Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice. Please note that other versions of this product are available. If you require documentation for alternative versions, please email or call

our technical team on technical@sealey.co.uk or 01284 757505.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

5.2.1. For example the maximum pressure in most vehicle turbo systems is

approximately 15psi (1bar) up to 25psi (1.7bar). A vehicle coolant system is

typically rated at 15psi.

5.2.2. A graduated approach to leakage testing is recommended.

5.3. TEST METHOD 1, (REFER TO FIG.2):

5.3.1. Select the correct air inlet adaptor and plug adaptor (fig.1) by first measuring

the hose diameter. Each adaptor has three diameters to fit different sizes of

hose.

5.3.2. Set regulator of tester to 5psi to check for large leaks with valve, open

(operating handle inline with the hose axis). and with the air coupling

disconnected.

5.3.3. Plug the outlet of the system with the appropriate blank end adaptor.

5.3.4. Connect the inlet adaptor, set at 5psi, to the system inlet.

5.3.5. Connect the air coupling to check for leaks at the pre-set (5psi). If a leak is

identified audibly or if the pressure gauge pointer falls, it indicates that the

system has a fault resulting in loss of pressure. Repair the leak and retest.

5.3.6. If no leaks are evident, regulate pressure to 10psi and repeat 5.3.5.

5.3.7. If no leaks are evident, regulate pressure to a maximum of 15psi or to the

manufacturer’s maximum pressure and retest as in 5.3.5.

5.3.8. If the gauge pointer remains stationary for one minute it will indicate that the

system is in good working order.

5.3.9. Release the pressure in the system by rotating the ball valve lever to align with hose axis.

5.3.10. Disconnect the quick coupler, clean and return all items to carry case.

5.4. TEST METHOD 2, (REFER TO FIG.2):

5.4.1. Set up as in test method 1: 5.3.1. to 5.3.5.

5.4.2. When the system is pressurized, close the ball valve. By closing the ball valve the system is isolated from the constant air supply. The

system can now be tested to ensure it is holding a constant pressure. By monitoring the pressure gauge over a period small leaks can

be detected, showing as a fall in pressure within the system.

6. MAINTENANCE

6.1. Always keep the plastic adaptors clean and free of oil and grease. Regularly clean with a solvent free cleaner. Ensure components are

dry before storage.

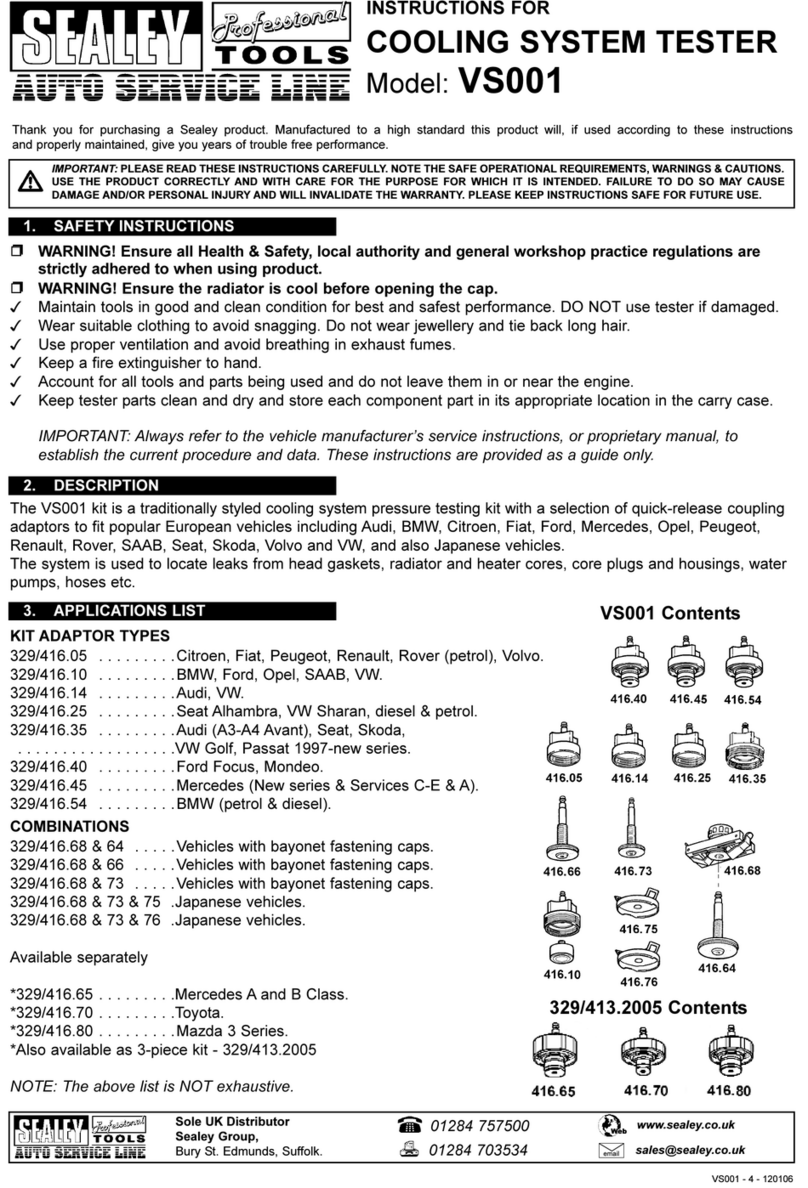

g.2

Example (left) shows the kit

testing a turbo system

intercooler for integrity.

Intercooler

Turbo

Engine

Typical turbocharger system

VS2030.V2 Issue:2 (H,F) 26/04/19

Original Language Version

© Jack Sealey Limited