HIFEI Technology Fulcrum Pro+ 300A User manual

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Brushless ESC Instructions

Thanks for purchasing Fulcrum series brushless speed controller manufactured by

Chongqing HIFEI Technology Co., Ltd. Fulcrum series ESC are super HV and

extremely powerful ESC for model aircraft and helicopter.

Contents

Part Ⅰ:Using Warnings … … … … … … … … … P2

Part Ⅱ:ESC Specifications … … … … … … … …P3-P6

Part Ш:Using the ESC … … … … … … … … … P7-P9

Part Ⅳ:Program the ESC by soft … … … … … …P10-P19

Part Ⅴ:Trouble shooting … … … … … … … … …P20

Part VI: Warranty Clause… … … … … … … … …P21-P24

Page 1

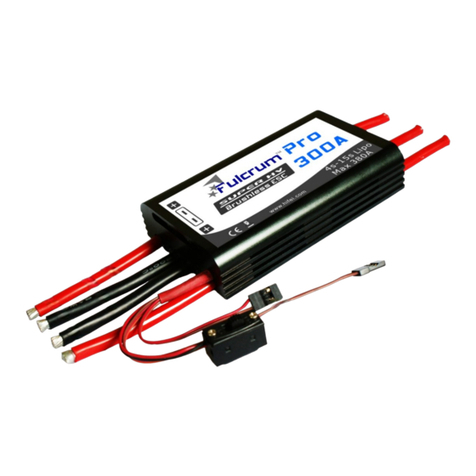

Pro/Pro+ 300A

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

ⅠUsing Warnings

·The brushless ESC is specially designed for R/C electric powered model aircrafts, helicopters

and EDF, which are not toys. It is suggested ONLY adults can run it, and little children must run it

under wardship of adults.

·Please read the ESC’s specifications and correctly connect ESC to battery pack at right voltage.

·When connecting the ESC to battery pack, please ensure the polarity is correct.

Incorrect polarity connecting will cause short-circuit and permanent damage to the ESC, such

damage is not covered by manufacturer’s WARRANTY.

·Before the flying, turn on the transmitter BEFORE powering on the receiver.

·When finish the flying, power off the receiver BEFORE turning off the transmitter.

·Never disconnect the battery pack while the motor is running, as this could cause damage to the

speed controller and/or motor.

·Connectors with low conductivity may cause erratic motor rotations or other unexpected

movements.

·Please keep the propeller away from humans or any other objects.

·It can change the motor’s rotation direction by swapping any two motor wires connecting.

·Each new ESC is preset with default parameters in factory, which can be assembled for flying

directly. But in order to obtain optimum power performance and well compatible to work with the

brushless motor. It is suggested to set the appropriate parameters before assemble it to hull for

flying.

·The ESC wick cut-off output when no signal is checked within 100ms.

·Please calibrate the throttle range of the transmitter when it is your first time to use a new

controller or when you change a new/different transmitter or receiver.

·When finish the using of Hifei software ‘ V4.xx’, close the software first, then pull out the USB

linker from your PC, or it may cause the crash of the computer.

Page 2

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

ⅡESC Specifications

● Microprocessor-controlled, extremely low resistance;

● Adopt advanced aluminum PCB process;

● Solid heat dissipation;

● Full protection soft, include signal close protection, temperature protection, motor block-up

protection.

● Auto detecting Lipo cells.

● ESC is fully programmable by Hifei USB linker on computer, and Hifei LCD program box;

● The firmware of the ESC is upgradeable from Internet when a new version of the software

available.

● Pro+ 300A is with built-in data logger, which can record down the Voltage、Current、Throttle、

Motor RPM and Temperature during flight.

● Read logged data by soft on PC or by Hifei LCD program box.

ⅡB: Features

ⅡC: ESC Models

ESC Voltage Current/Max BEC Size (mm) Weight

(incl. wires)

Fulcrum Pro 300A 4-15s Lipos

12-48s Ni-xx

300amp/350amp OPTO 119*73*26 395g

Fulcrum Pro+ 300A

(with built-in data

logger)

4-15s Lipos

12-48s Ni-xx

300amp/350amp OPTO 119*73*26 395g

Page 3

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

II D: Programmable Parameters

LVC Auto 4s

Lipo*

5s

Lipo

6s

Lipo

7s

Lipo

8s

Lipo

9s

Lipo

10s

Lipo

11s

Lipo

12s

Lipo

13s

Lipo

14s

Lipo

15s

Lipo

LVC/Lipo

2.5V 2.6V 2.7V 2.8V 2.9V 3.0V* 3.1V 3.2V

3.3V

Current Limiting Sensitivity Standard* Insensitivity Disabled

Brake Type Close* Soft brake Hard brake

Timing Advance Low* Middle High Auto*

Cutoff Type Hard cutoff* Soft cutoff

Start Type Soft start Standard* Fast start

Governor Mode

Auto*

(for airplane)

Low PWM

(for heli)

High PWM

(for Heli)

PWM Rate 8KHz*

Note:

1) PWM of Fulcrum Pro and Pro+ 300A ESC is 8KHz, which is not programmable.

2) Parameters with asterisk behind are the factory default settings of Fulcrum Pro/Pro+ 300A ESC.

3) When ‘LVC’ of ESC is set at ‘Auto’, the motor will emit beeps to detect the number of Lipo cells after

the two power beeps, and the red LED on ESC will blink in accompany with the beeps. ‘3.0v’ is the default cut-off

voltage of per Lipo cell when the LVC is set at ‘Auto’ detect.

For example: If connect ESC to a 4s Lipo battery pack, the motor will firstly emit ♪♪, then detect

the Lipo numbers ♪♪♪♪, and the red LED will blink four times. The low voltage cut-off is

calculated as ‘12.0V’.

4) Please ensure only when the battery packs is fully charged and it can set the LVC at ‘Auto’, it is

recommended to set the LVC at actual Lipo cells once the battery pack is over 4S cells.

Page 4

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Low voltage cut-off can protect battery from discharging too low and causing permanent

damaged to battery, especially important for Lithium polymer cells. It is strongly recommend to set the

LVC carefully before running.

The setting is to set low voltage cut-off of each Lipo cell.

‘Sensitivity’ setting is low over-current threshold, will shut down rapidly.

‘Standard’ is moderate over-current threshold, will shut down after a slight delay.

‘Insensitivity’ is high over-current threshold, will shut down after a slight delay. Recommend

only experienced modelers would change to use this programming feature.

‘Close’ current limiting detection disabled. only experienced modelers would use this option.

‘Brake disabled’ setting will close the brake function;

‘Soft brake’ will provide 20% of full braking power.

‘Low timing’ setting adjusts the timing at the range of 0º~15º, recommended for more lower

pole count brushless motors (such as 2 poles, or 4 poles). It gives more power and slightly less efficient;

‘Middle timing’ adjusts the timing at the range of 5º~20º, recommended for most brushless

motors. It gives a good balance of power and efficiency;

‘High timing’ adjusts the timing at the range of 15º~30º, recommended for higher pole count

motors. (such as 8, 10, 12, 14 poles or higher brushless outrunner motor)

‘Auto timing’ setting is automatically adjust the timing degree according to motor’s rotating

demand.

0°; 2°; 4°; 6°; 8°; 10°; 12°;14°; 16°; 18°; 20°; 22°; 24°; 26°; 28°; 30° are specific options for

timing advance.

Note: These options can be only set via software ‘Hifei V4.03’ or newer version, which was released after 4 Dec., 2012.

If you want to upgrade your old version software to have these timing advance, please download the software from

www.hifei.com.

0º and 30º are special settings, can be only selected for some special motors with manufactures special requirements.

Low voltage cut-off (LVC):

Cutoff Voltage/ cell :

ⅡE: Fulcrum Pro/Pro+ 300A ESC Parameters Features

E.g: if you use 2S(2 Lipo in series), you can choose ‘2s cells’; if you use 4S 1P battery packs, please set it

at ‘4s cells’.

E.g: if you set the LVC of per Lipo cell at ‘2.8V’, the LVC is set at ‘2s cells’, then the cut-off voltage of

the whole battery pack is ‘2.8*2’=5.6V; if the LVC per Lipo cell is set at ‘3.2V’, the cut-off voltage of

whole battery pack is ‘3.2*2’=6.4V.

Current Limiting :

Brake type :

Timing advance :

Page 5

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Cutoff type settings decide the way in which the ESC cutoff output to brushless motor when

the LVC works, or temperature/ signal-lost protection works.

‘Hard cutoff’: when the battery volts discharges to the set LVC value or soft protection

works, the motor will shut down immediately. Motor can be restarted by closing the throttle to the

lowest position and re-move the throttle as normal.

‘Soft cutoff’: when the battery volts discharges to the set LVC value or soft protection

works, the ESC will slowly reduce motor power to zero, you will notice a decrease in power and it is

time to dock.

‘Soft start’: very soft and smoothly start the motor, it will take more time.

‘Standard start’: start the motor at normal speed, it depends on the motor’s quality and

dynamic response.

‘Fast start’: start the motor fast, recommend this for racing.

.

‘Auto’ recommended for general fixed-wing aircraft.

‘Low RPM’ recommended for collective pitch helicopters. Used for low pole count motors

and low RPM on higher pole count motors.

‘High RPM’ recommended for collective pitch helicopters. Used for higher pole count

motors and higher RPM.

Note:

a. The poles mentioned above is the magnetic poles of brushless motor, not the stator numbers of

motor.

b. It is strongly recommended to have bench testing and choose appropriate parameters for your

configuration before assembling the ESC to hull for running.

Startup type:

Governor mode:

Cutoff type:

Page 6

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

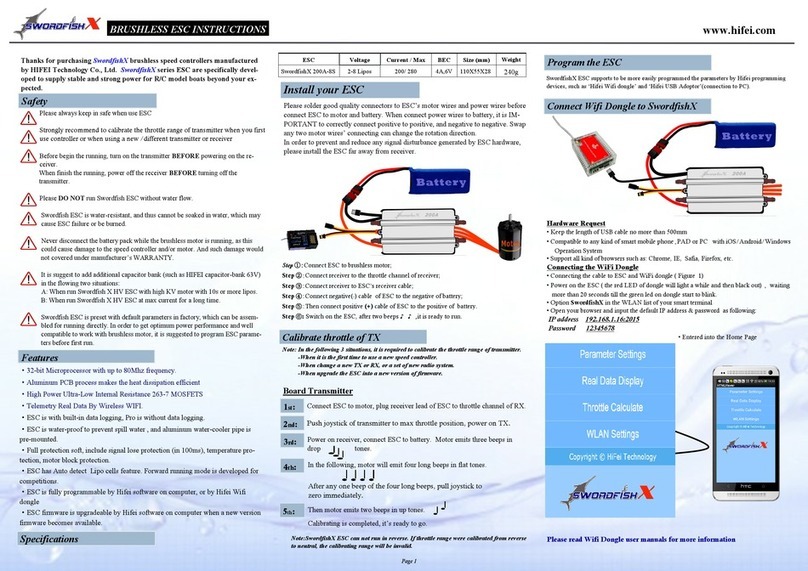

ШUsing the ESC

1st: Solder good quality connectors to ESC’s motor wires and power wires before connect ESC

to motor and battery.

Please connect the two negative power wires in parallel d simultaneously to negative polarity of

battery pack, and the two positive power wires in parallel simultaneously to the positive polarity of

battery pack.

2nd: Switch ’OFF’, connect ESC to brushless motor;

Swap any two motor wires connecting can change the rotation direction.

3rd: plug receiver lead to throttle channel of receiver;

If you use board transmitter radio, plug the receiver lead of ESC into CH3 of receiver;

If you use pistol transmitter radio, plug the receiver lead of ESC into CH2 of receiver.

4th: use separate receiver battery or UBEC to supply power for receiver.

In order to prevent and reduce any signal disturbance generated by ESC hardware, please

put the ESC far away from receiver.

5th: refer to the instructions to calibrate the throttle of TX.

ШA: Connect ESC to BL Motor, Receiver, battery

Page 7

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

1st: Correctly connect ESC to brushless motor, plug the receiver lead of ESC into the throttle channel

of the receiver (usually CH3);

2nd: Push the joystick of transmitter to the max throttle position, power on the transmitter.

3rd: Connect the ESC to battery, there are 3 beeps emitted from the motor.

4th: After the following 2 beeps ♪♪, immediately pull joystick to the minimum throttle.

5th: 2 beeps emitting, the calibrating finished.

Note: Motor is needed to install for acoustic guide. Meanwhile, please keep the propeller away from the

human beings or any objects.

ШB: Calibrate the Throttle Range of Transmitter

Note: in the following 3 situations, it is required to calibrate the throttle range of transmitter.

● When it is the first time to use a new speed controller.

● When change a new TX or RX, or a set of new radio system.

● When upgrade the ESC into a new version of firmware.

When running at the calibrated max throttle, the RED LED on the ESC will be blinking on to

indicate the ESC is giving the max throttle.

Max throttle (It will be 100% throttle point.)

Minimum throttle (It will be Zero throttle

Page 8

♪

♪

♪

♪

♪

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

—Set ESC’s parameters. Do testing on test-bed and select appropriate parameters for the

configuration.

—Check battery’s volts

—Use UBEC or separate receiver battery to power the receiver. Switch ‘ON’, the

green LED on ESC will light for a second and then extinguish. After the two power beeps,

it is time to go.

Fulcrum Pro 300A and Pro+ 300A ESC come with an anti-spark cables.

When run the ESC with 8s and more Lipo cells, please solder the anti-spark cable according to the

below instructions, which would reduce the sparks and prevent ESC from any damage.

ШC: ready to run !

Note:

When the battery volts discharge and drop down to the set LVC value, the ESC will cutoff output

to motor in the way of set ‘Hard’ or ‘Soft’ cutoff type, which notice it’s time to change battery pack.

When ESC cutoff output to motor, you can re-start the motor by moving throttle from 0 position

again. But ESC will cutoff again soon in 3 seconds.

Page 9

ШD: Wiring anti-spark cables

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Ⅳ Program the ESCs by Soft on PC

Fulcrum Pro/Pro+ 300A ESC supports to be fully programmed the parameters by

‘Swordfish Program soft’ on PC and ‘Hifei Program box’.

When program the ESC by soft, a ‘USB Linker’ is required to link the Swordfish ESC to PC.

‘USB Linker’ and ‘Hifei Program box’ are the parts sold separately. Here the instructions will guide

how to program the Swordfish 300A ESC controllers by soft on PC.

Please read the following instructions before programming. ⅣA: Install

‘Swordfish Program’ Software to PC

A. Personal computer with Windows XP/ Vista/ Windows 7 operation system.

B. CD-ROM drive (or access to Internet)

C. Available USB port

D. 8 Megabytes hard disk space

E. Computer screen resolution with 800X600, 1024X768(recommended) , 1280X1024

The hardware include Swordfish Pro/ Pro+ 300A ESC, USB Linker (sold separately), a set-up

CD (free to supply).

ⅣA: Install Software on PC

A-a: Computer Operation System Requirements

A-b: Hardware

Page 10

Swordfish 300A ESC USB Linker Set-up soft

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

- Insert the CD in the CD driver of the computer.

- Double click the icon ‘HiFei V4. xx’ Setup.

Note: if your computer is windows 7 operation system, DO NOT install the soft into hard disk ‘C’.

A-c: STEPS to install the soft

Page 11

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

—After click ‘Finish’ button, the software shortcutting icon “HiFei Vx.xx” appears on

computer desktop.

—Installation completed

Page 12

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

—Switch ‘OFF’ ESC.

—Connect ESC’s receiver lead to Hifei USB Linker in right polarity.

—Insert Hifei USB Linker to one of USB Ports of PC.

—Connect ESC to battery. Switch ‘ON’.

Note:

When ESC is successfully connected to computer, red LED on USB Linker will

light, and green LED on ESC will light.

If the green LED on ESC does not light, please check the connecting polarity between ESC’s

receiver lead and USB Linker; and ensure connecting is tight.

Battery

USB Linker

Switch

ON OFF

ⅣB: Connect Fulcrum Pro/Pro+ 300A to PC

Fulcrum

Pro/ Pro+

300A ESC

Page 13

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Note: when finish the using of Hifei software ‘ V4.xx’, close the software first, then pull out the USB

linker from your PC, or it may cause the crash of the computer.

— Double left click mouse the icon ‘Hifei Vx.xx’ on desktop.

— Click “open device” to enter into operations.

Note: Software V4.01 or newer version is improved to be able to automatically recognize right ‘Com

Port’, so there is no need to set ‘Com Port’ by hand, but click ‘open device’ to get into programming

interface.

— If connection succeed, it will jump into the following interface to program ESC settings. See the

following picture.

IVC: Fully Program ESC’s Paramaters

Page 14

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

-Click tab “upgrade’ as the picture shows below.

-Click ‘browse’ to select the new fireware which the ESC will be upgraded into.

When upgrade ESC’s firmware, correct firmware for the ESC is required.

For example, if you made a mistake to upgrade 300A ESC into other type HIFEI ESC, your

ESC could not work normally, or even the ESC will be damaged. Which is not covered by warranty.

ⅣD: Upgrade ESC’s firmware

Page 15

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

-Click ‘Start’ to get into the upgrading process, it will be finished within 20 seconds.

-See ‘ Download successfully’, Upgrading is finished.

Page 16

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

When connect Pro+ 300A ESC to PC, tabs ‘ Logger Configuration’ and ‘Show the Record ‘ will

auto highlight and can be clicked.

-Click tab ‘Show the Record’, input correct ‘Gear Rate’ and ‘Pole Number’ of used brushless

motor at the bottom of the soft interface.

If not use gear box, please keep it as default ‘1’, ‘Pole Number’ here indicates magnetic poles

of brushless motor, which is always a double number of 2.

—Click ‘Upload Record Data’ at the right bottom

IVE: Read Flight Data from Fulcrum Pro+ 300A

Click down arrow to choose

the color.

Page 17

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

-Logged flight data is showed as curves.

- It can change Y axis displaying content by setting at top right corner ‘Y axis’.

Note: a. Input correct poles number of motor is important to get more precise data of RPM.

b. Temperature is showed in centigrade.

c. There is ±2% physical deviation about data of RMP .

And ±5% deviation about data of max current.

And ±5% Celsius deviation about data of temperature.

Page 18

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

IV F: Logger Configuration

—Click tab ‘ Logger Configuration’ to change setting logger.

Cycle Record: ‘Not reverse’ indicates the data logger cannot record any more when the space

is filled up; ‘reverse’ indicates the data logger can record indefinitely by overlapping the former data

and do a cycle. ‘ Not reverse’ is the default.

Sample Rate is the frequency by which data logger samples the power data during

running. The default setting is 3 per second.

Please refer the following form about the recording time and minimum running time when set

sampling rate at different options.

Possible Recording Time means longest time data logger can record with the set sampling rate.

Minimum Running Time: ESC must run longer than the minimum running time, otherwise the

software can not read and display the data on the PC window.

Note: please DO

NOT

power

off

ESC

abnormally

while

not

moving

throttle

back

to

zero

position

,

otherwise

power

data

will

be

unavailable

.

Page 19

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Trouble Possible reason Shoot methods

When connect ESC to battery,

there is no two power beeps

emitted from brushless motor.

1. The battery voltage exceeds

the range of ESC’s working

voltage. May it is too low or

too high.

2. Motor is damaged, or the ESC

is not well connected with

motor.

1. Check battery’s voltage and

change suitable battery pack.

2.Check the connectors, ensure

ESC is tightly connected with

motor. Check motor whether it is

good.

Motor shut down suddenly even at

full throttle or when not decrease

the throttle.

1. Battery voltage discharge and

drop down to the set low cut-

off voltage, the ESC cut-off

output to motor to protect the

battery.

2. Temperature protection

1. Please stop the running and

change a new battery pack.

2. Stop running for a while until

the ESC’s temperature decrease

and recover to be normal.

When connect ESC to PC

according to the instructions, it

still cannot connect the ESC to PC

succefull for programming.

1. There is loose between USB

Linker to ‘USB port’ of PC.

2. The com port is not correct.

3. ESC’s receiver lead to USB

Linker is wrongly connected.

1.Plug out the USB Linker from

the PC, and re-plug it in.

2. Check the correct com port.

3.Check the connecting polarity

between ESC to USB Linker.

V Trouble shooting

Page 20

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Part VI : Warranty Clause

Thanks for purchasing Hifei Brushless Electronic Speed Controller (ESC). Here we guarantee all

Hifei ESC is made by strict workmanship standards and rigorously tested before leaving the factory.

But as ESCs are usually working under atrocious environment and other possible damage during

transportation, we commit under-warranty service and disclaimer in accordance with the following

clauses. We reserve the rights to change clauses without notification in advance.

Hifei Brushless ESCs are used for radio controlled electric model airplanes, boat s and cars. Which

are not toys, and must be used with much care. It is required to read the ESC user-manuals and

warnings before using. This warranty does not cover abuse, neglect, or damage due to incorrect

wiring, over voltage, or overloading.

Please read the warranty clause carefully. When request warranty, it is required to fill out the ‘

Warranty Form’ and send one copy of the form and a copy of purchase receipt with the ESC

together back to factory. Please note we do not accept request for refunding.

All Hifei ESCs are warranted for one year since the date of purchase from Hifei authorized dealers

which comply with the following under-warranty clauses.

In the following conditions, you can request a new replacement within 15 days since the purchase

date. (Purchase receipt or invoice must be provided)

The requested ESC must keep in new condition.

a) New ESC you got has defect on components or workmanship;

b) New ESC you got works abnormally in first testing.

Note: any change to a new ESC ( such as cutting short cables, unpack ESC, etc) will be disclaimed.

In the following situations, we commit free repairing to requested ESC.

Purchase receipt and warranty form are required to ship back together with the ESC.

a) the date exceeds 15 days , the defective ESC will be repaired and shipped back.

b) the ESC can not work or be damaged in testing, which is caused by the quality defects of ESC

within the valid warranty date.

Note: You bear the shipping cost for returning, and we pay the cost for shipping the repaired ESC back

to you.

We promise to repair the returned ESC and ship it within 5 working days since we received it.

VI A: Under Warranty Conditions

1) Replacement

2) Repair

Page 21

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

VI B: Disclaimer Conditions

In any of the following conditions, we disclaim the warranty

a) The purchase date over 1 year.

b) A valid purchase certificate and/or warranty form in not provided.

c) ESC was damaged due to not following the manuals or any misuse, such as overload using ESC,

ESC’s on-board overloading, affected by the humidity, incorrectly soldered connectors, incorrect

polarity the controller, misuse on other application, disconnect ESC from battery while motor is

rotating, etc.

d) The ESC is changed, disassembled and repaired by yourself or any other third party without

authorization from Hifei in advance.

e) The ESC is severely damaged and be irretrievable.

We also provide charge-repairing service to Hifei ESC which is disclaimed warranty. According to the

damage degree of the ESC, we will notify you the repairing fee and get your agreement before repair

it.

Note: you pay all the shipping cost.

When request warranty service, please firstly contact the shop where you purchase the ESC, or send e-

RMA number from Hifei. Please write the RMP number on ‘ Warranty Form’.

VI C: Charged Repairing Service

Page 22

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

RAM No.: ________

Warranty Form

Please fill out this Service-Request form and ship one copy with the ESC which you will ship back for service. We

will keep you informed about the inspection result as soon as possible after carefully checking, so please ensure your

email address correct. We sincerely appreciate for your support.

Those with asterisk * behind are required.

ESC Model: *___________ Purchase Date:*____________

Contact Person: *______________ E-mail: *_______________

II Detail Description of Problems Symptoms *

ⅠUsing info:*

When the ESC be problemed: (date)/ (month) / (year)

Detail symptom description:

Model airplane info Name_________________

Manufacturer______________

Length:______________

Wingspan:_____________

Battery*

Lithium-Polymer (Lipo) NiCad or NiMH

Cell Count___ ; Voltage ;

C Rating ; Mah Rating ;

Cell Count ; Voltage ;

Mah Rating ;

Motor*Manufacturer ;

Motor Size or Model ;

KV______________

No. of poles_________

Propeller*Prop manufacturer

Prop size (inch) / (mm)

Radio Manufacturer ; TX model ;

RX ; servo count ;

Page 23

Fulcrum Pro/Pro+ 300A Brushless Speed Controller Manuals www.hifei.com

Ⅲ Please notify us of your shipping address, phone call and e-mail, so we will ship the ESC after it is

repaired back to you. We will keep all your info confidential.

Ⅳ Please ship the ESC to our factory address:

Ⅴ Please ship one copy of purchase receipt with the ESC*.

Ⅴ

Your name Telephone

Shipping address

Street

City Country Postal code

E-mail

Company: Chongqing HIFEI Technology Ltd.

Address Street: 2nd Floor, K Building, 52 Keyuan 4th street, Gaoxin District,

City: Chongqing Country:P.R. China Postal code: 400041

Contact person Michelle Lee Telephone: +86 23 68621580

Page 24

This manual suits for next models

2

Other HIFEI Technology Controllers manuals

Popular Controllers manuals by other brands

Sullair

Sullair SUPERVISOR CONTROLLER instruction manual

Toho Electronics

Toho Electronics TTX-800 Operation manual

Chamberlain

Chamberlain LA500UL Wiring diagram

Mechatronics

Mechatronics eurosens DSS user manual

LXNAV

LXNAV RS485/CAN Remote installation manual

IFM Electronic

IFM Electronic AS-i Controller e AC1355 installation instructions

Asco

Asco WSDU-M Series Installation and maintenance instructions

Johnson Controls

Johnson Controls EDA-8000 Product/Technical Bulletin

NOVAK

NOVAK ATOM ESC operating instructions

Tapeswitch

Tapeswitch PRSU/4 Operating instructions manual

Dialogic

Dialogic 4000 Session installation guide

RMG

RMG AWFAWLC-044 manual