6061

AIR DRAW SCREEN

KTSCREEN

SCREEN W/ TUBE

K74V4144AIO

AIR DRAW ASSY COMPLETE

AIOGROM

GROMMET

D7147

UPPER DEFLECTOR

K74V30101F*

INJECTOR F (BLUE)

RKWS1AIO

AERATION MAINTANANCE KIT

Includes Blue Injector, Pistons, Stack Assy, Stack

Puller Tool, and Service Wrench

VARIES

DRAIN LINE FLOW CONTROL

~

*Injector may vary on larger tanks

11 of 11

Integrity Excellence Teamwork Innovation

FILTRATION MEDIA OVERVIEW

Media

Physical Characteristics

Description

Birm®

Color: black

Density: 40 –45 lbs. per CF

Mesh size: 10 x 50

Birm® is a granular, silica based, manganese dioxide coated, filter media commonly used for the

reduction of iron and/or manganese from water supplies. It acts as an insoluble catalyst to

enhance the oxidation reaction between dissolved oxygen in the water and the iron and

manganese compounds. The oxidized minerals are precipitated out of solution and removed by

filtration in the bed. Birm offers long material life with relatively low attrition loss, a wide

temperature performance range and extremely high removal efficiency. Regeneration is not

required. Certified to NSF/ANSI Standard 61.

BWS™

Aeration Mix

Color: black / brown / whitish

Density: 45 lbs. per CF

BWS Aeration Mix is a custom media blend for use with Aeration Iron Oxidizing (AIO) filters for

the reduction of iron and/or manganese from water supplies. It consists of a proprietary mixture

of Birm®, Calcite®, Corosex® and Filter Ag® medias for pH correction, oxidation acceleration,

and particle filtration in a single media tank. Due to the sacrificial nature of both Calcite and

Corosex, periodic replenishment will be required. Birm and Filter Ag are durable minerals with a

life expectancy of 8-10 years.

Calcite

Georgia

Marble

Color: whitish

Density: 100 lbs. per CF

Mesh size: 16 x 40

CaCO3: 95% min

MgCO3: 3.0% max

Calcite is a naturally occurring, crushed and screened white marble media which is used to

neutralize acidic or low pH waters to a neutral, less corrosive state. Upon contact with Calcite,

acidic waters slowly dissolve the calcium carbonate to raise the pH which reduces the potential

leaching of copper, lead and other metals found in typical plumbing systems. Calcite corrects pH

only enough to reach a non-corrosive equilibrium. It does not overcorrect under normal

conditions. Periodic backwashing will prevent packing, reclassify the bed and maintain high

service rates. The media will have to be periodically replenished as the Calcite is depleted. As

the Calcite’s calcium carbonate neutralizes the water, it will increase hardness and a softener

may become necessary after the neutralizing filter. Certified to NSF/ANSI Standard 61.

CENTAUR®

Catalytic

Activated

Carbon

Color: black

Density: 34 lbs. per CF

Mesh size: 12 x 40

CENTAUR is engineered carbon with enhanced catalytic properties to accelerate and promote

oxidation, reduction, decomposition, substitution reactions for the elimination of chloramines,

hydrogen sulfide and iron from drinking water. Advantages include low water-soluble ash content,

wide pH operating range, and it is not impregnated with metals or alkali, eliminating safety

concerns. Certified to NSF/ANSI Standard 42.

Chemsorb®

Color: light green

Density: 55 lbs. per CF

Mesh size: 14 x 40

Chemsorb is a natural Zeolite mineral with a highly porous granular surface area that provides

superior filtration down to 5 micron at high flows up to 12-18 gpm/ft². Advantages include the

removal of a wide range of colloidal and soluble inorganic contaminants by surface sorption,

chemical-binding, charge-neutralization, coagulation reactions, and/or ion-exchange phenomena.

Certified to NSF/ANSI Standard 61.

Corosex®

Color: brownish white

Density: 75 lbs. per CF

Mesh size: 6 x 16

Corosex® is a specially processed hard, bead-like magnesium oxide media, adapted for use in

filters to neutralize acidity by increasing the pH value. Corosex neutralizes free carbon dioxide in

water correcting acidic conditions and rendering it less corrosive. Corosex is a highly reactive

magnesium oxide and is most effective where pH correction is substantial or high flows are

required. Under certain low flow conditions, Corosex may over correct and create a highly basic

(high pH) condition. As Corosex’s neutralizes the water, it will increase hardness and a softener

may become necessary after the neutralizing filter. Certified to NSF/ANSI Standard 61.

Filter-AG®

Color: light gray to whitish

Density: 24 - 26 lbs. per CF

Mesh size: 10 x 34

Filter-AG is a granular pumicite media with a fractured and highly irregular surface area. This

unique structure creates a complex flow path allowing for maximum removal of suspended matter

throughout the filter bed. It typically removes suspended solids down to 20 –40 microns. Filter-

AG’s larger particle size creates less pressure loss and high dirt removal capacity resulting in

longer filter runs. Due to this and its lighter weight, it works very well in dual bed or multi-media

filtration systems (in addition to single beds). Certified to NSF/ANSI Standard 61.

Katalox

Light®

Color: black

Density: 66 lbs. per CF

Mesh size: 14 x 30

Katalox-Light® is an engineered catalytic ZEOSORB media coated with manganese dioxide. It is

used for high level filtration, color and odor removal, Iron, Manganese, Hydrogen sulfide removal,

and pH correction. Under certain conditions, an oxidizer such as H2O2may be used to accelerate

the catalytic oxidation on the surface of the media. Certified to NSF/ANSI Standard 61.

Greensand

Plus™

Color: black

Density: 85 lbs. per CF

Mesh size: 18 x 60

GreensandPlus™ is a granular, silica based, manganese dioxide coated, filter media commonly

used for the removal of soluble iron, manganese and hydrogen sulfide from well water. The

manganese dioxide coating acts as a catalyst in the oxidation reaction of iron and manganese.

Chemical regeneration is necessary. Depending on the application, regeneration may be

continuous (CR) or intermittent (IR). Certified to NSF/ANSI Standard 61.

MTM®

Color: dark brown

Density: 45 - 50 lbs. per CF

Mesh size: 12 x 50

MTM is a granular manganese dioxide filtering media used for reducing iron, manganese and

hydrogen sulfide from water. Its active surface coating oxidizes and precipitates soluble iron and

manganese. Hydrogen sulfide is oxidized to sulfur. The precipitates are then filtered out in the

granular bed and removed by backwashing. Chemical regeneration is necessary. Depending on

application, regeneration may be continuous or intermittent. Certified to NSF/ANSI Standard 61.

NOTES:

NOTES:

GROUP

The

Blake

GROUP

The

Blake

Serving New England, New York, Long Island,

Northern New Jersey and Northeastern Pennsylvania

RHODE ISLAND

VERMONT

BLAKE EQUIPMENT

RUTLAND

280 Quality Lane

Rutland, VT 05701

Phone: (800) 643-7100

MASSACHUSETTS

BLAKE EQUIPMENT

GREENFIELD

28 Butternut Street

Greeneld, MA 01301

Phone: (800) 628-1998

NEW HAMPSHIRE

BLAKE EQUIPMENT

CONCORD

34 Locke Road #5

Concord, NH 03301

Phone: (800) 552-0389

CONNECTICUT

THE BLAKE GROUP

Headquarters

4 New Park Road

East Windsor, CT

Phone: (800) 353-1100

BLAKE EQUIPMENT

EAST WINDSOR

6 New Park Road

East Windsor, CT 06088

Phone: (800) 593-7867

BLAKE EQUIPMENT

DANBURY

34 Executive Drive

Danbury, CT 06810

Phone: (800) 791-7867

MAINE

BLAKE EQUIPMENT

HERMON

1194 Odlin Road

Hermon, ME 04401

Phone: (800) 450-6822

BLAKE EQUIPMENT

PORTLAND

70 Ingersoll Drive Unit #1

Portland, ME 04103

Phone: (800) 308-2213

The Blake Group is a growing family of companies dedicated to providing our valued customers with

superior products and technologies in commercial, industrial, and residential markets, compliant with

industry standards and meeting all facets of our customers’ expectations.

BLAKE EQUIPMENT

EAST SYRACUSE

6059 Corporate Drive

East Syracuse, NY 13057

Phone: (800) 792-2346

NEW YORK

BLAKE EQUIPMENT

ONEONTA

Route 23 Southside

Oneonta, NY 13820

Phone: (800) 336-6611

BLAKE EQUIPMENT

PINE ISLAND

76 Skinner Lane

Pine Island, NY 10969

Phone: (800) 914-0099

BLAKE EQUIPMENT

ALBANY

13 Thatcher Street

Albany, NY 12207

Phone: (518) 465-0713

BLAKE EQUIPMENT

PASCOAG

222 Davis Drive

Pascoag, RI 02859

Phone: (800) 869-7677

This manual suits for next models

1

Table of contents

Popular Water Filtration System manuals by other brands

US Water Systems

US Water Systems Oxi-Gen 150-MO-1 Installation, operation and maintenance manual

FSI

FSI x100 Operator's guide

Pentair

Pentair 1.0 Service manual

TMC Aquarium

TMC Aquarium V2Bio 600 Instructions for installation and use

Blagdon

Blagdon Inpond 5 in 1 2000 manual

Watts

Watts WH-VIH1-SED-A-WHT-HSG Installation, operation and maintenance manual

RAINSHOWER

RAINSHOWER REFRESH Instruction guide

Wrekin Water

Wrekin Water SS15 Installation and operating instructions

SuperFish

SuperFish Pond Clear UVC 30000 user manual

EasyPro

EasyPro Eco-Clear EC2600 Instructions for Operation, Safety, Warranty

BWT

BWT Quick & Clean instruction manual

Oase

Oase FiltoClear 5000 manual