Highlander iP-2 User manual

The information and graphics contained in this document are the property of Highlander Musical Audio Products. Copying of any kind is prohibited, except for personal use only. © Highlander Musical Audio Products 1991-2009

For more information please visit our web site.

email: [email protected]

Contact us at:

USA & Canada Toll Free: 888.658.1819, Phone: 805.547.1410, Fax: 805.547.1228

870 Capitolio Way, Unit 3, San Luis Obispo, CA 93401

Dual System - Integrated Pickup and Preamp for Acoustic Guitar and Bass

Dual System - Integrated Pickup and Preamp for Acoustic Guitar and Bass

h

ighlanderpickups.com

ighlanderpickups.com

Thank you for purchasing the Highlander iP-2 Integrated Pickup System.

At Highlander we appreciate that it takes years of practice, dedication and personal growth

for an acoustic musician to develop the skills and spirit necessary to express themselves fully

through their music. Through years of practice, dedication and personal growth our highly

skilled team is crafting amplification equipment for these musicians that is so pure, we can all

fully appreciate and be moved by the true spirit of their music.

Built to take the rigors of the road, you can rely on a Highlander.

For optimum pickup pe

For o ptim um pic kup pe

rf

rf

ormance and ease of installation, please take a

orm ance a nd eas e of ins tall atio n, ple ase ta ke a

moment to read through this Installation Guide before beginning. Thank You.

moment to read through this Installation Guide before beginning. Thank You.

iP-2 INSTALLATION

iP-2 INSTALLATION

THIS INSTALLATION SHOULD ONLY BE UNDERTAKEN BY AN EXPERIENCED LUTHIER

THIS INSTALLATION SHOULD ONLY BE UNDERTAKEN BY AN EXPERIENCED LUTHIER

OR A GOOD WOODWORKER WITH EXPERIENCE WORKING ON ACOUSTIC STRINGED INSTRUMENTS.

OR A GOOD WOODWORKER WITH EXPERIENCE WORKING ON ACOUSTIC STRINGED INSTRUMENTS.

Using the wrong techniques or tools could result in permanent damage to your guitar.

Highlander is not responsible for any damage resulting from the installation of this pickup system.

Parts Included:

Qty. Description

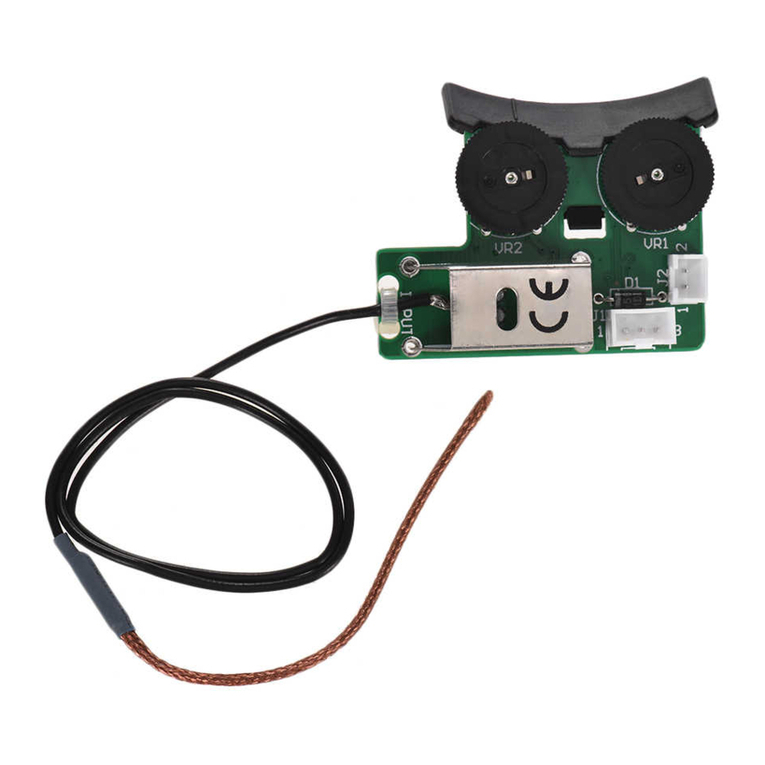

1 Pre-wired iP-2 Pickup/Preamp Assembly with an Access Jack

For connecting a 2nd source

2 Battery Holder Clips for 9 Volt Battery

3 Pieces of Self Adhesive Velcro® for cable strain relief

1 Stereo Mini-Plug for connecting a second transducer to the iP-2

Tools Required:

1) HAND DRILL or ELECTRIC DRILL (cordless preferred)

2) MILLING MACHINE or ROUTER AND SADDLE SLOTTING JIG

Used for routing the groove

3)* 17/32" (13.5mm) DRILL BIT, RELIEVED ON RAKE EDGES

Used for drilling guitar end block for the strap jack

4)* 9/16"-12 TPI NC TAP & MACHINIST'S TAP HANDLE

Used for threading end block to accept the strap jack

5)* 1/16" (1.6mm) DIAMETER BALL ENDED END MILL

Used for routing the groove in the bottom of the saddle slot

6) 3/32" (2.5mm) TWIST DRILL BIT

Used for drilling both holes in the saddle slot for the pickup

7) MILLING MACHINE or DISC / BELT SANDER or

MACHINIST'S VISE AND FILE. STRAIGHT EDGE

Used for reducing saddle height to

compensate for the pickup thickness

* The following installation tools are available from Highlander:

17/32" drill bit

9/16"-12TPI tap bit

1/16" router bit

These tools are available individually or as the 'iP-installation kit'

The information and graphics contained in this document are the property of Highlander Musical Audio Products. Copying of any kind is prohibited, except for personal use only. © Highlander Musical Audio Products 1991-2009

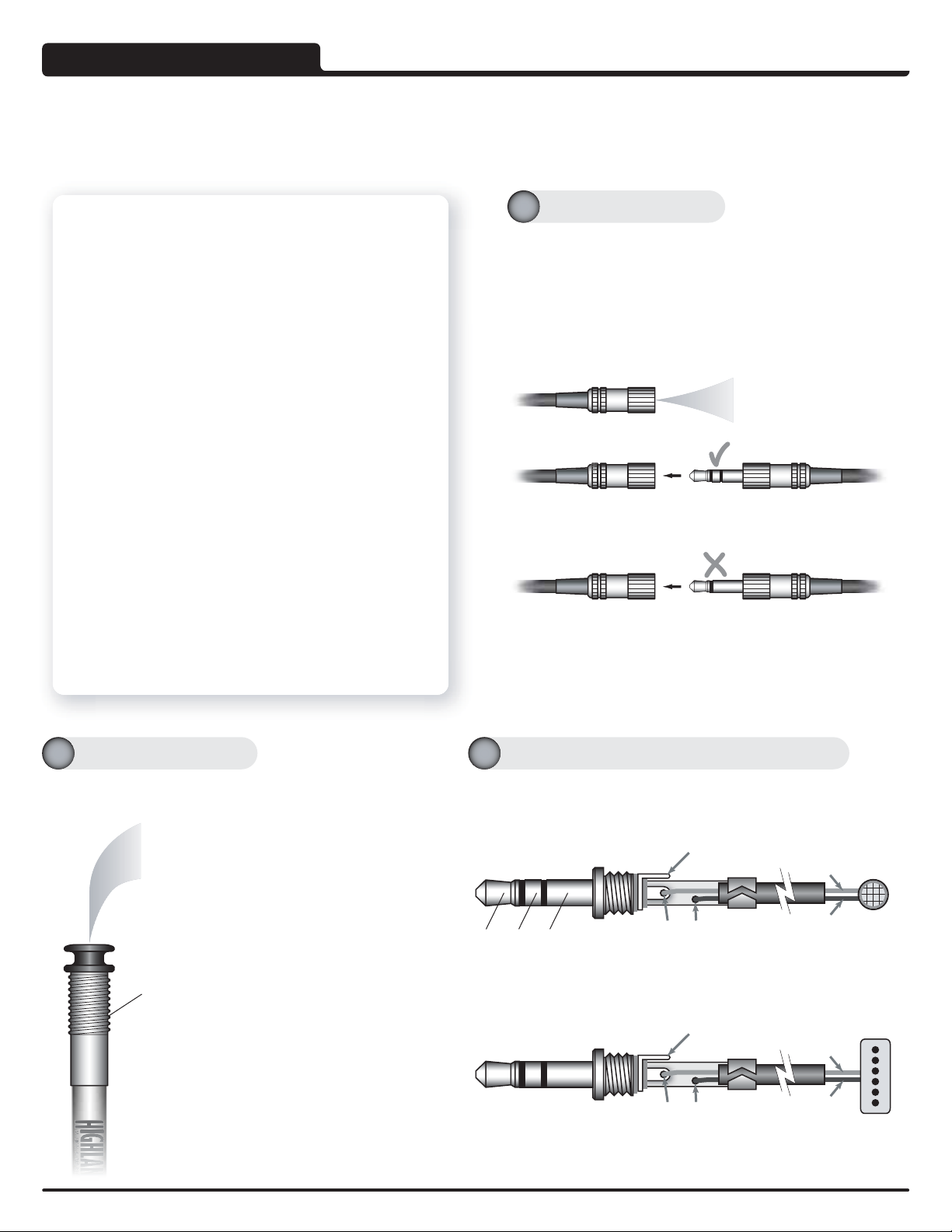

The 2nd source is hard wired

from the Tip of the Access Jack

to the Ring on the Output Jack.

The iP-2 does not include a 2nd

preamplifier for the 2nd source.

Output Jack

Tip: Pickup and Preamp Out

Ring: 2nd Source Out

Shield: Ground

This innovative screw thread is designed

to stay in place regardless of variations in

the end block as it expands and contracts

due to humidity and temperature changes.

By eliminating the typical machine thread

and nut, our preamp will never come loose

and require the awkward task of tightening

a nut at the end pin block inside the guitar.

The elegant strap button holds the strap

securely and will never untwist or loosen.

The iP-2 is turned on when a guitar cord is plugged in

and turned off when it is unplugged, saving the battery.

For more information check out our web site: highlanderpickups.com

ighlanderpickups.com

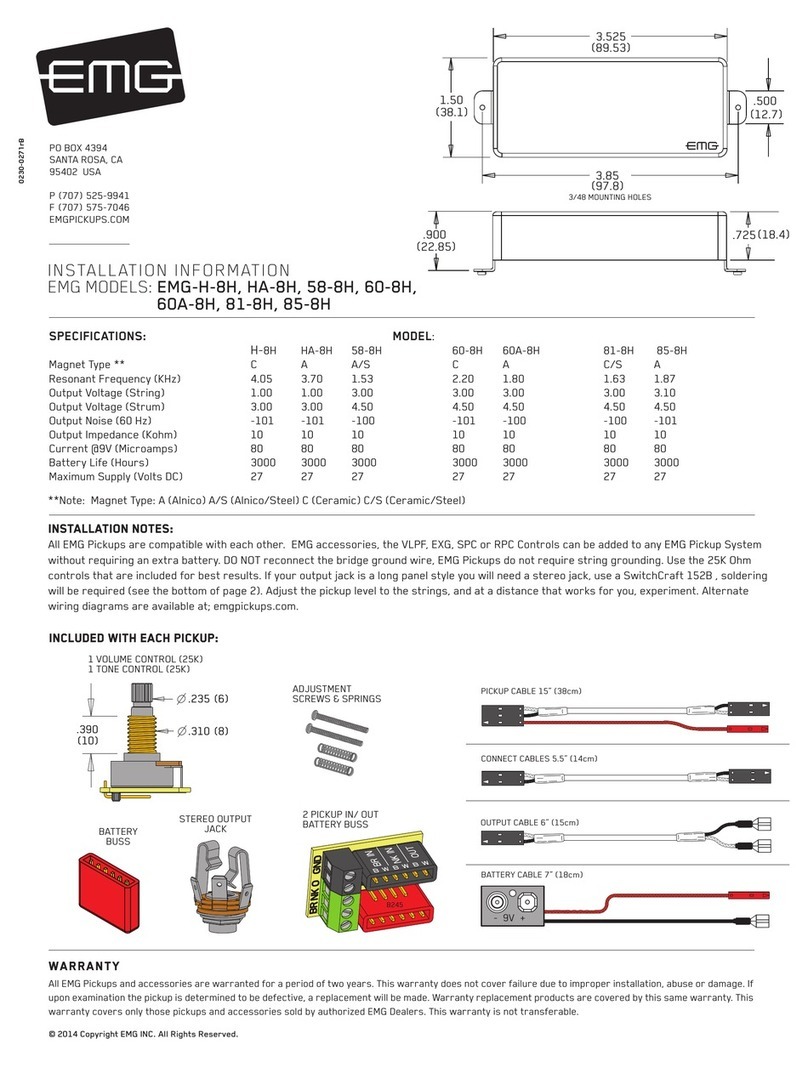

Tip Shield Shield

Ring must be left open

(unconnected)

Hot

Magnetic

Pickup

Tip Ring Tip Shield Shield

Sleeve

Ring must be left open

(unconnected) Electret

Condenser

Mic

Hot

Wiring for a Phantom Powered, Electret Microphone.

Wiring for a Phantom Powered, Electret Microphone.

Wiring for a Passive Magnetic, Sound Hole Pickup.

Wiring for a Passive Magnetic, Sound Hole Pickup.

Never use a Mono Male to connect to the Access Jack.

Never use a Mono Male to connect to the Access Jack.

+9 Volt power on the ring will be shorted out causing the battery

+9 Volt power on the ring will be shorted out causing the battery

to seriously overheat.

to seriously overheat.

If this inadvertenlty happens during installation, the battery has been

compromised and must be changed.

A High Quality 3.5mm Stereo Male is provided with every iP-2.

Always Use a Stereo Male to connect to the Access Jack.

Always Use a Stereo Male to connect to the Access Jack.

When connecting a mono source, the stereo plug must still be used

with the ring left unconnected.

Tip: 2nd Source Audio

Ring: +9 Volt for 2nd Source

Shield: Ground

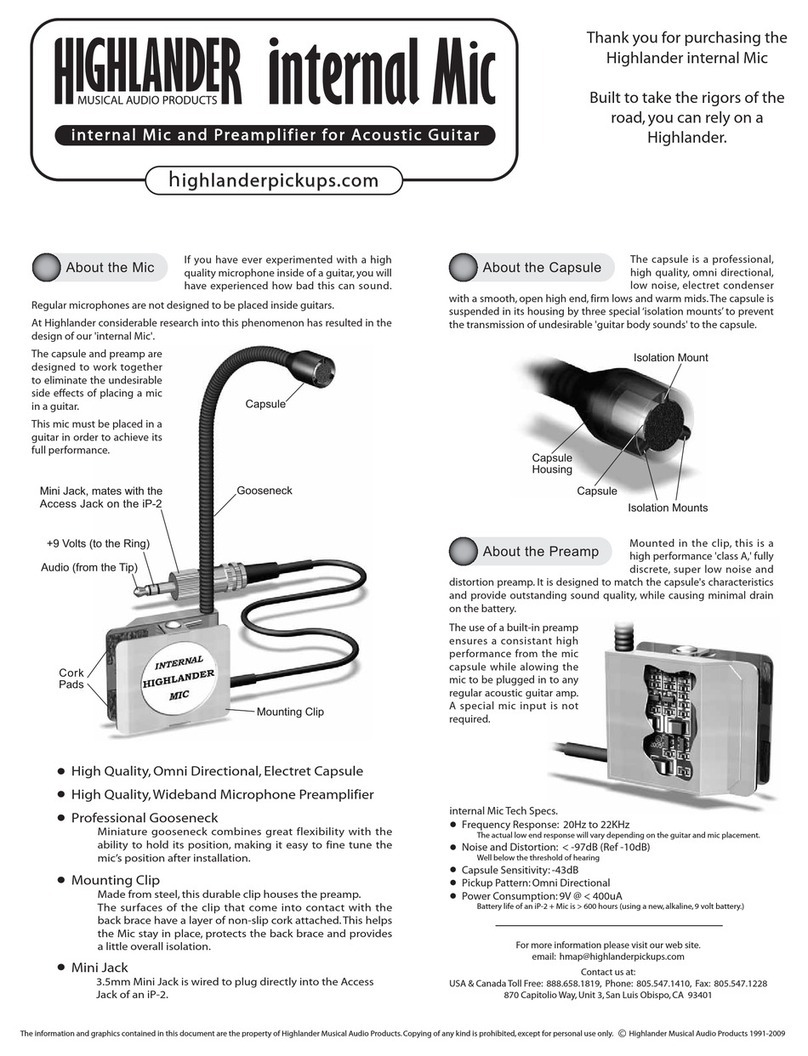

The Access Jack (AJ) is a 3.5mm Stereo Female Jack that enables a

2nd Source to be used with the iP-2 including a magnetic sound hole

pickup or an electret microphone such as our 'Internal Mic' . Power for

active pickups or electret microphones is provided on the ring of the AJ.

The power at the AJ is 'on' only when the guitar is plugged in.

Both signals are available separately at the output Jack, enabling both

sources to be connected to separate sound systems or amplifiers.

Both signals can be combined using a good quality mixer such as our

'Pro Acoustic Mix DI'.

About the Output Jack Typical wiring for the 3.5mm Stereo Mini Jack

About the Access Jack

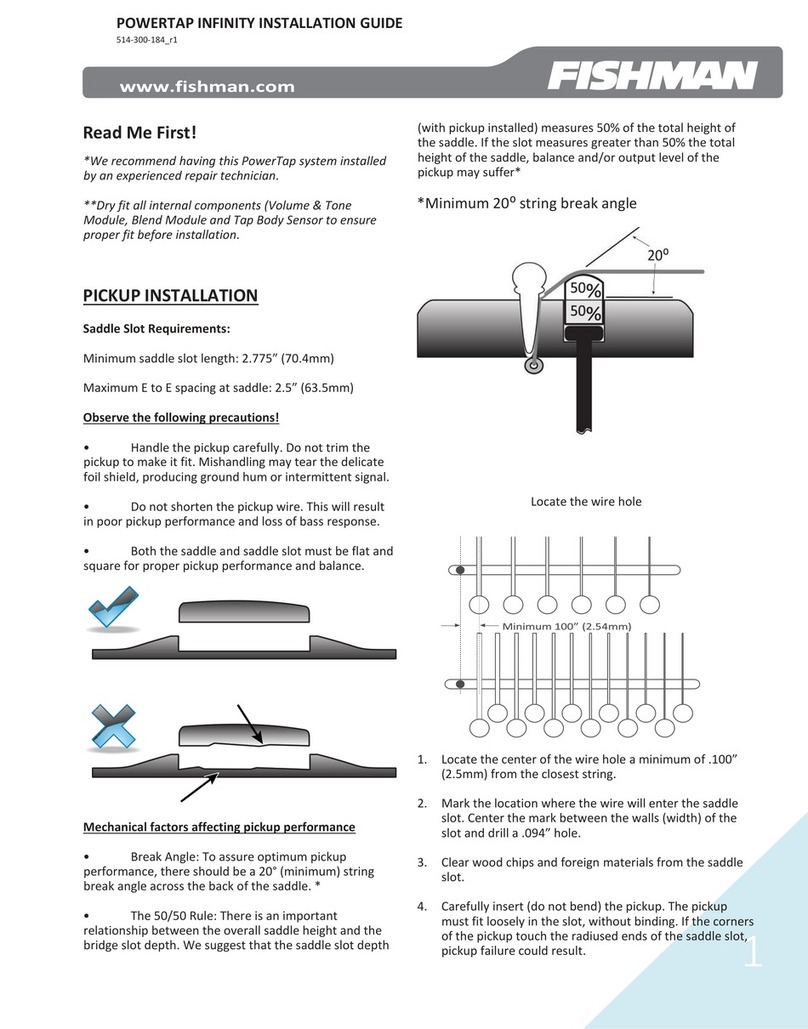

0.065" (1.65mm)

0.050”

(1.3mm)

3/32" Hole3/32" Hole

Bridge

Brace

Saddle Slot

Guitar Top Radius corner on both holes

Battery

Clips

The information presented here has been greatly enhanced over the years by listening

to the craftsmen who have installed countless numbers of these pickups. Thank you.

Remove the strings. Lightly scribe a line on the saddle or make a note of the saddle height. This is useful as a guide

when reseating the saddle at the original height. Remove the saddle.

Drill a 17/32” (13.5mm) hole. Be sure to drill at 90º to end block.

Use a relieved bit to avoid wood tear out or end block splitting.

One way to drill a clean hole is to ream out the hole with a tapered reamer until

the drill bit goes 0.1” (2.5mm) into the hole (through the side). Then drill the hole

through the block. Note: Some people run the drill in reverse.

Thread with a 9/16”-12TPI tap (at 90º to end block).

The performance of the Highlander Pickup is optimized by embedding it in a groove in the bridge. This

‘couples’ the pickup to the sound board of the guitar capturing all of its energy, vitality and nuances.

Velcro®

Velcro®

Velcro®

Preparing the B

Preparing the B

ri

r i

dge

dge

Thoroughly clean the area.

Push both clips onto a 9V

battery and attach the

connector.

Peel the backing off the

clips and press in place

on the back of the

guitar.

Prepare the bridge for the pickup.

See details of ‘Preparing the

Bridge’ below. See details of the

pickup installation

on the next page.

Avoid a sharp bend. It is important that

the pickup is bent around a radius.

If a 90° 'hole angle' is unavoidable then

make the radius as large as possible.

Drill two 3/32” (2.5mm) holes at an angle as shown below. Being careful not to damage the Brace (or other

parts of the structure), try to get as close to a 45° 'hole angle' as possible.

Route a Groove for the pickup using a saddle router jig and router with a 1/16”

(0.0625”) (1.6mm) ball ended cutter. The groove should be 0.05" (1.3mm) deep.

The groove should extend from one 3/32" hole to the other, it should be smooth

and flat. Any irregularities in the groove may cause string imbalance.

The battery position shown in this diagram is one possible placement option. The battery can also be mounted on the neck block.

The actual position will depend on the type of instrument involved, and the needs of the musician using it.

Applying a light coat

of lacquer to the area

where the battery

clips are to be

attached significantly

improves adhesion.

Wait until the lacquer

is fully dry before

applying the clips.

Excess cable is held in place on the back of the guitar with Velcro®. Cables

should be loosely coiled. The Velcro® ensures the cable will not be pinched.

AVOID SHARP BENDS, KINKS or TWISTS IN THE CABLES.

I

t

'

s

a

l

l

i

n

t

h

e

g

r

o

o

v

e

iP-2 INSTALLATION

iP-2 INSTALLATION

The information and graphics contained in this document are the property of Highlander Musical Audio Products. Copying of any kind is prohibited, except for personal use only.

©

Highlander Musical Audio Products 1991-2009

Highlander's 'Internal Mic' plugs

directly in to the Access Jack.

Check out our web site for

information on how to hook up

a variety of mics and pickups.

highlanderpickups.com

Access Jack

End

Block

Velcro the Access Jack in place.

Pass the pickup, battery snap and

Access Jack through the end-pin hole.

Insert the preamp into the end-pin

hole, apply a little wood glue (like

Elmers') to the thread and screw the

preamp into the end-pin hole by hand.

Use a chamois or rubber grip if

necessary. Do not use pliers or

anything similar as the strap nut may

be damaged.

Turn the wires inside the guitar to

prevent twisting.Untwist all the wires

before continuing. Excessive twisting of

the black pickup cable may cause hum.

Route the Pickup Groove

2b

2b

Drill Two Holes for the Pickup

2a

2a

Install Pickup

5

Install 2nd Transducer

6

Install Battery

4

Install Preamp

3

Modification

2

Preparation

1

Installing the Pickup

Installing the Pickup

Consistent String Balance is achieved with this 'Two Hole' installation.

Note: These types of 'Saddle Fits' may sound o.k. acoustically, however, the

saddle needs to be in full contact with the pickup for a good amplified sound

and to insure the best acoustic tone and sustain.

To help maintain the 'Saddle Fit' during variations in humidity and

temperature, lightly wax the bridge and the inside of the saddle slot. Be

sure to remove any excess wax from the slot and especially the groove.

Polishing the sides of the saddle helps create a smooth, sliding fit.

Pass the pickup up through the hole at the 'Low E' side of the bridge and then down through

the hole at the 'High E' side of the bridge.

1

Measure the difference in saddle height using either

the line scribed or the height measured in step .

Trim the difference from the

underside of the saddle.

The underside of the saddle

must be really flat.

Check with a straight edge.

Once the original saddle

height is achieved,

chamfer and debur the

bottom edges of saddle

to help prevent binding.

Check the saddle height.

Using the saddle or a piece of wood, apply just

enough pressure to seat the pickup in the groove.

'Low E' side

The saddle should move freely

up and down in the saddle slot.

Too loose

Too loose

and the saddle can

bind under string tension.

Too tight

Too tight

and the saddle

may not be fully seated.

Pickup

Saddle Material: Micarta®has a consistent density which

helps with string balance. Bone can be inconsistent, when

choosing a piece hold it to a light and look for even color.

The pickup will not function correctly if the tip is placed under the saddle, the tip must be inserted in the hole as illustrated above.

Removing the tip of the pickup or the use of solvents, super glue or lacquer on the pickup will compromise its operation and will void the warranty.

The consistent string balance achieved with this 'two hole' installation technique is due to the mechanical symmetry of having the same type of bend at

each end the pickup. This causes the mechanical forces such as sound vibrations that are acting on the pickup to be well balanced throughout the pickup.

The tip is a special electrically shielded

termination that helps to prevent hum and

interference even when the pickup is used

with an amplifier that is not grounded.

It also makes the pickup easier to handle.

Press the saddle down firmly on to the pickup and replace the strings. Start with the 'D' String. While tensioning it, press the

saddle back (away from the sound hole) and down to prevent the saddle from binding in the saddle slot.

Next, replace the 'G' String then the rest of the strings. Plug in and check the string balance and sound quality of the installation.

If the tip or the crimp comes into contact with

the brace they could vibrate and create an

unwanted sound. A soft pad between them and

the brace (like a piece of double stick foam on

the brace) can prevent any potential problems.

Tip

Crimp

We recommend that

strings be replaced

two at a time from

now on, it will help

maintain the stability

of the installation.

Maintain a small

gap between the

crimp and the top

of the guitar.

The information and graphics contained in this document are the property of Highlander Musical Audio Products. Copying of any kind is prohibited, except for personal use only. © Highlander Musical Audio Products 1991-2009

Install the Pickup in the Groove

5a

5a

Trim and Install the Saddle

5b

5b

Restringing

5c

5c

Check the 'Saddle Fit': This is important information for the correct operation of all under saddle pickups.

5

Pickup

Saddle

Other Highlander Accessories For Musical Instruments manuals