Hillphoenix OB-SC R-290 PRODUCE User manual

OB-SC (R-290)

PRODUCE

12/20

SINGLE/MULTI-DECK MERCHANDISER

I N S TA L L AT I O N & O P E R AT I O N S M A N U A L

Technical References ................................................. 2-7

General Information ........................................................8

Installation ................................................................ 9-10

Case Connections ...................................................11-12

Pre-Power Checklist .................................................... 13

Airflow & Defrost .......................................................... 14

Case Cleaning .........................................................15-17

Troubleshooting ........................................................... 18

Safety Devices & Service .......................................19-20

Parts Ordering .............................................................. 21

Appendices

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualified tech-

nicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized installation/

service contractors, please visit our website at www.hillphoenix.com.

ii

Important

D A N G E R

•

Indicates an immediate threat of death or seri-

ous injury if all instructions are not followed

carefully.

At Hillphoenix®, the safety of our customers and employees, as well as the ongo-

ing performance of our products, are top priorities. To that end, we include impor-

tant warning messages in all Hillphoenix installation and operations handbooks,

accompanied by an alert symbol paired with the word "DANGER", "WARNING", or

"CAUTION".

All warning messages will inform you of the potential hazard; how to reduce the

risk of case damage, personal injury or death; and what may happen if the in-

structions are not properly followed.

This manual must be stored near the display case where it can be easily consult-

ed. If this manual does not provide the information you require please contact

Hillphoenix for more information.

W A R N I N G

Indicates a potential threat of death or serious

injury if all instructions are not followed care-

fully.

•

C A U T I O N

Indicates that failure to properly follow instruc-

tions may result in case damage.

•

iii

Revision History

• new manual format_09/20

• NSF Listing Update_12/20

iv

TECHNICAL REFERENCE

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

GENERAL NOTES:

• "---" Indicates that the feature is not an option on this case model and/or the data is not yet available at this time.

SHIPPING WEIGHT

Case Weight

OB-SC ---

2

TECHNICAL REFERENCE

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

NOTES:

• "---" Indicates that the feature is not an option on this case model and/or the data is not yet available at this time.

• Listed discharge air velocity represents the average velocity at the peak of defrost measured from front facing

discharge wall vents to lower tier.

• RLA - Running Load Amps

• LRA - Locked Rotor Amps

SYSTEM REQUIREMENTS

Case

Length Volts Phase

Total

Amps

Minimum

Circuit

Ampacity

Maximum

Overcurrent

Protection

1 Tier 120 1 6.03 7.36 12.66

2 Tier 120 1 9.23 11.33 19.73

4 Tier 120 1 18.46 20.56 28.96

ELECTRICAL DATA

Case

Length

Fans Per

Case Volts

High Efficiency

Fans

Condenser

Fans

Amps Watts Amps Watts

1 Tier 1 120 0.30 25.0 0.43 25.0

2 Tier 1 120 0.30 25.0 0.53 30.0

4 Tier 2 120 0.60 50.0 1.06 60.0

GUIDELINES AND CONTROL SETTINGS

24hr Energy

Usage

(kWh/ft)

Suction Temperature

@ Case Outlet

(°F)

Superheat

Set Point @ Bulb

(°F)

Discharge Air

(°F)

Discharge Air

Velocity

(FPM)

--- 10 -15 Capillary Tube 28 150 -170

CONDENSING UNIT DATA

Case

Length Volts Phase BTUHs

RLA

(Amps)

LRA

(Amps)

Compressor

Qty Refrig. Qty Grams

1 Tier 120 1 2957 5.3 32.0 1 R290 1 126

2 Tier 120 1 3876 8.4 41.5 1 R290 1 90

4 Tier 120 1 3876 8.4 41.5 2 R290 2 90

DEFROST CONTROLS

Defrosts

Per Day

Run-Off

Time

(Min)

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(Min)

Termination

Temp

(°F)

Fail-Safe

(Min)

Termination

Temp

(°F)

Fail-Safe

(Min)

Termination

Temp

(°F)

6 --- --- --- 45 46 --- ---

3

TECHNICAL REFERENCE

PLEX

45 9/16" [115.7 cm]

PLEX

5 1/2" [14.0 cm]

31" [78.7 cm]

FRAME

40" [101.6 cm]

WOOD

40 3/4" [103.5 cm]

8" [20.3 cm]

34 1/2" [87.6 cm]

COMPRESSOR COMPARTMENT

(AIR FLOW BACK TO FRONT)

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL TEMP LOAD LIMIT

PRODUCT STOP

23 5/8" [60.0 cm]

5" [12.7 cm]

8" [20.3 cm]

OVERALL

34 1/2" [87.6 cm]

TOEKICK

27" [68.6 cm]

PLEX

31" [78.7 cm]

POWER SUPPL

Y

FRONT OF CASE

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

NOTES:

• Shown with optional wood cladding.

4

TECHNICAL REFERENCE

32 3/4" [83.1 cm] 32 3/4" [83.1 cm]

WOOD

28 15/16" [73.5 cm]

PLEX

33 3/4" [85.7 cm]

34 1/2" [87.6 cm] 34 1/2" [87.6 cm]

PLEX

5 1/2" [14.0 cm]

FRAME

28 3/16" [71.6 cm]

PLEX

38 1/16" [96.7 cm]

WOOD

33 1/4" [84.5 cm]

FRAME

32 1/2" [82.6 cm]

8" [20.3 cm]

69" [175.3 cm]

MID DECK

LOWER DECK

COMPRESSOR COMPARTMENT

(AIR FLOW BACK TO FRONT)

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL TEMP LOAD LIMIT

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL TEMP LOAD LIMIT

64" [162.6 cm]

28 1/2" [72.3 cm] 29" [73.7 cm]

5" [12.7 cm]

OVERALL

34 1/2" [87.6 cm]

26 5/8" [67.6 cm]

OVERALL

69" [175.3 cm]

PRODUCT STOP

23 5/8" [60.0 cm]

TOEKICK

27" [68.6 cm]

PLEX

31" [78.7 cm]

FRONT OF CASEPOWER SUPPL

Y

MID DECK LOWER DECK

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

NOTES:

• Shown with optional wood cladding.

5

TECHNICAL REFERENCE

32 3/4" [83.2 cm]32 3/4" [83.2 cm]

PLEX

38 1/16" [96.7 cm]

5 1/2" [14.0 cm]

FRAME

32 1/2" [82.6 cm]

WOOD

33 1/4" [84.5 cm]

PLEX

44 13/16" [113.8 cm]

WOOD

40" [101.6 cm]

FRAME

39 1/4" [99.7 cm]

8" [20.3 cm]

34 1/2" [87.6 cm] 34 1/2" [87.6 cm]

69" [175.3 cm]

PLEX

38 1/16" [96.7 cm]

WOOD

33 1/4" [84.5 cm]

FRAME

32 1/2" [82.6 cm]

8" [20.3 cm]

69" [175.3 cm]

34 1/2" [87.6 cm] 34 1/2" [87.6 cm]

32 3/4" [83.2 cm] 32 3/4" [83.2 cm]

UPPER DECK

MID DECK

5 1/2" [14.0 cm]

PLEX

33 3/4" [85.7 cm]

WOOD

28 15/16" [73.5 cm]

FRAME

28 3/16" [71.6 cm]

MID DECK

LOWER DECK

COMPRESSOR COMPARTMENT

(AIR FLOW BACK TO FRONT)

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICALTEMP LOAD LIMIT

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL TEMP LOAD LIMIT

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL TEMP LOAD LIMIT

3" CRITICAL TEMP LOAD LIMIT

6" NON-CRITICAL LOAD LIMIT

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

NOTES:

• Shown with optional wood cladding.

6

TECHNICAL REFERENCE

OVERALL

69" [175.3 cm]

PLEX

65 3/8" [166.1 cm]

28 7/16" [72.2 cm] 29 1/16" [73.8 cm]

PLEX

65 1/2" [166.4 cm]

26 5/8" [67.6 cm]

OVERALL

69" [175.3 cm]

28 7/16" [72.2 cm]29 1/16" [73.8 cm]

5" [12.7 cm]

UPPER

DECK

MID

DECK

MID

DECK

LOWER

DECK

FRONT OF CASE

POWER SUPPL

Y

TOEKCIK

61 1/2" [156.2 cm]

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

OB-SC Self-Service Open Multi-Deck Tiered Bulk Produce Merchandise

r

1, 2 & 4 Tier (Produce)

OB-SC

Rev. Date Rev. # Rev. Title

06-17-20 1 NEW STANDARDS

7

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical infor-

mation and will assist you with the installation and operation of your new Hillphoenix specialty cases. By closely following

the instructions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel

free to contact our Marketing Services group at the number listed below. Thank you for choosing Hillphoenix, and we wish

you the very best in outstanding food merchandising.

CASE DESCRIPTION

This manual specifically covers the OB-S (R-290) produce self-

service open single/multi-deck merchandiser.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-condi-

tioned store that maintains a 75°F (24°C) store temperature

and 55% (max) relative humidity (ASHRAE conditions). Case

operation will be adversely affected by exposure to excessively

high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation for

efficient performance.

THIS UNIT CONTAINS R-290 FLAMMABLE REFRIGERANT. USE

CAUTION WHEN HANDLING, MOVING OR SERVICING THE DISPLAY

CASE. AVOID DAMAGING THE REFRIGERANT TUBING WHICH COULD

INCREASE THE RISK OF A LEAK.

SHIPPING CASES

Transportation companies assume all liability from the time a

shipment is received by them until the time it is delivered to

the consumer. Our liability ceases at the time of shipment.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping dam-

age and/or shortages, please contact the Service Parts

Department at the number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's

agent; otherwise, the carrier may refuse the claim. If damage

becomes apparent after the equipment is unpacked, retain all

packing materials and submit a written request to the carrier

for inspection within 14 days of receipt of the equipment.

Failure to follow this procedure will result in refusal by the

carrier to honor any claims with a consequent loss to the

consumer.

If a UPS shipment has been damaged, retain the damaged

material, the carton and notify us at once. We will file a claim.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the highest

level of quality. Any claim for lost/missing items must be

made to Hillphoenix within 48 hours of receipt of the equip-

ment. When making a claim please use the number listed

below.

SERVICE PARTS & TECHNICAL SUPPORT

For service parts questions regarding our cases, please

contact our Service Parts Department at 1-844-HPX-PART

For technical questions regarding our cases, please contact

our Technical Support Department at 1-833-280-5714.

CONTACTING THE FACTORY

If you need to contact Hillphoenix regarding a specific fixture,

be certain that you have both the case model number and

serial number. (This information can be found on the data tag,

located at the top-left interior, rear exterior panel or interior

rear lower storage of the case. Location may vary based on

case design.)

Hillphoenix Specialty Products

703 Franklin Street, PO Box 478

Keosauqua, IA 52565

Website: www.hillphoenix.com

GENERAL INFORMATION

8

FLOOR PREP

1. Ask the general contractor if your current copy of the build-

ing dimensions are the most recently issued. Also, ask for

the points of reference from which you should take dimen-

sions to locate the cases.

2. Using chalk lines or a laser transit, mark the floor where

the cases are to be located for the entire lineup. The lines

should coincide with the outside edges of the case feet.

3. Move case as close as possible to its permanent location.

Remove all crating and shipping braces above the ship-

ping pallet. Loosen the plastic dust cover from the pallet,

but leave cover over the case to protect it while removing

the case from the pallet.

4. The power cord shipping brace (Fig. 1) can be removed

with a screw gun. As for case shipping braces, the same

would be applied with sled runner or caster constrction.

If the braces are metal brackets or locks they can be

removed with a screw gun. If they are wood blocks they

can be removed with a J-bar. Note: Shipping braces are

normally located at each corner of the case. Some case

models with casters will use bracing that surrounds the

casters entirely and some will use braces that affix to

the toekicks at each corner. (Shipping braces used vary

and are based on case design for best transport.)

5. Carefully, if horizontal supports, lift case up and off the

pallet. Remove dust cover. Installation hardware ships in

a marked packet located inside the case. Remove dust

cover. Installation hardware ships in a marked packet

located inside the case. (Hillphoenix self-contained display

cases are sometimes designed with casters. In most

situations, one or two persons can easily move the case

into position.) If there are casters simply roll them on to

LOCATION

This refrigerated display case has been designed for displaying

and storing perishable food product. It is engineered for air-

conditioned stores with a maximum ambient of 75°F and 55%

relative humidity.

When selecting the location for placement of this case, avoid

the following conditions:

Excessive Air Movement

1. Doors

2. Air-conditioned vents

3. Other air sources

Excessive Heat

1. Windows

2. Sun

3. Flood lamps 8 feet or less from the product

4. Other heat sources

the store floor to the proper staging area. First remove

all crating then all sled runner, caster, and/or power cord

shipping braces. (Dependent on case design.)

Fig. 1 Power cord shipping brace

SHIPPING BRACE

Fig. 2 Horizontal (sled runner) or vertical (caster) supports

SUPPORTS

6. Leveling is necessary to ensure proper operation of the

refrigeration system and drainage of the condensate.

Locate the highest point on the positioning lines as a ref-

erence for determining the proper height of the shim-pack

levelers. A laser transit is recommended for precision and

requires just one person. Level adjustable feet by twisting,

if applicable, or shim as necessary under vertical station-

ary or caster supports as this will help ensure that the

case is not settling over time.

7. Locate horizontal or vertical (caster) support positions

along the chalk line (Fig. 2). Spot properly leveled shim

packs at each support location.

8. (SLED RUNNERS) If necessary, drill a hole in each end of

every horizontal support (Fig. 3) and fasten to the floor

with concrete anchors. Note: The holes do not need to be

in the exact locations specified here. Be sure that the

anchors are close to the end of the horizontal supports

and at each corner of the case.

C A U T I O N

Failure to properly level the case could result in

lack of proper condensation drainage leading to

failure of the unit.

▲

CASE INSTALLATION

9

2. Once the case is properly placed on the shim packs,

check the vertical plumb of the case by placing a bubble

level on the rear wall. Add/remove shim packs as needed.

For the horizontal level, repeat this process after placing

the bubble level on the front sill.

3. Install the bumper, if applicable, into pre-attached bumper

track and snap into place. (Most self-contained cases ship

with bumper pre-installed.)

4. After sufficient time has passed to allow for bumper

shrinkage, cut away the excess bumper for final fit and fin-

ish. Be certain to use an appropriate cutting tool (tubing-

or PVC-cutter) to ensure a smooth cut.

5. Install case shelves and reconnect lights. Be aware that

differing shelf configurations will affect energy consump-

tion and case performance.

6. Install toekick/compressor compartment access panel

back onto the base of case, if applicable.

C A U T I O N

These cases are not designed for excessive

external weight. Do not walk on top or inside

of cases. Doing so may result in case damage

and/or personal injury.

▲

LINE-UP & INSTALLATION

Single Case

1. Move the case into position. Using a “J” bar, raise the end

of the case (under cross support), and lower the horizontal

support on to the shim packs. Repeat on the other end of

the case.

Fig. 4 Seismic anchoring locations (caster brackets)

BRACKET

Fig. 3 Seismic anchoring locations (sled runners)

9. (CASTERS) If necessary, attach two brackets at two sepa-

rate corners of the case (Fig. 4) and fasten to the floor

with concrete anchors. Note: The brackets do not need to

be affixed in the exact locations specified here. Howev-

er, be sure that the anchors are close to the corners and

that at least two brackets are used, one at each corner.

You can use more than two brackets for anchoring if you

want further support this way.

W A R N I N G

Be certain that your hands and feet are out of

the way before lowering the case. Failure to do

so may result in serious injury.

•

C A U T I O N

Locate the horizontal or vertical (caster) sup-

ports under unit before removing from pallet.

Failure to do so will damage the finished metal

if correct lift points are not identified prior to

removal.

•

C A U T I O N

Do not obstruct vetilation around the base of

the display case condensing unit. Obstructing

could cause the case to not operate correctly

and failure to maintain product temperatures.

•

CASE INSTALLATION

10

ELECTRICAL

Electrical hookups are made through the junction box which

can be accessed by removing the lower panel to the compres-

sor compartment.

When connecting to the power supply on the case, field wiring

should exit box from the side furthest away from case wiring to

allow more room inside for wiring connections. The case must

be grounded. For more detailed electrical wiring information

(see Appendix A1).

Prior to plugging in and starting up the case always check the

data tag located on the left end exterior panel or top interior of

the case, as well as the voltage label found on the main power

cord (Fig. 5) which can be found at the rear base panel. Note:

Check that the voltage of the receptacle you are going to

use for power and the voltage required for the case match.

C A U T I O N

Be certain that all electrical connections are

compliant with local codes.

▲

C A U T I O N

Be sure to remove all styrofoam shipping blocks

from piping and refrigerant lines. Failure to do

so may result in case damage.

•

C A U T I O N

Prior to plugging in and starting up the case.

Be certain that the voltage of the receptacle you

are going to use and the voltage required for the

case match. Failure to do so may result in case/

system damage.

•

REFRIGERATION & COMPRESSOR COMPARTMENT

A bottom mounted compressor compartment can be accessed

by removing the front or rear panel (Fig. 6). See Appendices

Fig. 5 Main power cord voltage label

VOLTAGE LABEL

Fig. 6 Compressor compartment

D A N G E R

CAUTION, RISK OF ELECTRIC SHOCK. If the

cord or plug becomes damaged, replace only

with a cord and plug of the same type.

•

D A N G E R

When carrying out maintenance tasks inside the

refrigerated case or compressor compartment,

it is essential to disconnect the power source to

the case from the main power.

•

CASE CONNECTIONS

for full instructions on how to program the Carel electronic

controller.

Access locations and/or R-290 compartment configurations

will vary based on case design. See technical references on

pages 4-7 for access locations and page 12 for a compressor

compartment diagram.

Pressure Switch & Power Supply

1. After the main power cord (Fig. 5) located at the base

panel of the case is plugged in and the power switch (Fig.

7) flipped to ON the case should begin normal operations.

2. The case should now be fully operational and functioning

when in the ON position.

Fig. 7 Lower panel power switch

POWER SWITCH

11

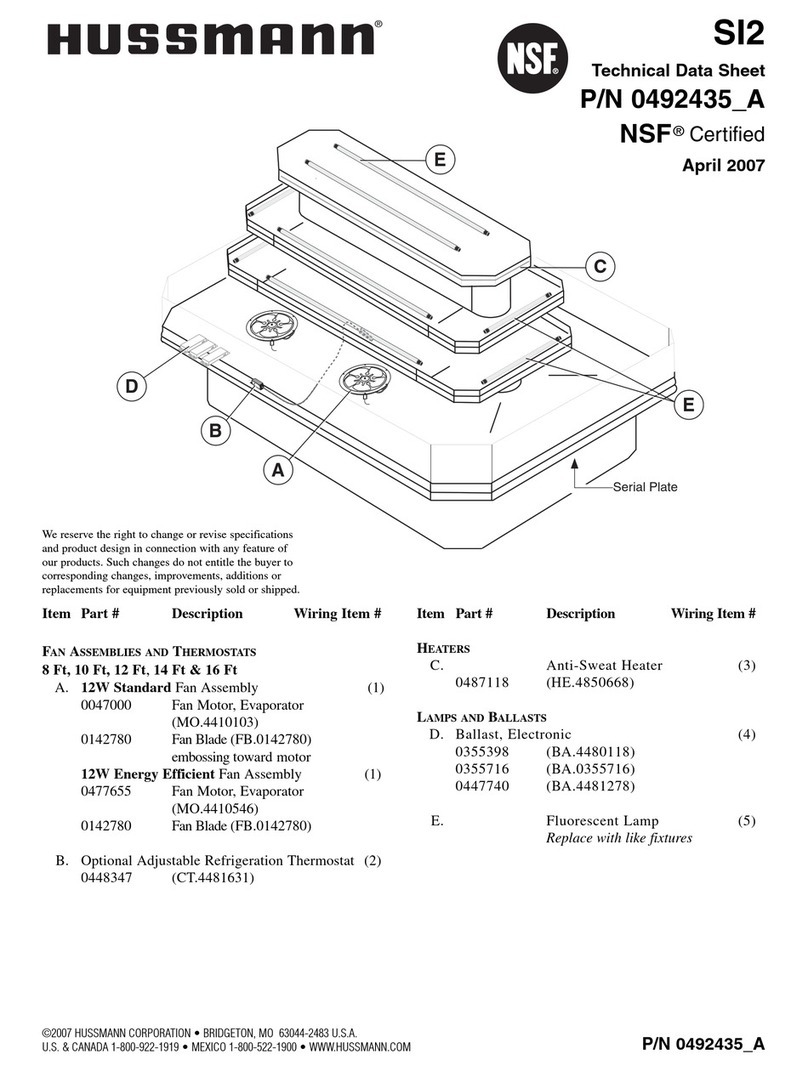

R-290 COMPRESSOR COMPARTMENT DIAGRAM

A Fan Guard

B Condenser Fan

C Pressure Switch

D Compressor

E Dissipater Pan

F Compressor Bracket

G High Side Access

H Condenser Bracket

I Filter Dryer

J Condenser Coil

Note: Access locations and/or compartment configurations will vary based on case design.

CASE CONNECTIONS

A

E

F

G

J

I

H

B

D

C

D A N G E R

ALWAYS CHECK THE THERMOSTAT CURRENT

RATING. It may have a limited current, as low

as 2A. If necessary protect digital thermostat

contacts with a contractor.

▲

12

Have you thoroughly examined the case for shipping damage? (see pg. 8)

Have you checked to ensure the case is horizontally level? (see pg. 9)

Have you checked all exposed refrigeration lines to ensure that they are not

kinked, dented or rubbing together and have installed the compressor com

partment access panel? (see pg. 11)

Have you checked and verified the voltage of the receptacle you are going to

use for power and the voltage required for the case match? (see pg. 11)

Have you verified the display case switch is in the OFF position prior to plug

ging in to the main power source? (see pg. 11)

Have you reviewed safety warning labels and verified all are present and in

good condition?

After powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

1. Check case temperature and adjust controller as needed. All display case

connections comply with the information/instructions?

2. Store the installation manual in the vicinity of the display case itself to

where it can be accessed and consulted by all members of staff involved in

the use of the refrigerator display case.

3. Before placing food in the display case, allow the case to operate for approx

imately two (2) hours and ensure the case is at the proper temp before

loading.

Before powering-up the case, be certain that all of the steps listed below have

been completed to ensure proper case functionality, safety and compliance with

warranty terms.

PRE-POWER CHECKLIST

13

Fig. 8 Airflow pattern (1-tier)

AIRFLOW & PRODUCT LOAD

Hillphoenix cases provide maximum product capacity within the

refrigerated air envelope. Please keep products within the ap-

propriate load limit.

It is important that you do not overload the food product display

so that it impinges on the airflow pattern (Fig. 8). Overloading

will cause malfunction and the loss of proper temperature lev-

els. The designed load limit is 3" above the deck for critical tem-

perature products and 6" for non-critical temperature products.

For full technical reference drawings with load limit lines refer

to pages 4-6.

DEFROST

Cases are equipped with Temperature Terminated Off-Time

defrost.

The defrost cycle is very important in that it ensures correct

operation of the case. It is activated and controlled by the

thermostat which temporarily stops the condensing unit, al-

lowing the evaporator to shed the build-up of ice. The control-

lers synchronize the defrost between condensing units via the

auxiliary ports.

W A R N I N G

Always keep product within the designated air

curtain. Failure to do so may result in case

malfunction and product losing proper tempera-

ture, resulting in sub-standard operation and

increased chances of food contamination.

▲

Note: The tier configuration will vary. The diagrams above depict the airflow for a 2-tier and/or 4-tier airflow pattern.

C A U T I O N

Proceed to the loading only once the display

case has reached the proper temperature set-

ting.

•

D A N G E R

FLAMMABLE

DANGER - Risk of Fire or Explosion. Flammable

Refrigerant Used. Do Not Use Mechanical De-

vices To Defrost Refrigerator. Do Not Puncture

Refrigerant Tubing.

•

AIFLOW & DEFROST

UPPER DECK MID DECK

MID DECK LOWER DECK

14

CASE CLEANING

A periodic cleaning schedule should be established to maintain

proper sanitation, insure maximum operating efficiency, and

avoid the corrosive action of food fluids on metal parts that are

left on for long periods of time. We recommend cleaning once

a week. Further suggestions for case cleaning include the fol-

lowing:

• To avoid shock hazard, be sure all electrical power is turned

off before cleaning. In some installations, more than one

disconnect switch may have to be turned off to completely

de-energize the case.

• All surfaces pitch downward to a deep-drawn drain trough,

funneling liquids to the center of the case where the waste

outlet is located for easy access. Check the waste outlet to

insure it is not clogged before starting the cleaning process

and avoid introducing water faster than the case drain can

carry it away.

• To clean the LED luminaires, shut off the lights in the case,

then wipe the luminaires down with a soft, damp cloth.

Avoid using harsh or abrasive cleaners as they may dam-

age the lights. Be certain that the luminaires are complete-

ly dry before re-energizing.

• Clean from top to bottom when cleaning the display case to

avoid cross contamination.

• If any potentially harmful cleaners are used, be certain

to provide a temporary separator (e.g., cardboard, plastic

wrap, etc.) between those cases that are being cleaned

and those that may still contain product.

• Avoid spraying any cleaning liquids directly on the electrical

connections.

• Allow cases to be turned off long enough to clean any frost

or ice from coil and pans.

• Remove toekick and clean underneath the case with a

broom and a long-handled mop. Use warm water and a dis-

infecting cleaning solution when cleaning underneath the

cases.

D A N G E R

▲

SHOCK HAZARD

Always disconnect power to case when servicing

or cleaning. Failure to do so may result in serious

injury or death.

Fans and Pressure Plate

1. Disconnect power to the case and wait for fans to come to

a complete stand-still.

C A U T I O N

Only lift the pressure plate and/or coil cover for

a qualified inspector or a trained service provid-

er. Failure to do so may result in damage to the

refrigerant system.

•

2. To reach the fans and pressure plate first remove the

base deck with help of the pre-drilled access lift supplied

(Fig. 9 & 10). Note: It is recommended that more than

one person lift the deck.

Fig. 9 Base deck pre-drilled access lift

Fig. 10 Base deck pre-drilled access lift

ACCESS LIFT

ACCESS LIFT

3. To access the underside of the fans first remove the

screws on the top ends and front sill of the pressure

plate cover (Fig. 11). Lift the pressure plate by use of the

provided lift handles (Fig. 11). There are hinges shared

between the pressure plate and coil covers. Note: It is

recommended that more than one person lift the pres-

sure plate. The topside of pressure plate will rest against

the topside of the coil cover, exposing the underside of the

pressure plate and fans.

4. Clean as necessary. Use a spray bottle filled with an ap-

proved mild detergent and warm water.

5. Be sure to move the pressure plate back to its original

position after cleaning and/or inspection is complete.

C A U T I O N

Use specific products for disinfection and clean-

ing: use soft, non-abrasive sponges and rags!

•

CASE CLEANING

15

C A U T I O N

Always be sure to move the pressure plate

and screw the coil cover back to their original

position after the cleaning and/or inspection is

complete. Failure to do so may result in damage

to the refrigerant system.

▲

Coil Inspection

1. Disconnect power to the case and wait for fans to come to

a complete stand-still.

2. Remove the top two screws at both ends of the coil cover

(Fig. 11), as well as the screws from the top ends and

front sill of the pressure plate cover (Fig. 11). Be sure to

save the removed screws for reassembly.

3. Carefully, without bending the sheet metal cover, with the

use of the handles provided, gently slide the coil cover

with the pressure plate assembly forward to expose the

evaporator coil.

W A R N I N G

•

Exercise extreme caution when working in a case

with the coil cover removed. The coil contains

many sharp edges that can result in severe cuts

to the hands and arms.

W A R N I N G

•

Exercise extreme caution when working in a case

with the pressure plate removed. The coil con-

tains many sharp edges that can result in severe

cuts to the hands and arms.

Condenser Air Intake Filter

Clean and remove the debris from the condenser air intake fil-

ter monthly. If filter is not cleaned regularly the head pressure

will rise and cut all power off to the compressor by means of the

pressure switch.

The filter will either have a slide-out screen or pull-off magnetic

application. Note: Prior to cleaning, be sure to remove the

filter from the case completely and move to a distance far

enough away that no debris will come in to contact with the

case or the product inside. Both can be cleaned with an air

hose and/or rinsed with water. Be sure to remove all debris

and wait until completely dry before placing back on to the

case. (Top mounted compressors will not have an air intake

filter.)

Cleaning Condensate Dissipator Pan

Inspect the dissipator pan (Fig. 12) at least once every six

months. Ensure you disconnect the electrical power supply

and make sure you DO NOT touch the elements as they reach

C A U T I O N

Be sure to clean the condenser air intake filter

monthly. Failure to do so may result in loss of

normal compressor functions and case damage.

•

CASE CLEANING

Fig. 11 Pressure plate, coil cover, screws and lift handle

PRESSURE PLATE

COIL COVER

LIFT HANDLE

4. Clean as necessary. Use a spray bottle filled with an

approved mild detergent and warm water.!This location

should be accessed by qualified personnel only.

5. Be sure to screw the coil cover back to its original position

after cleaning and/or inspection is complete.

D A N G E R

When carrying out cleaning work or maintenance on

the condensing unit it is essential to disconnect the

machine and all its accessories from the main power.

•

D A N G E R

DANGER OF BURNS

Be careful of the elements inside the condensate

dissipator pan: this operates at high temperature.

•

D A N G E R

FLAMMABLE

DANGER - Risk of Fire or Explosion. Flammable

Refrigerant Used. Do Not Use Mechanical De-

vices To Defrost Refrigerator. Do Not Puncture

Refrigerant Tubing.

•

16

PARTS SUBJECT TO WEAR & SPARE PARTS

Most spare parts carry clear, complete ID information. It is

important that the refrigerated case parts be replaced by

analogous parts of equivalent safety and quality: to order

spare parts please contact Hillphoenix, stating the case model

and serial number, found in this manual or on the case ID

plate, and provide a description of the component and the

desired quantity. Refer to the Parts section in the back of the

manual for parts ordering and to identify parts that may need

to be replaced.

Maintenance Weekly Monthly Half Yearly Yearly

Cleaning case o

Cleaning gas condenser o

Case visual check o

Safety labels visual check o

Check electric system o

Check water drainage system. o

Check refrigeration system o

General inspection o

Fig. 13 Recommended cleaning schedule

CASE CLEANING

Fig. 12 Cleaning the dissipator pan and condensing unit

CONDENSER

DISSIPATER PAN

Cleaning Condenser

The condensers used on the condensing units gather dust and

dirt and must be cleaned regularly. Under normal working con-

ditions this task must be executed at least once a month using

a soft-bristled brush and a vacuum cleaner. A dirty condenser

will reduce the display case performance: it will also result in

increased energy consumption. (Fig. 13)

UNSCHEDULED CASE MAINTENANCE

Unscheduled maintenance concerns all those tasks that can-

SCHEDULED MAINTENANCE TABLE

C A U T I O N

Do not pressure wash equipment as damage to

electrical components may result.

▲

not normally be carried out by the routine user as specified.

Such tasks require qualified personnel with specific technical

skills (e.g. refrigeration system specialists, electricians etc.)

and must be carried out at least once a year. See the sched-

uled maintenance table for a list of the main tasks. (Fig. 13).

If inspection reveals any rust, cracks and etc...it will be neces-

sary to carry out repairs and/or replacement of parts so that

the case meets code and the display case is in prime operat-

ing condition. To enhance safety, it is recommended that you

always seek the advice of a specialized technician before

carrying out any repair work.

high temperatures (necessary for evaporation inside the pan).

17

Table of contents

Other Hillphoenix Merchandiser manuals

Popular Merchandiser manuals by other brands

Hussmann

Hussmann D5X-E Field Installation

Arneg

Arneg BERGEN 2 BT/TN GI R290 Direction for Installation and Use

Hussmann

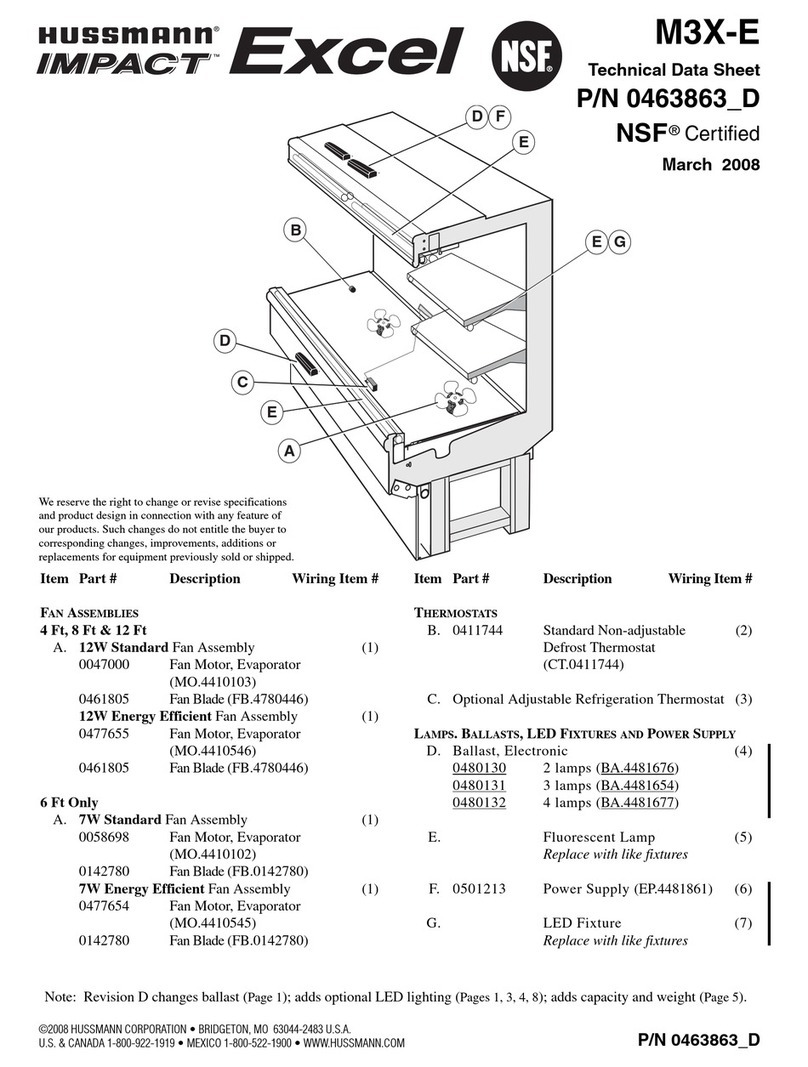

Hussmann Impact Excel P2X-E Technical data sheet

Hussmann

Hussmann EcoVision EZ Door Upgrade Installation & operation manual

Hoshizaki

Hoshizaki KD-90A parts list

Hussmann

Hussmann Impact Excel M3X-E Technical data sheet