Hillphoenix OHMA-NRG User manual

SELF-CONTAINED MERCHANDISER

INSTALLATION & OPERATIONS MANUAL

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix display cases be installed/

serviced by qualified technicians who have experience working with commercial refrigerated display merchandisers and storage cabinets.

For a list of Hillphoenix-authorized installation/service contractors, please visit our Web site at www.Hillphoenix.com.

O HMA - N RG

OHMAK-NRG

General Information ....................................... 2

Case Installation ............................................. 3

Case Connections .......................................... 4

Pre-Power Checklist ........................................ 5

Airow, Defrost & Temp Control ................... 6

Case Maintenance .......................................... 7

Appendix ......................................................... 8

Table of Contents

COMPONENT

C

L

A

S

S

I

F

I

E

D

EPH

COMPONENT

•P111801H

Copyright © 2018 by Hillphoenix

All rights reserved. No part of this document may reproduced or transmitted in any form or by any means - i.e., electronic

or mechanical, including photocopying, recording or any other information storage and retrieval system - without express

written permission from Hillphoenix.

REVISION HISTORY

ii

VERSION 2 (09/18)

•Updated data

VERSION 1 (05/18)

• new manual format

VERSION 1 (05/18)

• new manual format

•P111801H

VERSION 3 (11/18)

•Updated to add OHMAK-NRG

IMPORTANT NOTICES

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting sys-

tems or any of its display cases with shelf lighting systems

for direct or indirect exposure to water or other liquids. The

use of a misting system or water hose on a display case

with a shelf lighting system, resulting in the direct or indirect

exposure of the lighting system to water, can lead to a num-

ber of serious issues (including, without limitation, electri-

cal failures, re, electric shock, and mold) in turn resulting

in personal injury, death, sickness, and/or serious property

damage (including, without limitation, to the display itself,

to the location where the display is situated [e.g., store]

DANGER!

Indicates an immediate threat of death or

serious injury if all instructions are not fol-

lowed carefully.

CAUTION!

Indicates the potential threat of death or

serious injury if all instructions are not fol-

lowed carefully.

ATTENTION!

Indicates an important point of information

that is key to ensuring that case equip-

ment functions properly.

SERVICE NOTICE

To ensure proper functionality and optimum performance,

it is strongly recommended that Hillphoenix display cases

be installed/serviced by qualied technicians who have ex-

perience working with commercial refrigerated display mer-

chandisers and storage cabinets. For a list of Hillphoenix-

authorized installation/service contractors, please visit our

Web site at www.hillphoenix.com.

PRECAUTIONARY NOTICES

At Hillphoenix®, the safety of our customers and employ-

ees, as well as the ongoing performance of our products,

are top priorities. To that end, we call out important mes-

sages in all Hillphoenix installation and operations hand-

books with an accompanying alert symbol paired with the

words "DANGER!", "WARNING!", or "ATTENTION!". All

of these important messages will inform you of potential

haz-ards and dangers to personal safety and health - as

well as risks of case damage - if the instructions are not

carefully followed.

and to any surrounding property). DO NOT use misting

systems, water hoses or other devices that spray liquids

in Hillphoenix display cases with lighted shelves.

If a misting system or water hose is installed or used on a

display case with a shelf lighting system, then Hillphoenix

shall not be subject to any obligations or liabilities

(whether arising out of breach of contract, warranty, tort

[including negligence], strict liability or other theories of

law) directly or indirectly resulting from, arising out of or

related to such installation or use, including, without

limitation, any per-sonal injury, death or property

damage resulting from an electrical failure, fire, electric

shock, or mold.

P079211M, REVO

WARNING: UNDER NO CIRCUMSTANCES should

any component be replaced or added without

consulting Hillphoenix Field Service Engineering.

Utilizing im-proper components may result in serious

injury to per-sons or damage to the system.

iii

•P111801H

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical

information and will assist you with the installation and operation of your new Hillphoenix display cases. By closely fol-

lowing the instructions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel

free to contact our Marketing Services group at the toll-free number listed below. Thank you for choosing Hillphoenix, and

we wish you the very best in outstanding food merchandising.

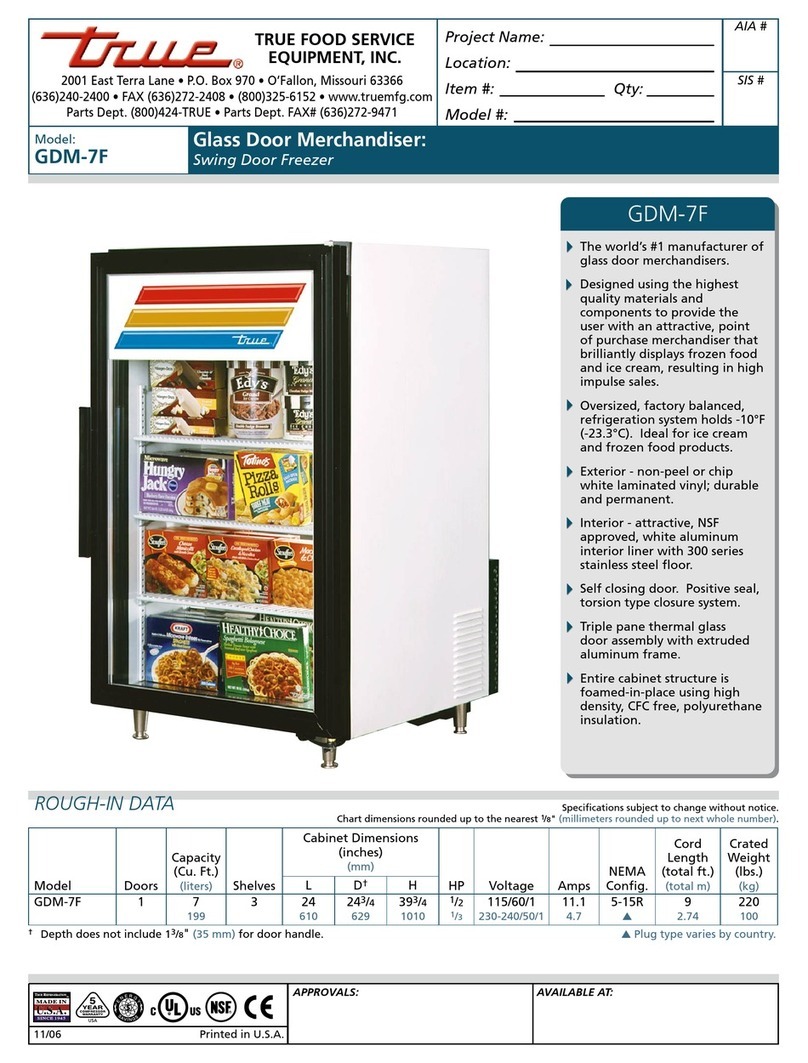

CASE DESCRIPTION

This manual covers OHMA self-contained merchandiser

(for operational data and case dimensions, see Appendix

A).

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-

conditioned store that maintains a 75°F (24°C) store tem-

perature and 55% (max) relative humidity (CRMA

condi-tions). Case operation will be adversely affected by

expo-sure to excessively high ambient temperatures

and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate

ventilation for efficient performance.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping

damage and/or shortages, please contact the Service

Parts Department at 1-800-283-1109.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the car-

rier's agent; otherwise, the carrier may refuse the claim. If

damage becomes apparent after the equipment is

unpacked, retain all packing materials and submit a

written request to the carrier for inspection within 14

days of receipt of the equipment.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the

high-est level of quality. Any claim for lost/missing items

must be made to Hillphoenix within 48 hours of receipt of

the equipment.

SERVICE & TECHNICAL SUPPORT

For service or technical questions regarding display cases,

please contact our Case Division Customer Service

Department at the toll-free number listed below. For ques-

tions regarding our refrigeration systems or electrical distri-

bution centers, please contact our Systems Division

Customer Service Department at 1-770-388-0706.

PARTS ORDERING

If you need to contact Hillphoenix regarding specific

fixtures/parts, call 1-800-283-1109 and ask for a Service

Parts Representative. Provide the following information

about the part you are ordering:

•Model number and serial number* of the case for which

the part is intended.

•Length of the part (if applicable).

•Color of part (if painted) or color of polymer part.

•Whether part is for left- or right-hand application.

•Quantity

*Serial plate is located inside the case on the top-left side.

If the parts are to be returned for credit, ask the Parts

Department to furnish you with a Return Material

Authorization Number.

Hillphoenix

1925 Ruffin Mill Rd.

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m to 5 p.m EST

Tel: 1-800-283-1109

Fax: 804-526-7450

Web site:

www.Hillphoenix.com

GENERAL INFORMATION

ATTENTION!

Installation of 3rd-party materials may

result in diminished case performance.

2

•P111801H

CASE INSTALLATION

MOVING CASES

Hillphoenix display cases are generally shipped to

stores with casters installed on the base frame. The

casters make the job of moving cases easier for

everyone involved in the shipping and installation

process, as well as reducing the chance of damage

from raising and lowering cases with ”J” bars to

place them on dollies, skates or rollers. In most

situations, one or two persons can easily move the

case into position.

When the cases arrive at the store, simply roll them on to

the store floor to the proper staging area. Occasionally,

cases are shipped with skid boards attached to help with

stabilization. In these instances, the casters should be at-

tached after the case is removed from the truck.

Removing the casters is an easy process. Simply flatten

and remove the cotter pins that are holding the casters in

place (see Fig. 1). Then lift the case with a “J” bar and

slide the caster assemblies out. The dismantled casters

can now be discarded.

FLOOR PREP

1. Ask the general contractor if there have been changes

in the building dimensions since the print you are using

was issued. Also, ask for the points of reference from

which you should take dimensions to locate the cases.

2. Using chalk lines or a laser transit, mark the oor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

base frame.

3. Leveling is necessary to ensure proper case alignment

and to avoid potential damage. Locate the highest

point on the positioning line as a reference for deter-

mining the proper height of the shim-pack levelers. A

laser transit is recommended for precision and requires

just one person.

4. Locate the position of the base frame and spot properly

leveled shim packs at the appropriate locations.

LINE-UP & INSTALLATION

1. Remove anything from the cases that may interfere

with case joining (eg. shipping braces).

2. Roll the rst case into position. Using a “J” bar , raise

the end of the case (under cross support), remove the

casters, and place the base frame on the shim packs.

Repeat on the other end of the case.

3. Once the base frame is properly placed on the shim

packs, check the vertical level by placing a bubble level

plumb to the rear edge of the case; then add/remove

shim levels as needed. To check the horizontal level,

repeat this process after placing the bubble level on

the rear sill.

4. If seismic brackets were ordered, see Appendix F for

detailed installation instructions.

TRIM OUT

Attach the front panel to the baseframe using the screws

provided.

Fig. 1 Removing the casters is an easy process. Simply

flatten and remove the cotter pins that are holding the

casters in place. Then lift the case with a “J” bar and

slide the caster assemblies out. The dismantled casters

can now be discarded.

CASTER

COTTER

PIN

CAUTION!

Be certain that your hands and feet are

out of the way before lowering the case

after the removal of the casters. Failure

to do so may result in serious injury.

3

•P111801H

CASE CONNECTIONS

REFRIGERATION

Refrigeration components for OHMA are easily accessible

in the tank and beneath the case.

The expansion valve and suction line 1/4” access valve

are both located on the front-left side of the tank. These

components may be reached removing the front panel and

pulling out the sliding component tray that houses all of

the internal case components. For a detailed illustration of

internal case components, see Appendix H.

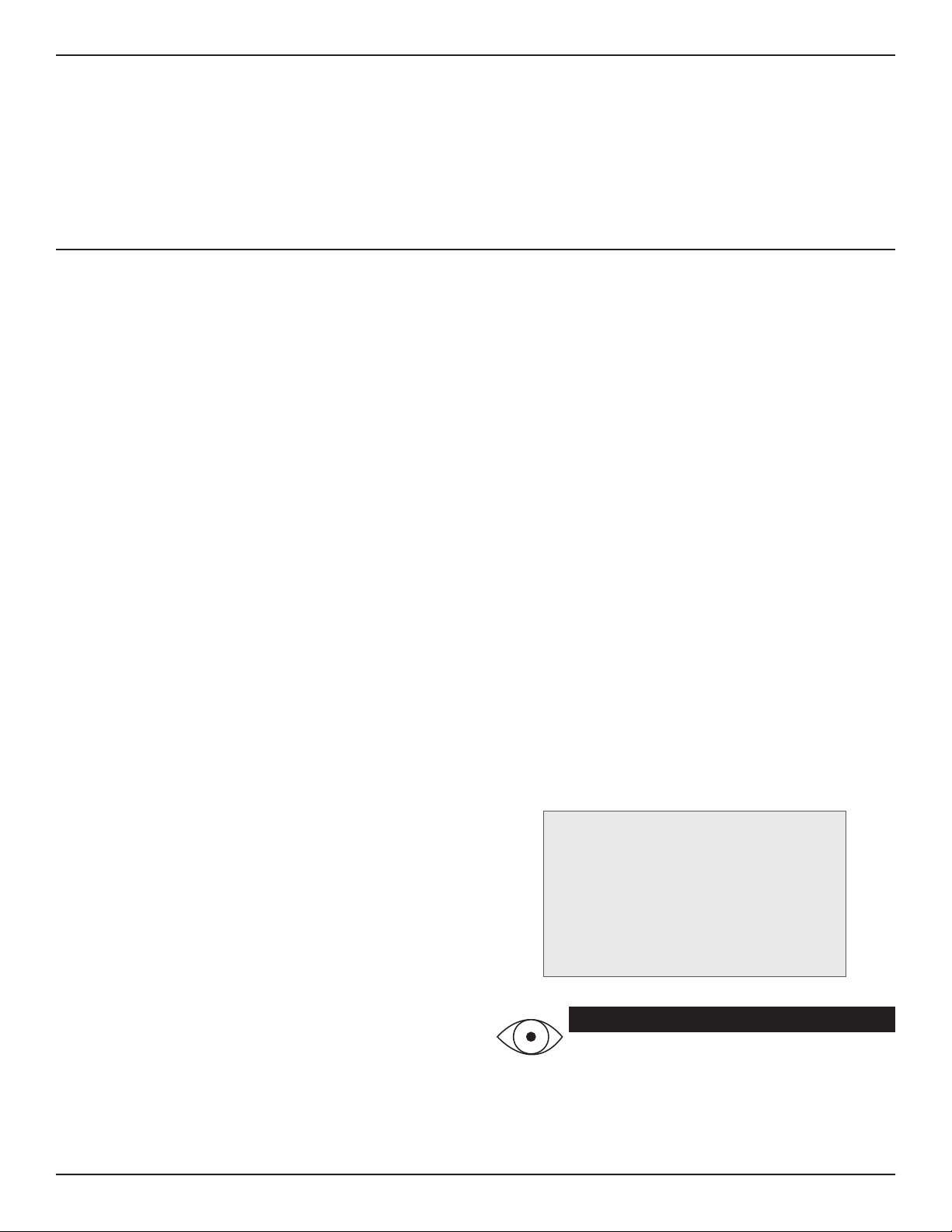

PLUMBING

The “P” trap assembly – attached to the case at the fac-

tory so no assembly is required – directs the case drainage

to the evaporative drain pan (Fig. 2). The case drain is

located front-and-center in the case for convenient access

– simply remove the front panel and slide out the compo-

nent tray. Should any future maintenance issues arise,

it is important to note the outlet is specially molded with

PVC material and the “P” trap is constructed of PVC. Care

should be given to make certain that all connections are

water tight and are sealed with appropriate PVC primer and

PVC cement.

Be certain that the case is properly leveled to ensure prop-

er drainage.

ELECTRICAL

OHMA cases come pre-wired with a NEMA L14-30P

twist-lock plug (250 volt, 4-prong).

NEMA L14-30P

PLUG

(TWIST LOCK)

A Dixell XR04CX digital controller is provided

for case operation and programming. The

controllers are lo-cated inside the electrical junction box

and are utilized ac-cording to your temperature

preference. For detailed in-structions for the Dixell

controller, see Appendix E.

"P" TRAP

Fig. 2 Drain "P" trap

ATTENTION!

Be certain to clear the case of any loose

packaging or case materials before ener-

gizing the case. Failure to do so may re-

sult in case damage or malfunction.

ATTENTION!

Be certain that all piping and electrical

connections comply with local codes.

4

•P111801H

PRE-POWER CHECKLIST

Before powering-up the case, be certain that all of the steps listed below

have been completed to ensure proper case functionality, safety and com-

pliance with warranty terms.

Have you thoroughly examined the case for shipping damage? (see

pg. 2)

Have you removed and discarded the casters? (see pg. 3)

Have you checked the vertical plumb of the case? The horizontal

level? (see pg. 3)

Have you removed any loose packaging or materials? (see pg. 4)

5

•P111801H

AIRFLOW, DEFROST & TEMP CONTROL

AIR FLOW & PRODUCT LOAD

Cases have been designed to provide maximum product

capacity within the refrigerated air envelope. Please keep

products within the load limit line shown on the diagram

below (Fig. 4).

It is important that you do not overload the food product dis-

play so that it impinges on the air ow pattern. Overloading

will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections

are covered.

DEFROST & TEMPERATURE CONTROLS

OHMA cases are equipped with timed-off defrost. When

timed-off defrost is used, the refrigeration cycle is turned off

by the case controls for a specified amount of time; there-

fore, there are generally no active defrost components uti-

lized.

The discharge air probe monitors the temperature of the

discharge air and may be used as the defrost termination

sensor. The probe can generally be found behind the rear

baffle, in the upper baffle, or in front of the honeycomb.

For more detailed information on suggested defrost times

and settings, see Appendix A. Further adjustment may be

required depending on store conditions.

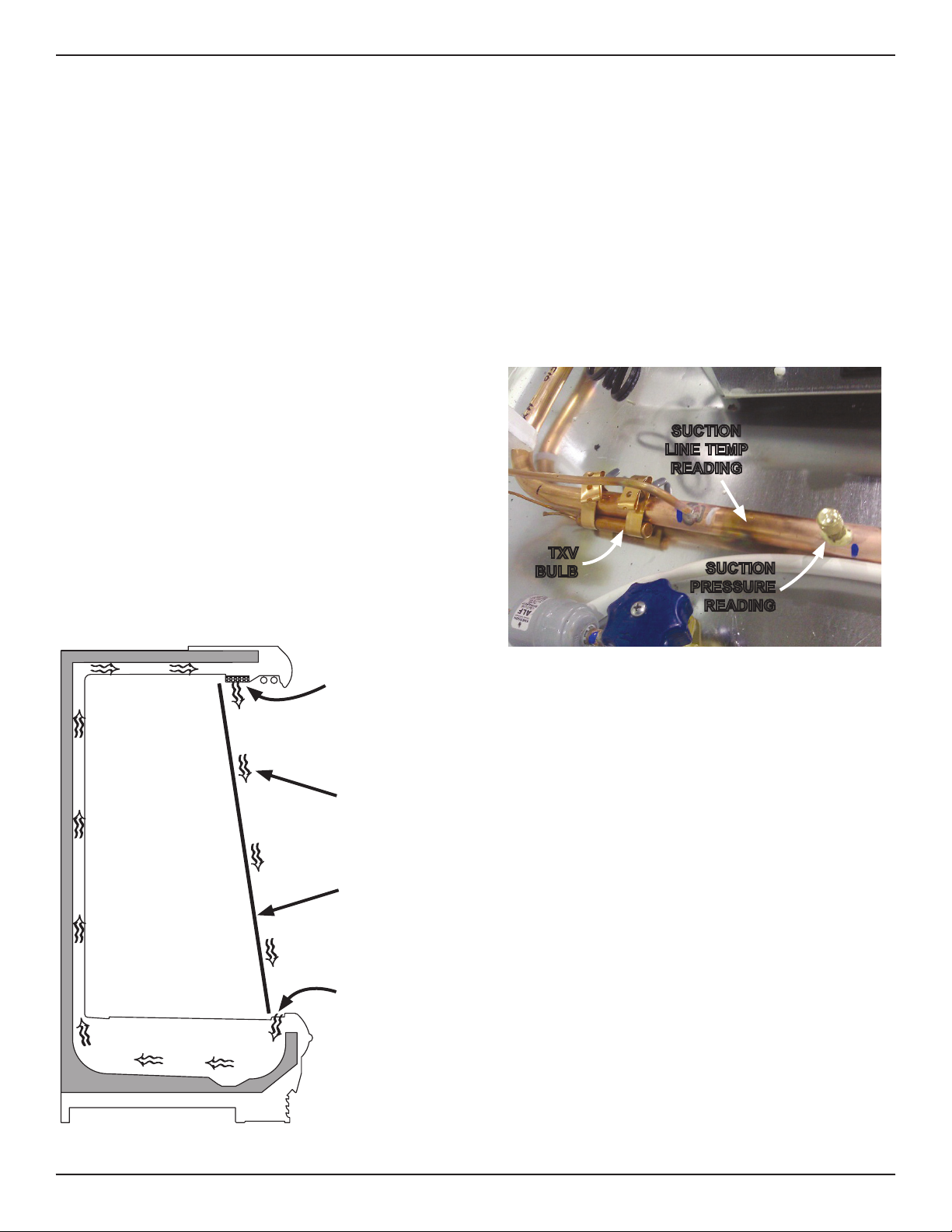

Fig. 5 Obtain pressure and temperature readings

SUCTION

LINE TEMP

READING

SUCTION

PRESSURE

READING

TXV

BULB

DETERMINING SUPERHEAT

To identify proper superheat settings, complete the follow-

ing:

1. Obtain suction pressure from access port; obtain suc-

tion line temperature from area near TXV bulb at the

outlet of evaporator coil (Fig. 5).

2. Using the suction pressure reading, convert pressure

to temperature using temperature pressure chart (see

Appendix D).

3. Subtract the converted temperature reading from the

actual temperature reading for superheat setting.

Fig. 4 Airflow

RETURN

AIR

DISCHARGE

AIR

AIR FLOW

LOAD

LIMIT

6

•P111801H

CASE MAINTENANCE

CASE CLEANING

Cases are designed to facilitate cleaning. All surfaces

pitch to a deep-drawn drain trough that angles toward the

front-center of the case where the waste outlet is located

for easy access.

The coil is covered to prevent waste fluids from entering,

but it is easily accessible for cleaning: remove the front

panel, slide out the case component tray, remove the coil-

cover fasteners, then lift and remove the coil cover. With

the coil cover removed, be certain to exercise extreme cau-

tion when working in the case - the coil has many sharp

edges that can result in serious injuries. When cleaning is

complete, be certain that both the plenum and coil cover

are properly closed in order to avoid air leaks.

CLEANING PROCEDURES

A periodic cleaning schedule should be established to

maintain proper sanitation, insure maximum operating ef-

ficiency, and avoid the corrosive action of food fluids on

metal parts that are left on for long periods of time. We

recommend cleaning once a week.

•To avoid shock hazard, be sure all electrical power is

turned off before cleaning. In some installations, more

than one disconnect switch may have to be turned off

to completely de-energize the case.

•Check waste outlet to insure it is not clogged before

starting the cleaning process and avoid introducing

water faster than the case drain can carry it away.

•Avoid spraying cleaning solutions directly on electrical

connections.

•Allow cases to be turned off long enough to clean any

frost or ice from coil and pans.

•Use mild detergent and warm water. When necessary,

water and baking soda solution will help remove case

odors. Avoid abrasive scouring powders or pads.

•Clean underneath the case with a broom and a long

handled mop.

•Use warm water and a disinfecting cleaning solution

when cleaning underneath the cases.

DANGER!

Always disconnect power to case when

servicing or cleaning. Failure to do so

may result in serious injury or death.

CAUTION!

Exercise extreme caution when working

in a case with the coil cover removed.

The coil contains many sharp edges that

can result in severe cuts to the hands and

arms.

ATTENTION!

Power cord must be pushed back through

the plenum opening before removing the

fan basket. Failure to do so may result in

damage to the power cord.

7

•P111801H

a1 - a2 ................................................................................................................. ohma operational Data & Case Dimensions

B1 - B2 ................................................................................................................................................................... eleCtriCal Wiring

C1 ........................................................................................................................................................................................... set points

D1 ................................................................................................................................ sporlan pressure-temperature Chart

e1 .............................................................................................................................................................. DiXell Case Controller

f1 - f5 ............................................................................................................................................. seismiC BraCKet installation

g1 ................................................................................................................................................................... peg hooK information

h1 ........................................................................................................................................... internal Case Component laYout

APPENDIX

8

•P111801H

Rev #Rev Date: Revision Description:

ALL MEASUREMENTS ARE TAKEN PER

ASHRAE-72-2005 SPECIFICATIONS. Hillphoenix

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT OF

ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMA-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMA-NRG

110-27-17 DOE 2017

REFERENCE NOTES FOR ENGINEERING DATA

REFERENCE NOTES FOR CROSS SECTIONS

* : STUB-UP AREA

** : RECOMMENDED STUP-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

• Front sill height and overall case height varies with base frame height

•Ends add approximately 1" to case height, 1/2" to the back & 1" to the front

• Wiring to the top adds approximately 4" to case height

•A 2" minimum air gap is required between the rear of the case and a wall

•Back panels add approximately 1" to the rear of the case

• Available shelf sizes: 18", 20" & 22"

• Dashed line signify area inside base rail behind kick plate

• Casters add approximately 2 1/4" to case height

• Listed discharge air velocity represents the average velocity at the peak of defrost.

• Temperature and defrost settings listed below are recommended start-up settings. Final operational settings

may need to be adjusted for the store conditions in which the case operates.

•LED lights only.

• Maximum of 3 rows of Standard Output LED lighted shelves.

• 3rd row or nose lights are not available.

• 2 rows of standard or 1 row of cornice high output LED lights only.

• 6" thermopane front required.

•P111801H

Rev #Rev Date: Revision Description:

ALL MEASUREMENTS ARE TAKEN PER

ASHRAE-72-2005 SPECIFICATIONS. Hillphoenix

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT OF

ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMA-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMA-NRG

110-27-17 DOE 2017

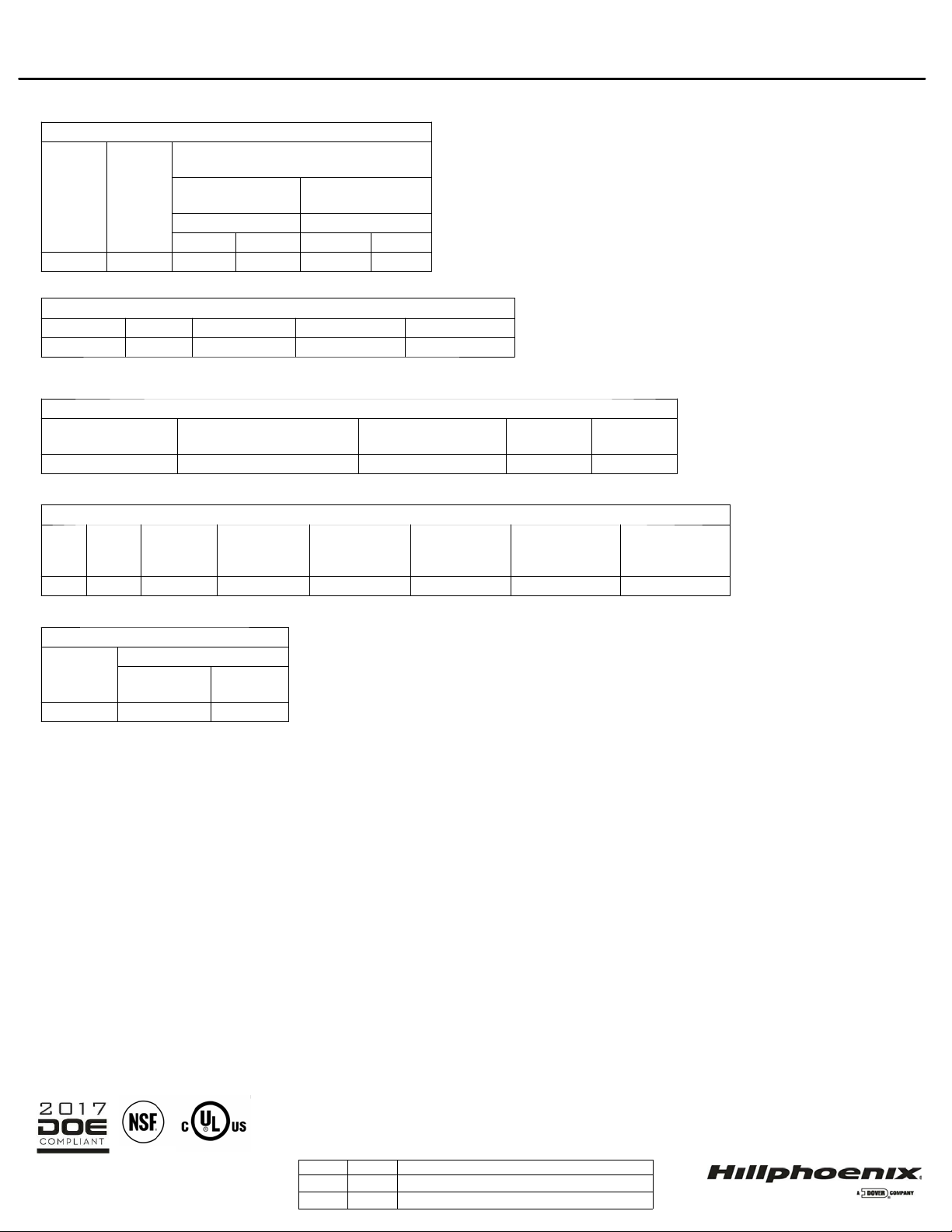

SYSTEM REQUIREMENTS

Volts Phase Frequency (Hz) Plug Style Cord Length

208 1 60 NEMA L14-30P 120"

LIGHTING DATA

Lights

Per Row

Light

Length

Clearvoyant v4 LED Lighting

(Per Lifght Row)

Standard Power

(Cornice or Shelf)

High Power

(Cornice Only)

120 Volts 120 Volts

Amps Watts Amps Watts

2 3' 0.08 9.4 0.20 23.8

GUIDELINES AND CONTROL SETTINGS

24 hour Energy

Usage

Suction Pressure @ Case

Outlet (psig).

Superheat Set Point

@ Bulb

Discharge

Air

Discharge

Air Velocity

47.6 (kWh) 52-54 6-8 °F 30.0 °F 210 FPM

CONDENSING UNIT DATA

Volts Phase

Frequency

(Hz) Horsepower

Running Load

Amps (RLA)

(Amps)

Locked Rotor

Amps (LRA)

(Amps) Refrigerant

Lbs. of

Refrigerant

208 1 60 1 1/4 9.2 54.0 R404A 5.5

DEFROST CONTROLS

Defrosts

Per Day

Timed-Off Defrost

Fail-Safe

(Min)

Termination

Temp

6 30 (Min) 42 °F

•P111801H

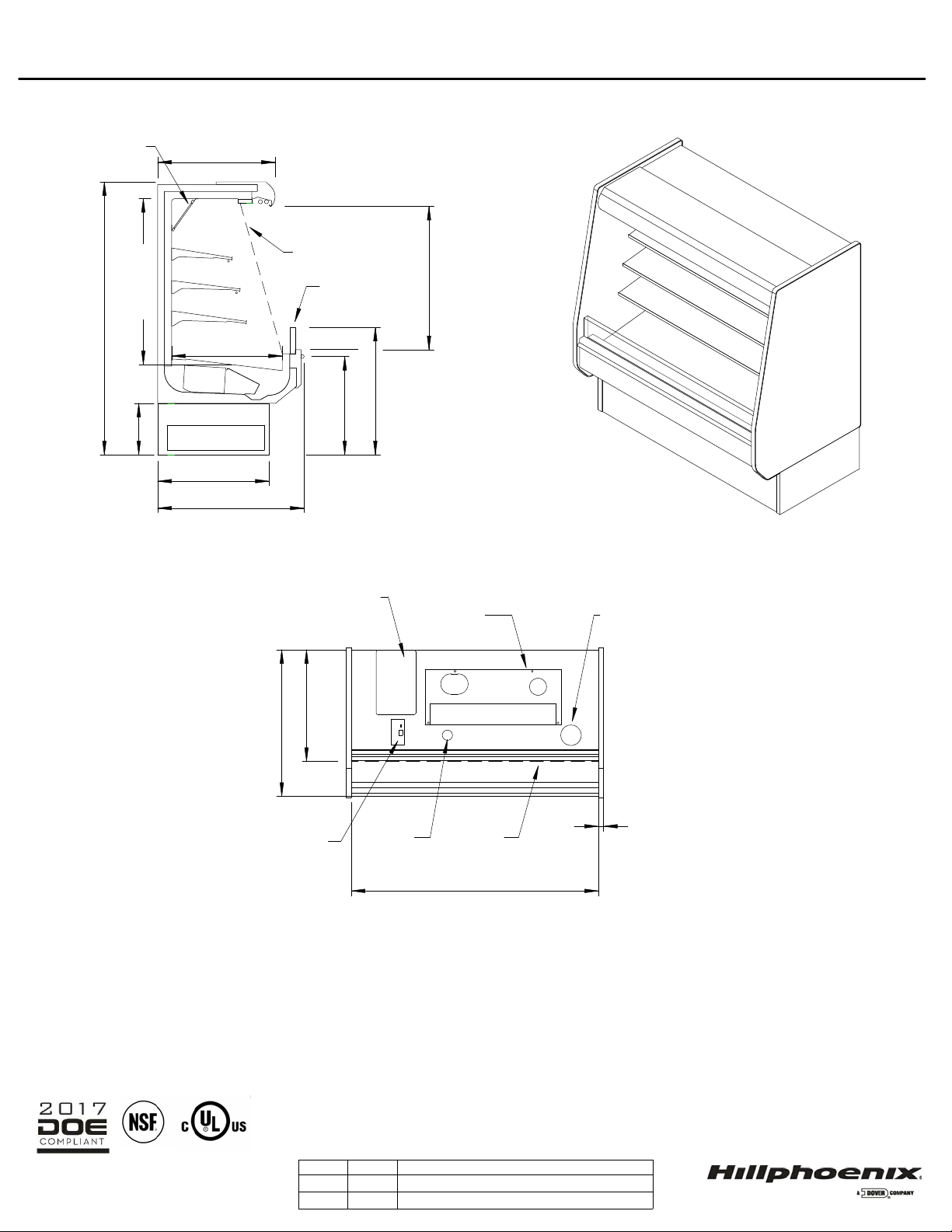

42 11/16" [108.4 cm]

28 5/8" [72.7 cm]

18 in

20 in

22 in

PLENUM

COIL

48 3/8" [122.8 cm]

79 1/2" [201.9 cm]

15" [38.1 cm]

32 1/2" [82.6 cm]

32 1/4" [81.9 cm]

LOAD LIMIT

LINE

6" THERMOPANE

GLASS WITH

FLAT FRONT

9" MIRROR

37 1/16" [94.2 cm]

34 1/4" [87.0 cm]

41 3/4" [106.0 cm]

42 11/16" [108.4 cm]

72" [182.9 cm]

ELECTRICAL

JUNCTION BOX

1 1/2" [3.8 cm] {END}

CONDENSING

UNIT

DRAIN PAN

Front of case

32 1/2" [82.5 cm]

KICKPLATE

LOCATION

DRAIN

EGRESS

REFRIGERATION

EGRESS

Rev #Rev Date: Revision Description:

ALL MEASUREMENTS ARE TAKEN PER ASHRAE-72-

2005 SPECIFICATIONS. Hillphoenix REFRIGERATED

DISPLAY CASES FOR SALE IN THE UNITED STATES

MEET OR EXCEED DEPARTMENT OF ENERGY 2017

REQUIREMENTS.

COMPONENT

OHMA-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMA 6'

110-27-17 DOE 2017

•P111801H

Rev

#

Rev Date:

Revision Description:

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

COMPONENT

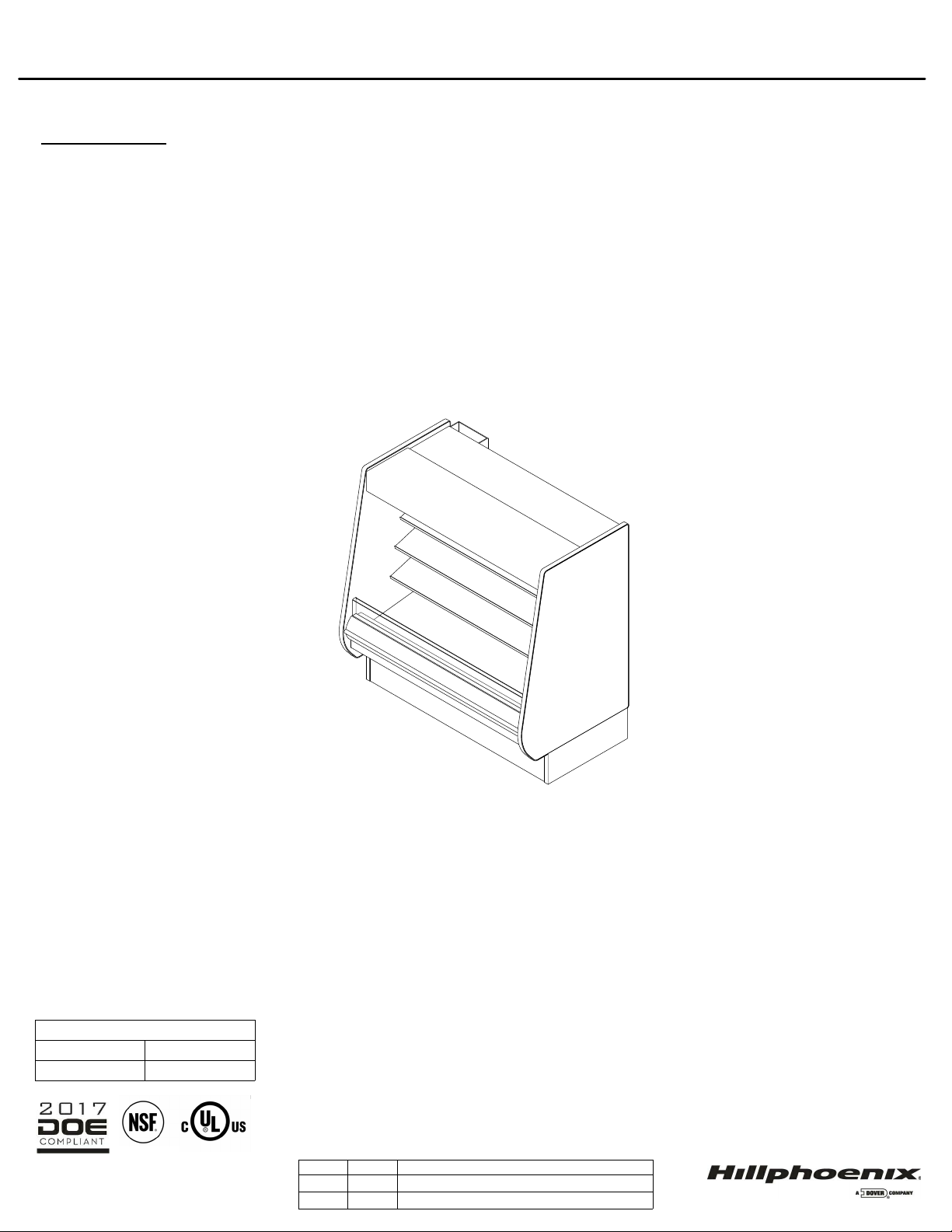

OHMAK-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMAK-NRG

28-7-18 NEW STANDARDS

39-19-18 DATA UPDATE

GENERAL NOTES

•" ---" indicates that the feature is not an option for this case model and/or the data is not yet available.

• LED lights only.

• Maximum of 3 rows of standard output LED lighted shelves.

• Nose lights are not available.

SHIPPING WEIGHT

Case Weight

OHMAK-NRG ---

Rev

#

Rev Date: Revision Description:

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMAK-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMAK-NRG

28-7-18 NEW STANDARDS

39-19-18 DATA UPDATE

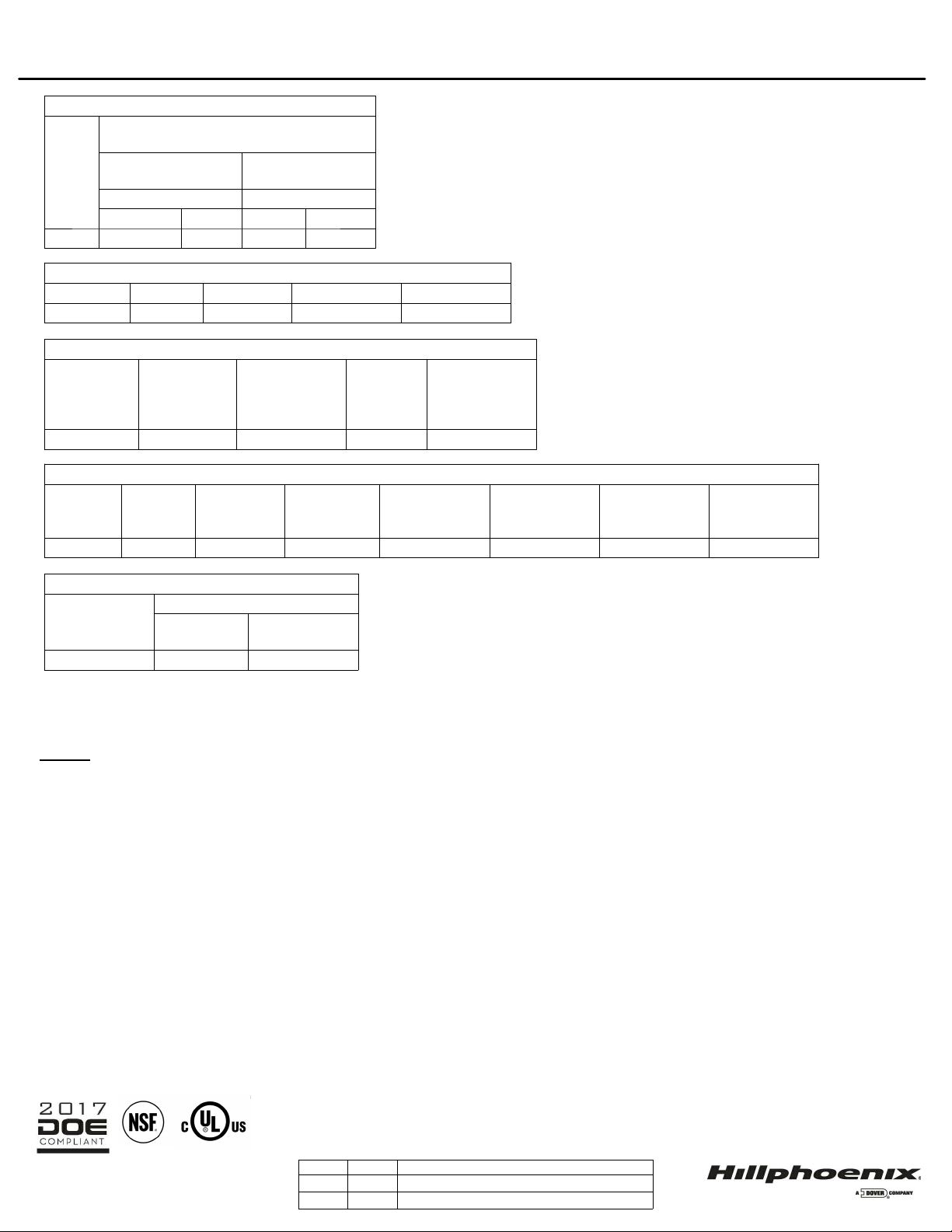

NOTES

• "---" indicates that the feature is not an option for this case model and/or the data is not yet available.

• Listed discharge air velocity represents the average velocity immediately after defrost.

• Temperature and defrost settings listed below are recommended start-up settings. Final operational settings

may need to be adjusted for the store conditions in which the case operates.

LIGHTING DATA

Lights

per row

Clearvoyant v4 LED Lighting

(Per Light Row)

Standard Power

(Cornice or Shelf)

High Power

(Cornice Only)

120 Volts 120 Volts

Amps Watts Amps Watts

2 0.08 9.4 0.20 23.8

GUIDELINES AND CONTROL SETTINGS

24hr Energy

Usage (kWh)

Suction

Pressure @

Case Outlet

(psig)

Superheat Set

Point @ Bulb

(°F)

Discharge

Air (°F)

Discharge Air

Velocity (FPM)

47.6 52-54 6 - 8 30.0 210

DEFROST CONTROLS

Defrosts Per

Day

Timed-Off Defrost

Fail-Safe

(Min)

Termination

Temp (F)

63047

SYSTEM REQUIREMENT

Volts Phase Frequency Plug Style Cord Length

208 1 60 NEMA L14-20P 120"

CONDENSING UNIT DATA

Volts Phase Frequency Horsepower

Running Load

Amps (RLA)

(Amps)

Locked Rotor

Amps (LRA)

(Amps) Refrigerant

Lbs. of

Refrigerant

208 1 60 1 1/4 9.2 54.0 R404A 5.5

Rev

#

Rev Date: Revision Description:

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMAK-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMAK-NRG

112-1-17 DOE 2017

28-7-18 NEW STANDARDS

OHMAK-NRG (Meal Kit) Case Configuration

Case Model

OHMAK-NRG (Meal Kit) Base

Model

OHMAK-NRG (Meal Kit)

Configured Options

Length 6' n/a

Case Use Meal Kits n/a

Base Frame 15" n/a

Exterior Color CC Stainless

LH End Type Solid Square

RH End Type Solid Square

End Skins Interior: SA, Exterior: CC Painted/Painted

Stainless/Stainless

End Trim Type/Color Black PVC Stainless

Front Type Flat Front Origin 2

Front Panel Type Contour Flat

ColorBand Panel Finish CC Stainless

Sill Cap Finish Stainless Painted

Cornice Type Flat Curved

Cornice Finish Painted Stainless

Tank Finish Painted Aluminum Stainless

Interior Color CC White Stainless

Baffle Finish CC White Stainless

Frame Finish CC White

Flue Panel Finish CC White Stainless

Deck Pan Type Plastic Metal

Deck Pan Finish/Color Black White Galvanized

Painted Stainless

Mirror Size 9.75"

Wire Rack Type Telescopic Fixed Front Lip Height

Wire Rack Finish Black White Stainless

Shelf Depth 18", 20", 22"

PTM Type AL PVC

LED Type Standard High

LED Color 30k 35k 40k

Cornice Lighting Type 2 Row 1 Row

Refrigerant R404a

Piping Top

Defrost Off Cycle

Fans (HE, STD) ECM

Refrigeration Accessories None Optional: Solenoid,

Thermostat

Thermometer Std

Probe None Optional: Electronic

Sensor

Special Instructions Shiploose Condensing Unit +

Drain Pump + Pan

Optional: Fully Installed

Condensing Unit +

Pump + Pan

CORNICE

OPTIONS

FRONT

OPTIONS

CURVED CORNICE

ORIGIN 2 FRONT

WITH 6" THERMOPANE

FLAT FRONT FLAT FRONT

WITH 6" THERMOPANE

37 1/8" [94.2 cm] 37 1/8" [94.4 cm]

TANK

TANK

Rev

#

Rev Date: Revision Description:

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMAK-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMAK-NRG

28-7-18 NEW STANDARDS

39-19-18 DATA UPDATE

34 1/4"

33 5/8"

42 11/16" [108.4 cm]

28 5/8" [72.7 cm]

18 in

20 in

22 in

28 3/8" [72.1 cm]

CONDENSING UNIT

PLENUM

COIL

46 7/8" [119.1 cm] INTERIOR HEIGHT

79 1/2" [201.9 cm] CASE HEIGHT

15" [38.1 cm]

32 1/2" [82.6 cm]

36 7/8" [93.7 cm]

41 7/8" [106.4 cm] VISUAL DISPLAY

32 1/4" [81.9 cm]

LOAD LIMIT

31 1/8" [79.0 cm]

6" THERMOPANE

GLASS WITH

FLAT FRONT

9" MIRROR

81 3/4" [207.6 cm] SHIPPING HEIGHT

43 1/4" [109.9 cm]

72" [182.9 cm]

32 1/2" [82.6 cm]

26 1/8" [66.4 cm]

ELECTRICAL

JUNCTION BOX

DRAIN PAN

CHIMNEY FOR

HOT AIR EXHAUST

32 3/8" [82.2 cm]**

1 1/2" [3.8 cm] {END}

CONDENSING

UNIT

1 1/2" PVC DRAIN

CONNECTION

27 7/16" [69.6 cm]

Rev

#

Rev Date: Revision Description:

A

LL MEASUREMENTS ARE TAKEN PER

A

SHRAE-72-2005 SPECIFICATIONS. HILLPHOENIX

REFRIGERATED DISPLAY CASES FOR SALE IN THE

UNITED STATES MEET OR EXCEED DEPARTMENT

OF ENERGY 2017 REQUIREMENTS.

COMPONENT

OHMAK-NRG High Multi-Deck Self-Contained Merchandiser

6' (Meat)

OHMAK-NRG

28-7-18 NEW STANDARDS

39-19-18 DATA UPDATE

ATTENTION

ELECTRICIAN

:FOR SAFETY AND CODE

COMPLIANCE GROUND

FIXTURE AT TIME OF

INSTALLATION

:CAUTION

RISK OF ELECTRIC

SHOCK. MORE THAN ONE

POWER-SUPPLY.

DISCONNECT

ALL POWER-SUPPLIES

BEFORE SERVICING.

P901598E - R5

WIRE ID

Wiring iDentifiCation

B1

•P111801H

Wiring Diagram

B2

•P111801H

This manual suits for next models

1

Table of contents

Other Hillphoenix Merchandiser manuals

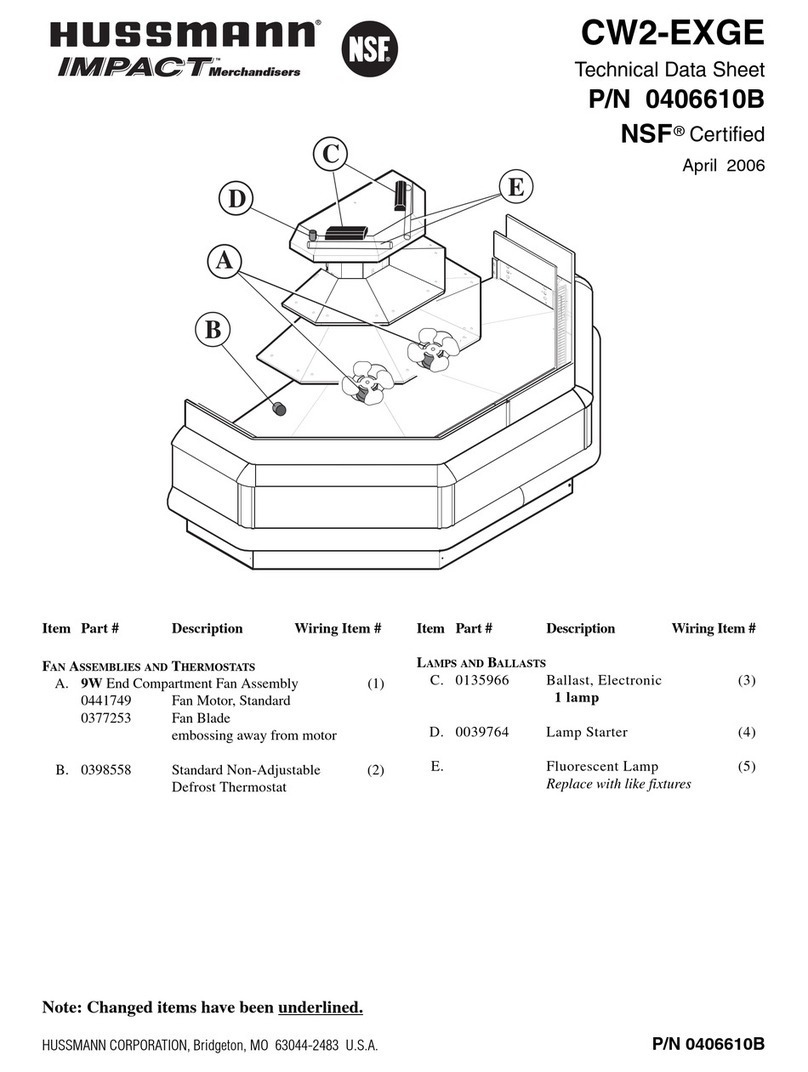

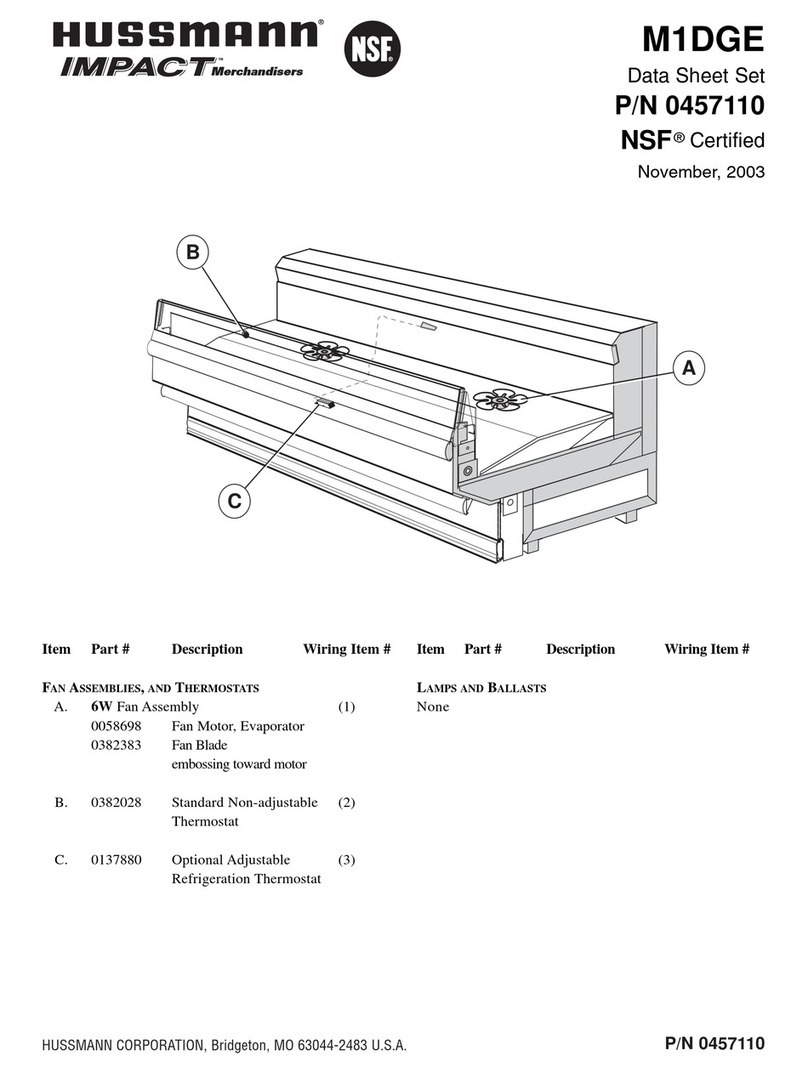

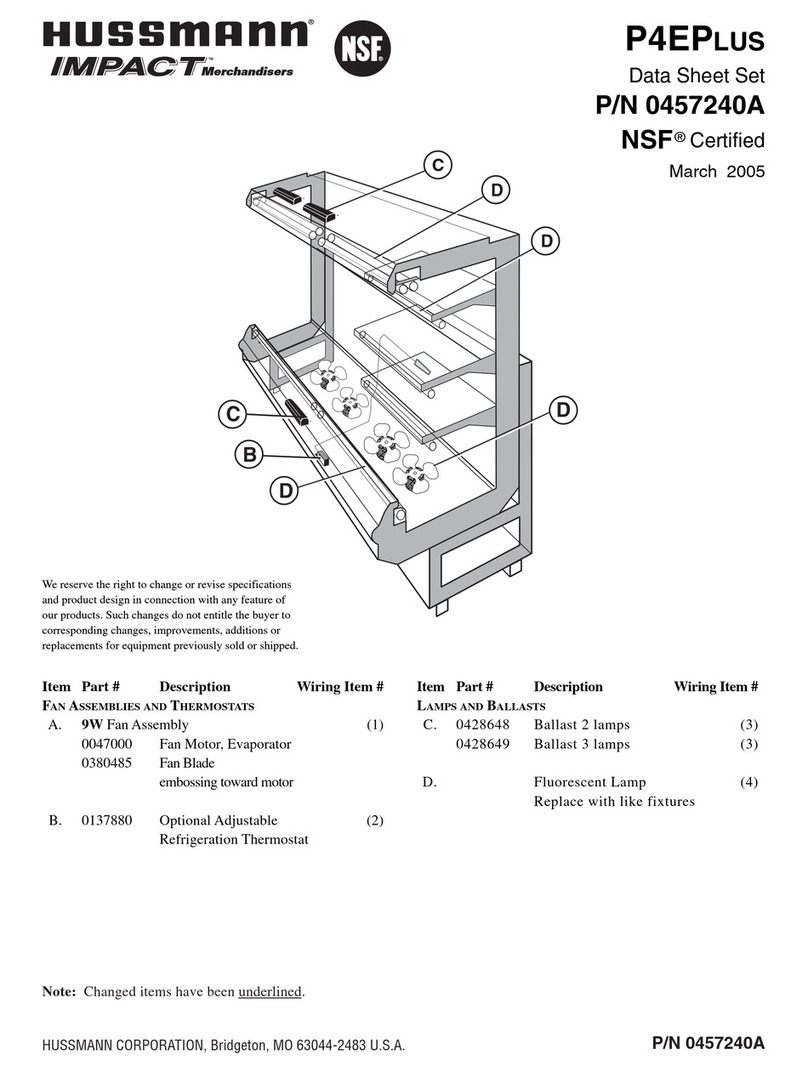

Popular Merchandiser manuals by other brands

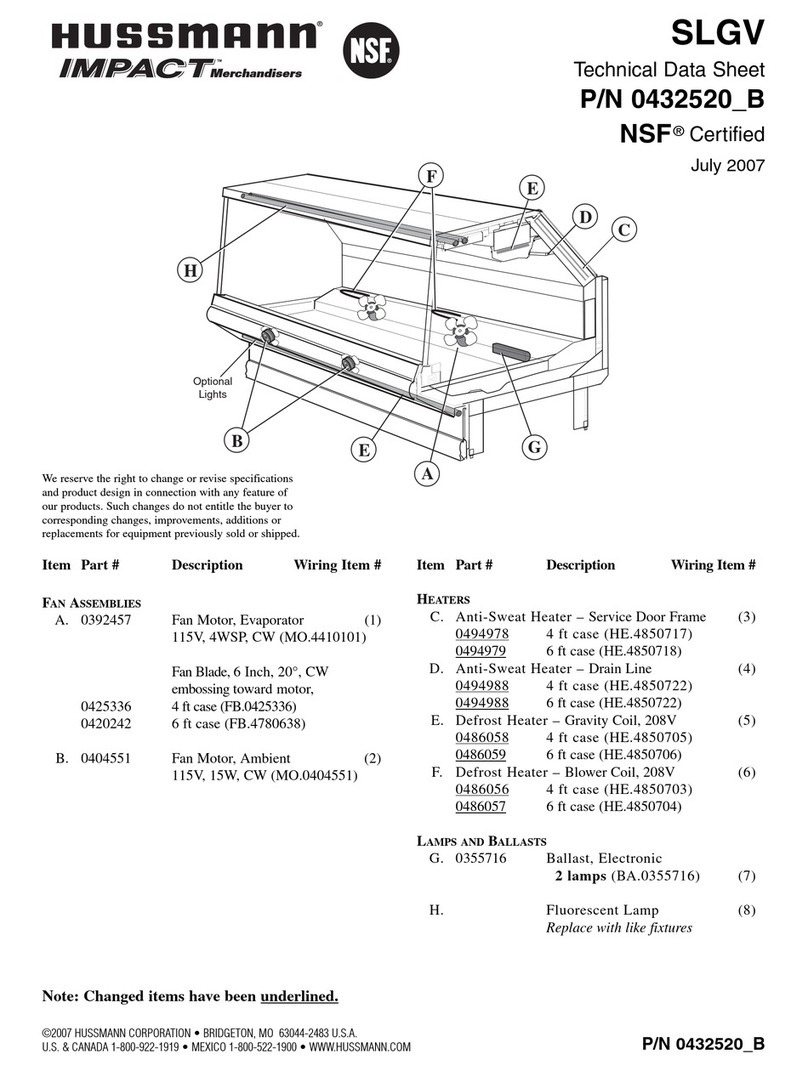

Hussmann

Hussmann SLGV Technical data sheet

Silver King

Silver King SKCTMDI Technical manual and replacement parts list

Hussmann

Hussmann IMPACT LW Technical data sheet

Hussmann

Hussmann Specialty ProductsCR3FO Technical data sheet

RCm

RCm RCM-77-N14NF instruction manual

Hussmann

Hussmann ESBD Technical data sheet