Hillphoenix JNRBHSA Quick start guide

JNRBHSA

JNRZHSA

P112746E

V.1 R.04

08/19

REACH-IN SELF-CONTAINED MERCHANDISER

INSTALLATION & OPERATIONS MANUAL

General Information ............................................... 6

Installation & Trim Out .....................................7-17

Connections & Piping ..........................................18

Pre-Power Checklist ............................................19

Airflow & Case Temperature ................................20

Fans & Case Cleaning .........................................21

Parts Ordering ......................................................22

Appendices ...........................................................23

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualified tech-

nicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized installation/

service contractors, please visit our website at www.hillphoenix.com.

ii

iii

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting systems or any of its display cases with shelf lighting systems for direct or

indirect exposure to water or other liquids. The use of a misting system or water hose on a display case with a shelf lighting sys-

tem, resulting in the direct or indirect exposure of the lighting system to water, can lead to a number of serious issues (including,

without limitation, electrical failures, fire, electric shock, and mold) in turn resulting in personal injury, death, sickness, and/

or serious property damage (including, without limitation, to the display itself, to the location where the display is situated [e.g.,

store] and to any surrounding property). DO NOT use misting systems, water hoses or other devices that spray liquids in Hillphoe-

nix display cases with lighted shelves.

If a misting system or water hose is installed or used on a display case with a shelf lighting system, then Hillphoenix shall not

be subject to any obligations or liabilities (whether arising out of breach of contract, warranty, tort [including negligence], strict

liability or other theories of law) directly or indirectly resulting from, arising out of or related to such installation or use, including,

without limitation, any personal injury, death or property damage resulting from an electrical failure, fire, electric shock, or mold.

P079211M, REVO

R-744 (CO2NOTICE)

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744(CO2), pressure relief and pressure-regulating relief valves may need to be installed

based on the system capacity. The valves need to be located such that no stop valve is positioned between the relief valves and

the parts or section of the system being protected.

When de-energizing refrigeration units containing R-744 (CO2), venting of the R-744 (CO2) refrigerant may occur through the

pressure regulating relief valves. These valves are located on the refrigeration system and not on the case model. If venting

does occur, the valve must not be defeated, capped, or altered by any means.

WARNING: Under no circumstances should any component be replaced or added without consulting HILL PHOENIX Field

Service Engineering. Utilizing improper components may result in serious injury to persons or damage to the system.

iv

Important

DANGER

▲

Indicates an immediate threat of death or

serious injury if all instructions are not followed

carefully.

At Hillphoenix®, the safety of our customers and employees, as well as the ongoing performance of our products, are top

priorities. To that end, we include important warning messages in all Hillphoenix installation and operations handbooks,

accompanied by an alert symbol paired with the word "DANGER", "WARNING", or "CAUTION".

All warning messages will inform you of the potential hazard; how to reduce the risk of case damage, personal injury or

death; and what may happen if the instructions are not properly followed.

WARNING

Indicates a potential threat of death or serious

injury if all instructions are not followed careful-

ly.

▲

CAUTION

Indicates that failure to properly follow instruc-

tions may result in case damage.

▲

!

!

!

v

Revision History

• New Manual Format_08/14

• Manual Update_05/18

• Manual Update_01/19

• Manual Update_04/19

• Appendix F Update_05/19

• Technical Reference Sheet Update_08/19

6

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical information

and will assist you with the installation and operation of your new Hillphoenix specialty cases. By closely following the instructions,

you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel free to

contact our Marketing Services group at the number listed below. Thank you for choosing Hillphoenix, and we wish you the very

best in outstanding food merchandising.

CASE DESCRIPTION

This manual specifically covers the JNRBHSA and JNRZHSA

reach-in self-contained merchandiser.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-condi-

tioned store that maintains a 75°F (24°C) store temperature

and 55% (max) relative humidity (ASHRAE conditions). Case

operation will be adversely affected by exposure to excessively

high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation for

efficient performance. Machine-room temperatures must be

maintained at a minimum of 65°F in winter and a maximum

of 95°F in summer. Minimum condensing tem-peratures

should be no less than 70°F.

SHIPPING CASES

Transportation companies assume all liability from the time a

shipment is received by them until the time it is delivered to

the consumer. Our liability ceases at the time of shipment.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping dam-

age and/or shortages, please contact the Service Parts

Department at the number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's

agent; otherwise, the carrier may refuse the claim. If damage

becomes apparent after the equipment is unpacked, retain all

packing materials and submit a written request to the carrier

for inspection within 14 days of receipt of the equipment.

Failure to follow this procedure will result in refusal by the

carrier to honor any claims with a consequent loss to the

consumer.

If a UPS shipment has been damaged, retain the damaged

material, the carton and notify us at once. We will file a claim.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the highest

level of quality. Any claim for lost/missing items must be

made to Hillphoenix within 48 hours of receipt of the equip-

ment. When making a claim please use the number listed

below.

SERVICE & TECHNICAL SUPPORT

For service or technical questions regarding display cases,

please contact our Case Division Customer Service

Department at the toll free number listed below. For questions

regarding our refrigeration systems or electrical distribution

centers, please contact our Systems Division Customer

Service Department at 1-833-280-5714.

CONTACTING THE FACTORY

If you need to contact Hillphoenix regarding a specific fixture,

be certain that you have both the case model number and

serial number (this information can be found on the data tag,

located on the top-left interior of the case). When you have

this information, call the toll-free number below and ask for a

Service Parts Representative.

GENERAL INFORMATION

Hillphoenix

1925 Ruffin Mill Rd

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m. to 5 p.m.)

Tel: 1-800-283-1109/Fax: 804-526-7450

Website: www.hillphoenix.com

7

CASE INSTALLATION

DELIVERY

1. At delivery, depress ratchet to loosen strap from case top

to trailer wall. Unhook strap from wall – save strap for later

step.

2. For maximum flexibility at delivery, each case is provide with

a special base frame. The case has 2” tall perment feet and

a quick-drop undercarriage with casters. If loading dock is

present at store, simply wheel the case off the trailer on its

casters.

3. If store doorway prohibits case entry when on its

delivery casters, the undercarriage may be removed to

reduce overall case height under 80”. To remove under-

carriage, lift case 1” to 2” (maximum) from ground so

that case weight is removed from the casters. Cut-outs

provided in the rear and front skid-rails are a designat-

ed lift point for fork truck blades.

4. The case may also be lifted manually using a J-bar.

*Important: Place lift blade within the 6” space behind

the front foot. Metal reinforcement is provided in this

designated lift area.* Place wood blocking entirely

beneath base feet to hold case while undercarriage is

removed.

CAUTION!

Use adequate equipment, follow all safety

requirements and ensure blades are fully

under case prior. See Appendix I for Lifting

Locations

8

CASE INSTALLATION

5. Once all screws are removed, (two 3/8 Hex screws located

next to the large arrows in the photo above) the skid rails

and caster assemblies will drop away from the case.

6. Copper lines at top rear are held to case by clamps –

remove clamps and flex copper lines down and to rear of

case if required to pass through the store doorway. The

screws have ¼” hex head.

7. The case wiring exits into a permanent enclosure at top

left rear of case. Flexible conduit is provided from this

enclosure to the case controller box. Remove screws (1/4”

hex head) and reposition controller box if required to pass

underneath the store doorway.

8. Shipping braces are attached to the open end of cases

with 2 bolts. Remove the braces (9/16” hex head) if re-

quired to pass underneath the store door way.

9

CASE INSTALLATION

9. Once case is prepared per prior step, it can be moved thru

80” door way by lifting through the base feet. *WARINING:

If lifted through base feet, blades must be fully past the

second set of base feet. Attach ratchet strap from case top

anchor point to lifting equipment. Case to be hovered with-

in ¼” from ground level . Installer responsible to comply

with all OSHA, local, and customer safety requirements.

Installer responsible to provide equipment ad-equately

sized for the task.*

10.Hydraulic pallet-rack jacks, or other manual methods may

be used, provided care is taken to protect the case, and

designated lift points are used.

Lift through base feet.

Clear second set of base feet.

Connect rachet strap from the top to the bottom.

Hydraulic Jack

Protect case and use designated lift points.

10

CASE INSTALLATION

11. Remove 3.25” riser feet from inside of the case (the ris-

ers are shipped loose so the case can deliver through short

doorways). Lift the case at designated areas. If using pal-

let jack, avoid damaging the drain hub (centered left-right

on case). Slide 1 riser under each 1 permanent base foot.

Tabs at rear will nest into foot – align pre-punched holes

on front vertical flange and secure with provided #8 TEK

screws (two places per riser). Once risers are secured, the

case can be shimmed beneath the risers.

Lift case in designated areas.

Avoid the drain hub when using pallet jack.

3.25” Riser

Align pre-punched holes.

#8 TEK screws (2 per riser).

Risers secured.

Case shimmed beneath risers.

11

CASE INSTALLATION

FLOOR PREP

1. Confirm with the general contractor that you have the

most current building dimensions, then ask for the

points of reference from which you should take dimensions to

locate the cases.

2. Using chalk lines or a laser transit, mark the floor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3. Leveling is necessary to ensure proper case alignment

and to avoid potential case damage. Locate the highest

point on the positioning lines as a reference for

determining the proper height of the shim-pack levelers.

A laser transit is recommended for precision and

requires just one person.

4. Locate the basehorse positions along the chalk lines,

then spot properly leveled shim packs at each location.

LINE-UP & INSTALLATION

Single Case

1. Roll the case into position, leaving a minimum of 2” between

the wall and back of case. This space must be unobstructed and

is required in order to leave sufficient room for airflow behind the

case.

2. Using a “J” bar, raise the end of the case (under cross

support), remove the caster assembly (Fig. 1) and lower

the basehorse on to the shim packs. Repeat on the

other end of the case.

3. Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by placing

a bubble level on the shelf standard. Add/remove shim

packs as needed. For the horizontal level, repeat this

process after placing the bubble level on the front sill.

Multi-Case

1. Remove any shelves, shipping braces, mirror assemblies,

etc. Shelf clips and shipping braces can be discarded.

Keep all other loose items such as kick plates, end kick plates,

nose bumper, fascia, etc. for later in the installation process.

2. Remove the return air grill at the case joint. The grill

lifts out without fasteners and may be easily removed

to gain clear access to the case-to-case joining bolts.

3. Follow the single-case installation instructions for the

first case, then position the next case in the line-up approximate-

ly 3’ away. Remove the casters on the end that is closest to the

first case.

4. Apply the foam tape gasket (supplied) and two beads

of butyl or silicone sealant to the end of the first case

(Fig. 1). From the opposite end, push the second case

to a position that is approximately 6” from the first case,

then remove the remaining casters and position case

on the shim packs.

5. Push the cases tightly together, then lightly bolt them

together through the holes that are provided (Fig. 1).

Tighten all the joining bolts until all margins are equal.

Be careful not to over tighten.

6. Repeat steps 3–6 of this sequence for all remaining

cases. Be certain to properly level all cases.

7. See Appendix B for seismic bracket installation instruc-

tions.

Fig. 1 Bolt holes, foam tape gasket and sealant

12

CASE INSTALLATION

TRIM OUT

Drain and Pump Notes:

For the best energy conservation, Hillphoenix recommends

the use of floor drains at the store.

Configurations exist (having ‘FD” at end of the case model

name) which restrict certain selections and tailor the case

for use with store floor drains. For “FD” configured cases,

simply glue up the ship loose P-trap , cleanout, and Tee to

route condensate to the floor drain.

Other case configurations (non-”FD”) allow ordering of

options (pumps and burn-off pans) that manage the conden-

sate for stores without floor drains. The following section

discusses the install of these condensate pumps and

burn-off pans.

Unpack pump, PVC drain trap, and 20 feet of plastic tubing.

Glue supplied PVC drain parts to the drain hub. Orient PVC

drain as needed to allow easy clean-out access for future:

typically clean-out to right side, with tube nipple facing left.

Place pump receptacle under case and ensure conduit /

wires are terminated to main junction box on case top.

Cut short section (18” typical) of tube. Connect from PVC

drain outlet nipple to pump inlet (choice of 4 removable

caps) Push tube toward short edge of pump IMPORTANT: If

tube pushed towards long end of pump it may interfere with

float that is located beneath motor. The RED ‘ALARM” light

will turn on if tube is holding float up. If the tube holds float

down, the motor will not engage to pump water. To correct,

pull out excess tube, and re-orient away from motor / float.

Install long section of tube from pump outlet (nipple) and

route to top of case and into evaporative condensate pan.

PVC Drain Trap Pump receptacle

Pump Short tube section to pump inlet

Push towards short edge of pump.

Red “Alarm” light

Long tube section from pump

outlet nipple.

Pump Outlet Nipple

Assembled.

13

CASE INSTALLATION

DRAIN and PUMP SET-UP

1. 1. The shipped-loose evaporation pan gets installed at

the rear left top of case. Cut away an excess section (18”

to 24” typical) of the plastic tubing for use in laterstep.

2. Hook “V” of metal cover under flange and rotate cover

onto pan.

3. Install platic bushing in cover. Place tube (from pump)

through bushing to grip and into pan.

4. Place end of tube into cut-out section of cover, so that

pumped condensate water is directed into the pan.

5. Place the short (18”) section of tubing onto the over-

flow tube of the pan, and direct the tube to the rear

back of the case. (In event of components wearing out

in future, water will be directed to the floor rather than

collecting on the case top).

6. Fasten pan to the case with #8 screws provided.

14

CASE INSTALLATION

TRIM OUT

1. Seal the interior case-to-case joints with caulk (supplied),

then apply acrylic tape (supplied) over the pipechase

seam (Fig. 2). The tape acts as a watershed preventing

water from settling in the case joint.

Fig. 2 Sealing the pipe chase

Fig. 3 Front panel trim is install behind

bumper tracks. (Example shown with a

bumper track. Location and style of track

plus bumper [if ordered] may vary.)

2. Re-install shelves (or peg hook assemblies if applicable).

Be aware that differing shelf configurations will affect

energy consumption and case performance.

3. Properly align the front panels as needed, then install the

front panel joint trim (Fig. 3). If bumper track is installed,

loosen the screws in the track—work outward from the

gap between front panels—to provide the space needed

for installing the front panel trim. Retighten the screws

when finished.

6. Install supplied sex bolts bolts through each frame,

capturing trim, and tighten to compress sealant that was

applied per page 11 (Fig. 4).

Fig. 4 Trim shown after install [bolt

located above index finger].

4. When sealing frame to frame, or frame to foamed-parti-

tion, the Anthony door may need be removed. Release

tension from closing mechanism. Depress spring clip at

top of door. Pull top door hinge from receptacle and set

door aside.

5. Use a clamp to close gap between frame and foam

partition, which compresses sealant (applied prior on

page 11). Tightly secure the frame to the partition using

flat-head self-tapping (#6) screws provided. There should

be no gap between the frame and foamed-partition when

doneFor case-to-case joints, carefully push the T-bar case

frame joint trim into the space between the frames

7. Install end kick-plates before front kick-plate. End kick-

plate is same whether left or right.

8. Slide end kick-plate front to rear, under end. When front

flange is about 9/16” from base foot, slide under case –

then slide final 9/16” rearward so that metal tabs nest

behind case base feet. Front flange of end kick-plate is

captured when the front kick-plate is installed (See Fig.

5).

15

CASE INSTALLATION

CONDENSING UNIT

The boxes of each shipped-loose, charged, condensing units

are marked to identify the case to which they belong. *Import-

ant! Match the condensing unit to its corresponding case.

Case and condensing unit have Parket 5000-series quick-con-

nect refrigeration fittings. When field mating the fittings,

Parker recommends to “Lubricate the black poppet faces with

system-compatible lubrication as well as threads on male

fitting. Then torque (18-20 ft-lb.) the fittings”.

Tighten the thread quick-connects fully. *IMPORTANT: Note

that the case and condensing unit are shipped charged

with refrigerant. The units are not pumped down, but are

shipped in “ready to install and run” configuration. Take care

to connect lines completely and confirm that leak paths are

avoided.*

Secure condensing unit to case top after refrigeration connec-

tion are made.

Match the refrigeration quick-connects of the condensing unit

to those on the mating case.

ATTENTION

Note that the case and condensing unit are shipped

charged with refrigerant.

▲

!

16

CASE INSTALLATION

Retrieve shipped-loose intake guard from inside case. Nest

top edge into “V” retainer flange at top of air-block. Fasten

bottom to case.

Intake guard assembled to air block.

Retrieve shipped-loose condensing unit air-block from inside

case. Match cut outs to condensing unit and fasten by back-

ing out and re-installing screws from the condenser coil.

17

CASE INSTALLATION

NOISE DAMPENER [OPTIONAL]

The noise damper helps to reduce the noise level of

the condensing unit.

Slide the right-hand panel into place using the provided

slot on the back of the fascia shroud. Repeat on

the left side of the condenser. If you need to, cut out

enough of the foam to fit over any piping that may be

obsturcting the panel.

Install the top panel by sliding under the protruding

metal edge of the fascia shroud, then fitting the top

panel’s “teeth” into the cut-outs of the side panels to

complete the installation.

Attach right-hand panel to front fascia.

Attach left-hand panel to front fascia.

Complete assembly.

Top panel installs under metal edge, filling in the pre-cut slots.

18

REFRIGERATION

The condensing unit (Fig. 5) is located on top of the case

for easy access. Refrigerant piping runs down the rear of

the case to and from the coil. The expansion valve and

other controls, which are located on the left-hand side

of the case, are accessed by lifting the left-hand deck

pans—lifting the fan plenum is not required.

Before operating the case, be certain to remove any shipping

blocks that protect the refrigeration lines during shipping.

If it becomes necessary to penetrate the case tank

in any area, be certain to seal any open gaps afterwards

with canned-foam sealant and white RTV.

PLUMBING

The drain outlet is specially molded out of PVC material

and is located at the front-center of the case for convenient

access. The “P” trap that is furnished with the case

is constructed of schedule 40 PVC pipe (Fig. 6). Case

run-off should be channeled to a floor drain located under-

neath the case.

NOTE: floor-drain cases are intended for use with

floor drains only—evaporative heater pans are neither

permitted nor offered with floor-drain case configurations

per DOE requirements.

Since the kickplate is shipped loose with the case, you

should have open access to the drain line area during instal-

lation. If the kickplate has been installed, you will find

it easy to remove. Simply remove the kickplate joint trim,

then unscrew the upper and lower kickplates from the

kickplate supports and remove (see Trim Out instructions

on pages 12-14).

Care should be given to ensure that all connections are

water-tight and sealed with the appropriate PVC or ABS

cement.

ELECTRICAL

Electrical connections are made in the electrical junction

box located at the top rear-left of the case (Fig. 7). The

cases use a Carel IR33+ case controller. Lighting for reach-

in door cases is pre-installed during manufacturing. Lighting

controlled through motion sensors is stan-dard on the case.

If using Anthony door/frame, the anti-sweat control through

embedded controller is standard offering on the case. For any

questions or service needs, please contact our Case Division

Customer Service Department.

CASE CONNECTIONS

ATTENTION

Connections are illustrated in dimensional drawing

found in Appendix A.

▲

!For more detailed electrical wiring information, see Appendix

E. For more detailed information on the Carel

IR33+ controller and setpoints, see Appendix F.

ATTENTION!

If brazing is necessary, place wet rags

around the area to avoid tank damage.

ATTENTION!

Be certain that all piping and electrical

connections comply with local codes.

ATTENTION!

Case requires 4-Wire Power From Store.

Neutral Wire Must be connected prior to

starting case or else damage may occur.

Fig. 6 Condensing unit on top of case

Fig. 7 “P” trap; drain line

Fig. 8 Electrical junction box on top of

case

19

PRE-POWER CHECKLIST

Have you thoroughly examined the case for shipping damage? (see pg. 8)

Have you removed and discarded casters? (see pg. 8)

Have you checked the vertical plumb of the case? The horizontal level?

(see pg. 8)

Have you applied the foam tape gasket and sealant to the end breakers of

adjoining case? (see pg. 11)

Have you sealed the case-to-case joints by applying caulk and acrylic tape to

the pipe-chase seam? (see pg. 14)

Have you removed the shipping blocks from the refrigeration lines?

(see pg. 8)

Before powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

20

AIRFLOW & DEFROST

Fig. 9 Airflow; probe, sensor locations

AIR FLOW & PRODUCT LOAD

Do not overload the food product display so that it impinges

on the air flow pattern—doing so will result in diminished

performance and loss of proper temperature levels, particu-

larly when the discharge honeycomb and return air grille

are covered. Please keep products within the load limit line

shown on the diagram below (Fig. 8).

JNRZHSA cases utilize electric defrost. The defrost

termination probe is mountes into the coil package from

the left end of the coil. The discharge air probe monitors

the termperature of the discharge air and is found behind

the plug button in the upper flue panel.

For more detailed information on suggested defrost

times and settings, see page 2. Further adjustment

may be required depending on store conditions.

DETERMINING SUPERHEAT

To identify proper superheat settings, complete the following:

1. Obtain suction pressure from the access port. Obtain the

suction line temperature from the area near the TXV bulb

at the outlet of the evaporator coil (Fig. 10).

2. Using the suction pressure reading and the Sporlan®

temperature-pressure chart (Appendix C), convert pres-

sure-to-temperature.

3. Finally, subtract the converted temperature reading from

the actual temperature reading. The resulting number is

the superheat setting—once this has been determined,

adjust the TXV as needed to obtain the proper setting.

Fig. 11 Obtain pressure and temperature readings

DEFROST & TEMPERATURE CONTROLS

Hillphoenix cases utilize electric, hot gas, or timed-off

defrost. The primary components used for the defrost

cycle are the various defrost termination sensors, which

work to terminate the defrost cycle in the case.

JNRBHSA cases utilize Off-Time defrost. The defrost termina-

tion probe is housed at rear wall, behind the lower

rear baffle (Fig 9). The discharge air probe monitors the tem-

perature of the discharge air and may be used as the defrost

termination sensor. The probe can generally be found

behind the rear baffle, in the upper baffle, or in front of the

honeycomb.

NOTE: If the discharge air probe is used for defrost termina-

tion, none of the termination sensors listed earlier will be

installed in the case.

Fig. 10 Airflow; probe, sensor locations

This manual suits for next models

1

Table of contents

Other Hillphoenix Merchandiser manuals

Popular Merchandiser manuals by other brands

True

True GDM-12FC Specifications

Gamko

Gamko MAXIGLASS MG3 user manual

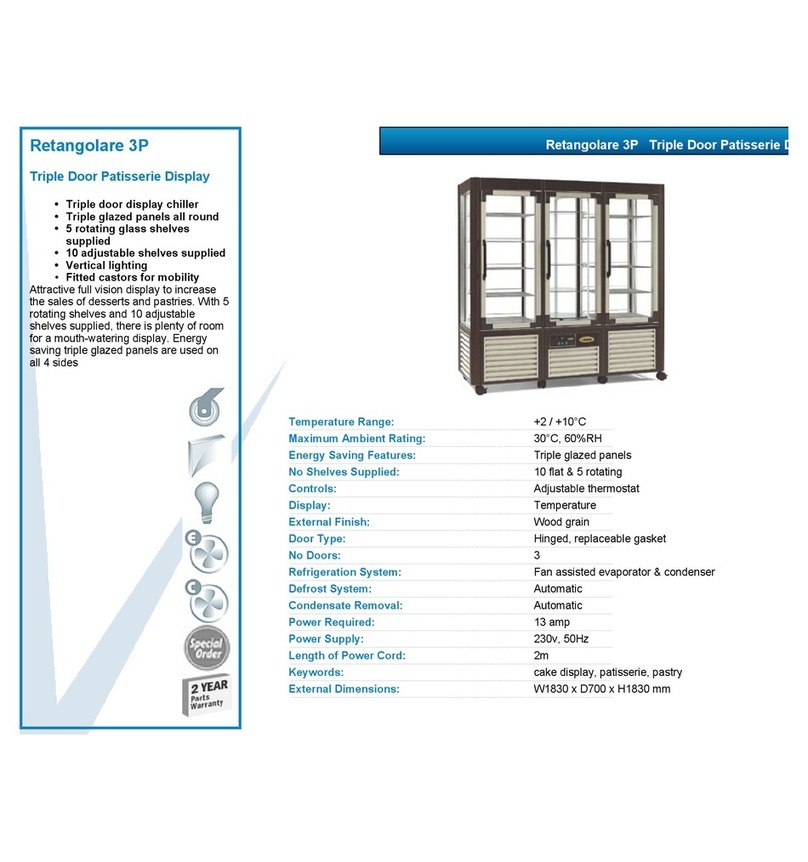

VALERA

VALERA RETANGOLARE 3P datasheet

Crane Merchandising Systems

Crane Merchandising Systems BevMax MEDIA user guide

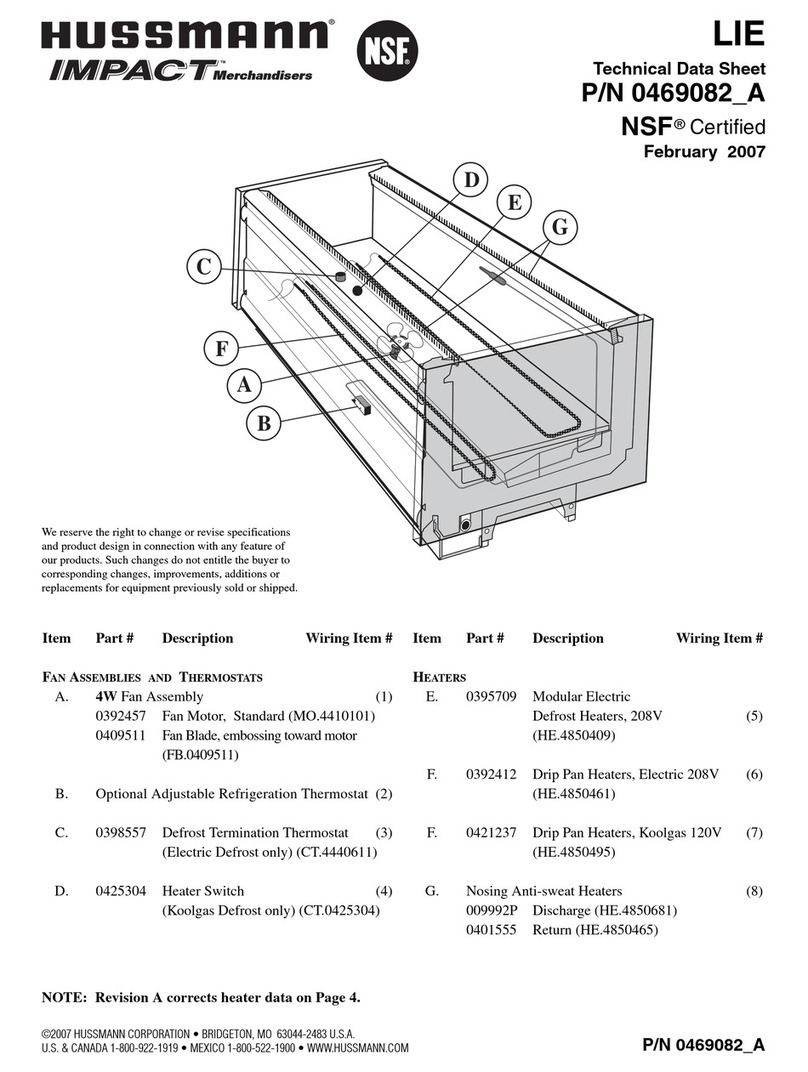

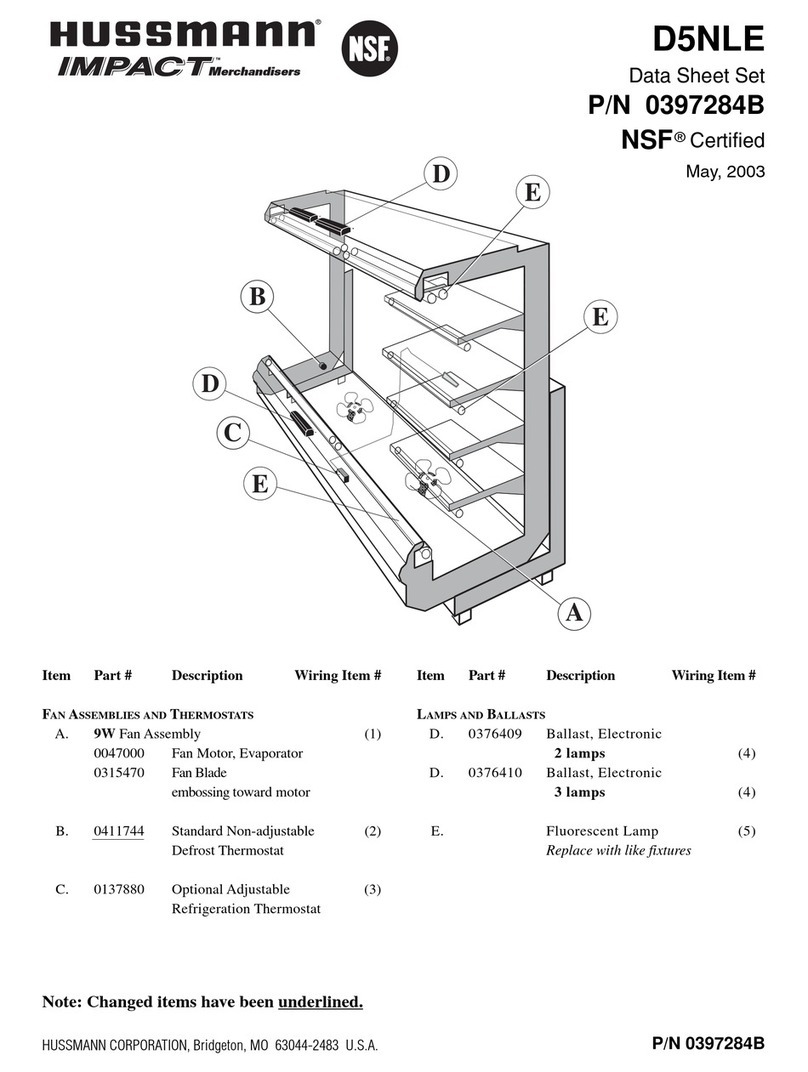

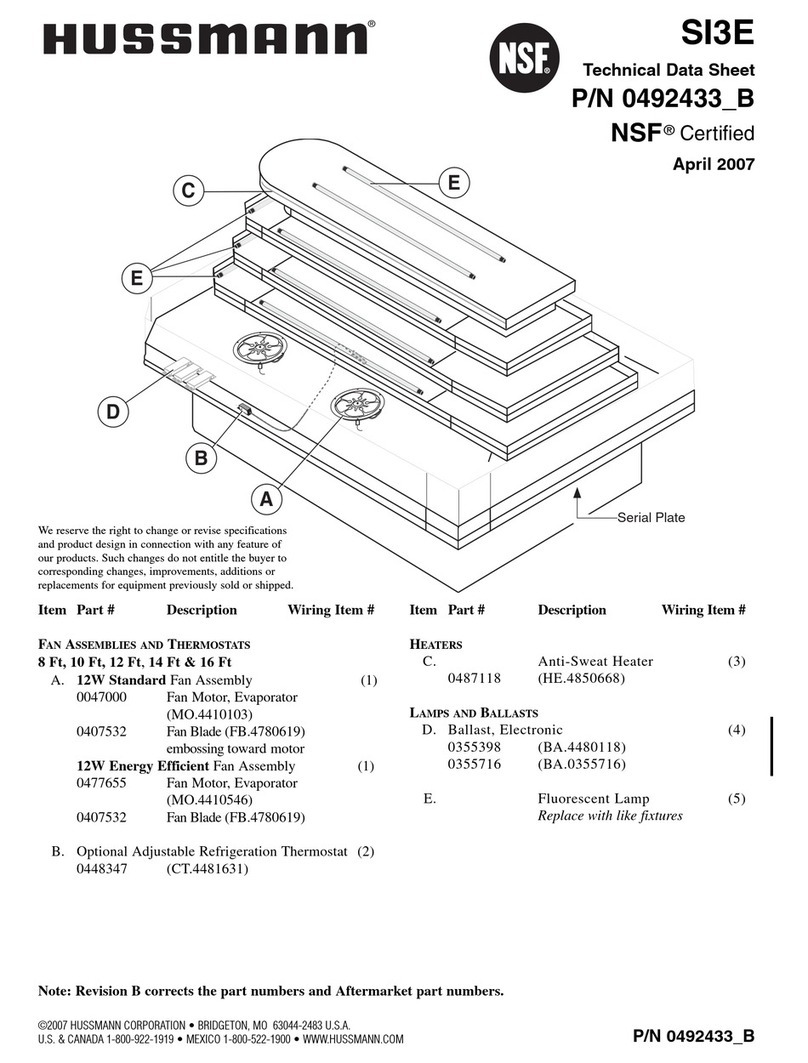

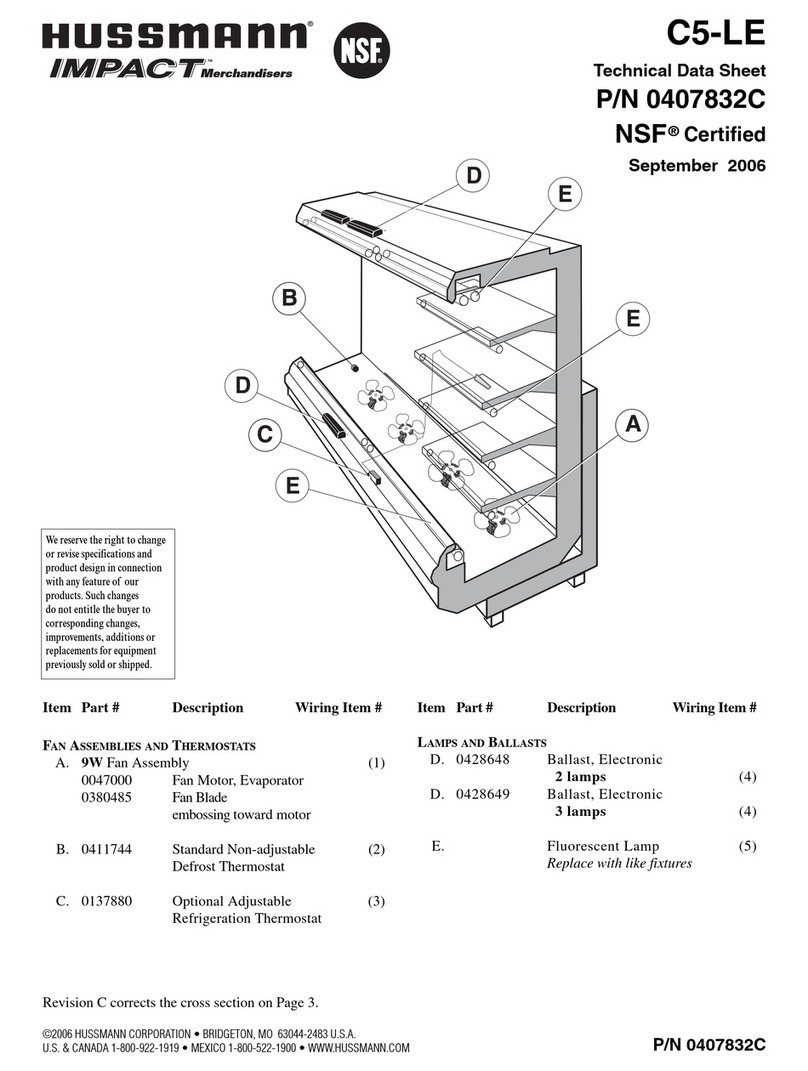

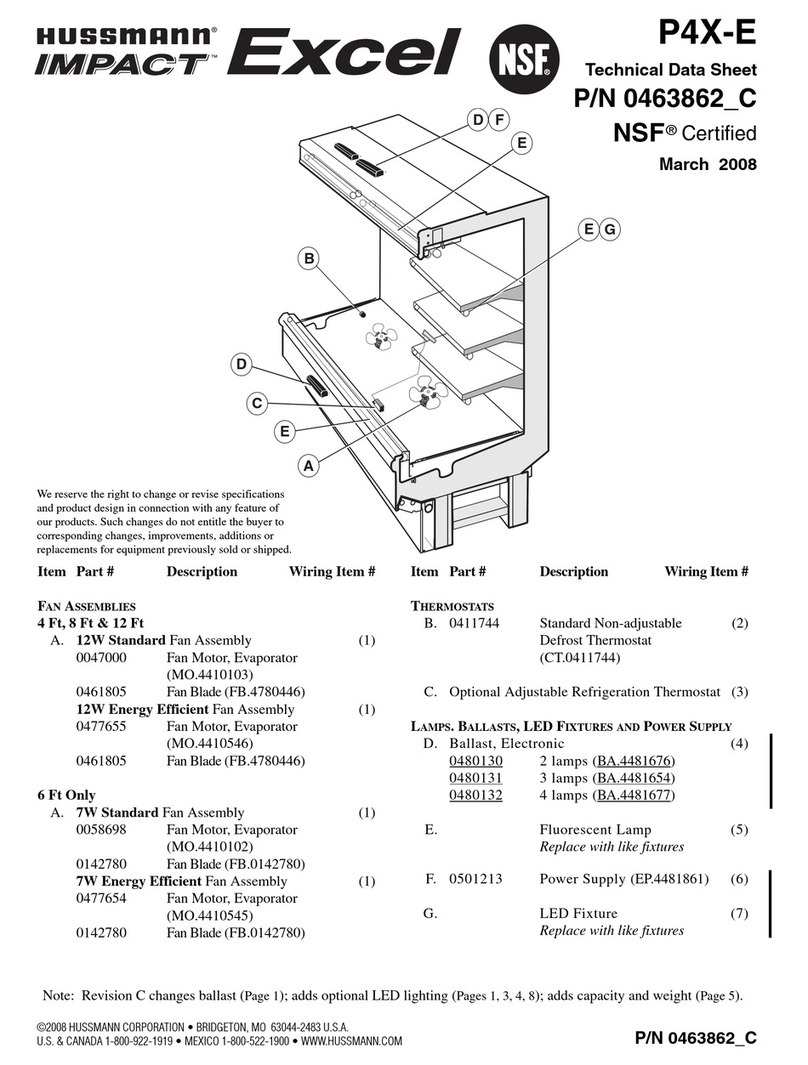

Hussmann

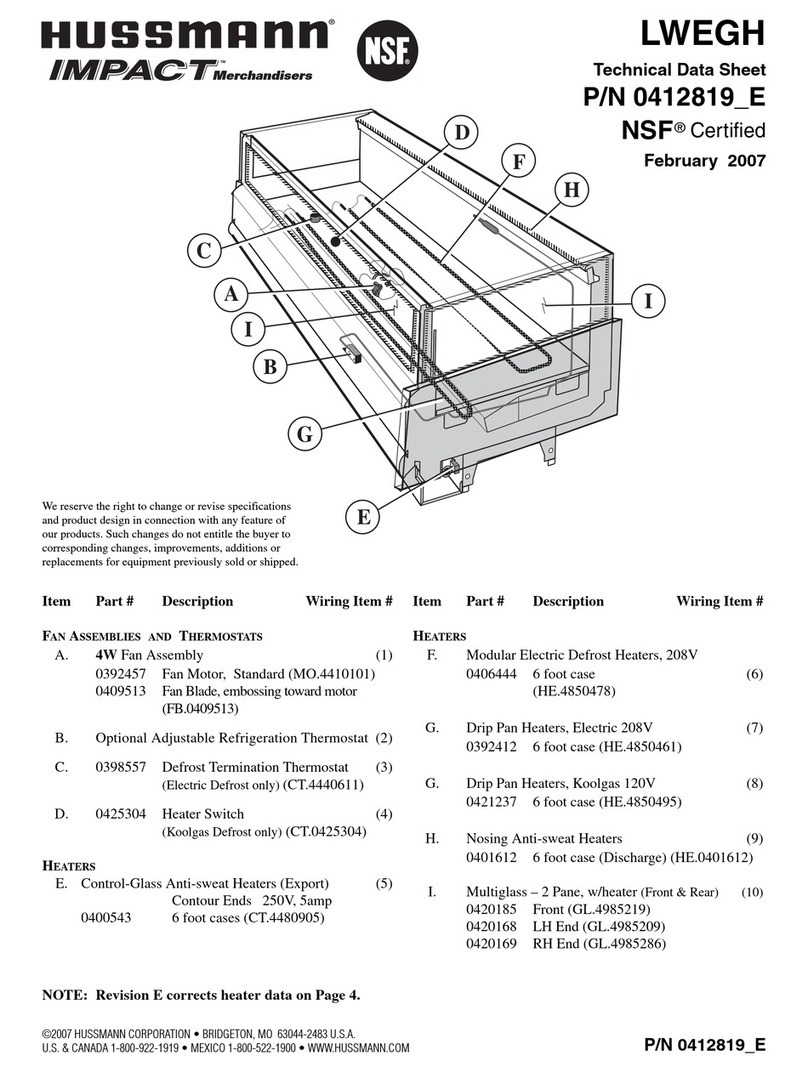

Hussmann IMPACT LWEGH Technical data sheet

Electrolux Professional

Electrolux Professional Kelvinator KCHGICM23FB Installation and service manual