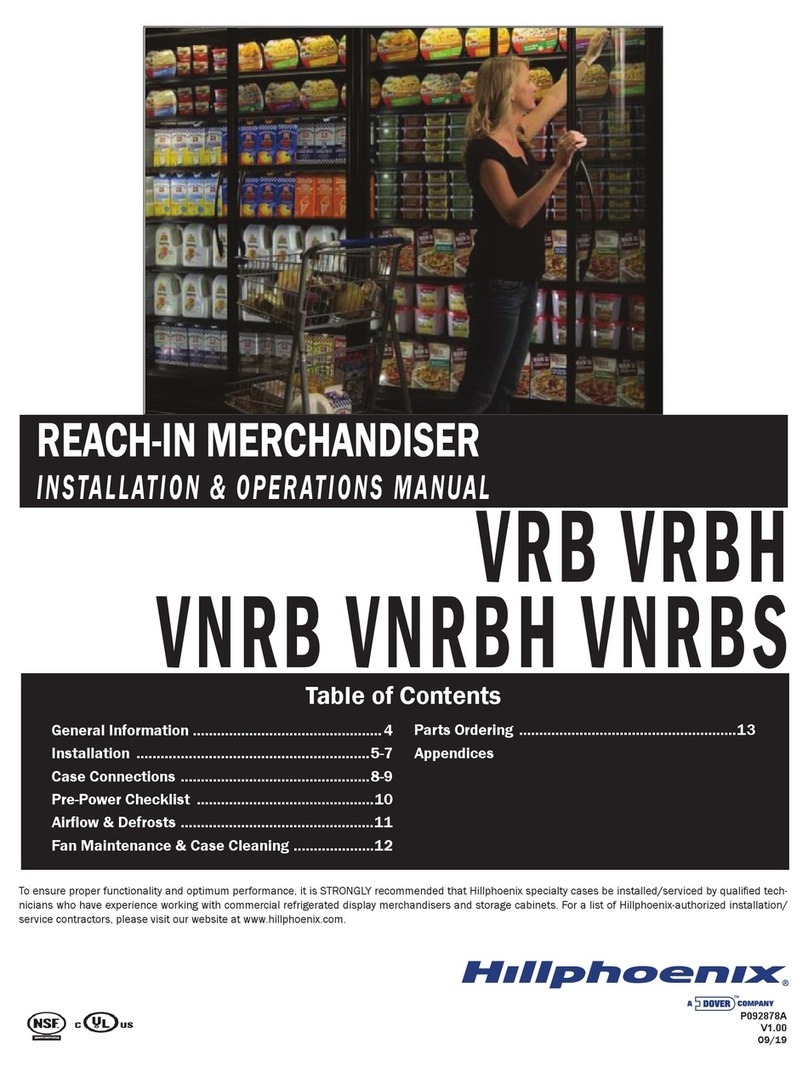

Hillphoenix UPL-NRG Owner's manual

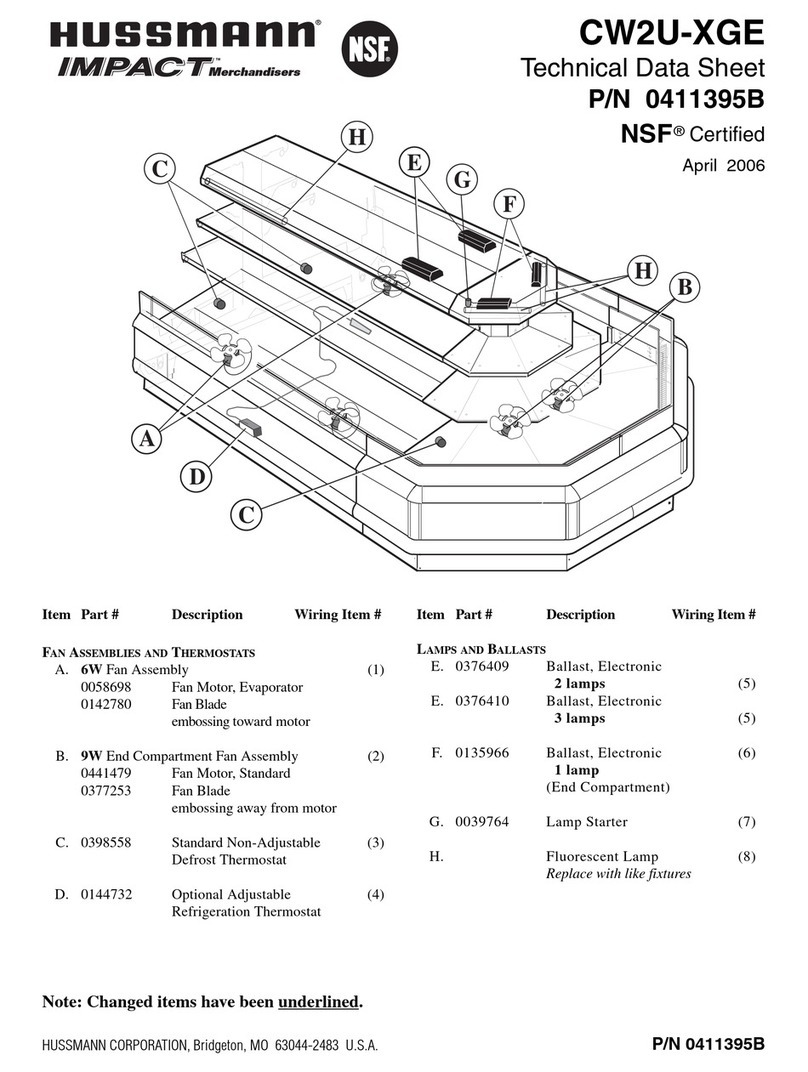

UPL-NRG

P079451B

Rev. 0 06/10

Table of Contents

Energy Data.......................................................2

Case Dimensions..............................................3

General Information .........................................4

Installation......................................................5-6

Case Connections............................................7

Airflow, Defrost & Temp Control.....................8

Use & Maintenance...........................................9

Parts Ordering ................................................10

Appendix A: Wiring Diagrams

Installation & Operation Handbook

SINGLE-DECK CASE

COMPONENT

ii

Important

DANGER

▲

Indicates an immediate threat of death or se-

rious injury if all instructions are not followed

carefully.

At Hill PHOENIX®, the safety of our customers and employees, as well as

the ongoing performance of our products, are top priorities. To that end, we

include important warning messages in all Hill PHOENIX installation and

operations handbooks, accompanied by an alert symbol paired with the word

"DANGER", "WARNING", or "CAUTION".

All warning messages will inform you of the potential hazard; how to reduce

the risk of case damage, personal injury or death; and what may happen if the

instructions are not properly followed.

WARNING

Indicates a potential threat of death or seri-

ous injury if all instructions are not followed

carefully.

▲

CAUTION

Indicates that failure to properly follow instruc-

tions may result in case damage.

▲

iii

LIABILTY NOTICE

For Cases with Shelf Lighting Systems

Hill PHOENIX does NOT design any of its shelf lighting systems or any of its dis-

play cases with shelf lighting systems for direct or indirect exposure to water or

other liquids. The use of a misting system or water hose on a display case with

a shelf lighting system, resulting in the direct or indirect exposure of the lighting

system to water, can lead to a number of serious issues (including, without limita-

tion, electrical failures, fire, electric shock, and mold) in turn resulting in personal

injury, death, sickness, and/or serious property damage (including, without limita-

tion, to the display itself, to the location where the display is situated [e.g., store]

and to any surrounding property). DO NOT use misting systems, water hoses

or other devices that spray liquids in Hill PHOENIX display cases with lighted

shelves.

If a misting system or water hose is installed or used on a display case with a

shelf lighting system, then Hill PHOENIX shall not be subject to any obligations or

liabilities (whether arising out of breach of contract, warranty, tort [including neg-

ligence], strict liability or other theories of law) directly or indirectly resulting from,

arising out of or related to such installation or use, including, without limitation,

any personal injury, death or property damage resulting from an electrical failure,

fire, electric shock, or mold.

P079211M, REVO

iv

R-744 (CO2) NOTICE

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744 (CO2), pressure relief and pressure-reg-

ulating relief valves may need to be installed based on the system capacity. The

valves need to be located such that no stop valve is positioned between the relief

valves and the parts or section of the system being protected.

When de-energizing refrigeration units containing R-744 (CO2), venting of the

R-744 (CO2) refrigerant may occur through the pressure regulating relief valves.

These valves are located on the refrigeration system and not on the case model.

If venting does occur, the valve must not be defeated, capped, or altered by any

means.

WARNING: Under no circumstances should any component be replaced or

added without consulting Hill PHOENIX Field Service Engineering. Utilizing

improper components may result in serious injury to persons or damage to

the system.

v

UPL-NRG

ENERGY DATA

Electrical Data

Defrost Controls

1 NOTE: “- - -” not an option on this case model.

2 BTUH/ft notes:

- Listed BTUH/ft indicate parallel operation. Conventional ratings may be approximated by multiplying listed rating by 1.13.

- Add 132 BTUH/ft when aftermarket merchandising accessories are utilized to determine the total BTUH load.

3 Average discharge air velocity at peak of defrost.

Guidelines & Control Settings

Model 2BTUH/ft

Superheat

Set Point @ Bulb

(F)

Evaporator

(F)

Discharge

Air

(F)

Return

Air

(F)

Discharge3

Air Velocity

(FPM)

UPL-NRG 500 6-8 26 30 40 250

Model

Defrosts

per Day

Electric Defrost Timed-Off Defrost Hot Gas Defrost Reverse Air Defrost

Fail-Safe

(min)

Termination

Temp (F)

Fail-Safe

(min)

Termination

Temp (F)

Fail-Safe

(min)

Termination

Temp (F)

Fail-Safe

(min)

Termination

Temp (F)

UPL-NRG 6 - - - - - - 45 42 - - - - - - - - - - - -

Model

Fans

per

Case

High Efciency

Fans

Anti-Condensate

Heaters Defrost Heaters

120 Volts 120 Volts 208 Volts 240 Volts

Amps Watts Amps Watts Amps Watts Amps Watts

UPL-NRG 8’ 2 0.17 20 - - -1- - - - - - - - - - - - - - -

2

CASE DIMENSIONS

NOTES:

* STUB-UP AREA

** RECOMMENDED STUB-UP CENTERL INE FOR ELECTRICAL AND HUB DRA INS

- ENDS ADD APPROXIMATELY 1 INCH TO CASE HEIGHT

- A 2" M INIMUM AIR GAP IS REQUIRED BETWEEN THE REAR OF THE CASE AND A WALL

- BACK PANELS ADD APPROXIMATELY 1" TO THE REAR OF THE CASE

35 1/16 in

[89.1 cm]

**

39 3/8 in

[99.9 cm]

41 5/16 in

[104.9 cm]

31 11/16 in

[80.5 cm]

FRONT OF CASE

C

L

1 1/2 in [3.8 cm]{END}

96 in [243.8 cm] (8' CASE)

35 7/16 in

[90.0 cm]

46 7/16 in

[117.9 cm]

48 7/16 in

[123.1 cm]

8 5/8 in [21.9 cm]

33 1/4 in [84.4 cm]

25 1/16 in

[63.6 cm] 8 in

[20.3 cm]

3 13/16 in [9.7 cm]

22 11/16 in

[57.6 cm]

16 13/16 in [42.7 cm]

8 11/16 in [22.1 cm]

4 in[10.2 cm] 28 5/8 in

[72.7 cm]

REFRIGERATION

REAR REFRIGERATION

(11 3/4" OFF OF FLOOR)

22 9/16 in [57.3 cm]

20 1/16 in [51.0 cm]

35 3/16 in

[89.4 cm]

1 1/2" PVC DRAIN

CONNECTION

33 9/16 in

[85.3 cm]

6 13/16 in [17.2 cm]*

31 11/16 in [80.5 cm]

39 3/8 in [99.9 cm]

5 1/8 in

[13.1 cm]

41 5/16 in [104.9 cm]

JUNCTION BOX

(STANDARD)

ELECTRICAL

3

Thank you for choosing Hill PHOENIX for your food merchandising needs. This handbook contains important technical

information and will assist you with the installation and operation of your new Hill PHOENIX display cases. By closely fol-

lowing the instructions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel

free to contact our Marketing Services group at the toll-free number listed below. Thank you for choosing Hill PHOENIX,

and we wish you the very best in outstanding food merchandising.

GENERAL INFORMATION

CASE DESCRIPTION

This manual specifically covers the UPL-NRG single-deck

produce merchandiser.

STORE CONDITIONS

Hill PHOENIX cases are designed to operate in an air-con-

ditioned store that maintains a 75°F (24°C) store tempera-

ture and 55% (max) relative humidity (CRMA conditions).

Case operation will be adversely affected by exposure to

excessively high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation

for efficient performance. Machine-room temperatures

must be maintained at a minimum of 65°F in winter and a

maximum of 95°F in summer. Minimum condensing tem-

peratures should be no less than 70°F.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping

damage and/or shortages, please contact the Service

Parts Department at the toll-free number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carri-

er's agent; otherwise, the carrier may refuse the claim. If

damage becomes apparent after the equipment is

HILL PHOENIX

1925 Ruffin Mill Rd.

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m to 5 p.m EST)

Tel: 1-800-283-1109/Fax: 804-526-7450

Web site: www.hillphoenix.com

unpacked, retain all packing materials and submit a written

request to the carrier for inspection within 14 days of

receipt of the equipment.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the high-

est level of quality. Any claim for lost/missing items must

be made to Hill PHOENIX within 48 hours of receipt of the

equipment.

TECHNICAL SUPPORT

For technical questions regarding display cases, please

contact our Case Division Customer Service Department at

the toll-free number listed below. For questions regarding

our refrigeration systems or electrical distribution centers,

please contact our Systems Division Customer Service

Department at 1-770-388-0706.

CONTACTING THE FACTORY

If you need to contact Hill PHOENIX regarding a specific

fixture, be certain that you have both the case model num-

ber and serial number (this information can be found on

the serial plate, located on the upper top flue panel on the

right-hand side). When you have this information, call the

toll-free number below and ask for a Service Parts

Representative.

4

INSTALLATION

MOVING CASES

Hill PHOENIX display cases are generally shipped to

stores with casters installed on the base frame. The cast-

ers make the job of moving cases easier for everyone

involved in the shipping and installation process, as well as

reducing the chance of damage from raising and lowering

cases with ”J” bars to place them on dollies, skates or roll-

ers. In most situations, one or two persons can easily

move the case into position.

When the cases arrive at the store, simply roll them on to

the store floor to the proper staging area. Occasionally,

cases are shipped with skid boards attached to help with

stabilization. In these instances, the casters should be

attached after the case is removed from the truck.

Removing the casters is an easy process. Simply flatten

and remove the cotter pins that are holding the casters in

place (Fig. 1). Then lift the case with a “J” bar and slide

the caster assemblies out. The dismantled casters can

now be discarded.

FLOOR PREP

1. Ask the general contractor if your current copy of the

building dimensions are the most recently issued. Also,

ask for the points of reference from which you should

take dimensions to locate the cases.

2. Using chalk lines or a laser transit, mark the floor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3. Leveling is necessary to ensure proper case align-

ment and to avoid potential case damage. Locate the

highest point on the positioning lines as a reference for

determining the proper height of the shim-pack level-

ers. A laser transit is recommended for precision and

requires just one person.

4. Locate basehorse positions along the chalk line. Spot

properly leveled shim packs at each basehorse loca-

tion.

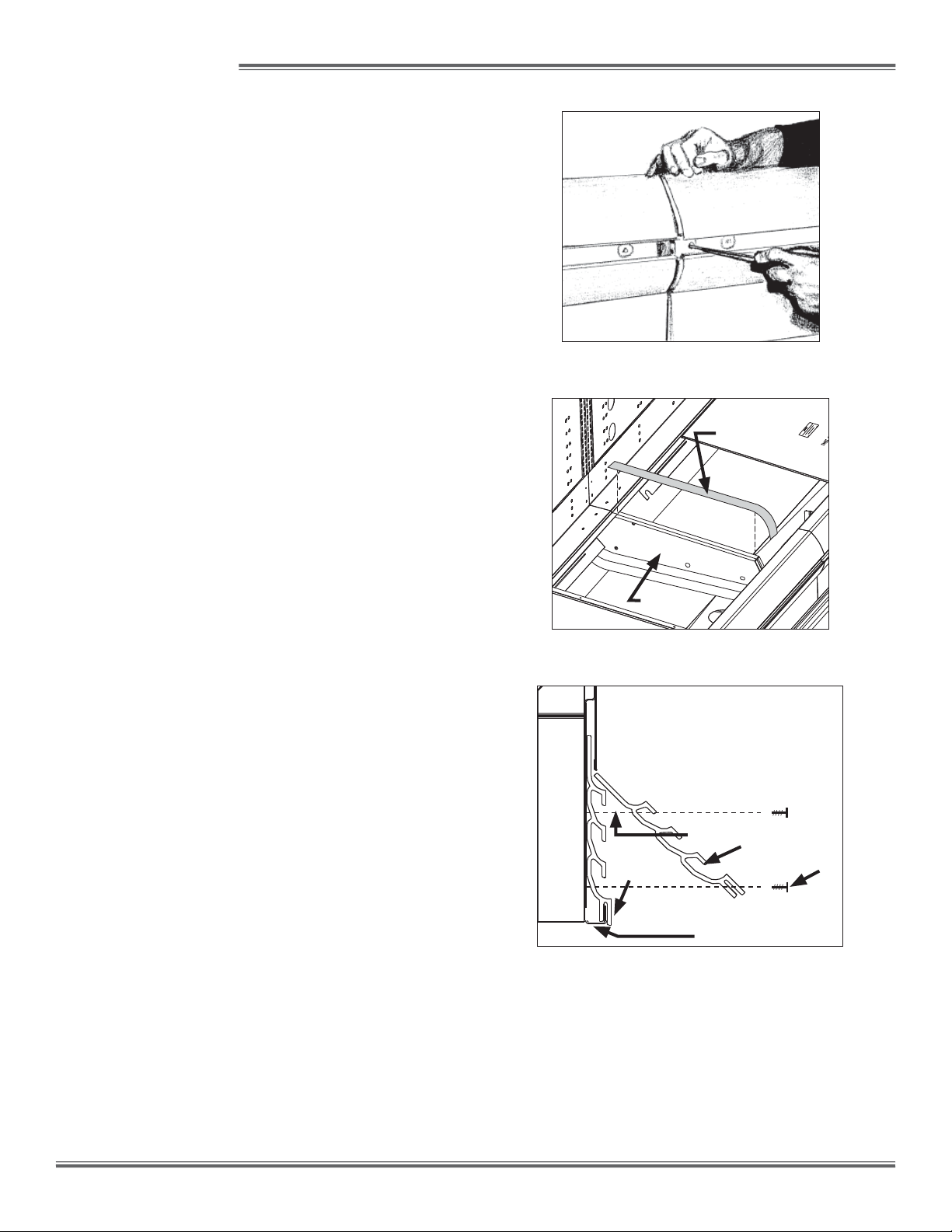

Fig. 1 Caster assembly

CASTER

WARNING

Be certain that your hands and feet are out of

the way before lowering the case after the

removal of the casters. Failure to do so may

result in serious injury.

▲

J-BAR

LINE-UP & INSTALLATION

Single Case

1. Roll the case into position. Using a “J” bar , raise the

end of the case (under cross support), remove the

caster assembly and lower the basehorse on to the

shim packs. Repeat on the other end of the case.

2. Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by plac-

ing a bubble level on the rear wall. Add/remove shim

packs as needed. To check the horizontal level, repeat

this process after placing the bubble level on the front

sill.

Multi-Case

1. Remove any loose items from the cases that may

interfere with case joining (e.g. shipping braces, mirror

assemblies, etc). Be certain to keep all loose items

close to the case in which they shipped as they will

be used later in the installation process.

2. Follow the single-case installation instructions (above)

for the first case, then position the next case in the line-

up approximately 3’ away. Remove the casters on the

end that is closest to the first case.

3. Apply the foam tape gasket (supplied) and a bead of

butyl or silicone sealant to the end breaker of the first

case. From the opposite end, push the second case to

a position that is approximately 6" from the first case,

then remove the remaining casters and position case

on the shim packs.

4. Push the cases tightly together, then lightly bolt them

together through the holes that are provided. Tighten

all the joining bolts until all margins are equal. Be care-

ful not to over tighten.

5. Repeat steps 3 and 4 of this sequence for all remaining

cases. Be certain to properly level all cases.

5

TRIM OUT

1. If a master bumper is included, locate the hole in the

center of the master bumper joint. Using a screw driver

as a lever, slide the case-to-case joint to the center of

the joint between the two cases (Fig. 2). Slide the mas-

ter bumpers left or right to close the seams as required,

working outwards from the center of the line-up to the

ends.

2. Close the seam where the bumper joins the case end.

The bumper joint closes the seam that may develop

if the master bumper is moved away from the end to

close the case-to-case joint seam.

3. Seal the case-to-case joints with caulk (supplied), then

apply acrylic tape (supplied) over the pipe-chase seam

(Fig. 3). The tape acts as a watershed preventing wa-

ter from settling in the case joint.

4. Close the joints of the front panel, sliding the joint trim

left-or-right as needed.

5. Attach the “J” rail with the supplied screws (Fig. 4).

6. Insert top of kickplate into the kickplate retainer. Slide

the kickplate up into the retainer, then down onto the “J”

rail (Fig. 4). Be certain that the bottom of the kickplate

is fitted over extruding "lip" of the "J" rail.

7. If a master bumper is present, insert nose bumper

into master bumper channel. Roll nose bumper into

channel along entire lineup, up to 96’. We recommend

leaving an additional 6" of nose bumper at the ends to

allow for shrinkage during the first 24-48 hours follow-

ing case start-up.

8. After sufficient time has passed to allow for bumper

shrinkage, cut away the excess bumper for final fit and

finish. Be certain to use an appropriate cutting tool

(tubing- or PVC-cutter) to ensure a smooth cut.

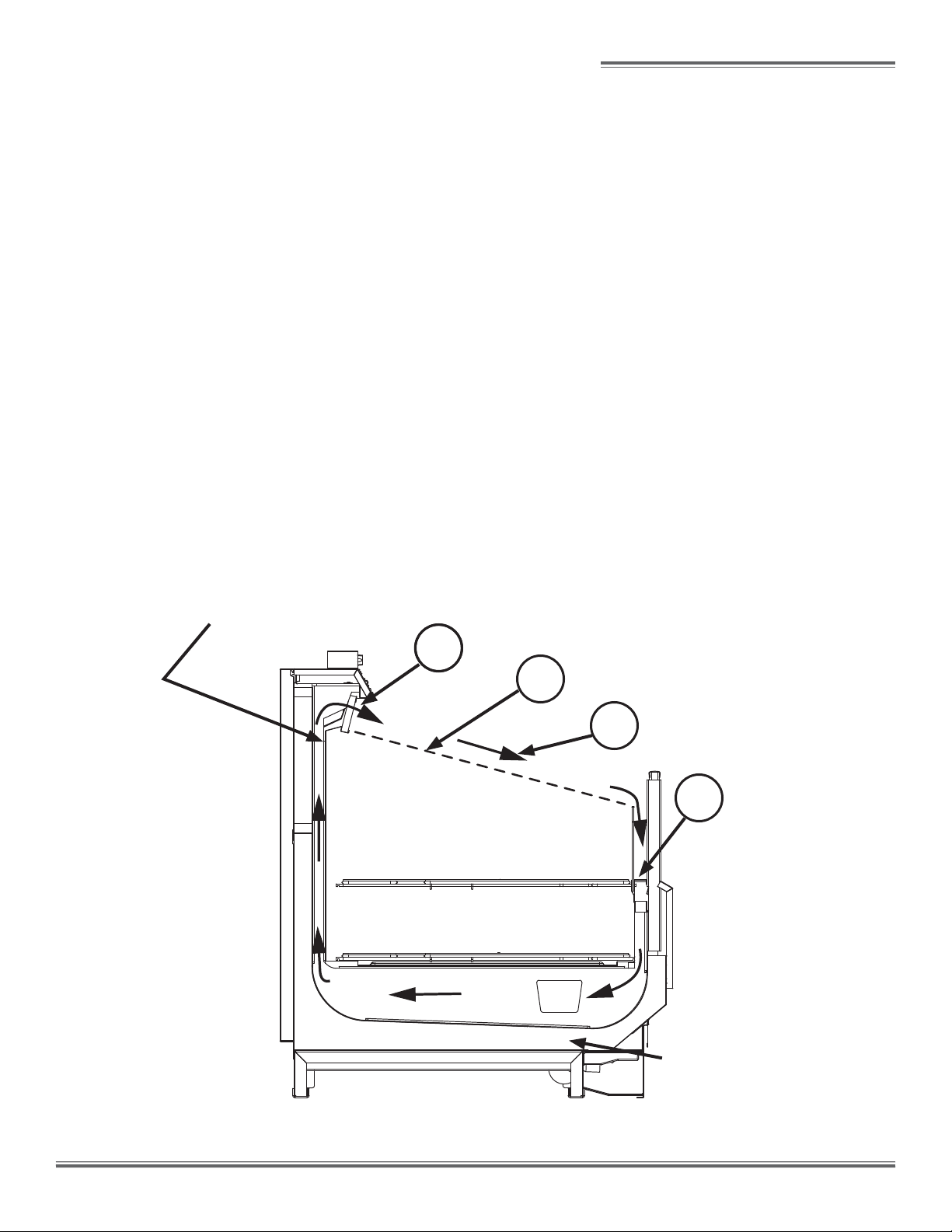

Fig. 3 Sealing the pipe chase

PIPE

CHASE

ACRYLIC

TAPE

Fig. 2 Case-to-case joint

INSTALLATION

Fig. 4 "J" rail and kickplate installation

1. Attach "J" rail using

supplied screws.

2. Slide kickplate UP into

kickplate retainer recess.

3. Drop the kickplate

DOWN onto the "J" rail lip.

KICKPLATE

2

3

"J" RAIL

1

6

CASE CONNECTIONS

REFRIGERATION

As the diagram below indicates, the coil outlet hole is

positioned forward on the right-hand side of the case, fully

visible in front of the fan plenum.

The expansion valve and other controls - located on the

left-hand side of the case - are accessible without lifting the

fan plenum and may be reached by lifting the deck pans.

If it becomes necessary to penetrate the case bottom, be

certain to seal it afterwards with canned-foam sealant and

white RTV.

PLUMBING

The drain outlet is specially molded out of PVC material

and is located in the center of the case for convenient ac-

cess. The “P” trap, furnished with the case, is constructed

of schedule 40 PVC pipe. Care should be given to ensure

that all connections are water-tight and sealed with the ap-

propriate PVC or ABS cement.

The drain lines can be run left or right of the tee with the

proper pitch to satisfy local drainage requirements. Since

the kickplate is shipped loose with the case, you should

have open access to the drain line area during installation.

35 1/16 in

[89.1 cm]

**

39 3/8 in

[99.9 cm]

41 5/16 in

[104.9 cm]

31 11/16 in

[80.5 cm]

FRONT OF CASE

C

L

1 1/2 in [3.8 cm]{END}

96 in [243.8 cm] (8' CASE)

8 11/16 in [22.1 cm]

4 in[10.2 cm] 28 5/8 in

[72.7 cm]

REFRIGERATION

REAR REFRIGERATION

(11 3/4" OFF OF FLOOR)

22 9/16 in [57.3 cm]

20 1/16 in [51.0 cm]

35 3/16 in

[89.4 cm] JUNCTION BOX

(STANDARD)

ELECTRICAL

1 1/2" PVC DRAIN

CONNECTION

33 9/16 in

[85.3 cm]

MODEL

UPL-NRG

REMOVE THE SHIPPING BLOCKS THAT PROTECT THE

REFRIGERATION LINES DURING SHIPMENT BEFORE

OPERATING THE CASE.

REMOVE

If the kickplate has been installed, you will find it very easy

to remove. Simply lift the kickplate up from the "J" rail and

pull it out, away from the case. See the Trim Out section

on page 6.

ELECTRICAL

Electrical hookups are made to a junction box located at

the bottom-left-front of the case.

For case-to-case wiring, run conduit between the junction

boxes. When connecting to the junction box on the bottom-

left side of the case, field wiring should exit box from the

right side (furthest away from case wiring) to allow more

room inside for wiring connections.

CAUTION

If any brazing is necessary, place wet rags

around the area to avoid tank damage.

▲

7

AIRFLOW, DEFROST & TEMP CONTROLS

case on the bottom-left side (Fig. 5). To access the thermo-

stats, you must first remove the kick plate, then remove the

junction box cover. For instructions on removing the kick-

plate, see the Trim Out section of this manual on page 6.

It is important to consult the control setting guidelines shown

on page 2 before setting defrost times. Further adjustment

may be required depending on store conditions.

AIR FLOW & PRODUCT LOAD

Hill PHOENIX cases provide maximum product capacity

within the refrigerated air envelope. Please keep products

within the load limit line shown on the diagram below.

It is important that you do not overload the food product dis-

play so that it impinges on the air flow pattern. Overloading

will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections

are covered.

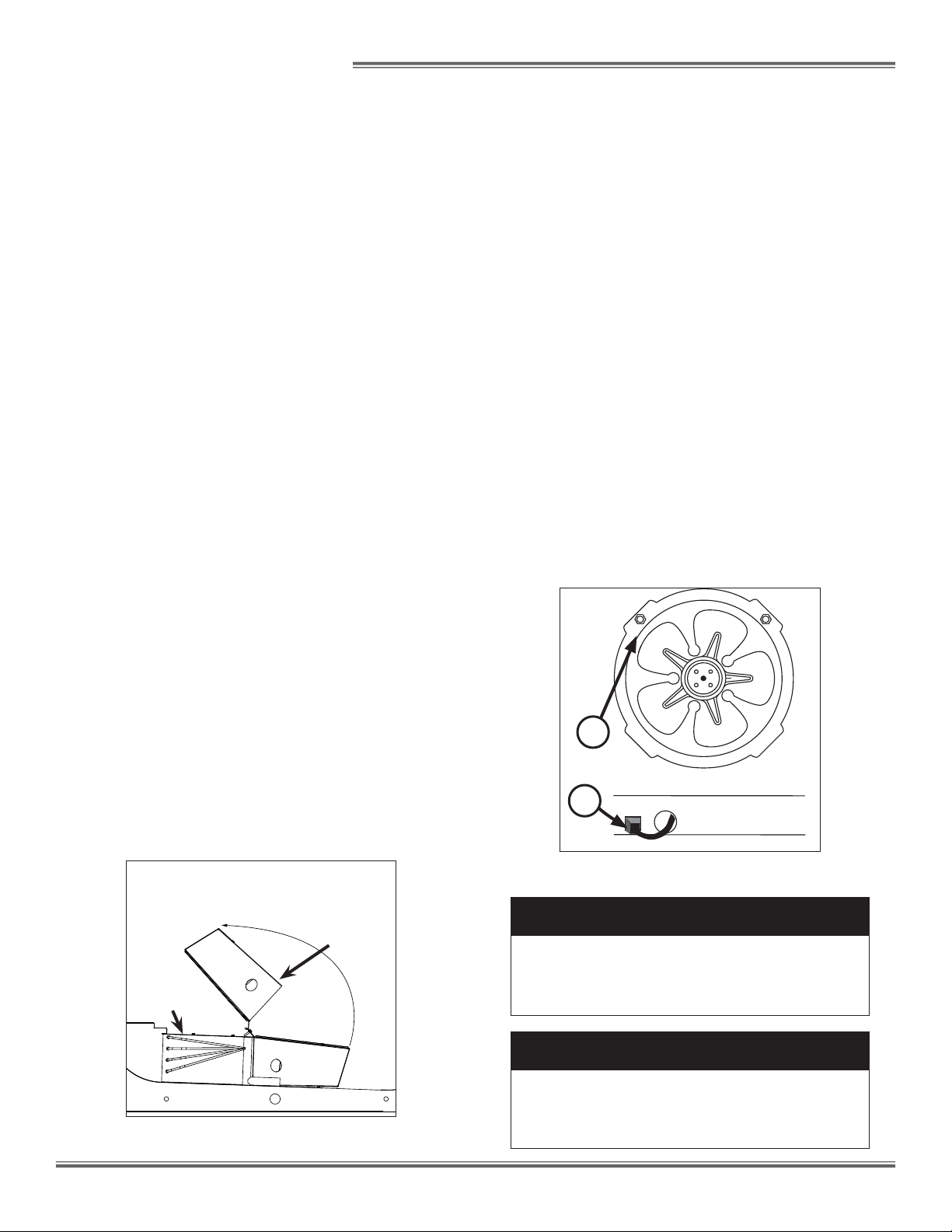

DEFROST & TEMPERATURE CONTROLS

UPL-NRG cases are equipped with Timed-Off defrost.

The rear baffle (Fig. 5) contains the sensor bulb for tem-

perature control and the discharge air probe. The defrost

termination control thermostat and the temperature control

thermostat are located in the junction box underneath the

Fig. 5 Airflow; probe, sensor locations.

Temperature control sensor bulb

Discharge air probe

Defrost termination control thermostat

Temperature control thermostat

MODEL

UPL-NRG

1. DISCHARGE AIR

2. LOAD LIMIT

3. AIR CURTAIN

4. RETURN AIR

1

1

2

3

4

8

SINGLE PIECE FAN PLENUM LIFT UP

PLENUM

COVER

COIL

COVER

SINGLE PIECE FAN

PLENUM SWINGS UP

FOR EASY CLEANING

USE & MAINTENANCE

CLEANING PROCEDURES

• A periodic cleaning schedule should be established to

maintain proper sanitation, insure maximum operating

efficiency, and avoid the corrosive action of food fluids

on metal parts that are left on for long periods of time.

We recommend cleaning once a week.

• To avoid shock hazard, be sure all electrical power is

turned off before cleaning. In some installations, more

than one disconnect switch may have to be turned off to

completely de-energize the case.

• All surfaces pitch downward to a deep-drawn drain

trough, funneling liquids/ to the front of the case where

the waste outlet is located for easy access. Check

waste outlet to insure it is not clogged before starting

the cleaning process and avoid introducing water faster

than the case drain can carry it away.

• The coil is covered to keep food fluids from entering

but is easily accessible when coil cleaning is required.

Simply remove the screws; lift and remove the plenum

cover; then lift and remove the coil cover. Be certain that

both the plenum and coil cover are properly closed and

secured after cleaning to avoid air leaks.

• If any potentially harmful cleaners are used, be certain

to provide a temporary separator (e.g., cardboard, plas-

tic rap, etc.) between those cases that are being cleaned

and those that may still contain product.

• Avoid spraying cleaning solutions directly on electrical

connections.

• Allow cases to be turned off long enough to clean any

frost or ice from coil and pans.

• Remove kickplate and clean underneath the case with a

broom and a long-handled mop. Use warm water and a

disinfecting cleaning solution when cleaning underneath

the cases.

DANGER

▲

SHOCK HAZARD

Always disconnect power to case when servic-

ing or cleaning. Failure to do so may result in

serious injury or death.

WARNING

▲

Exercise extreme caution when working in a

case with the coil cover removed. The coil

contains many sharp edges that can result in

severe cuts to the hands and arms.

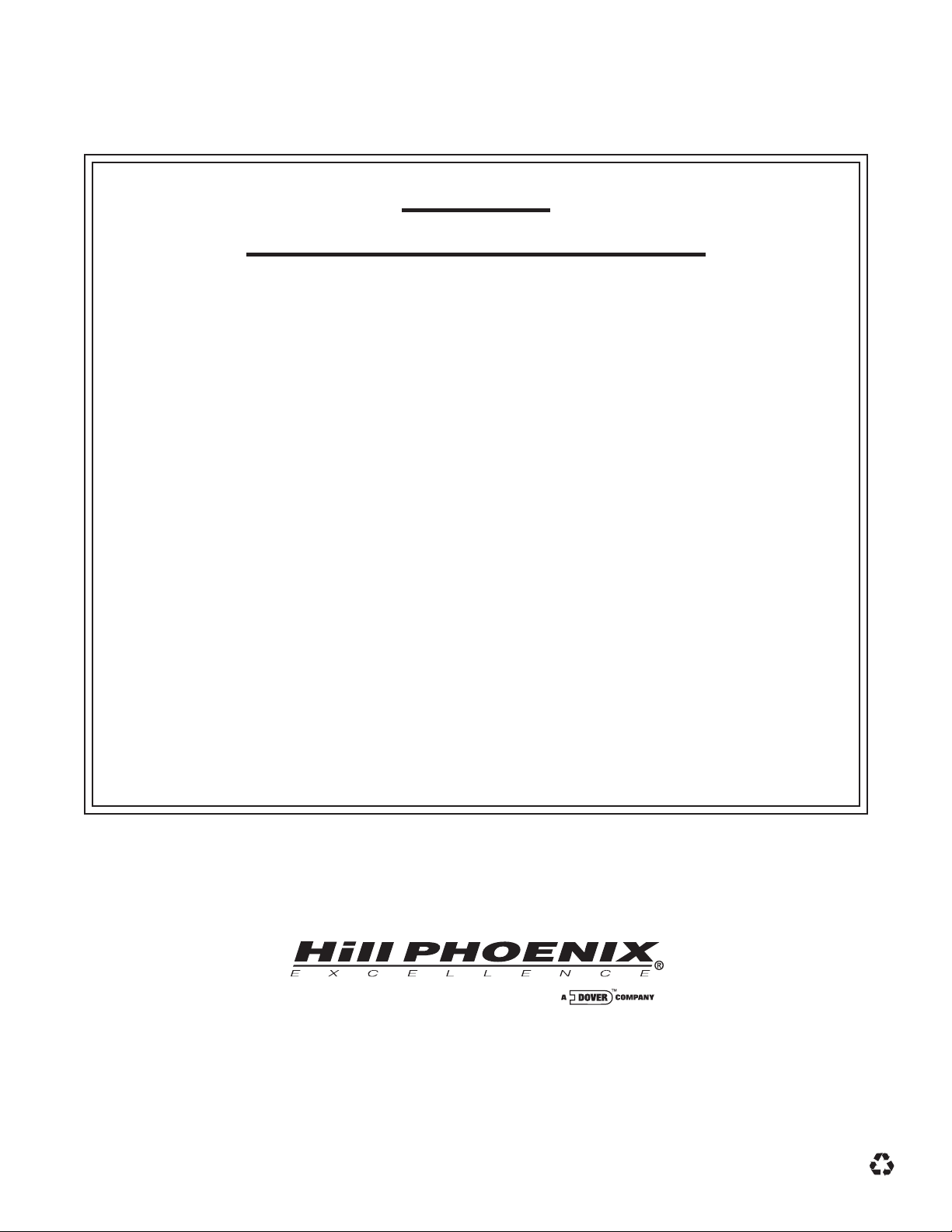

FANS

The evaporator fans are equipped with 16-watt fan motors.

Motors have a counter-clockwise rotation when viewed

from the shaft end.

The fan blades are 8” in diameter with a 20fan blade

pitch. It is important that the blade pitch be maintained as

installed. Do not attempt a field modification by alter-

ing the blades.

Fan motors may be changed with an easy two-step pro-

cess without lifting up the plenum, thereby avoiding the

necessity to unload the entire product display to make a

change:

1. Unplug the fan motor, easily accessible outside the

plenum. Push power cord back through plenum

opening.

2. Remove two fasteners, then lift out the entire fan

basket.

Reverse procedure when re-installing fan basket.

FAN ASSEMBLY

1

2

9

Contact the Service Parts Department at:

1-800-283-1109

Provide the following information about the part you are

ordering:

• Model number and serial number of the case for

which the part is intended.

• Length of the part (if applicable).

• Color of part (if painted) or color of polymer part.

• Whether part is for left- or right-hand application.

• Quantity

*Serial plate is located on the back of the case on the right-hand side.

If the parts are to be returned for credit, ask the Parts

Department to furnish you with a Return Material

Authorization Number.

PARTS ORDERING

10

APPENDIX A:

WIRING DIAGRAMS

NOTES

NOTES

06/00

WARRANTY

HEREINAFTER REFERRED TO AS MANUFACTURER

FOURTEEN MONTH WARRANTY. MANUFACTURER’S PRODUCT IS WARRANTED TO BE FREE FROM DEFECTS

IN MATERIAL AND WORKMANSHIP UNDER NORMAL USE AND MAINTENANCE FOR A PERIOD OF FOURTEEN

MONTHS FROM THE DATE OF ORIGINAL SHIPMENT. A NEW OR REBUILT PART TO REPLACE ANY

DEFECTIVE PART WILL BE PROVIDED WITHOUT CHARGE, PROVIDED THE DEFECTIVE PART IS RETURNED TO

MANUFACTURER. THE REPLACEMENT PART ASSUMES THE UNUSED PORTION OF THE WARRANTY.

This warranty does not include labor or other costs incurred for repairing, removing, installing, shipping, servicing, or

handling of either defective parts or replacement parts.

The fourteen month warranty shall not apply:

1. To any unit or any part thereof which has been subject to accident, alteration, negligence, misuse or

abuse, operation on improper voltage, or which has not been operated in accordance with the

manufacturer’s recommendation, or if the serial number of the unit has been altered, defaced, or removed.

2. When the unit, or any part thereof, is damaged by fire, flood, or other act of God.

3. Outside the continental United States.

4. To labor cost for replacement of parts, or for freight, shipping expenses, sales tax or upgrading.

5. When the operation is impaired due to improper installation.

6. When installation and startup forms are not properly complete or returned within two weeks after startup.

THIS PLAN DOES NOT COVER CONSEQUENTIAL DAMAGES. Manufacturer shall not be liable under any circumstanc-

es for any consequential damages, including loss of profit, additional labor cost, loss of refrigerant or food products,

or injury to personnel or property caused by defective material or parts or for any delay in its performance hereunder

due to causes beyond its control. The foregoing shall constitute the sole and exclusive remedy of any purchases

and the sole and exclusive liability of Manufacturer in connection with this product.

The Warranties are Expressly in Lieu of All Other Warranties, Express of Implied and All Other Obligations or

Liabilities on Our Part. The Obligation to Repair or Replace Parts or Components Judged to be Defective in

Material or Workmanship States Our Entire Liability Whether Based on Tort, Contract or Warranty. We Neither

Assume Nor Authorize Any Other Person to Assume for Us Any Other Liability in Connection with Our Product.

MAIL CLAIM TO:

Hill PHOENIX

Display Merchandisers

1925 Ruffin Mill Road

Colonial Heights, VA 23834

1-800-283-1109

Hill PHOENIX

Refrigeration Systems &

Electrical Distribution Products

709 Sigman Road

Conyers, GA 30013

770-285-3200

Warning

Maintenance & Case Care

When cleaning cases the following must be performed

PRIOR to cleaning:

To avoid electrical shock, be sure all electric power is

turned off before cleaning. In some installations, more

than one switch may have to be turned off to complete-

ly de-energize the case.

Do not spray cleaning solution or water directly on fan

motors or any electrical connections.

All lighting receptacles must be dried off prior to inser-

tion and re-energizing the lighting circuit.

Please refer to the Use and Maintenance section of this installation manual.

BDM0610

1925 Ruffin Mill Road, Colonial Heights, VA 23834

Due to our commitment to continuous improvement, all specifications are subject to change without notice.

Hill PHOENIX is a Sustaining Member of the American Society of Quality.

Visit our web site at www.hillphoenix.com

Tel: 1-800-283-1109

Table of contents

Other Hillphoenix Merchandiser manuals

Popular Merchandiser manuals by other brands

Polar Electro

Polar Electro CD229-A instruction manual

Structural Concepts

Structural Concepts Harmony HMG3953 Installation and operating manual

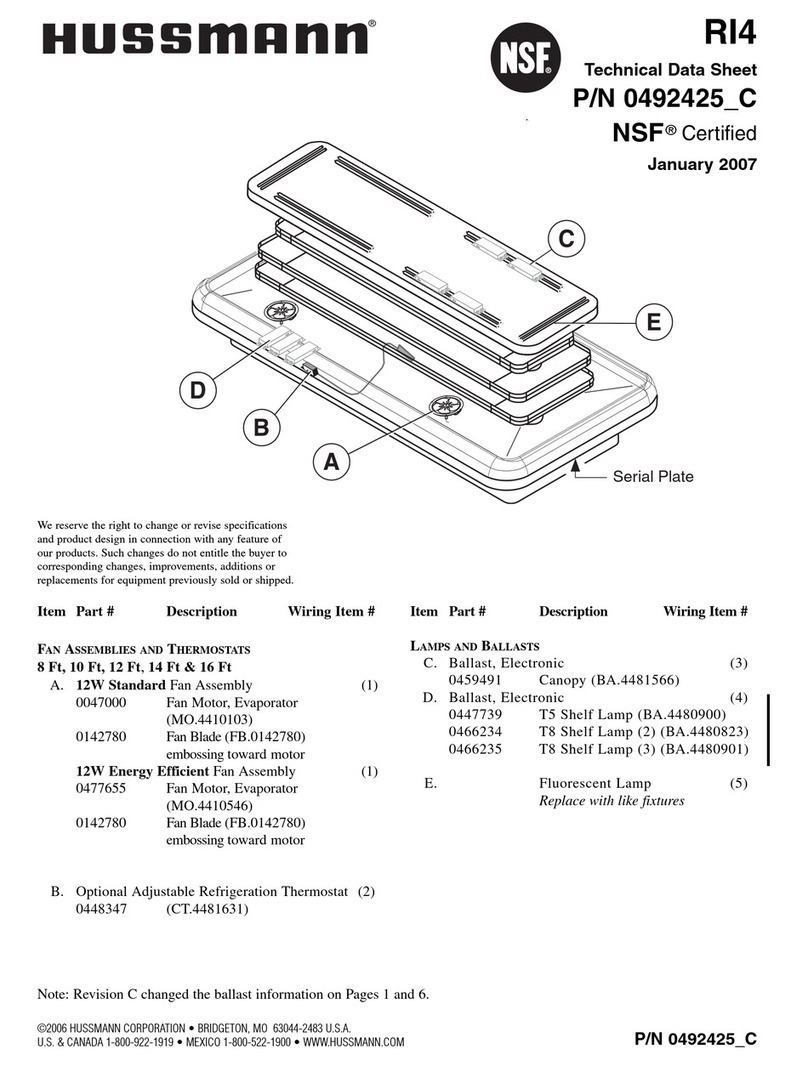

Hussmann

Hussmann P4NX-EP Technical data sheet

Lincat

Lincat SCR785 User and installation instructions

Hussmann

Hussmann LG installation instructions

saro

saro SC 70 Operation instructions

Summit

Summit Classic CL181WBV instruction manual

Hussmann

Hussmann HEDN Installation and operation guide

Howard McCray

Howard McCray R-CFS35-10 Specifications

Hussmann

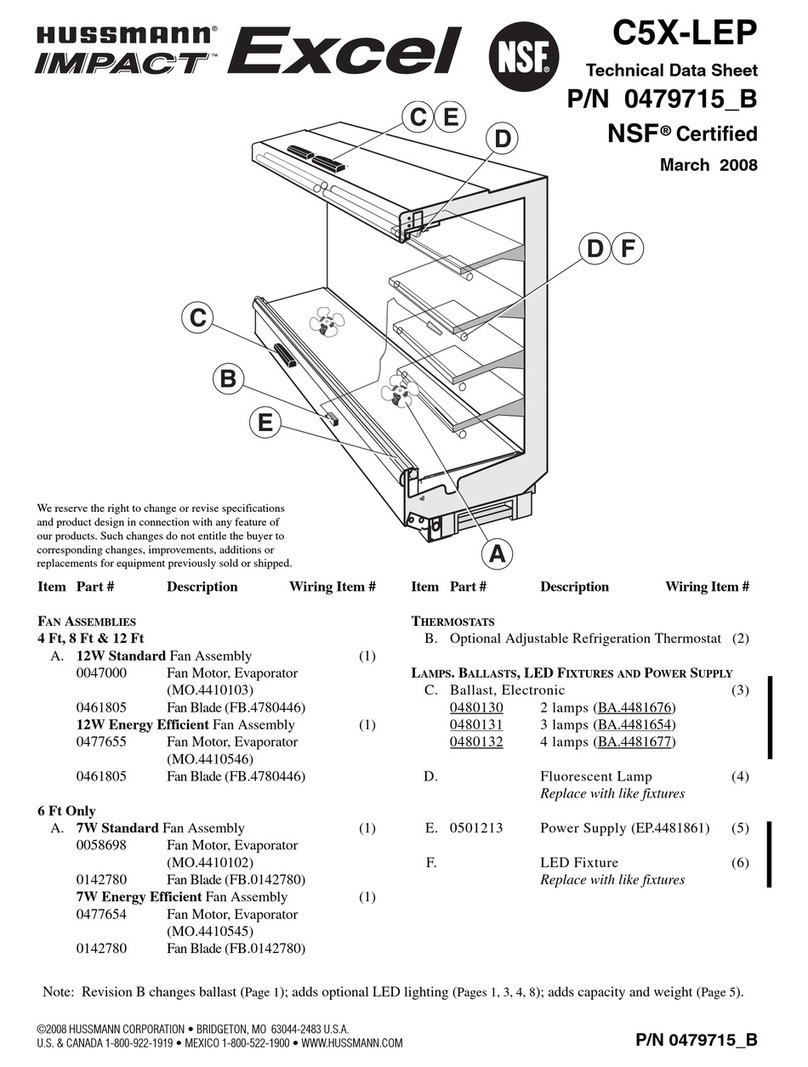

Hussmann impact Excel C5X-LEP Technical data sheet

Delfield

Delfield Shelleyspeed SPH-40E Specifications

Lincat

Lincat Seal C6A/75B Installation, operating and servicing instructions