Sullair SUPERVISOR CONTROLLER User manual

SUPERVISOR CONTROLLER™

and WS CONTROLLER

SEQUENCING & PROTOCOL MANUAL

(Including Supervisor II Deluxe Controller™)

INSTRUCTION

MANUAL

Part Number

02250161-162

©Sullair Corporation

KEEP FOR

FUTURE

REFERENCE

AIR CARE SEMINAR

TRAINING

Sullair Air Care Seminars are courses that provide hands-on instruction in the proper operation, maintenance

and service of Sullair equipment. Individual seminars on Industrial compressors and compressor electrical

systems are presented at regular intervals throughout the year at a dedicated training facility at Sullair’s

corporate headquarters in Michigan City, Indiana.

Instruction includes discussion of the function and installation of Sullair service parts, troubleshooting of the

most common problems, and actual equipment operation. The seminars are recommended for maintenance

and service personnel.

For detailed course outlines, schedule and cost information contact:

Sullair Corporate Training Department

1-888-SULLAIR or 219-879-5451 (ext. 5363)

www.sullair.com

Or Write -

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department

TABLE OF CONTENTS

1. SAFETY AND INTRODUCTION 1

1.1 SAFETY 1

1.2 SUPERVISOR CONTROLLER, SUPERVISOR II AND WS CONTROLLERS 1

1.3 SEQUENCED COMPRESSOR SYSTEMS 1

2. SEQUENCING WITH MULTIPLE CONTROLLERS 3

2.1 NORMAL OPERATION 3

2.2 COMPRESSOR SYSTEM 3

2.3 WIRING AND PIPING 4

2.4 MACHINE PREPARATION PRIOR TO SEQUENCING 4

2.5 SYSTEM OPERATION 5

2.6 SYSTEM SETUP AND TUNING 6

2.6.1 GENERAL SEQUENCING RULES 7

2.7 CHANGING SEQUENCE PARAMETERS 7

2.8 SEQUENCE PARAMETER NAMES 8

2.9 SYSTEM DISPLAY- SUPERVISOR CONTROLLER 10

2.10 SYSTEM DISPLAY- SUPERVISOR II DELUXE 10

2.11 SYSTEM DISPLAY- WS CONTROLLER 11

2.12 REMOVING A MACHINE FROM SEQUENCE FOR MAINTENANCE 11

2.13 CALIBRATION OF P2 PRESSURE TRANSDUCERS 12

2.13.1 SUPERVISOR P2 PRESSURE TRANSDUCER CALIBRATION 12

2.13.2 SUPERVISOR II DELUXE P2 PRESSURE TRANSDUCER CALIBRATION 13

2.13.3 WS CONTROLLER P2 PRESSURE TRANSDUCER CALIBRATION 13

2.14 FULL LOAD FEATURE 13

3. SEQUENCING WITH VARIABLE SPEED DRIVE COMPRESSORS 15

3.1 VARIABLE SPEED DRIVE APPLICATIONS 15

3.2 SETUP FOR FIXED SPEED MACHINES AND A VSD COMPRESSOR 15

3.3 SETUP FOR MULTIPLE VSD COMPRESSORS 16

4. OPERATION WITH REMOTE CONTROLLERS 17

4.1 NORMAL OPERATION 17

4.2 CONTROLS WIRING AND ADJUSTMENT – SUPERVISOR CONTROLLER 17

4.3 CONTROLS WIRING AND ADJUSTMENT – SUPERVISOR II DELUXE 18

4.4 CONTROLS WIRING AND ADJUSTMENT – WS CONTROLLER 19

OPERATOR IS REQUIRED TO READ

ENTIRE INSTRUCTION MANUAL

Continued

TABLE OF CONTENTS

5. SEQUENCING TIMERS FOR EFFICIENT OPERATION 21

5.1 RECOVERY TIME AND DELAYED START TIMER 21

5.2 TIMER OPERATION EXAMPLES 22

5.2.1 EXAMPLE 1– UNLOAD OPERATION 22

5.2.2 EXAMPLE 2– LOAD OPERATION 22

5.2.3 EXAMPLE 3– STARTING EXAMPLE 23

5.2.4 EXAMPLE 4– STARTING EXAMPLE 23

5.3 SEQUENCING TIMERS SUMMARY 24

6. CONTROLLER COMMUNICATION PROTOCOL 25

6.1 RECOVERY TIME AND DELAYED START TIMER - OVERVIEW 25

6.2 ADVANTAGES OF BROADCAST MODE 25

6.3 RS-485 SERIAL CHANNEL 26

6.4 TIME SLICING OF THE RS-485 SERIAL CHANNEL 26

6.5 MESSAGE FORMAT 27

6.6 MESSAGE TYPES 27

6.7 DATA TYPES 29

TELEPHONES, FAX AND ADDRESSES BACK COVER

Section 1

SAFETY AND

INTRODUCTION

1

1. SAFETY AND INTRODUCTION

1.1 SAFETY

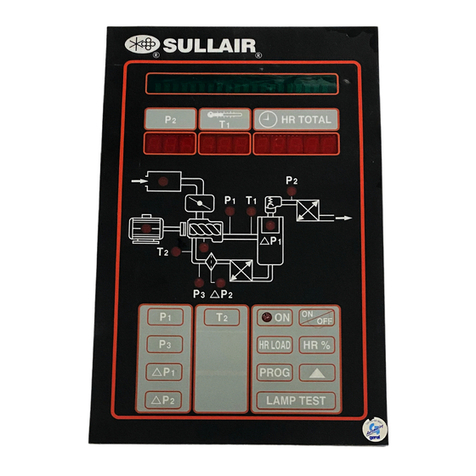

1.2 SUPERVISOR CONTROLLER, SUPERVISOR II AND WS CONTROLLERS

This manual describes sequencing of multiple compressors with Supervisor Controller,

Supervisor II Deluxe or WS Controller. The term "controller" is used to apply to any of

the three devices, however, specific differences will be highlighted in the places where

they apply. Although each controller differs considerably in individual compressor

functions and user interface, they behave similarly in sequence capabilities. Any of the

controllers can be mixed within a compressed air system consisting of multiple machines.

Refer to the specific controller instruction manual for details on compressor operation and

adjustment of the controller.

1.3 SEQUENCED COMPRESSOR SYSTEMS

Compressor sequencing refers to using multiple compressors to meet the demands for

compressed air. This may be a simple duplex system or may consist of multiple

compressors used in applications with widely varying demands. The main concept for all

configurations is for the compressors to operate automatically when compressed air is

needed and to automatically stop if not needed. A properly designed system can offer

substantial reductions in operating cost over a single large compressor.

Many duplex systems are designed with one primary compressor accompanied by one

spare compressor. This configuration allows the system to remain operational during

maintenance of a machine. The controller efficiently runs the compressors to meet the

varying demands during the day and runs the backup compressor only when needed.

The Supervisor, Supervisor II Deluxe, and WS Controllers all feature internal sequencing

functions. The Supervisor Controller requires a separate communications module for

these features. The machines operate as a distributed control system (rather than a

The Operator should be familiar with all safety measures as described in the

Supervisor Controller, Supervisor II Deluxe, or WS Controller Instruction

manuals

(

whichever

p

ertains

)

.

Machines should be off-line and not running when making parameter changes.

Unexpected machine operation may occur.

NOTE

For information specific to the Supervisor Controller, Supervisor II Deluxe, o

r

WS Controller, consult the Instruction Manual for that specific controlle

r

model.

Section 1

SAFETY AND

INTRODUCTION

2

master-slave relationship) so the system remains operational even if a member is taken

off-line. Both the Supervisor Controller and WS Controller can be configured with up to

16 machines in a sequence system. When one or more Supervisor II Deluxe Controllers

are in the system, the maximum number of machines is eight. Refer to Section 2 for

details.

A system with one or more variable-speed compressors offers additional opportunities for

control. Refer to Section 3 for details on sequencing with variable speed compressors.

Section 4 covers application of controllers in master-controlled systems.

Section 5 describes the operation of timers used in an internal sequencing system.

Section 6 contains technical details of the hardware and protocol used on the

communication bus. Other equipment may monitor the communication bus for data and

assessment of system performance.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

3

2. SEQUENCING WITH MULTIPLE CONTROLLERS

2.1 NORMAL OPERATION

The Supervisor, Supervisor II Deluxe, and WS Controllers all feature internal functions

that enable sequencing of multiple machines.

•To enable a Supervisor Controller in the system, press the START pad and

REMOTE pad on the keypad.

•Enable the Supervisor II Deluxe by simply pressing the AUTO pad.

•Enable the WS Controller by simply pressing the START pad .

•Stop any individual compressor by pressing the STOP pad for that unit. The

remaining compressors will continue to operate as needed.

The Supervisor Controller has a Remote keypad on the display module that is used to

enable and disable the controller from any sequencing mode currently programmed.

When the Remote key is first pressed after sequencing has been programmed, the

sequencing mode will be enabled and the REMOTE LED on the Display Module will

illuminate. Pressing the Remote keypad again will turn off the LED and disable the

sequencing mode. The compressor will then operate as though it is not in any

sequencing mode. The process will be reversed when the Remote keypad is pressed

again.

2.2 COMPRESSOR SYSTEM

Internal controller sequencing is designed to operate a group of (2-16) compressors

feeding a common header. As air demands change, the compressors will be controlled

to deliver the required compressed air in an efficient manner. If a group of similar

compressors is used, the controllers can be set up to automatically rotate operation to

equalize run time. The controllers can also be configured for a desired order of

compressor operation. The three modes of sequencing operation are described below:

SEQUENCE HOURS - The order a compressor is set to run in a sequence operation

based on the machine’s sequence hours. In this mode, machines are started and

loaded depending on the SEQUENCE HOURS (Seq. Hrs) parameter. Typically the

machine with the next lowest number of sequence hours will be the next in sequence to

start and load. The sequence hours parameter is similar to run hours except that it can

be changed. A machine taken out of sequence will be skipped and the machine with

the next lowest number of hours in the sequence will be next to start and load. While

Sequence Hours mode is active, digital inputs for Remote control are disabled and

Rotate hours function is disabled.

COM NUM - In this mode, a machine is started and loaded depending on the

COMMUNICATION NUMBER parameter assigned to the machine. Operation is

exactly the same as the SEQUENCE HOURS method (see above) except the

communications number is used to determine machine sequence instead of sequence

hours. Typically, the machine having a com number that is one number higher than the

previous started machine will be the next to start and load. A machine taken out of

sequence will be skipped and the machine with the next consecutive comm number in

the sequence will be next to start and load. Digital inputs for Remote control are

disabled.

SEQUENCE HOURS with ROTATE Hours Enabled – This SEQUENCE hours

configuration applies only to two-machine applications that supply a demand for only

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

4

one machine. DO NOT enable this mode in systems with more than two machines

(See ROTATE hours parameter setting for more information). Digital inputs for remote

control are disabled.

2.3 WIRING AND PIPING

Control signals are passed along a simple network cable, Belden 9842 or similar. This

cable has two twisted pairs with a shield. Twisted pairs usually have one color coded

wire twisted with a black or white wire.

For Supervisor Controllers, one twisted pair is connected to ISO+ and ISO- on the

Supervisor Comm module. Make sure that the color coded wire is connected at ISO+

and the white or black wire is connected at ISO-. Both wires of the other twisted pair

must be connected to ISO GND. The wire shield must be connected to ground at one

end only.

For Supervisor II Deluxe Controllers, the color coded wire is to be connected to J2-16

and the white or black wire to J2-17. Both wires of the other twisted pair are to be

connected to J2-18.

For WS Controllers, connections may be made to either J11 or J12. The color coded

wire is connected to PF 485+ and the white or black wire connects to PF 485-. Both wires

of the other twisted pair are to be connected to PF 485C.

For the most efficient operation in a sequential system, the P2 (line pressure) transducers

of all machines should be connected to a common header, down stream of individual

dryers, etc. Note that the dP1 (separator maintenance delta pressure) may need to be

calibrated to take into account the extra pressure drop of the down stream equipment.

Refer to Section 2.13 for steps on calibrating the system pressure readings.

2.4 MACHINE PREPARATION PRIOR TO SEQUENCING

For each machine to be connected in the sequence:

1. Complete all machine startup procedures as required for stand-alone operation.

Refer to the specific compressor operator and controller manual for each machine.

2. Calibrate the P2 signal for all machines to read the same pressure at the common

header. Each controller must be calibrated to read the same P2 pressure (±1 psi) of

the common header psi.

If necessary, recalibrate the P2 signal for each controller in the system. Refer to Section

2.13 for procedure on pressure calibration.

3. Program each machine with a different COM ID number (i.e.1, 2, 3, etc.).

4. Set the following parameters the same for each machine (except for VSD

applications).

DO NOT enable the Rotate Hours mode when the above situation is NOT true.

Unexpected starts and stops may occur when manually starting or stopping a

machine in the sequence.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

5

a. UNLOAD psi

b. LOAD psi

c. BAUD RATE (Supervisor II only). Baud Rate for Supervisor and WS is fixed

at 9600.

d. SEQUENCE mode (COM ID or HOURS)

e. LAST COM

f. LOWEST (minimum pressure before a machine is started)

g. RECOVER time (normally set at 10)

h. Leave ROTATE hours disabled except for the specific application described

in Section 2.8.

i. Set all sequence hour parameters the same unless it is desired to force

certain machines to initially run longer than others in the HOURS mode.

5. Start the machines for sequencing as described in Section 2.1. Machines will start

immediately if the P2 system pressure is low. On a fully pressurized system the

machines will go into a standby state until a demand is recognized.

2.5 SYSTEM OPERATION

The following example describes how machines are started, fully loaded and unloaded by

the sequencing mode selected. The Automatic mode provides the means for each

machine to stop by timing out on its unload timer when the sequencing order indicates

the machine is to be unloaded.

For this example three machines are in a system with the load pressure set at 100,

unload limit pressure at 110 psig (7.6 bar), lowest pressure limit at 90 psig (6.2 bar), and

Recovery Time at 10 seconds (default value). All machines are stopped.

1. When the pressure drops below 102 psig (7.6 bar) a timer starts counting down from

120 seconds, if the pressure continues to drop the timer will count down faster

(increments will be shorter).

2. When the timer expires or the pressure drops below 90 psig (6.2 bar) the first (or

next) machine in the sequence is started.

3. If the pressure does not go above 90 psig (6.2 bar) for 10 seconds (Recovery Time)

the second (or next) machine in the sequence will start. This process will continue

until all machines are started or loaded.

4. As machines are started and loaded, there will be only one machine that is

modulating, the others will be forced to "FULL LOAD". The modulating (trim)

machine will load at 2 psig (0.14 bar) above the load pressure parameter, 102 psig

(7.03 bar) in this example, and unload at 2 psig (0.14 bar) below unload pressure

parameter, 108 psig (7.4 bar) in this example. The reason for this narrow

load/unload band is to keep all machines from loading and unloading at the same

time.

5. If the pressure rises above the unload pressure -2 psig (0.14 bar) to 108 psig (7.4

bar) the trim machine will unload (display will read "UNLOADED") and the next

machine in the sequence will switch from full load to trim.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

6

6. If, after Recovery Time, the pressure is still above 108 psig (7.4 bar) then the

current trim machine will unload. This process can continue until all machines are

unloaded.

7. If the pressure falls below load pressure +2 psig (0.14 bar) or 102 psig (7.03 bar) the

first machine in the sequence will load and operate as the trim machine.

8. If after the Recovery Time the pressure is still below 102 psig (7.03 bar) then the

trim machine will go to full load and the next machine in the sequence will load and

become the trim machine.

2.6 SYSTEM SETUP AND TUNING

Table 2.1 lists settings for a system of low pressure (90-100 psig (6.2 to 6.9 bar))

machines used in a typical sequencing configuration. The Trim High & Low Setpoints are

not user settable parameters. These values are calculated from the Unload and Load

pressures. The Trim High Setpoint is 2 psi (0.14 bar) below the Unload pressure. The

Trim Low Setpoint is 2 psi (0.14 bar) above the Load pressure.

Table 2.1 Low Pressure Machine Settings (typical)

Machine Setting: Value

Unload Pressure 100 psig (6.9 bar)

Trim High Setpoint (calculated parameter) 98 psig (6.8 bar)

Trim Low Setpoint (calculated parameter) 92 psig (6.3 bar)

Load Pressure 90 psig (6.2 bar)

Lowest pressure 85 psig (5.9 bar)

Recover time (seconds) 10

Note that the unload pressure is set to 100 psi (6.9 bar) and not 110 psi (7.6 bar) as is

normal on a stand alone machine. A stand alone machine set up at 100 psi (6.9 bar) to

110 psi (7.6 bar), starts to modulate above 100 psi (6.9 bar) and the horsepower is

reduced. However, in a sequenced system a machine may be forced to full load, which

would draw more than the rated horsepower above 100 psi (6.9 bar). Therefore, the

modulation band of machines in a sequencing system should be set up to be 10 psi (0.7

bar) lower than their rated pressure.

All running machines in a sequence operate either at full load or unloaded except for one

which is operated as the trim machine. The trim machine unloads when the line pressure

rises above the Trim High setpoint.

Trim High and Trim Low setpoints signal the trim machine to unload before the fully

loaded machines and load before the unloaded machines. Otherwise, all machines

would load and unload at the same time.

LOWEST pressure parameter specifies the lowest pressure allowed before immediately

starting a machine. A machine may also be started if the line pressure drops below the

Trim Low setpoint for a determined period of time.

RECOVER time keeps multiple machines from loading, unloading or starting at the same

time. A timer is reset when a machine loads, unloads or loads after a start. Decisions to

load, unload or start another machine are deferred until the timer reaches the RECOVER

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

7

time setpoint. Note that the timer starts when a machine is added or taken away from the

system.

If the pressure recovers within the RECOVER time, and then at a later time the pressure

drops below the Trim Low setpoint, the next machine in sequence will load immediately.

The shorter the recovery time the more responsive the system to load changes.

However, the system would be less energy efficient with shorter recovery times since the

machines may not shut off as often. The more frequently a machine loads the less likely

it is to stay unloaded and shut off after the Unload timer expires. Refer to Section 5 for

details on Recovery Timers.

The RECOVER TIME has a default value of 10 seconds. This parameter may be

adjusted in one second intervals from 2 to 59 seconds.

2.6.1 GENERAL SEQUENCING RULES

The following rules apply to load, unload and start of machines in a sequence. Note that

the terms “highest” and “lowest” refer respectively to machines with the highest and

lowest SEQ HRS or COM ID.

Rule 1. Only the highest loaded machine will trim; the rest will be forced to full load.

Rule 2. The trim machine will unload when the line pressure rises above the Trim High

setpoint.

Rule 3. The next highest loaded machine will then become the trim machine. If

pressure remains above the Trim High setpoint, the new trim machine will

unload after Recovery Time expires. This process will continue until enough

machines are running and loaded to maintain proper system pressure.

Rule 4. The lowest unloaded machine will load (trim) when the line pressure drops

below the Trim Low setpoint. If the pressure remains below the Trim Low

setpoint the next Unloaded or Sequence Stopped machine will load or start

after the Recovery Timer expires. This process will continue until enough

machines are running and loaded to maintain proper system pressure.

Rule 5. The lowest stopped machine will start when the line pressure drops below the

Trim Low setpoint, and after a variable time out period (up to 120 sec.). This

time out is dependent on how far the line pressure is below the Trim Low

setpoint. The farther the line pressure is below the setpoint the shorter the

time to start.

Rule 6. The lowest stopped machine will override the above variable time out feature

and start when the line pressure drops below the Lowest Pressure setpoint,

and after the recovery timer expires.

2.7 CHANGING SEQUENCE PARAMETERS

Supervisor Sequence Parameters

Perform the following steps to change sequence parameter settings using the Supervisor

Controller:

1. Press the Down arrow key until the SEQUENCING menu is displayed.

2. Press Enter .

3. Use the Up and Down arrow keys to navigate through the menu selections to

the parameter to be edited.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

8

4. Press Enter to select the parameter for editing.

5. If a numeric value is to be entered, Use the Right and Left arrow keys to

position the cursor over the number digit to be changed.

6. Use the Up and Down arrow keys to change the parameter value.

7. Press Enter to save the changed value.

Supervisor II Deluxe Sequence Parameters

Perform the following steps to change sequence parameter settings using the Supervisor

II Deluxe Controller:

1. Push the Program key until the top line of the display identifies the sequence

parameter to be changed.

2. Press the Up arrow and/or Logo keys to increment the sequence parameter

value or press the Down/Lamp Test key to decrement the value.

3. Push the Program key to save the changed value. The next sequence

parameter will then be displayed.

Changing Sequence Parameters – WS Controller

Refer to the WS Controller PC User Interface Manual for instructions on changing

sequence parameters. The following sequence parameters can be changed at the WS

PC User Interface:

PARAMETER OPTIONS

Sequence by.................Disabled, Remote, Slave, Hours, COM Number

Sequence hours............Integer value for sequence hours setting

Com number.................1 - 16

Machines.......................1 - 16

Low press (PSI)............30 psi - 248 psi

Recover time.................2 sec. - 60 sec.

Rotate ...........................Integer value for number of rotate hours

2.8 SEQUENCE PARAMETER NAMES

Listed below are names of Supervisor and WS Controller sequence parameters that can

be modified when sequencing is enabled. Supervisor II Deluxe sequence parameters are

shown in parenthesis with the numerical order in brackets. The WS Controller uses a PC

interface to modify parameter values.

Sequence by (SEQUENCE[9]) - Select the desired sequencing mode.

Sequence hours - The maximum value for sequence hours is 100,000. A rollover to

zero will occur if that number is exceeded.

(SEQ HRS[17]) - Pushing the Logo key will increment this value by 1000 hours, the

Up arrow key will increment by 100 hours and the Down/Lamp Test key will

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

9

decrement by 100 hours. The maximum value for this parameter is 30,000 hours. The

number will roll over to zero if this number is exceeded.

Com Number (COM ID#[7]) - Must be unique ID number for every machine in the

system. If there are three machines in a system, for example, they must be numbered 1,

2 and 3. Up to 16 machines may be sequenced in systems using Supervisor and WS

Controllers. Systems containing one or more Supervisor II Deluxe controllers are limited

to eight compressors in a sequence.

Machines (LAST COM[12]) - Set as the total number of machines in a system.

Low Press (LOWEST[13]) - Set as the lowest allowable pressure before a machine has

to start. Normally this is 5 to 10 psi (0.3 to 0.7 bar) below the load pressure. If the

system pressure drops below this limit then the machine with the lowest SEQ HRS or

COM ID is started immediately. A machine will also start if the pressure is below the Trim

Low Setpoint for a period of time. The length of this time period is 0 to 120 seconds

depending on the pressure and is controlled by the Delayed Start Timer. The closer the

pressure is to LOWEST pressure the shorter the time. For example if the pressure drops

below the Trim Low Setpoint by 1 psi (0.07 bar), and remains there, a machine will start

in 120 seconds. If the pressure drops near LOWEST PRESSURE then a machine will

start after just a few seconds. Refer to Section 5 for details on Delayed Start Timer

operation.

Recover Time (RECOVER[14]) - Recovery time. This parameter adds a delay between

subsequent start, load and unload commands. Refer to Section 5 for further explanation

of Sequencing Timer operation.

Rotate (ROTATE[15]) - Rotate time for two-machine systems only. The rotate parameter

forces the trim machine to stop (allowing the other machine to start). The trim machine

will stop when its sequencing hours are more than a stopped machine sequencing hours

based on the rotate hours value.

For example, consider a two-machine system with SEQUENCING hours of 1000 and

ROTATE of 50 hours on each machine. If one machine is started and continuously

loaded, it will run until it's sequence hours are 1050 (50 hours more than the stopped

machine) then stop. The other machine will start and run until it's sequence hours are

1100 (50 more than the stopped machine) then stop, and so the machine will rotate back

and forth every 100 hours.

DO NOT enable Rotate mode when more than two machines are connected in a

sequence. Unexpected starts and stops may occur when manually starting o

r

stopping a machine in the sequence for maintenance.

NOTE

There are some systems where the trim machine never unloads or stops and

the second machine is never required in normal sequence operation. This

applies specifically to a two-machine system where one machine runs all the

time and the other is used onl

y

for backu

p

.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

10

(BAUD RATE[8]) – All controllers in a system must be set to the same Baud Rate. The

Supervisor and WS Controller baud rate is fixed at 9600 baud. The Supervisor II Deluxe

allows adjustment of the serial communications baud rate, usually set to 9600.

2.9 SYSTEM DISPLAY- SUPERVISOR CONTROLLER

The Supervisor Controller System Menu allows the user to observe the status of other

compressors in a sequence. The option is useful when monitoring, troubleshooting and

calibrating the compressor system. To access the System Menu and view the status of

the machines:

1. Press the up arrow until the word “SYSTEM” appears on the bottom line of the

display screen.

2. Press Enter.

3. Use the down and up arrows to scroll through the data relating to each machine

in the sequence.

Data for the machines will appear in five columns across the display screen. The first

column of the display shows the machine Comm numbers (#1 through the total number

of machines in the system) set by parameter LAST COM. The second column shows the

status (Stat) of each machine as noted in the following chart. The third column displays

the machine sequence hours (Hrs) parameter. The fourth column shows the Capacity

(Cap) at which the machine is delivering air. The heading of the fifth column displays the

highest P2 pressure in the system with the P2 pressure for each respective machine

displayed down the column. Status letters appearing in lower case indicate the machine

has a fault or warning.

The status letters that may appear on the Supervisor display are:

B – Standby R - Remote or sequence stop

E - E-Stop S - Starting

F - Full Load T - Trim (loaded and modulating)

L - Loaded U - Unloaded

M - Manual stop X - Remote Disable (WS Controller only)

2.10 SYSTEM DISPLAY- SUPERVISOR II DELUXE

The Supervisor II Deluxe SYSTEM menu allows the user to observe the status of other

compressors in a sequence. The option is useful when monitoring, troubleshooting and

calibrating the compressor system. To access the System Menu and view the status of

the machines in the sequence:

1. While in the main display, push the Logo key.

2. Press the “Display” ( ) key. The top line of the display will show the numbers 1

through the number of machines in the system (maximum of 8 for the Supervisor

II). The second line shows the status of each machine. Status letters in lower

case indicate the machine has a fault or warning.

The status letters that may appear on the Supervisor II Deluxe display are:

B – Standby R - Remote or sequence stop

E - E-Stop S - Starting

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

11

F - Full Load T - Trim (loaded and modulating)

L - Loaded U - Unloaded

M - Manual stop X - Remote Disable (WS Controller only)

If the Up arrow key is pushed the system line pressure is displayed. If the Up

arrow key is pushed again the line pressure and sequence hours of the first machine is

displayed. If the Up arrow key is pushed again, data for the next machine is

displayed. Subsequent press of the Up arrow key allows for viewing of data for each

machine in the system. A press of the Lamp Test key reverts back to the preceding

display.

2.11 SYSTEM DISPLAY- WS CONTROLLER

The system display for monitoring sequencing of WS Controllers is accessed via the WS

PC software program. Refer to the WS PC User Interface Manual for steps to viewing

parameter data of machines in a sequence.

2.12 REMOVING A MACHINE FROM SEQUENCE FOR MAINTENANCE

To temporarily disable a machine from sequencing for maintenance:

1. Press the STOP pad and/or E-Stop Button.

2. Remove power from the machine to serviced.

3. Apply the appropriate Lockout/Tagout procedure.

The rest of the networked machines will continue to sequence properly.

To restore a machine to the network:

1. Restore power to the compressor.

2. Pull out the E-stop if it has been pressed.

3. To enable a Supervisor Controller in the system, press the START pad and

REMOTE pad on the keypad.

4. Enable the Supervisor II Deluxe by simply pressing the AUTO pad.

5. Enable the WS Controller by simply pressing the START pad .

If the sequencing parameters have not been changed, the machine will sequence in at

the appropriate time. A machine operating in Sequence Hours mode may be moved up

or down in the sequencing start priority by revising that machine's sequence hours before

enabling sequencing.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

12

NOTE

When a machine is permanently removed from a sequence, the COM NUMBERS

should be reassigned to the remaining machines and the LAST COM value

must be changed to match the total number of machines still in the sequence.

NOTE

All program changes must be accomplished while the machine is manually

stopped.

2.13 CALIBRATION OF P2 PRESSURE TRANSDUCERS

Each individual compressor is equipped with a pressure transducer. Over time, it is

possible that the reading from one machine’s pressure transducer may read differently

from another machine. Prior to sequencing and periodically, Controllers should be

calibrated to reflect the same measurement of P2 pressure through out the system.

Perform the calibration when the system is at a stable pressure.

2.13.1 SUPERVISOR P2 PRESSURE TRANSDUCER CALIBRATION

Perform the following steps to calibrate the Supervisor Controller P2 pressure reading:

1. Measure the pressure using an independent certified gauge.

2. Enter the password to access the Supervisor Calibration menu.

a. If the password is not equal to zero, navigate to the password line.

b. Press the ENTER key.

c. Enter a value that is four more than the existing number.

d. Press the ENTER key. The number should go to zero.

e. Repeat this process if a keying error occurs that does not release the password.

3. Change the calibration parameter for P2 so that the Pressure value at the Supervisor

reads the same as the gauge.

a. Use the Down arrow key to navigate to the line that reads CAL P2. The

display will show the current P2 reading and the calibration parameter (+7 to -7).

b. Press the ENTER key to adjust the value.

c. Use the Up arrow key to increase the reading and the Down arrow key to

decrease the reading.

d. Press the ENTER key. The Enter key must be pressed after setting the

calibration parameter to make it permanent.

e. Return to the main display by pressing ESC.

4. Recheck the pressure to ensure the display reading is correct.

Section 2

SEQUENCING WITH

MULTIPLE CONTROLLERS

13

2.13.2 SUPERVISOR II DELUXE P2 PRESSURE TRANSDUCER CALIBRATION

Perform the following steps to calibrate the Supervisor II Deluxe Controller pressure

reading:

1. Measure the pressure using an independent certified gauge.

2. Enter the following special key sequence to enter the Calibration menu: Logo , Up

arrow , Display , Lamp Test , Program .

3. Ensure that the first line of the display reads CAL P1, if not push the Display key and

enter the above key sequence again.

4. When the first line of the display reads CAL P1 push the Program key. The first line

of the display will then read CAL P2. The second line of the display will show the

calibration parameter (range +7 to -7) and the current P2 pressure reading.

5. Change the calibration parameter for P2 so that the pressure value at the Controller

reads the same as the gauge.

a. Use the Up arrow key to increase the reading and the Lamp Test key to

decrease the reading.

b. Push the PROGRAM key. The Program key must be pressed after setting

the calibration parameter to make it permanent.

6. Recheck the pressure to ensure the display reading is correct.

2.13.3 WS CONTROLLER P2 PRESSURE TRANSDUCER CALIBRATION

Perform the following steps to calibrate the WS Controller pressure reading:

Calibrate the WS Controller P2 pressure using the WS PC User Interface. Refer to the

WS PC User Interface Manual for details.

Recheck the pressure to ensure the display reading is correct.

2.14 FULL LOAD FEATURE

The full load feature energizes a solenoid valve on the machine that forces the base

machine(s) to full load when being sequenced. Spiral valve machines may also require a

relay that de-energizes the spiral control solenoid valve during full load mode.

14

NOTES

Section 3

SEQUENCING WITH VARIABLE

SPEED DRIVE COMPRESSORS

15

3. SEQUENCING WITH VARIABLE SPEED DRIVE COMPRESSORS

3.1 VARIABLE SPEED DRIVE APPLICATIONS

A multiple-compressor system can be designed using a variable-speed-drive (VSD)

compressor combined with other VSD compressors or fixed speed compressors. The

most efficient use of a VSD machine in sequencing is to set it up to always be the trim

machine and always running. This is accomplished using existing Sullair sequencing

logic as explained in the following sections.

3.2 SETUP FOR FIXED SPEED MACHINES AND A VSD COMPRESSOR

The fixed-speed machines in a mixed sequence system must always be set up for

load/unload operation. If controlled with Supervisor II Deluxe controllers, the pressure

regulator/s must be made to have no effect by setting the system to operate below the

effective range of the regulators. If controlled by the Supervisor Controller or WS

Controllers, the controls may be programmed for Load/No load operation. In this

configuration, the Full Load valve is energized any time the machine is running, thus

defeating modulation. Alternately, the Full Load solenoid valve may be rewired to the

Load output with any of the controllers (Supervisor Controller, Supervisor II Deluxe, or

WS) to achieve the same results. In all cases, care must be taken to not overload the

compressors by limiting operation to pressures within the capability of the drive motor.

See Table 3.1 for suggested settings of compressors in a mixed sequence configuration.

These settings are typical for a target system pressure of 99 psi at discharge of

compressors.

Table 3.1 Mixed System Settings (Target Pressure: 99 psi)

Parameter VSD Compressor

Settings Fixed-Speed Compressor(s)

Settings

Unload Setpoint 104 102

Load Delta 6 6

VSD Setpoint 99

Com # COM #1, 2 (, 3, 4, etc.)

Lowest Pressure 90

Since this machine is to always be the trim machine, no Full Load action is needed. The

Max Speed input signal should be disabled unless more than one VSD machine is in the

same sequence.

In this configuration, only the fixed-speed compressors are sequenced and the VSD

machine is run with its sequencing disabled. The Sequence hours mode can then be

used to automatically rotate the fixed-speed machines, or the fixed-speed machines may

be sequenced based on Com #.

Depending on the application and system demands, the VSD compressor can either be

run continuously or in the AUTO mode. This will allow the unload time to be minimize to

as low as an immediate stop on unload.

This arrangement sets the VSD machine to always restart at a higher pressure than the

fixed-speed machines thus forcing it to always operate as the trim machine. By adjusting

Section 3

SEQUENCING WITH VARIABLE

SPEED DRIVE COMPRESSORS

16

the VSD Unload time in AUTO mode and the fixed-speed restart times, rapid cycling and

hunting can be minimized.

The pressure regulator of a fixed-speed L (100 psi) compressor does not begin to throttle

until 101 - 102 psi. As a result, the pressure regulator has no effect, and the machine will

operate Load/Unload with or without the full load solenoid valve. The net result is that the

VSD compressor will always be running and able to modulate; the fixed-speed machines

would come on and go off as needed but operate Load/Unload.

Note that the normal load delta becomes narrower while operating a sequenced system.

The settings above will load at 97 and unload at 101 psi. The system will typically

maintain 98-100 psi.

3.3 SETUP FOR MULTIPLE VSD COMPRESSORS

With pressure-controlled VSD circuits, configure all compressors by Sequence Hours or

Com Number, as desired. Enable the Max. Speed Input function. All but one of the

compressors will be full-loaded, thus limiting the pressure to the rated value of the

machines.

With serial-controlled VSD circuits, configure all compressors by Sequence Hours or

Com Number, as desired. The controllers allow all machines to run at reduced speeds to

match delivery to demand. Unneeded machines will be stopped automatically. If the

compressors are L (100 psi) machines, set the program points as shown in Table 3.2:

Target system pressure at discharge of compressors: 95 psi

Table 3.2 Multiple VSD System Settings

Parameter VSD Compressor Settings

Unload Setpoint 102

Load Delta 8

VSD Setpoint 98

Lowest Pressure 90

Recover Time 10 sec.

Parameters may require adjustment based on system capacity and application.

Unload Setpoint should NEVER be more than 2 psi above package rating.

Note that the normal load delta becomes narrower while operating a sequenced system;

the settings above will load at 95 and unload at 101 psi. The system will typically

maintain 97-99 psi.

Other manuals for SUPERVISOR CONTROLLER

2

This manual suits for next models

2

Table of contents

Other Sullair Controllers manuals

Sullair

Sullair Supervisor II User manual

Sullair

Sullair 02250160-842 User manual

Sullair

Sullair Supervisor IE User manual

Sullair

Sullair WSPC User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair SUPERVISOR CONTROLLER Series User manual

Sullair

Sullair 900 User manual

Sullair

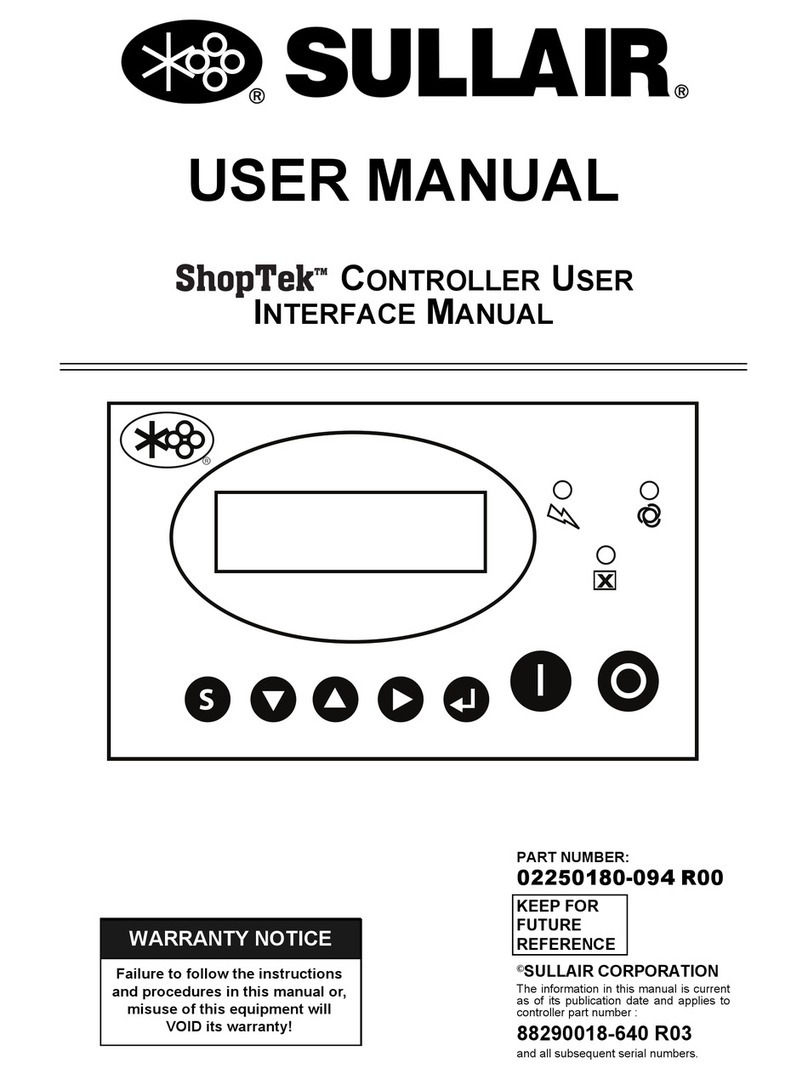

Sullair ShopTek User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

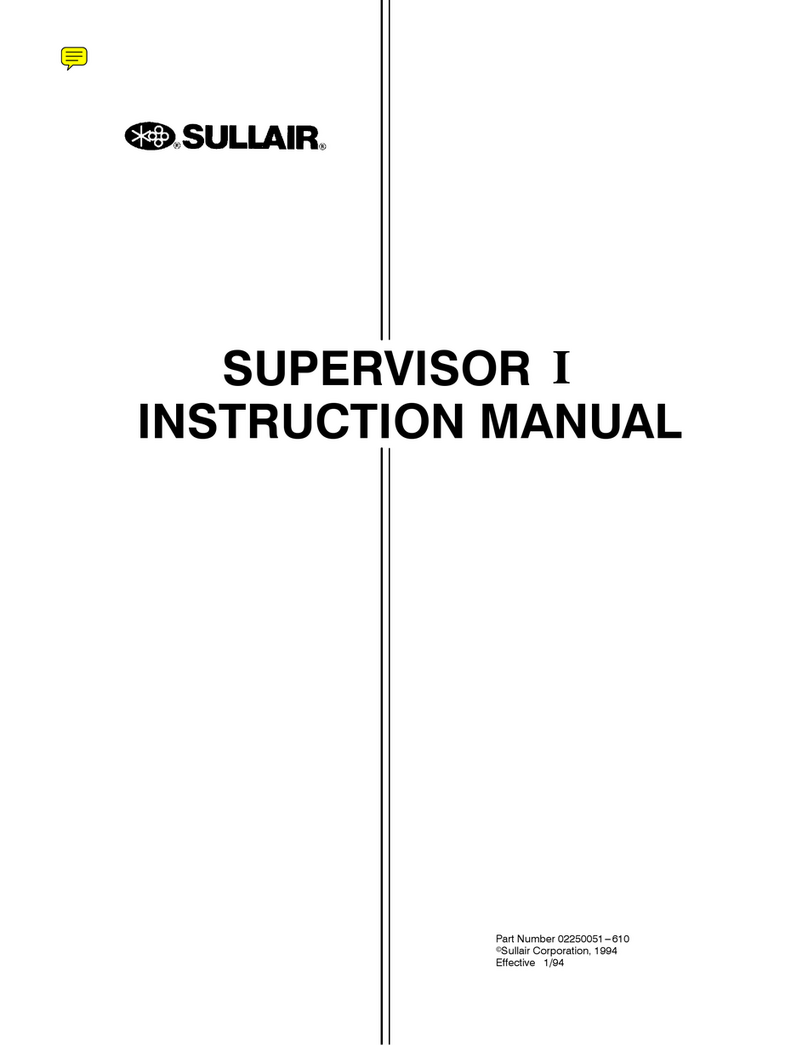

Sullair SUPERVISOR I User manual