RMG AWFAWLC-044 User manual

RMG

RMG AUTOMATION

+91 9940594413

Advanced Wireless Long Range

Fully Automatic Water Level Controller

Model : AWFAWLC-044

www.rmgautomation.com

http://rmgautomation.com [email protected]

User Manual

1. INTRODUCTION

Water saving is Lifesaving. RMG Automation introduces an automated way

to save water. AWFAWLC-044 is a Radio Frequency Based Wireless Water Level

Controller with Indicators, in which it helps to ascertain the level of water in the

over head tank & sump as well as automatically control the motor pump. The

motor is switched ON automatically when the water level in the over head tank is

low, making sure water is present in the under ground tank (sump). The motor is

switched OFF automatically when the tank becomes full, or when the sump is

empty. It also has low voltage, high voltage and dry run indications.

The maximum range that the product can work in line of site is 700 to 1000

meters. It has 2 outdoor transmitter units and 1 indoor controller unit. The

transmitter units are placed near the water tanks, whereas the controller unit is

placed near the motor pump control switch/starter location. This product is

suitable for underground to over head tank setup.

2. DESCRIPTION

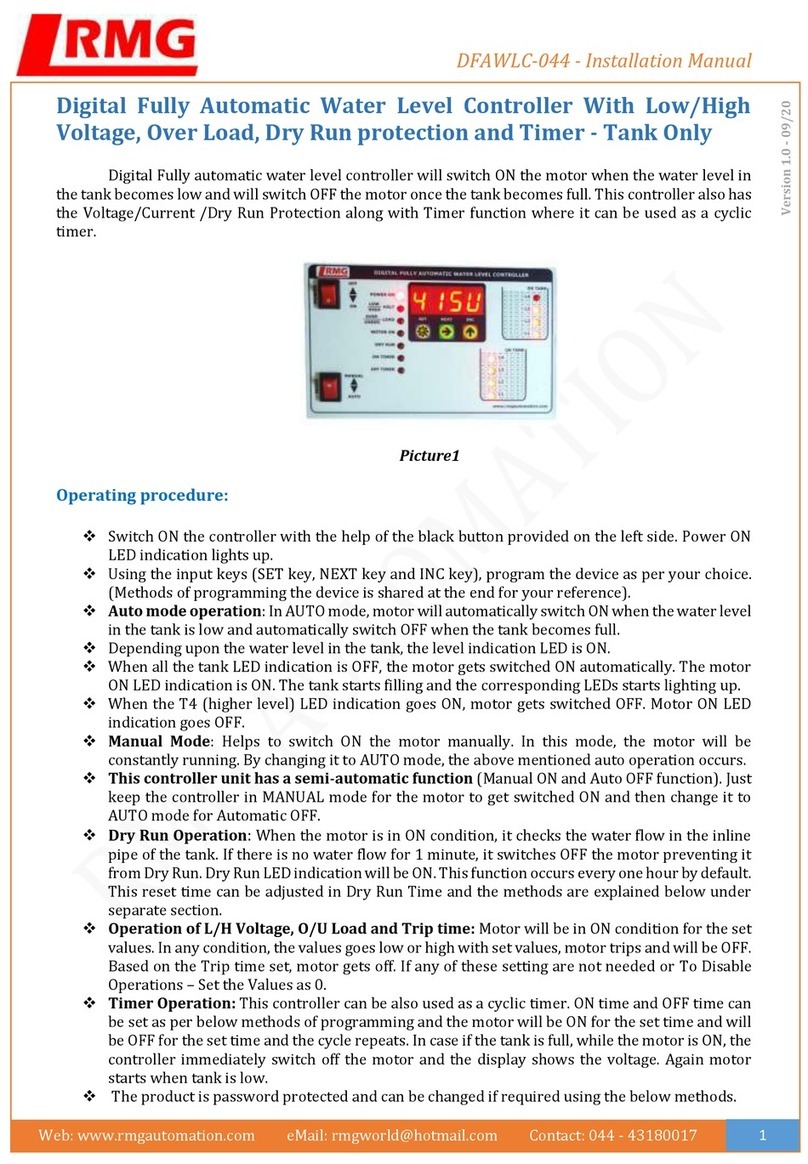

2.1 CONTROLLER / RECEIVER

ŸPower ON/OFF switch – used to switch ON / OFF the device.

ŸPower ON LED – shows ON/OFF status of device.

ŸON button – Used for manual motor ON. And for pairing the controller with

transmitter.

ŸOFF button – Used for manual motor OFF. And to enable/disable dry run option.

ŸRF SIGNAL LED – shows the signal status. When it blinks the communication

between transmitter & controller is good. When it is continuously glowing, it

means there is no communication.

ŸL/H VOLT LED - shows high/low voltage indication. If the LED glows motor will

not run and protect from voltage uctuations.

ŸDRY RUN LED - It indicates the dry run of motor and glows when there is no

water in the inlet of the tank for 90 seconds.

ŸMOTOR ON LED - It indicates the motor ON/OFF status.

ŸLevel Indicator LEDs - These LEDs shows the water levels of the tank and

sump. There are 4 level indications for both, each with 25%,50%,75% and

2.2 TRANSMITTER

ŸRF signal LED – It blinks once when the battery is inserted. It also blinks

whenever the controller device asks it for the water level.

ŸCharging LED – glows when battery is charging (red LED)

ŸCharging complete LED– glows when battery is fully charged (blue LED)

ŸSolar panel – 6V/100mA solar panel for charging battery.

ŸLi-ion battery – 3.7V rechargeable battery.

3. TOOLS REQUIRED

ŸDrill gun, Simple hammer

ŸWooden gattas

ŸScrews for mounting units on wall

ŸLine tester

ŸWire stripper

Ÿ1.5Sq.mm Wire for power &

control wiring

ŸInsulation tape, Cable (6 core)

1

Caution: Switch off the main power while doing the Power Connection.

Step 1: Wall mount the Controller unit nearby motor pump switch/starter

location. The location chosen should be near the window or in open space to ensure

good signal strength.

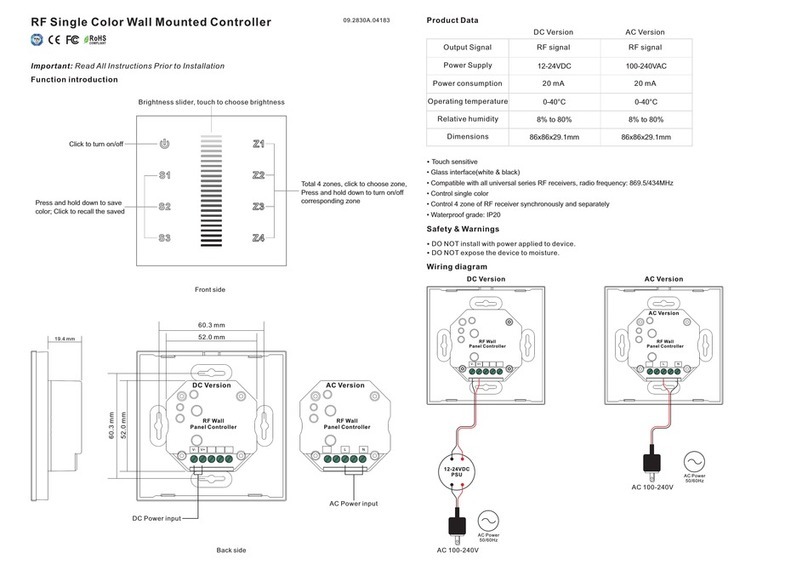

Step 2: As per your model purchased, Connect AC supply (AC 230/440V) to 1st

and 2nd terminal of the controller as shown in the gure1 or gure2.

Step 3: For switch or MCB, connect 3rd and 4th terminal of device in parallel to

the switch as shown in gure1.

4. INSTALLATION

PROCEDURE

Step 4: For starter type connection refer to gure2 & Figure3. In case of other

types of connections or doubt what's app to 9940594413 or call 044-43180017

Step 5: Turn ON the controller. Now, Power ON LED will glow. Unscrew the top

panel of transmitter. There is a battery holder inside it. Put the given Li-ion battery

inside the case, according to polarity. RF Signal LED blinks once.

Step 6: Take the transmitter near the overhead / underground tank. To check the

communication between transmitter and controller, Press the push button inside

transmitter for more than 16 seconds. RF Signal LED blinks two times with 5

seconds interval. This ensures the perfect communication between them. .

Step 7: Now power off the controller unit. Contact type sensor connection: Take

the sensors and cut them according to the levels of the tank and join them with

the sensors lines of transmitter as per color coding. (Refer gure4). Magnetic

oat sensor connection: These sensors has 2 wires. Use any one wire in each

sensor as common. Other wire left in each can be used for levels.

Step 8: Immerse the sensors in the water tank and place at 25%, 50%, 75%,

100% levels. Dry run sensor should be xed in the inlet of the tank. Join black &

green wire of transmitter to this sensor. No dry run connection for UG tank.

Step 9: Close the top panel of the transmitter using the screws. Place the solar

panel facing sun light using the double side tape.

This completes the installation 2

water

Inlet

(Brown)25%

(Red)50%

( )75%Orange

( )100%Yellow

(Black)CN

(Green)

DryRun

Figure1: 1Φ SWITCH/MCB

Figure3: 1Φ Starter

Figure4:

Trasnmitter

Figure2: 3Φ Starter

3Φ

MOTOR

R Y B

ON

OLR

NV

COIL

A1

A2

OFF

Remove

this wire

1Φ

MOTOR

AC230V

P N

ON

OLR

NV

COIL

A1

A2

OFF

Remove

this wire

AC 230V

P N

MCB /

SWITCH

1Φ

MOTOR

5. OPERATING PROCEDURE

ŸPower ON the controller unit.

ŸDepending upon the water level in tanks, the level indication LEDs are ON.

ŸIf the water level goes low, controller automatically TURNS ON the motor (only

when sump has water), during this time MOTOR ON LED glows. When the tank

becomes full, controller unit automatically TURNS OFF the motor. Motor will get

off even when sump level is low.

S.No

Error

Solutions

1

No

communicati

on between

controller

and

transmitter

a. Check whether any obstacles are there in between

transmitter and receiver units like large trees, buildings

etc.(Repeater can be added if necessary).

b. Check the battery in transmitter whether it is

connected correctly without any loose contacts.

c. Check whether the battery is completely drained out, If

so, charge the battery using the USB port in it for instant

charging.

2

Dry run is

not working

a. Check whether dry run option is enabled in controller

unit. Keep the controller in pairing mode. Press ON

button and without removing the nger turn ON the

controller. If DRY RUN LED is ON, the dry run option is

enabled. If DRY RUN LED is in OFF state, the dry run is

disabled.

b. Check the dry run connection on the tank whether it

has any loose contacts. If so correct it.

3

Tank level

indicator

LEDs are off

If one or all the level indicator LEDs are not glowing,

a. Check common sensor connection is correctly made. If

any loose contacts correct it.

b. Check all the sensor connections if they are having any

loose contacts. Also, check if the cable lines are intact.

6. TROUBLESHOOTING METHODS

3

ŸPAIRING PROCEDURE: The units are generally paired and given. In case of

any trouble at the time of installation, users can pair the units once again.

ŸPress the Green ON button and do not take the nger out while doing this.

Turn ON the controller. All the tank level LEDs will blink. It means the device

is ready for pairing.

ŸIn transmitter, there is a Push button inside it. By pressing the push button

and without taking out the nger from it, insert the battery into the battery

holder. Now the RF Signal LED inside transmitter blinks once and all the

tank level LEDs goes off in the controller unit. Thus pairing is completed.

ŸDRY RUN ENABLE/DISABLE: Set the controller in pairing mode. Use the

OFF button to enable or disable the dry run function which is denoted with

Dry Run LED indication.

Table of contents

Other RMG Controllers manuals