Hillphoenix VRBH User manual

VRB VRBH

VNRB VNRBH VNRBS

P092878A

V1.00

09/19

REACH-IN MERCHANDISER

INSTALLATION & OPERATIONS MANUAL

General Information ............................................... 4

Installation ..........................................................5-7

Case Connections ...............................................8-9

Pre-Power Checklist ............................................10

Airflow & Defrosts ................................................11

Fan Maintenance & Case Cleaning ....................12

Parts Ordering ......................................................13

Appendices

Table of Contents

To ensure proper functionality and optimum performance, it is STRONGLY recommended that Hillphoenix specialty cases be installed/serviced by qualified tech-

nicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized installation/

service contractors, please visit our website at www.hillphoenix.com.

ii

iii

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting systems or any of its display cases with shelf lighting

systems for direct or indirect exposure to water or other liquids. The use of a misting system or water hose

on a display case with a shelf lighting system, resulting in the direct or indirect exposure of the lighting

system to water, can lead to a number of serious issues (including, without limitation, electrical failures,

fire, electric shock, and mold) in turn resulting in personal injury, death, sickness, and/or serious proper-

ty damage (including, without limitation, to the display itself, to the location where the display is situated

[e.g., store] and to any surrounding property). DO NOT use misting systems, water hoses or other devices

that spray liquids in Hillphoenix display cases with lighted shelves.

If a misting system or water hose is installed or used on a display case with a shelf lighting system, then

Hillphoenix shall not be subject to any obligations or liabilities (whether arising out of breach of contract,

warranty, tort [including negligence], strict liability or other theories of law) directly or indirectly resulting

from, arising out of or related to such installation or use, including, without limitation, any personal injury,

death or property damage resulting from an electrical failure, fire, electric shock, or mold.

P079211M, REVO

iv

Important

DANGER

▲

Indicates an immediate threat of death or

serious injury if all instructions are not followed

carefully.

At Hillphoenix®, the safety of our customers and employees, as well as the ongo-

ing performance of our products, are top priorities. To that end, we include import-

ant warning messages in all Hillphoenix installation and operations handbooks,

accompanied by an alert symbol paired with the word "DANGER", "WARNING", or

"CAUTION".

All warning messages will inform you of the potential hazard; how to reduce the

risk of case damage, personal injury or death; and what may happen if the in-

structions are not properly followed.

WARNING

Indicates a potential threat of death or serious

injury if all instructions are not followed careful-

ly.

▲

CAUTION

Indicates that failure to properly follow instruc-

tions may result in case damage.

▲

!

!

!

v

Revision History

• new manual format_9/19

4

Thank you for choosing Hillphoenix for your food merchandising needs. This handbook contains important technical infor-

mation and will assist you with the installation and operation of your new Hillphoenix specialty cases. By closely following

the instructions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel

free to contact our Marketing Services group at the number listed below. Thank you for choosing Hillphoenix, and we wish

you the very best in outstanding food merchandising.

CASE DESCRIPTION

This manual specifically covers the VNRB, VNRBS, VNRBH,

VRB, and VRBH.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-condi-

tioned store that maintains a 75°F (24°C) store temperature

and 55% (max) relative humidity (ASHRAE conditions). Case

operation will be adversely affected by exposure to excessively

high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation for

efficient performance. Machine-room temperatures must be

maintained at a minimum of 65°F in winter and a maximum

of 95°F in summer. Minimum condensing tem-peratures

should be no less than 70°F.

SHIPPING CASES

Transportation companies assume all liability from the time a

shipment is received by them until the time it is delivered to

the consumer. Our liability ceases at the time of shipment.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping dam-

age and/or shortages, please contact the Service Parts

Department at the number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's

agent; otherwise, the carrier may refuse the claim. If damage

becomes apparent after the equipment is unpacked, retain all

packing materials and submit a written request to the carrier

for inspection within 14 days of receipt of the equipment.

Failure to follow this procedure will result in refusal by the

carrier to honor any claims with a consequent loss to the

consumer.

If a UPS shipment has been damaged, retain the damaged

material, the carton and notify us at once. We will file a claim.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the highest

level of quality. Any claim for lost/missing items must be

made to Hillphoenix within 48 hours of receipt of the equip-

ment. When making a claim please use the number listed

below.

SERVICE & TECHNICAL SUPPORT

For service or technical questions regarding display cases,

please contact our Case Division Customer Service

Department at the toll free number listed below. For questions

regarding our refrigeration systems or electrical distribution

centers, please contact our Systems Division Customer

Service Department at 1-770-388-0706.

CONTACTING THE FACTORY

If you need to contact Hillphoenix regarding a specific fixture,

be certain that you have both the case model number and

serial number (this information can be found on the data tag,

located on the top-left interior of the case). When you have

this information, call the toll-free number below and ask for a

Service Parts Representative.

GENERAL INFORMATION

Hillphoenix

1925 Ruffin Mill Rd

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m. to 5 p.m.)

Tel: 1-800-283-1109/Fax: 804-526-7450

Website: www.hillphoenix.com

5

CASE INSTALLATION

FLOOR PREP

1. Ask the general contractor if your current copy of the

building dimensions are the most recently issued. Also,

ask for the points of reference from which you should

take dimensions to locate the cases.

2. Using chalk lines or a laser transit, mark the fl oor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3. Leveling is necessary to ensure proper case alignment

and to avoid potential case damage. Locate the high-

est point on the positioning lines as a reference for

determining the proper height of the shim-pack level-

ers. A laser transit is recommended for precision and

requires just one person.

4. Locate basehorse positions along the chalk lines. Spot

properly leveled shim packs at each basehorse loca-

tion.

LINE-UP & INSTALLATION

Single Case

1. Roll the case into position, leaving a minimum of 2" be-

tween the wall and back of case. Using a “J” bar, raise

the end of the case (under cross support), remove the

caster assembly (Fig. 1) and lower the basehorse on to

the shim packs. Repeat on the other end of the case.

2. Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by placing

a bubble level on the shelf standard. Add/remove shim

packs as needed. For the horizontal level, repeat this

process after placing the bubble level on the front sill.

Multi-Case

1. Remove any shelves (discard the shelf clips) and/or

loose items (e.g. shipping braces, mirror assemblies,

etc) from the cases that may interfere with case join-

ing. Keep all loose items as they will be used later

in the installation process.

2. Remove the return air grill at the case joint. The grill

lifts out without fasteners and may be easily removed

to gain clear access to the case-to-case joining bolts.

3. Follow the single-case installation instructions for the

fi rst case, then position the next case in the line-up ap-

proximately 3’ away. Remove the casters on the end

that is closest to the fi rst case.

4. Apply the foam tape gasket (supplied) and a bead of

butyl or silicone sealant to the end of the fi rst case (Fig.

2). From the opposite end, push the second case to

a position that is approximately 6" from the fi rst case,

then remove the remaining casters and position case

on the shim packs.

CAUTION!

Be certain that your hands and feet are

out of the way before lowering the case

after the removal of the casters. Failure

to do so may result in serious injury.

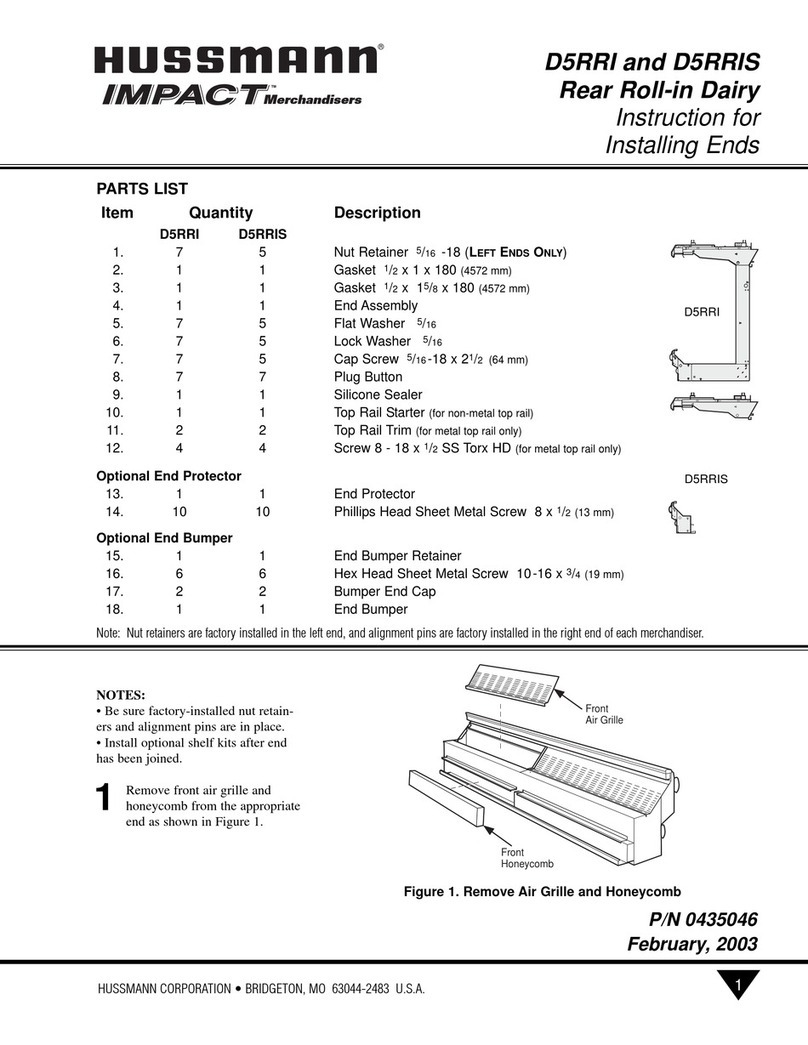

Fig. 1 Removing the casters is an easy process. Simply flatten and

remove the cotter pins that are holding the casters in place. Then

lift the case with a “J” bar and slide the caster assemblies out. The

dismantled casters can now be discarded.

COTTER

COTTER

PIN

PIN

CASTER

CASTER

= bolt holes

X = foam tape gasket

O = butyl or silicone sealant

NOTE: It is recommended that

cases be bolted together in

the numbered order indicated

in the diagram.

1

2

5

4

Fig. 2 Bolt holes, foam tape gasket and sealant

3

6

CASE INSTALLATION

Fig. 5 Front panel joint trim

Fig. 3 Sealing the pipe chase

ACRYLIC

TAPE

PIPE

CHASE

TRIM OUT

1. Seal the case-to-case joints with caulk (supplied), then

apply acrylic tape (supplied) over the pipe-chase seam

(Fig. 3). The tape acts as a watershed preventing wa-

ter from settling in the case joint.

If non-insulated plexiglass partitions are included, see

Appendix * for installation instructions.

Re-install shelves (or peg hook assemblies if appli-

cable). Be aware that differing shelf confi gurations

will

affect energy consumption and case performance. If

peg hook assemblies are to be installed, see Appen-

dix ) for more information.

Install the front panel (Fig. 4). The front panel bottom

insert is a painted panel that ships loose with the case.

The panel is inserted upward under the door frame ex-

teriors and is supported without fasteners by setting

the panel on the tabs as shown.

Make any adjustments that are necessary to properly

align the front panels, then install the front panel trim

that is supplied (Fig. 5).

6. Inside the case, use the supplied sex bolts to close the

gap between the frames (Fig. 6). On the outside, run

a thin bead of caulk along the case-to-case seam, then

carefully push the T-Bar case frame joint trim into the

space between the frames (Fig. 7).

Fig. 4 Install front panel

FRONT PANEL

(TOP INSERT)

FRONT PANEL

(BOTTOM INSERT)

FRONT

FRONT

PANEL

PANEL

TRIM

TRIM

Fig. 6 Sex bolts for closing case frame gap

SEX BOLT

Loosen the cornice joint at case end (cornice screws

are located on top of the case). Be certain that cornice

joints and pins are properly aligned. Cases are now

ready to be joined.

Push the cases tightly together, then lightly bolt them

together through the holes that are provided (Fig. 2).

Tighten all the joining bolts until all margins are equal.

Be careful not to over tighten.

Repeat steps 3–6 of this sequence for all remaining

cases. Be certain to properly level all cases.

Install the seismic brackets (if included). See Appen-

dix + for installation instructions.

7

CASE INSTALLATION

Fig. 8 Attach kickplate with supplied screws

KICKPLATE

KICKPLATE

RETAINER

SCREWS

Fig. 7 T-Bar case frame joint trim seals case frame gap

T-BAR

T-BAR

CASE FRAME

CASE FRAME

JOINT

JOINT

FRAME

FRAME

GAP

GAP

7. Install the front kickplate (Fig. 8) to the kickplate re-

tainer as shown. Install the end kickplates with screws

provided and insert the plug buttons.

8. Install the case top fascia (if included). See Appendix

D for installation instructions.

9. Install electric display modules (if included). See Ap-

pendix E for installation instructions.

10. If the case is outfi tted with a factory-installed, snap-on

bumper track, install the snap-on track bumper onto

the track, up to 96 feet. For rigid bumper, cut for as

tight a fi t as possible–to allow for minor shrinkage fol-

lowing start-up–and install. For rolled bumper, Hill-

phoenix recommends leaving an additional 6 inches of

nose bumper at the ends to allow for shrinkage during

the fi rst 24–48 hours following case start-up (Fig. 9).

11. After suffi cient time has passed, cut away the excess

bumper for fi nal fi t and fi nish. Be certain to use an ap-

propriate cutting tool (tubing- or PVC-cutter) to ensure

a smooth cut.

Fig. 9 Leave 6 inches of extra bumper

8

CASE CONNECTIONS

ATTENTION!

If brazing is necessary, place wet rags

around the area to avoid tank damage.

REFRIGERATION

There are two refrigeration piping options for this case fam-

ily: standard and rear top-box. Standard piping penetration

is located at the front-right area of the case, fully visible in

front of the fan plenum. The rear-box top option consists of

piping enclosed in a foam box that exits at the back-right of

the case, near the top.

Expansion valve and other controls—located on the left-

hand side of the case—are accessed by lifting the two left-

hand deck pans (lifting the fan plenum is not required).

Before operating the case, be certain to remove the ship-

ping blocks (Fig. 10) that protect the refrigeration lines dur-

ing shipping. If it becomes necessary to penetrate the case

tank in any area, be certain to seal any open gaps after-

wards with canned-foam sealant and white RTV.

ATTENTION!

Connections are illustrated in dimensional

drawings found LQ$SSHQGL[$.

Fig. 10 Remove the shipping blocks

REMOVE

REMOVE

95%VRBH

915%915%+915%6

For piping locations in other case models,

see pages RIFDVHGLPHQVLRQV

4 in [10.2 cm]

(9 1/4 in OFF OF FLOOR)

28 1/2 in

[72.3 cm]

120 in [304.8 cm] ( 4 DOOR )

A

B

C

D

E

L

CKICK PLATE

LOCATION

42 3/8 in

[107.5 cm]

38 5/8 in

[98.0 cm]

31 3/4 in

[80.6 cm]

BASE FRAME

1 1/2" PVC DRAIN

CONNECTION

RISER

2 DOOR CASE

ONLY

60 in [152.4 cm] ( 2 DOOR )

90 in [228.6 cm] ( 3 DOOR )

150 in [381.0 cm] ( 5 DOOR )

ELECTRICAL

JUNCTION BOX

(WIRING PER

LOCAL CODES)

28 3/8 in

[72.1 cm]

35 1/8 in

[89.3 cm]

**

NOTES:

* : STUB-UP AREA

** : RECOMMENDED STUP-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

· ENDS ADD APPROXIMATELY 1" TO CASE HEIGHT, 1/2" TO THE BACK & 1" TO THE FRONT

· A 2" MINIMUM AIR GAP IS REQUIRED BETWEEN THE REAR OF THE CASE AND A WALL

· SUCTION LINE (ALL LENGTHS) - 5/8"

· LIQUID LINE (ALL LENGTHS) - 3/8"

· AVAILABLE SHELF SIZES: 24", 27"

8 3/4 in [22.2 cm]

REFRIGERATION

9

ATTENTION!

Be certain to clear the case of any loose

packaging or case materials before ener-

gizing the case. Failure to do so may re-

sult in case damage or malfunction.

ATTENTION!

Be certain that all piping and electrical

connections comply with local codes.

PLUMBING

The drain outlet is specially molded out of PVC material

and is located in the front-center of the case for convenient

access. The “P” trap, furnished with the case, is construct-

ed of schedule 40 PVC pipe (Fig. 11). Be certain that all

connections are water-tight and sealed with the appropri-

ate PVC or ABS cement.

Fig. 11 “P” trap; drain line

The drain lines can be run left or right of the tee, with the

proper pitch to satisfy local drainage requirements. Since

the kickplate is shipped loose with the case, you should

have open access to the drain line area during installation.

If the kickplate has been installed, you will fi nd it easy to

remove. Simply lift the kickplate up from the "J" rail and

pull it out, away from the case (see Trim Out section on

pages ).

ELECTRICAL

Electrical hookups are made to a junction box located top-

rear-left of the case (Fig. 12).

For case-to-case wiring, run conduit between the junction

boxes or run wiring through the raceway. For more detailed

electrical wiring information, see Appendix %.

LIGHTING

Lighting for reach-in door cases is pre-installed during the

manufacturing process. The main door frame light switch

is located inside the case on the door frame mullion.

For cases featuring horizontal cornice lighting, a toggle

switch is located on the left hand top flue panel.

For any questions or service needs, please contact our

Case Division Customer Service Department toll-free at

1-800-283-1109.

"P"

"P"

TRAP

TRAP

DRAIN

DRAIN

LINE

LINE

Fig. 12 Junction box RQWRSRIcase

CASE CONNECTIONS

10

PRE-POWER CHECKLIST

Before powering-up the case, be certain that all of the steps listed below

have been completed to ensure proper case functionality, safety and com-

pliance with warranty terms.

Have you thoroughly examined the case for shipping damage? (see

pg.

Have you removed and discarded the casters? (see pg.

Have you checked the vertical plumb of the case? The horizontal

level? (see pg. )

Have you applied the foam tape gasket and sealant between adjoining

cases? (see pg. )

Have you sealed the case-to-case joints by applying caulk and acrylic

tape to the pipe-chase seam? (see pg. )

Have you removed the shipping blocks from the refrigeration lines?

(see pg. )

Have you sealed any tank penetrations? (see pg.

ATTENTION!

Be certain to clear the case of any loose

packaging or case materials before ener-

gizing the case. Failure to do so may re-

sult in case damage or malfunction.

11

AIRFLOW & DEFROST

SUCTION

SUCTION

LINE TEMP

LINE TEMP

READING

READING

TXV

TXV

BULB

BULB

SUCTION

SUCTION

PRESSURE

PRESSURE

READING

READING

Fig. 1 Obtain pressure and temperature readings

AIR FLOW & PRODUCT LOAD

It is important that you do not overload the food product dis-

play so that it impinges on the air fl ow pattern—overloading

will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections

are covered. Please keep products within the load limit

line shown on the diagram below (Fig.1).

DEFROST & TEMPERATURE CONTROLS

The refrigeration cycle is simply turned off by the case

controls for a specified amount of time; therefore, there are

generally no active defrost components utilized.

The discharge air probe monitors the temperature of the

discharge air and may be used as the defrost termination

sensor. The probe can generally be found behind the rear

baffle, in the upper baffle, or in front of the honeycomb.

NOTE: if the discharge air probe is used for defrost termi-

nation, none of the termination sensors listed earlier will be

installed in the case.

For more detailed information onsuggested defrost

times and settings, see $SSHQGL[ $.Further adjustment

may be required depending on store conditions.

DETERMINING SUPERHEAT

To identify the correct superheat settings, complete the fol-

lowing steps:

Obtain suction pressure from the access port. Obtain

the suction line temperature from the area near the

TXV bulb at the outlet of the evaporator coil (Fig. 1).

Using the suction pressure reading and the Sporlan®

temperature-pressure chart (Appendix &), convert

pressure-to-temperature.

Finally, subtract the converted temperature reading

from the actual temperature reading. The resulting

number is the superheat setting—once this has been

determined, adjust the TXV as needed to obtain the

proper setting.

RETURN

AIR

DISCHARGE

AIR

AIR FLOW

LOAD

LIMIT

Fig. 13 Airflow

12

FAN MAINTENANCE & CASE CLEANING

FANS

Reach-in door cases feature electronically commutated

(ECM) fan motor assemblies, whereby the fan blade, fan

motor, and basket are integrated into a single unit.

)an assemblies may be changed with an easy two-step

process without lifting up the plenum, thereby avoiding the

necessity to unload the entire product display to change

the fan assembly:

Unplug the fan motor (Fig. 1) from the receptacle on

the exterior of the fan plenum. Push the power cord

back through the plenum opening.

Remove fasteners, then lift out the entire fan basket.

(Reverse procedure when re-installing fan assembly.)

DANGER!

SHOCK HAZARD

Always disconnect power to case when

servicing or cleaning. Failure to do so

may result in serious injury or death.

ATTENTION!

Power cord must be pushed back through

the plenum opening before removing the

fan basket. Failure to do so may result in

damage to the power cord.

CLEANING PROCEDURES

A periodic cleaning schedule should be established to

maintain proper sanitation, insure maximum operating ef-

ficiency, and avoid the corrosive action of food fluids on

metal parts that are left on for long periods of time. We

recommend cleaning once a week.

•To avoid shock hazard, be sure all electrical power is

turned off before cleaning. In some installations, more

than one disconnect switch may have to be turned off

to completely de-energize the case.

•All surfaces pitch downward to a deep-drawn drain

trough, funneling liquids and other debris to the waste

outlet. Check waste outlet before starting the cleaning

process to insure it is unclogged. Avoid introducing

water faster than the case drain can carry it away.

•Lift the fan plenum to gain access to the coil for clean-

ing and maintenance (Fig. 1).

Fig. 1 Single-piece fan plenum and coil cover

SINGLE PIECE FAN

SINGLE PIECE FAN

PLENUM SWINGS

PLENUM SWINGS

UP FOR EASY

UP FOR EASY

CLEANING

CLEANING

FAN

FAN

PLENUM

PLENUM

COIL

COIL

CAUTION!

Exercise extreme caution when working in

a case with the coil cover removed. The

coil contains many sharp edges that can

cause severe cuts to the hands and arms.

2

2

Fig. 1 Fan basket

1

1

•To clean the lights, shut off the lights in the case, then

wipe them down with a soft, damp cloth. Avoid using

harsh or abrasive cleaners as they may damage the

lights. Be certain that the lights are completely dry be-

fore re-energizing.

•If any potentially harmful cleaners are used, be cer-

tain to provide a temporary separator (e.g., cardboard,

plastic wrap, etc.) between those cases that are being

cleaned and those that may still contain product.

•Avoid spraying cleaning solutions directly on electrical

connections.

•Allow cases to be turned off long enough to clean any

frost or ice from coil and pans.

•Remove kickplate and clean underneath the case with

a broom and a long-handled mop. Use warm water

and a disinfecting cleaning solution when cleaning un-

derneath the cases.

13

PARTS ORDERING

Contact the Service Parts Department at:

1-800-283-1109

Provide the following information about the part you are ordering:

• Model number and serial number* of the case for which the part is intended.

• Length of the part (if applicable).

• Color of part (if painted) or color of polymer part.

• Whether part is for left- or right-hand application.

• Quantity

*Serial plate is located inside the case on the top-left side.

If the parts are to be returned for credit, contact the Parts Department. Do not send parts without

authorization.

14

APPENDIX

A ......................................................................................... Technical Reference Sheet

B ......................................................................................... Electrical Wiring Diagrams

C ........................................................................ Sporlan Pressure-Temperature Chart

D ........................................................................................................... Case Top Fascia

E .............................................................................................. Electric Display Module

F .................................................................................................................... Peg Hooks

G ................................................................................ Non-Insulated Acrylic Partitions

H ......................................................................................................... Seismic Brackets

A1: TECHNICAL REFERENCE SHEET

$

//0($685(0(176$5(7$.(13(5

$

6+5$(63(&,),&$7,216+,//3+2(1,;

5()5,*(5$7('',63/$<&$6(6)256$/(,17+(

81,7('67$7(60((725(;&((''(3$570(17

2)(1(5*<5(48,5(0(176

&20321(17

915% 1DUURZ5HDFK,Q0HUFKDQGLVHU

'RRU%HYHUDJH'DLU\'HOL0HDW

915%

*(1(5$/127(6

IRRW%L6ZLQJFDVHVFRQVLVWRIGRRUV

IRRW%L6ZLQJFDVHVFRQVLVWRIGRRUV

IRRWFDVHVVLQJOHVZLQJFRQVLVWRIGRRUV

IRRWFDVHV%LVZLQJFRQVLVWRIGRRUV

IRRWFDVHVVLQJOHVZLQJFRQVLVWRIGRRUV

IRRWFDVHV%LVZLQJFRQVLVWRIGRRUV

'RRUIUDPHVDUHKHDWHG'RRUVDUHQRWKHDWHG

/LJKWLQJFRQWUROV RFFXSDQF\VHQVRUVDUHUHTXLUHG

2SWLRQ2(03URYLGHG/LJKWLQJFRQWUROVRQRIIDUHVWDQGDUGXQOHVVRWKHUZLVHVSHFLILHG

2SWLRQ(QG8VHU3URYLGHG/LJKWLQJFRQWUROVVKRXOGEHEDVHGRQRFFXSDQF\VHQVRUV

6+,33,1*:(,*+7

&DVH :HLJKW

915%

5HY'DWH 5HY 5HY7LWOH

'$7$83'$7(

(1'9,(:83'$7(

A2: TECHNICAL REFERENCE SHEET

$

//0($685(0(176$5(7$.(13(5

$

6+5$(63(&,),&$7,216+,//3+2(1,;

5()5,*(5$7('',63/$<&$6(6)256$/(,17+(

81,7('67$7(60((725(;&((''(3$570(17

2)(1(5*<5(48,5(0(176

&20321(17

915% 1DUURZ5HDFK,Q0HUFKDQGLVHU

'RRU%HYHUDJH'DLU\'HOL0HDW

915%

(/(&75,&$/'$7$

&DVH

/HQJWK

)DQV3HU

&DVH

+LJK(IILFLHQF\)DQV

9ROW

$PSV :DWWV

'RRU

'RRU

'RRU

'RRU

/,*+7,1*'$7$

&DVH

/HQJWK 'RRU6L]H

23

23)UHQFK6ZLQJ

2QO\

9ROWV 9ROWV

$PSV :DWWV $PSV :DWWV

'RRU

'RRU

'RRU

'RRU

5HY'DWH 5HY 5HY7LWOH

'$7$83'$7(

(1'9,(:83'$7(

$17,&21'(16$7('$7$

&DVH/HQJWK 'RRU6L]H

)UDPHV 9LVWD)UDPHV

8Q+HDWHG'RRUV 8Q+HDWHG'RRUV

(/0'(/0+, 9LVWD&,

9ROWV 9ROWV

$PSV :DWWV $PSV :DWWV

'RRU

'RRU

'RRU

'RRU

A3: TECHNICAL REFERENCE SHEET

$

//0($685(0(176$5(7$.(13(5

$

6+5$(63(&,),&$7,216+,//3+2(1,;

5()5,*(5$7('',63/$<&$6(6)256$/(,17+(

81,7('67$7(60((725(;&((''(3$570(17

2)(1(5*<5(48,5(0(176

&20321(17

915% 1DUURZ5HDFK,Q0HUFKDQGLVHU

'RRU%HYHUDJH'DLU\'HOL0HDW

915%

127(6

LQGLFDWHVWKDWWKLVIHDWXUHLVQRWDQRSWLRQRQWKLVFDVHPRGHO

'DWDOLVWHGLVIRU2SWLPD[5DGLDQW)RURWKHUOLJKWLQJRSWLRQVSOHDVHFRQWDFW\RXUVDOHVUHSUHVHQWDWLYH

/LVWHGGLVFKDUJHDLUYHORFLW\UHSUHVHQWVWKHDYHUDJHYHORFLW\DWWKHSHDNRIGHIURVW

7HPSHUDWXUHDQGGHIURVWVHWWLQJVOLVWHGDERYHDUHUHFRPPHQGHGVWDUWXSVHWWLQJV)LQDORSHUDWLRQDOVHWWLQJVPD\QHHGWREH

DGMXVWHGIRUWKHVWRUHFRQGLWLRQVLQZKLFKWKHFDVHRSHUDWHV

7KHUHFRPPHQGHGHYDSRUDWRUWHPSHUDWXUHVPD\QHHGWREHDGMXVWHGEDVHGRQV\VWHPVHWXSVWRUHFRQGLWLRQVHWF7KH

PLQLPXPUHFRPPHQGHGHYDSRUDWRUWHPSHUDWXUHLV)EHORZWKHOLVWHGHYDSRUDWRUWHPSHUDWXUH

/LJKWZDWWDJHVDERYHUHIOHFWUXQWLPH7RGHWHUPLQHDFWXDOGDLO\HQHUJ\XVDJHDW)5+FRQGLWLRQVUHGXFHWKHOLJKW

ZDWWDJHVDERYHE\

*8,'(/,1(6$1'&21752/6(77,1*6

$SSOLFDWLRQ &DVH/HQJWK

'RRU

6L]H

%78+IW 6XSHUKHDW6HW

3RLQW#%XOE

)

(YDSRUDWRU

)

'LVFKDUJH

$LU)

'LVFKDUJH$LU

9HORFLW\)30

&RQYHQWLRQDO 3DUDOOHO

%HYHUDJH 'RRU

%HYHUDJH

%HYHUDJH

%HYHUDJH

%HYHUDJH

%HYHUDJH

%HYHUDJH

'HOL 'RRU

'HOL

'HOL

'HOL

'HOL

'HOL

'HOL

0HDW 'RRU

0HDW

0HDW

0HDW

0HDW

0HDW

0HDW

'()5267&21752/6

'HIURVWV3HU

'D\

7LPHG2II'HIURVW

)DLO6DIH

0LQ

7HUPLQDWLRQ

7HPS)

5HY'DWH 5HY 5HY7LWOH

'$7$83'$7(

(1'9,(:83'$7(

A4: TECHNICAL REFERENCE SHEET

$

//0($685(0(176$5(7$.(13(5

$

6+5$(63(&,),&$7,216+,//3+2(1,;

5()5,*(5$7('',63/$<&$6(6)256$/(,17+(

81,7('67$7(60((725(;&((''(3$570(17

2)(1(5*<5(48,5(0(176

&20321(17

915% 1DUURZ5HDFK,Q0HUFKDQGLVHU

'RRU%HYHUDJH'DLU\'HOL0HDW

915%

5HY'DWH 5HY 5HY7LWOH

'$7$83'$7(

(1'9,(:83'$7(

6(&21'1$785('$7$

&DVH0RGHO

1RRI

&RLOV $SSOLFDWLRQ )URQW6LOOKHLJKW

%78+)7 *30IW

'5

6XSSO\)OXLG

7HPS)

'LVFKDUJH$LU

7HPS)

&RQYHQWLRQDO 3DUDOOHO

915%'RRU %HYHUDJH 6WG5HDFK,Q

915%'RRU 'HOL 6WG5HDFK,Q

915%'RRU 0HDW 6WG5HDFK,Q

915%'RRU %HYHUDJH 6WG5HDFK,Q

915%'RRU 'HOL 6WG5HDFK,Q

915%'RRU 0HDW 6WG5HDFK,Q

915%3HU)RRW %HYHUDJH 6WG5HDFK,Q

915%3HU)RRW 'HOL 6WG5HDFK,Q

915%3HU)RRW 0HDW 6WG5HDFK,Q

915%3HU)RRW %HYHUDJH 6WG5HDFK,Q

915%3HU)RRW 'HOL 6WG5HDFK,Q

915%3HU)RRW 0HDW 6WG5HDFK,Q

6(&21'1$785('$7$

&DVH0RGHO

1RRI

&RLOV $SSOLFDWLRQ )URQW6LOOKHLJKW

6XSSO\)OXLG

7HPS)

1RRI

'HIURVW

7LPHG2II'HIURVW :DUP)OXLG'HIURVW

)DLO6DIH

0LQ

7HUPLQDWLRQ

7HPS)

)DLO6DIH

0LQ

7HUPLQDWLRQ

7HPS)

915%'RRU %HYHUDJH 6WG5HDFK,Q

915%'RRU 'HOL 6WG5HDFK,Q

915%'RRU 0HDW 6WG5HDFK,Q

915%'RRU %HYHUDJH 6WG5HDFK,Q

915%'RRU 'HOL 6WG5HDFK,Q

915%'RRU 0HDW 6WG5HDFK,Q

915%3HU)RRW %HYHUDJH 6WG5HDFK,Q

915%3HU)RRW 'HOL 6WG5HDFK,Q

915%3HU)RRW 0HDW 6WG5HDFK,Q

915%3HU)RRW %HYHUDJH 6WG5HDFK,Q

915%3HU)RRW 'HOL 6WG5HDFK,Q

915%3HU)RRW 0HDW 6WG5HDFK,Q

127(6

$OOPHGLXPWHPSHUDWXUHGDWDOLVWHGLVIRUE\ZW3523</(1(*/<&2/

,QKLELWHG3URS\OHQH*O\FROVROXWLRQZLWKZDWHUVXFKDV'RZIURVWRUHTXLYDOHQW'RZIURVWLVDWUDGHPDUNRIWKH'RZ&KHPLFDO

&RPSDQ\

)ORZUDWHVDUHGHWHUPLQHGE\$6+5$(WHVWFRQGLWLRQVDQGPD\QHHGWREHDGMXVWHGEDVHGRQVWRUHFRQGLWLRQV

)ORZUDWHVDUHSHUFDVH

This manual suits for next models

4

Table of contents

Other Hillphoenix Merchandiser manuals

Popular Merchandiser manuals by other brands

New Air

New Air NGR-036-H product manual

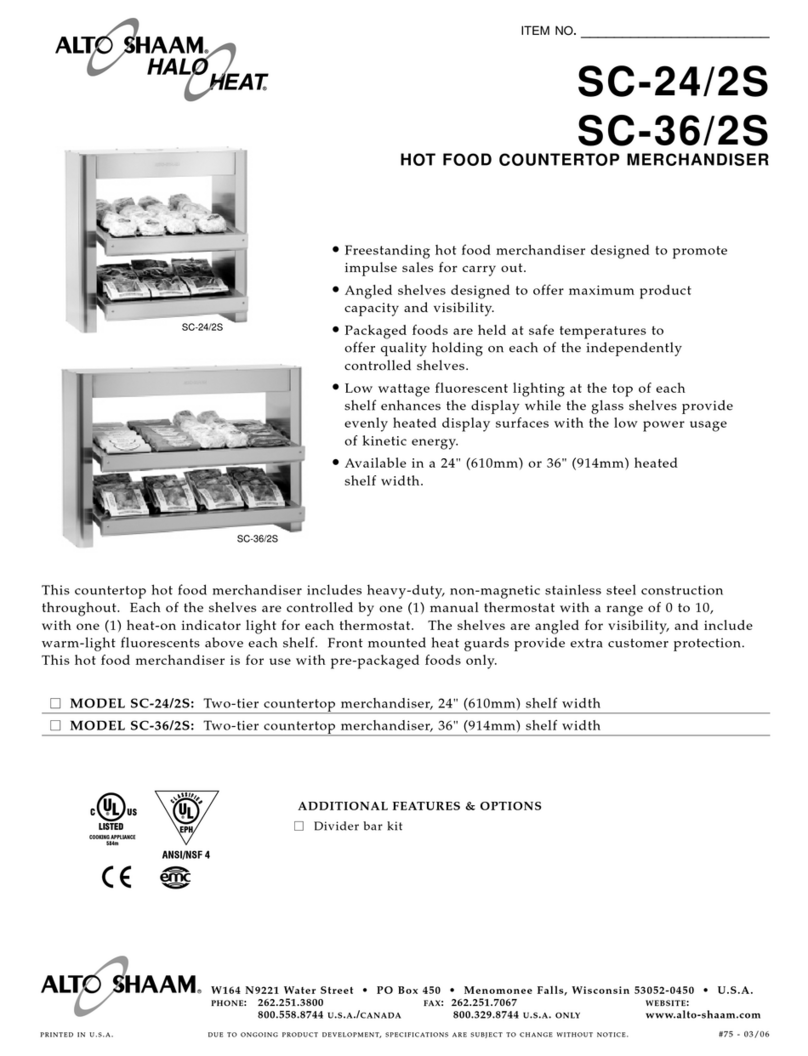

Alto-Shaam

Alto-Shaam SC-24/2S Specifications

Alto-Shaam

Alto-Shaam SC-24/2S Installation, operation and maintenance manual

Alto-Shaam

Alto-Shaam HSM-38/3S Installation, operation and maintenance

Turboair

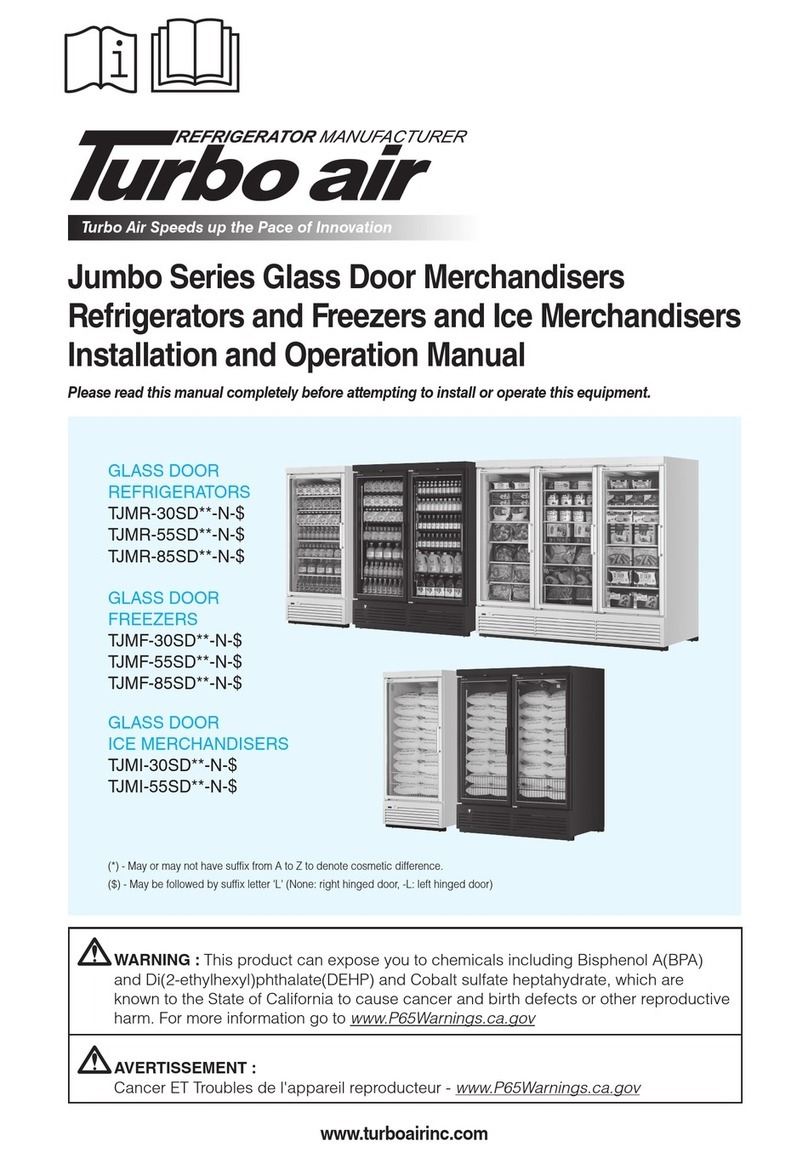

Turboair Jumbo TJMR-30SD N Series Installation and operation manual

Hussmann

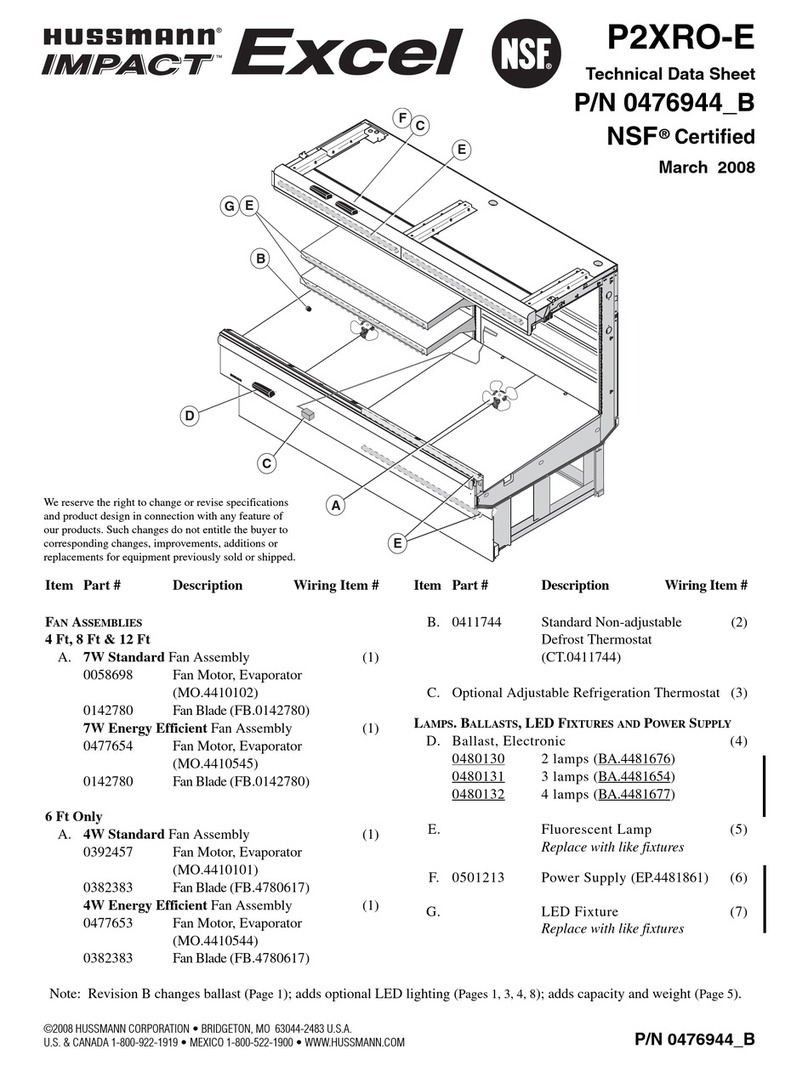

Hussmann P2XRO-E Technical data sheet

Hussmann

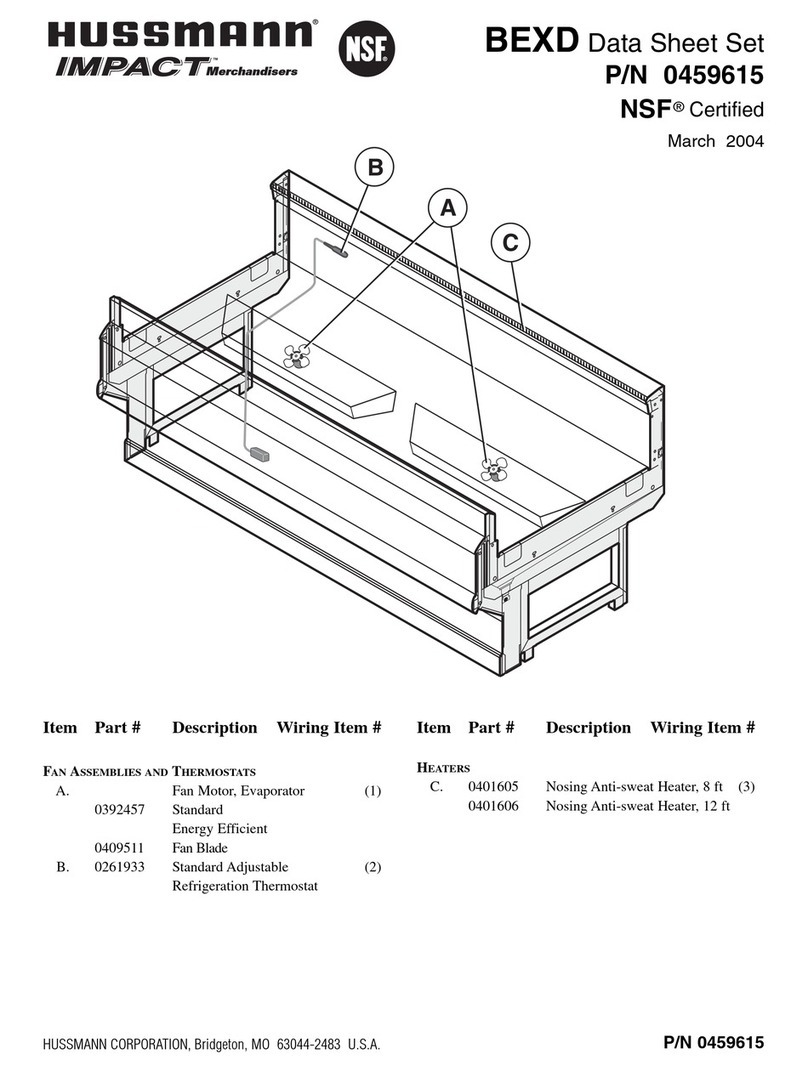

Hussmann BEXD datasheet

Carrier

Carrier TYLER Advantage Series Installation & service manual

Hussmann

Hussmann RDI Technical data sheet

Hussmann

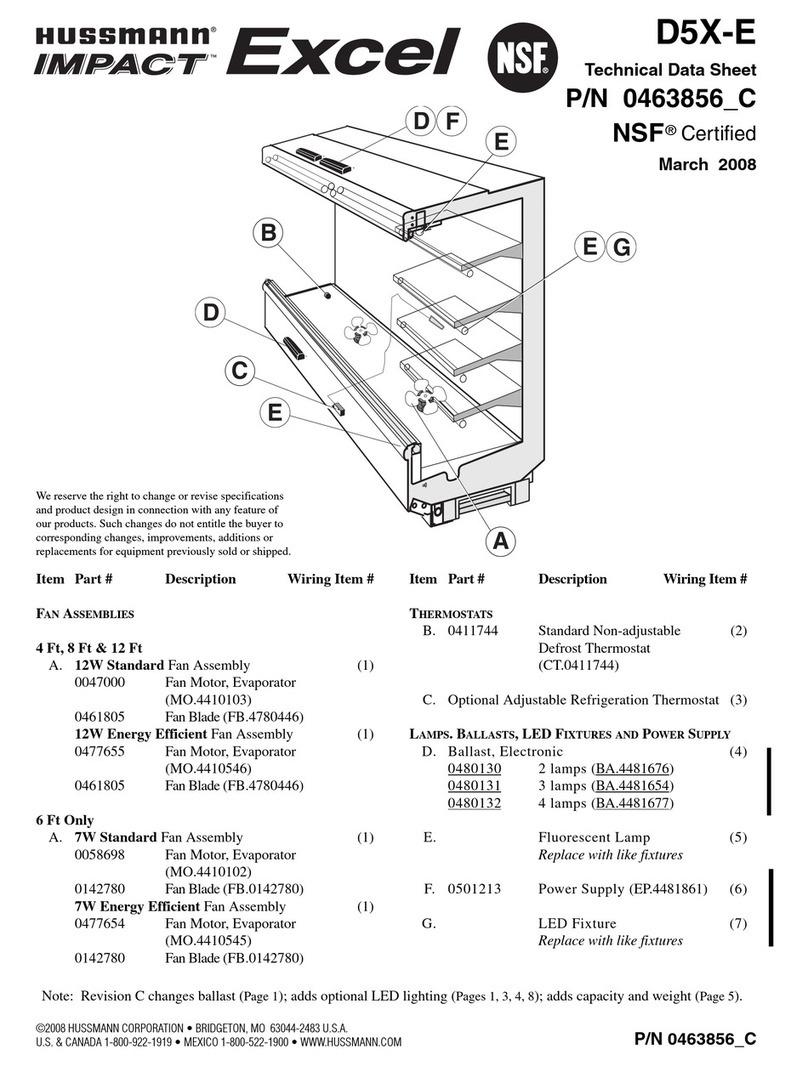

Hussmann D5X-E Technical data sheet

Hussmann

Hussmann Impact F2XLG Installation and operation manual

Hussmann

Hussmann IMPACT D5RRI Parts installation and removal guide