CASE INSTALLATION

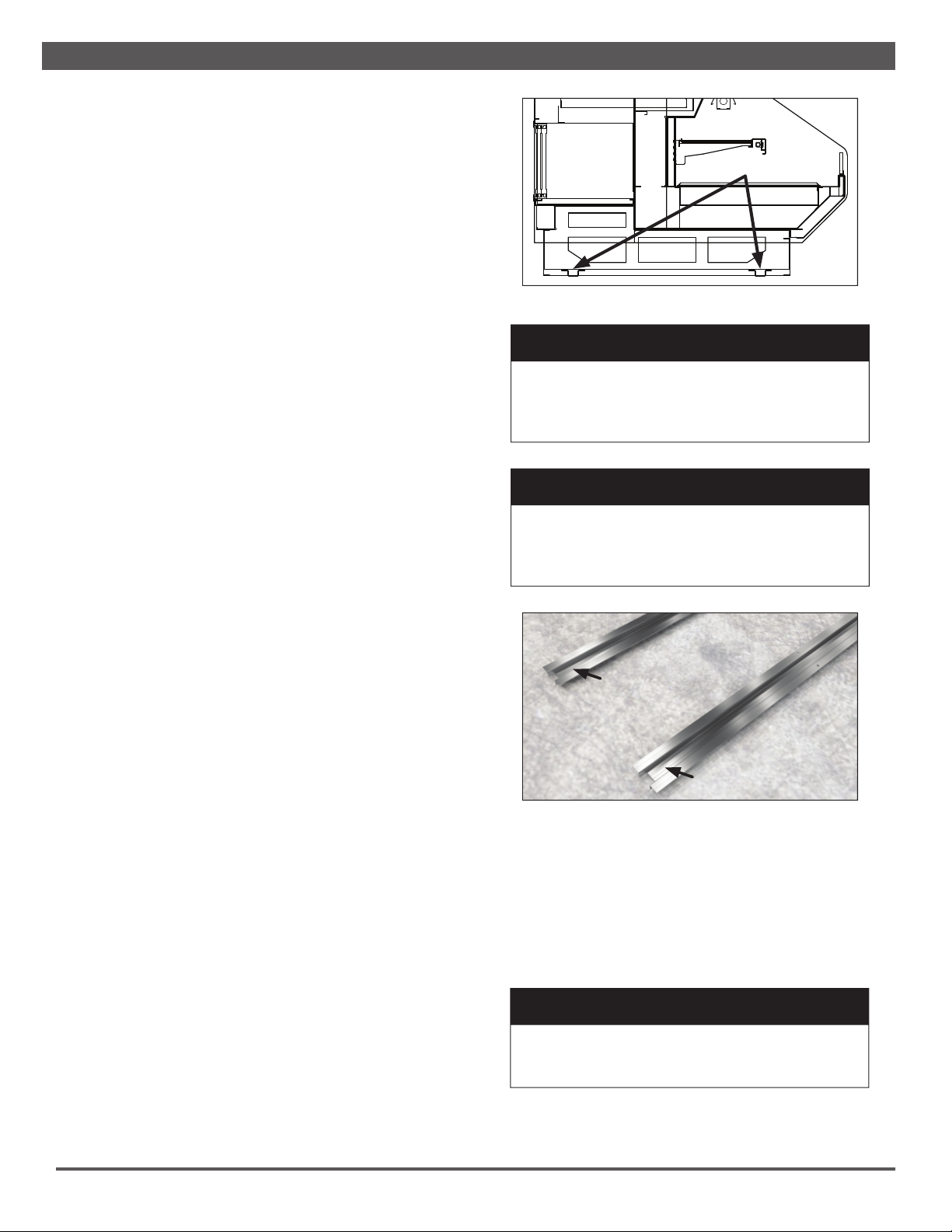

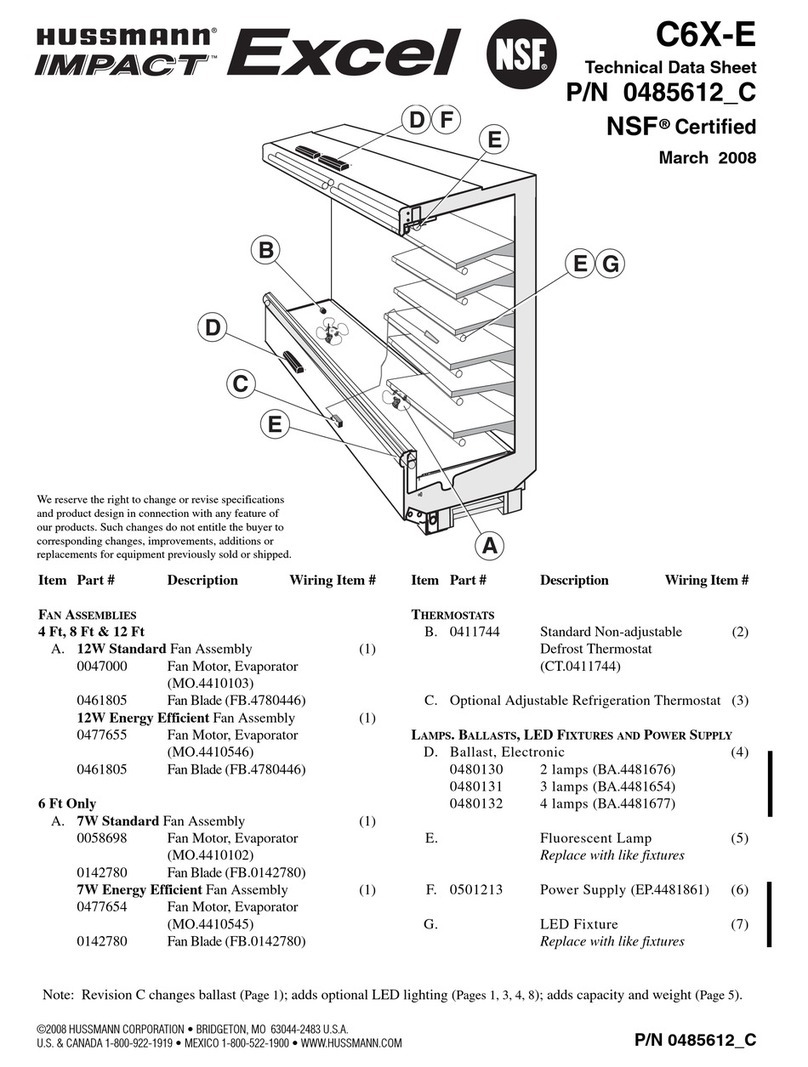

Fig. 1 Horizontal supports

SUPPORTS

FLOOR PREP

1. Ask the general contractor if your current copy of the build-

ing dimensions are the most recently issued. Also, ask for

the points of reference from which you should take dimen-

sions to locate the cases.

2. Using chalk lines or a laser transit, mark the floor where

the cases are to be located for the entire lineup. The lines

should coincide with the outside edges of the case feet.

3. Move case as close as possible to its permanent location.

Remove all crating and shipping braces above the ship-

ping pallet. Loosen the plastic dust cover from the pallet,

but leave cover over the case to protect it while removing

the case from the pallet.

4. Shipping braces with a sled runner construction can either

have metal brackets that can be removed with a screw

gun, or wood blocks that can be removed with a J-bar.

Note: Shipping braces are normally located at each

corner of the case. (Shipping braces used vary and are

based on case design for best transport.)

5. Carefully, if horizontal supports, lift case up and off the

pallet. Remove dust cover. Installation hardware ships in a

marked packet located inside the case.

6. Leveling is necessary to ensure proper operation. Locate

the highest point on the positioning lines as a reference

for determining the proper height of the shim-pack level-

ers. A laser transit is recommended for precision and

requires just one person. Level adjustable feet by twisting,

if applicable, or shim as necessary under horizontal sup-

ports as this will help ensure that the case is not settling

over time.

7. Locate horizontal support positions along the chalk line

(Fig. 1). Spot properly leveled shim packs at each support

location.

8. If necessary, drill a hole in each end of every horizontal

support (Fig. 2) and fasten to the floor with concrete

anchors. Note: The holes do not need to be in the exact

locations specified here. Be sure that the anchors are

close to the end of the horizontal supports and at each

corner of the case.

LOCATION

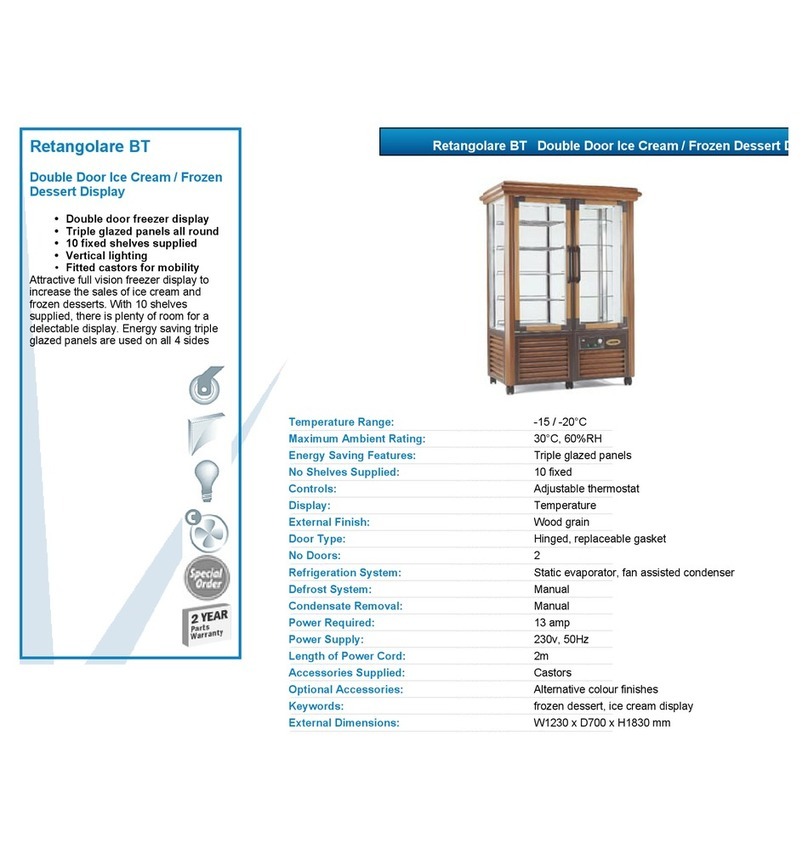

This hot display case has been designed for displaying and

storing perishable food product. It is engineered for air-con-

ditioned stores with a maximum ambient of 75°F and 55%

relative humidity.

When selecting the location for placement of this case, avoid

the following conditions:

Excessive Air Movement

1. Doors

2. Air-conditioned vents

3. Other air sources C A U T I O N

Locate the horizontal supports under unit before

removing from pallet. Failure to do so will dam-

age the finished metal if correct lift points are

not identified prior to removal.

▲

2. Once the case is properly placed on the shim packs, check

the horizontal level of the case by placing a bubble level

on the front sill. Add/remove shim packs as needed.

LINE-UP & INSTALLATION

Single Case

1. Move the case into position. Using a “J” bar, raise the end

of the case (under cross support), and lower the horizontal

support on to the shim packs. Repeat on the other end of

the case.

C A U T I O N

These cases are not designed for excessive

external weight. Do not walk on top or inside

of cases. Doing so may result in case damage

and/or personal injury.

▲

W A R N I N G

Be certain that your hands and feet are out of

the way before lowering the case. Failure to do

so may result in serious injury.

▲

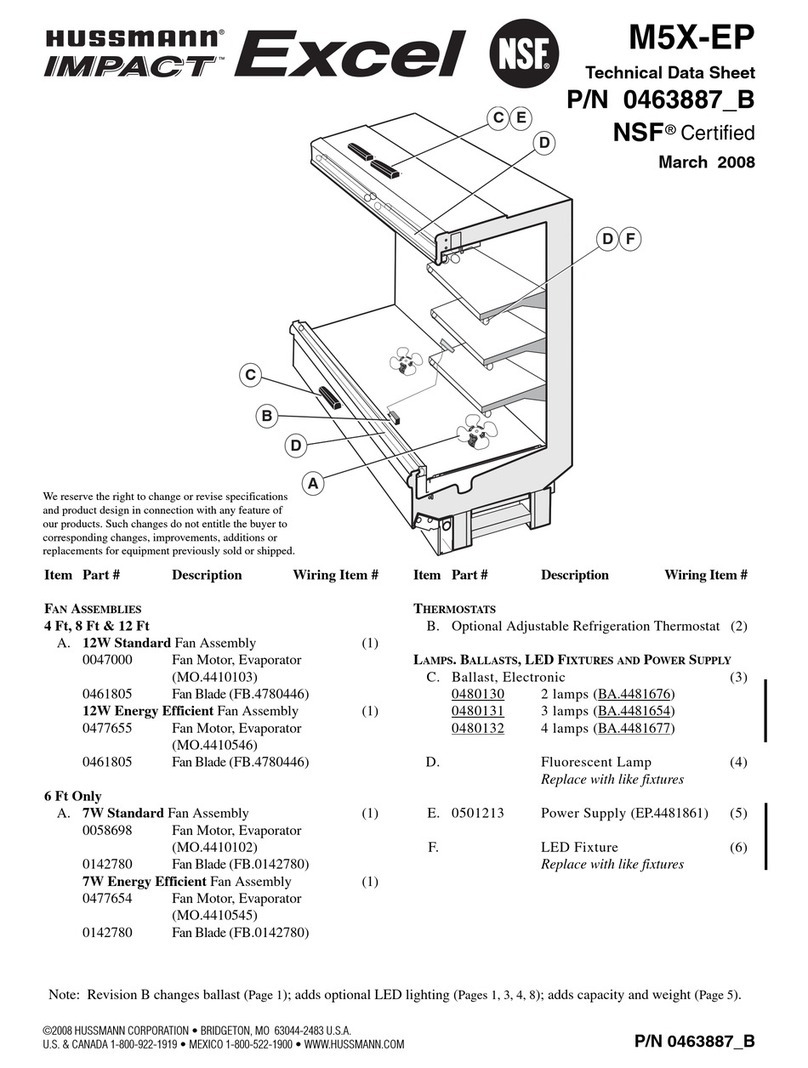

Fig. 2 Seismic anchoring locations

8