Hillstone HACM415-250X User manual

OMHACM415250

OPERATINGMANUAL

for

ACLOADBANK

type

HACM415250X

issue1

SerialNo.M37205

1

OMHACM415250

CONTENTS

INTRODUCTION 3

SAFETYCONSIDERATIONS 4

CONNECTIONPROCEDURE 5

OPERATINGINSTRUCTIONS 6

SPECIFICATION 8

RATINGTABLES 9

RATINGTABLE400APowerLineConnectors: 9

RATINGTABLE63A,Red,5Pin,PanelPlug: 10

RATINGTABLE32A,Red,5Pin,PanelPlug 11

RATINGTABLE16A,Red,5Pin,PanelPlug 11

RATINGTABLE32A,Blue,3Pin,PanelPlug 12

RATINGTABLE16A,Blue,3Pin,PanelPlug 12

MAINTENANCEPROCEDURES 13

FAULTFINDINGPROCEDURES 13

CERTIFICATEOFCONFORMITY 14

Theinformationcontainedinthisdocumentisconsideredcorrectatthetimeof

printingandgiveningoodfaith.HillstoneProductsbearsnoresponsibilityforthe

accuracyofthedatagivenoranyresponsibilityresultingfromtheuseofthe

equipment.

AdministrationAddress&ManufacturingAddress

Unit1&2,

FreetownBusinessPark,

HudcarLane,

Bury,

Lancashire,

BL96HD,

U.K.

Tel: +44(0)1617633100

Fax: +44(0)1617633158

Email:[email protected]

Web:www.hillstone.co.u

2

OMHACM415250

INTRODUCTION

TheloadbankHACM415250X(seefig1)isdesignedfortesting415VAC3phOR

240VAC1ph,50hzcircuits.

Theunitcomprisesofpreset,forcecooled,highpoweredresistorchannelswhich

allowsmanualadjustmentoftheloadcurrentvia12xchannelswitches.

Theloadbankisforcecooledbyasinglephasepoweredcoolingfanwhichtogether

withthecontrolsaresuppliedfromL1ofthetestsource.

Safetyfeaturesincludeinternalfuseprotection,fanmotoroverloadprotection,control

circuitprotectionandautoshutoffintheeventofamainsinterruption..

Thecaseisdesignedforoutdooruse(inawellventilatedarea).

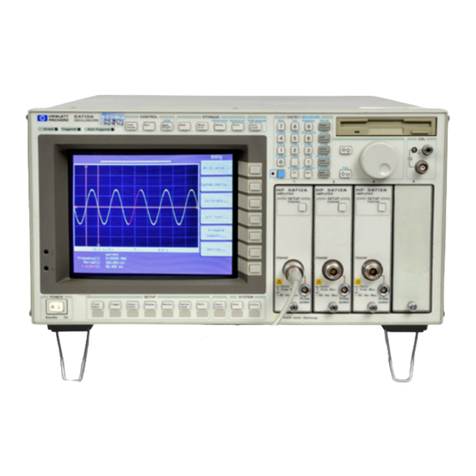

fig1:photoshowsfrontoftheHACM415250Xloadbank

3

OMHACM415250

SAFETYCONSIDERATIONS

1. Theunitshouldonlybeoperatedbycompetentelectricalengineerswhoare

completelyfamiliarwiththeoperationandspecificationoftheloadbank.

2. TheequipmentisdesignedforACoperationonlyandthereforemustnotbe

usedonDCloadssuchasbatteries.

3. Operatorsmustensurethatinterconnectingcablesarecorrectlyratedtocarry

therequiredloadcurrentandadequatelyinsulatedtopreventthepossibilityof

electricshock.

4. Only1circuitmustbetestedatatime.

5. Onlythecircuitundertestmusthaveitsmcbclosed.

6. Thepanelplugcoversmustremainfittedtotheplugwhenisnotinuse.

7. Wheninusetheloadbankshouldbecordonedoffusingsafetybarriers.

8. Theloadbankshouldonlybeoperatedinanareawithadequateventilation.

9. Careshouldbetakenastheexhaustairoutletwillbehot.

10.Cablesmustbepositionedawayfromtheairexhaust

11. Duringoperationtheloadbankshouldnotbecoveredorpositionedtorestrict

airflow.

12.Caution–somemetalsurfaceswillbehotduringoperation

13.Attheendofanytestthefansshouldbekeptrunningfor5minutesonnoload

toremovetheresidualheatfromtheloadbankcase.

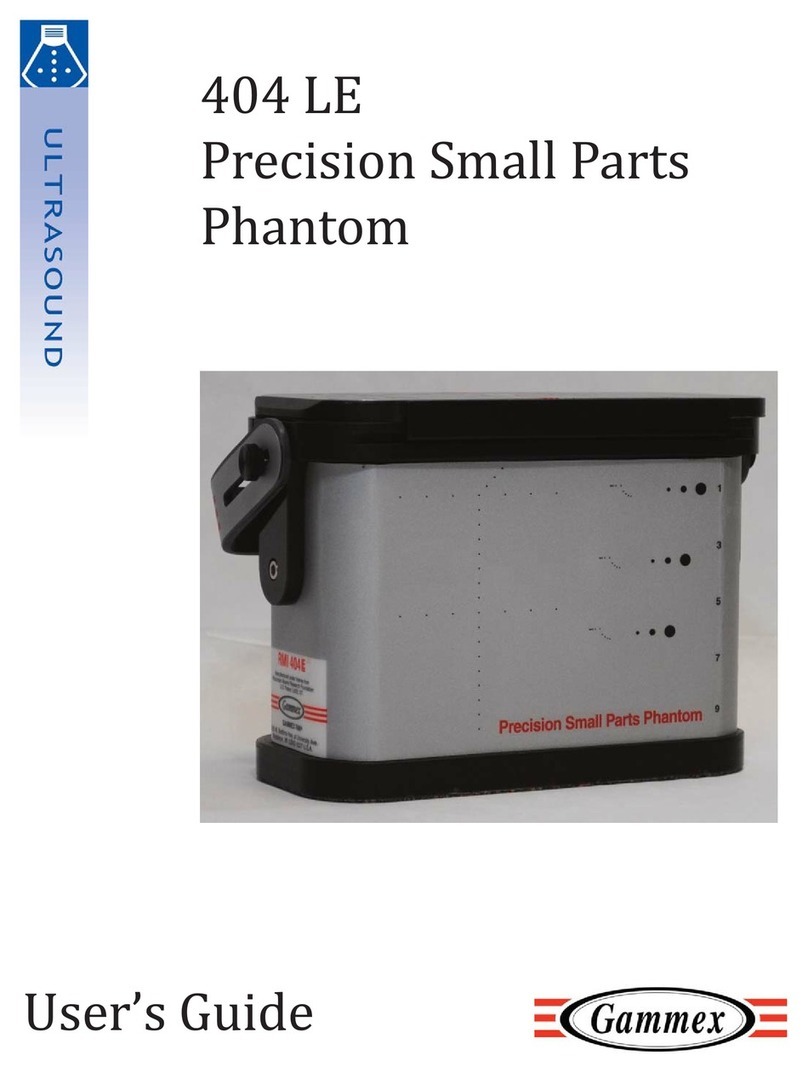

fig2:photoshowstheHACM415250Xloadbank

4

OMHACM415250

CONNECTIONPROCEDURE

A. Ensurethepowersourcetobetestediscompatiblewiththeloadbankoperating

voltageandfrequency.

B. Ensurethepowersourceisdeenergised.

C. Donotattempttooperatetheloadbankabovethemaximumoperatingvoltage.

D. Connecttheloadcabletotheplugrequiredfortest.

E. Plugtheselectedtestcableintothematchingloadbanktestsocket.

F. Ensurethepowercablesarecorrectlyconnectedtothepowersource(seefig3)

observingcorrectphaserotation.

PhaseConductorLine1 PhaseConductorLine2 PhaseConductorLine3

NeutralConductor ProtectiveConductorEarth

fig3:colourcodingrequiredforloadbankconnections

G. Ensuretheneutralandearthareconnectedcorrectly.

fig4:photoshowsthepowerlineconnectorsbelowthearrayofpanelplugs.

5

OMHACM415250

OPERATINGINSTRUCTIONS

Operatorsshouldreadthe

SAFETYCONSIDERATIONSandCONNECTIONPROCEDURE

beforecarryingoutthefollowingoperatinginstructions

1. Ensureallpanelsareinplaceontheloadbank.

2. EnsureallpanelmountedswitchesareintheOFFposition.

3. EnergisethepowersourcefromtheUPSorgenerator.

4. ClosetheMCBforthetestplugtobeused

fig5:photoshowstheMCBpanel

IMPORTANT:ONLY1MCBTOBECLOSEDATANYTIME

5. Movetheselectorswitchtothepositionofthetestsockettobeused.

fig6:photoshowstheSelectorSwitch

6

OMHACM415250

6. Pressthegreenstartbutton.

7. Ensurethefanrotatesinthecorrectdirectionwithexhaustairbeingexpelledfrom

theexhaustgrill.

8. Theavailablechannelswillbeilluminatedbeloweachswitch.

9. Selectloadrequiredusingtheamberloadchannelswitches,refertoratingtable.

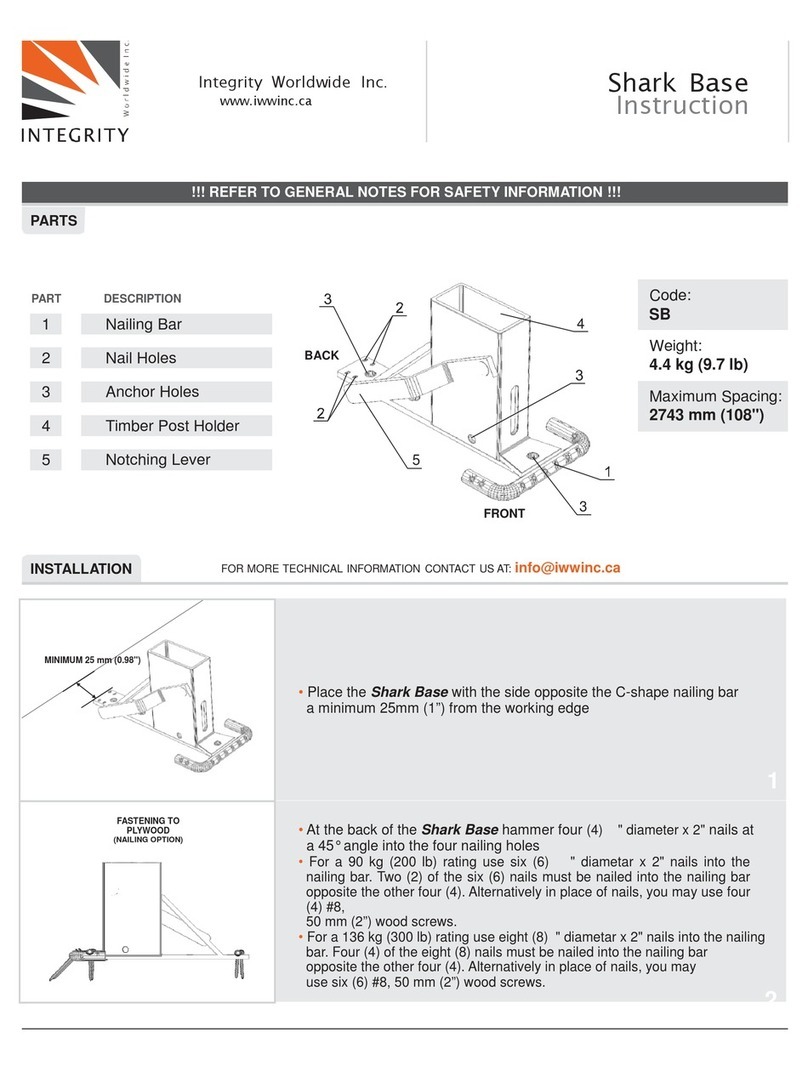

fig7:photoshowschannelswitches,startandstopbuttons,emergencystopbutton

andthephasesequencealarmLED

10. AttheendofthetestpresstheredStopbuttontodisabletheloadchannels.

11. Theloadbankfanshouldbelefttorunoffloadforanautomatic5minute

cooldownperiodtocooltheresistorelements.

12. IsolatetheUPSorgeneratorpowersource

13. OpentheMCB

14. DONOTremovethepowercircuitwiththeloadcircuitenergised.

TheredEMERGENCYSTOPbuttoncanbeusedasanEmergencyDisconnectat

anytimeduringatesttodisconnectallloadcircuitsandthefansupply.

7

OMHACM415250

SPECIFICATION

Typeref HACM415250X

Maxoperatingvoltage 415Vthreephase

Maxcurrentrating 369Aperphase

Maxpowerrating 265KWthreephase

OperatingFrequency 50Hertz

Connection 16A,singlephase,3pin,panelplug

32A,singlephase,3pin,panelplug

16A,threephase,5pin,panelplug

32A,threephase,5pin,panelplug

63A,threephase,5pin,panelplug

400A,powerlineconnectors

Control Switchedchannels

Resistortolerance +/7.5%

Operatingambient temperature 0to+50degC

Storageambienttemperature 0to+80degC

PLC Millenium3SmartXB2624VDC

PLCExtension Millenium3SmartXR1024VDC

Operatingambient temperature 0to+40degC

Storageambienttemperature 0to+80degC

Lifting Forkliftpockets

Loadbankdimensions Length 1930mm

Width 850mm

Height 1120mm

Weight 358kgs

8

OMHACM415250

RATINGTABLES

RATINGTABLE400APowerLineConnectors:

AvailableChannels

ChannelWatts@415V

I@240V(LN)

Fan

8856W

12.3A

1

1000W

1.39A

2

1000W

1.39A

3

3000W

4.17A

4

3000W

4.17A

5

3000W

4.17A

6

3000W

4.17A

7

9000W

12.5A

8

18000W

25A

9

18000W

25A

10

36000W

50A

11

54000W

75A

12

108000W

150A

Total

265856W

369.2A

9

OMHACM415250

RATINGTABLE63A,Red,5Pin,PanelPlug:

AvailableChannels

ChannelWatts@415V

I@240V(LN)

Fan

8856W

12.3A

1

1000W

1.39A

2

1000W

1.39A

3

3000W

4.17A

4

3000W

4.17A

7

9000W

12.5A

8

18000W

25A

Total

43856W

60.9A

10

OMHACM415250

RATINGTABLE32A,Red,5Pin,PanelPlug

AvailableChannels

ChannelWatts@415V

I@240V(LN)

Fan

8856W

12.3A

1

1000W

1.39A

2

1000W

1.39A

3

3000W

4.17A

4

3000W

4.17A

5

3000W

4.17A

6

3000W

4.17A

Total

22856W

31.7A

RATINGTABLE16A,Red,5Pin,PanelPlug

AvailableChannels

ChannelWatts@415V

I@240V(LN)

Fan

8856W

12.3A

1

1000W

1.39A

2

1000W

1.39A

Total

10856W

15.1A

11

OMHACM415250

RATINGTABLE32A,Blue,3Pin,PanelPlug

AvailableChannels

ChannelWatts@240V

I@240V(LN)

Fan

2952W

12.3A

1

333W

1.39A

2

333W

1.39A

3

1000W

4.17A

4

1000W

4.17A

5

1000W

4.17A

6

1000W

4.17A

Total

7618W

31.7A

RATINGTABLE16A,Blue,3Pin,PanelPlug

AvailableChannels

ChannelWatts@240V

I@240V(LN)

Fan

2952W

12.3A

1

333W

1.39A

2

333W

1.39A

Total

3618W

15.1A

12

OMHACM415250

MAINTENANCEPROCEDURES

Theloadbankshouldnotrequireanyspecialmaintenance,howeveraswithany

electricalequipmentperiodicchecksshouldbecarriedouttoensuretheequipmentis

inasafeandsatisfactorycondition.

Thefollowingperiodicchecksarerecommendedontheloadbank;

1. Checktheinletandoutletgrillsarefreefromobstruction.

2. Checkthecontrolsandterminalareundamaged.

3. Checkthefanrotatesfreelywithoutobstruction.

4. Checkconnectioncablesareundamaged.

FAULTFINDINGPROCEDURES

Thefollowingfaultfindingprocedureisintendedtoidentifysimpleoperationalerrors

andhasbeencategorisedintotwopossibleproblemareasasfollows;

FANCOOLINGNOTOPERATIONAL

Checkthepowersourceisavailable.

Checktheinterconnectingcableconnections.

Checktheloadcableisconnectedtothechosenpanelplug

ChecktheMCBisclosedfortheconnectedpanelplug

Checktheselectorswitchisinthecorrectpositionfortheconnectedpanelplug

Checkthefanmotoroperates.

Checkforairblockage.

Checkfanbladesaresecuredtomotorshaft.

LOADBANKDOESNOTPROVIDESUFFICIENTLOADCURRENT

Checkthepowersourceisattherequiredvoltage.

Anyfaultsnotcorrectedbycarryingouttheaboveproceduresmayrequirethe

internalwiringorcomponentsoftheloadbanktobeinspectedfordamage.

ImportantNote:

Isolatetheloadbankfromanypowersourcebeforeremovingany

covers.Testingtheloadbankwiththecoversremovedshouldnotbe

carriedoutasitpresentsariskofinjuryordeathbyelectricshock.

Repairorreplacementshouldbecarriedoutbythemanufacturer.

13

OMHACM415250

Units1&2FreetownBusinessPark

HudcarLane,Bury,Lancs.

BL96HD.UK

Tel:+44(0)1617633100

Fax:+44(0)1617633158

CERTIFICATEOFCONFORMITY

Customer M.O.D

Quotenumber Q2T8779

HillstoneManufacturingref M37205

Equipmenttyperef HACM415250

Equipmentdescription Loadbank

Quantitysupplied 1

Dateofmanufacture February2017

Note:

Thisdocumentcertifiesthatthewholeoftheitemsdetailedabovehavebeenmanufactured,

testedandinspectedandunlessotherwisestatedconforminallrespectswiththerequirements

ofthecontractororderandinaccordancewiththefollowing.

●LowVoltageDirective2006/95/EC

●EMCdirective2004/108/EC:

○ BSEN6100063 2007amendmentsfor2011

○ BSEN6100061 2007

○ BSEN6100064 2007amendmentsfor2011

●HillstoneProductsQualityAssuranceproceduresISO9001:2008

14

Table of contents

Other Hillstone Test Equipment manuals