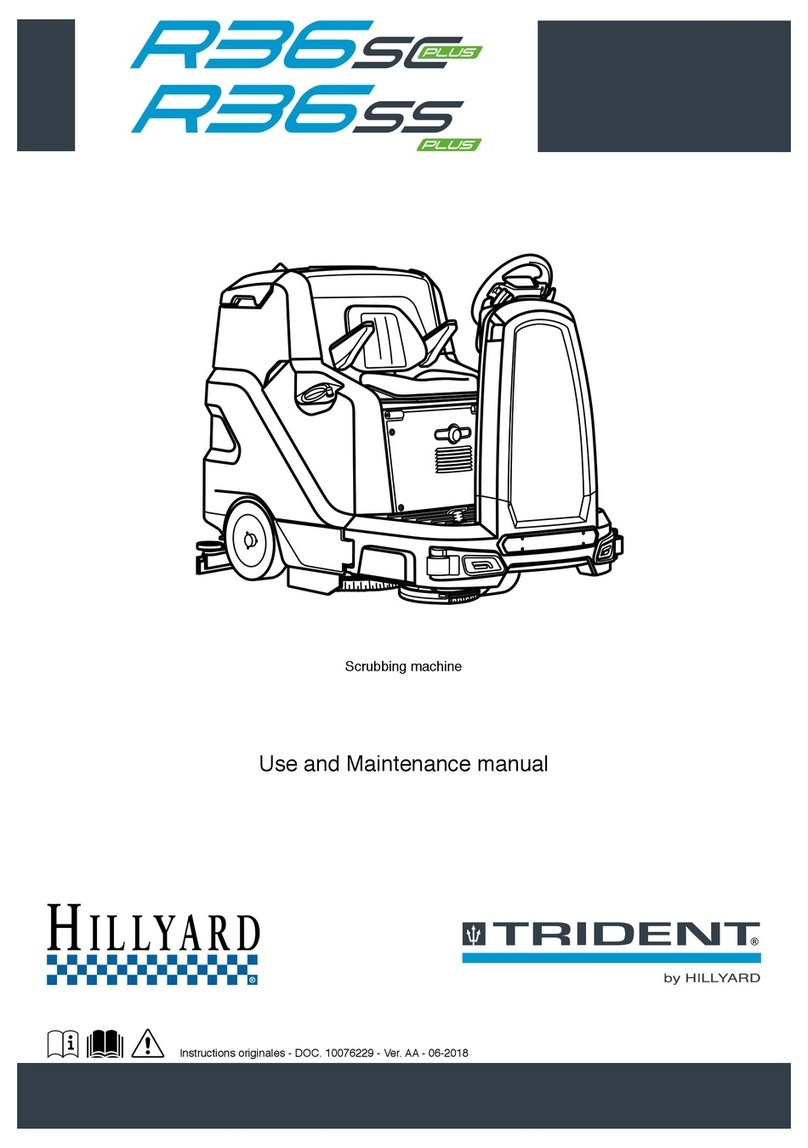

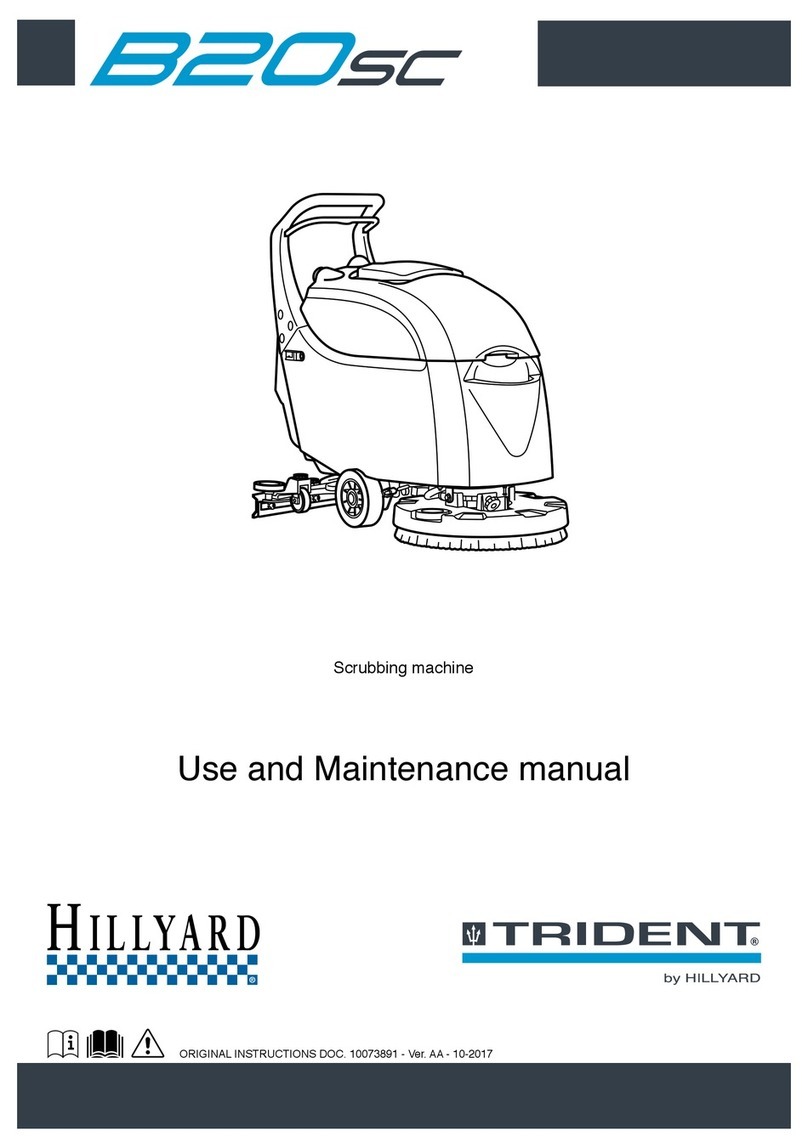

Hillyard TRIDENT R30SC User manual

Scrubbing machine

Use and Maintenance manual

Original instructions - DOC. 10075358- Ver. AA - 11-2017

The machine's main components are the following:

1. Right-hand splash guard pre-assembly.

2. Scrubbing brush head.

3. Squeegee body.

4. Hour meter display – battery charge level.

5. Headlights (optional).

6. Tail lights (optional).

7. Vacuum motor air intake lter.

8. Vacuum motor air duct lter.

9. Recovery tank lter.

10. Detergent solution lter.

11. Main key switch.

12. Blinking light (optional).

13. Brush head extra pressure LED indicator.

14. Brush head control lever.

15. Electric brake control lever.

16. Detergent solution tap control lever.

17. Squeegee control lever.

18. Brush head extra pressure selection lever.

19. Reverse gear selection lever.

20. Service brake pedal.

21. Drive pedal.

22. Horn button.

23. Adjustment button for HDC system detergent solution (optional).

24. HDC system activation button (optional).

25. Emergency button.

26. Operator seat

27. Recovery tank lid.

28. Recovery tank.

29. Solution tank.

30. Right hatch.

31. Left hatch.

32. Squeegee support.

33. Solution tank drainage shaft cap.

34. Solution tank cap.

35. Squeegee vacuum hose.

36. Solution tank rapid lling hose.

37. Solution tank level hose.

38. Recovery tank drainage hose.

39. Steering wheel.

40. Left-hand splash guard pre-assembly.

41. Detergent tank cap.

42. Detergent level tube.

43. Activation button for tank cleaning kit (optional).

MAIN MACHINE COMPONENTS

3

17

43

14

22

1

30

29

28

27

12

26

40

31

25

3

35

33

5

6

38

42

24

23

13

39

41

16

9

19

11

34

36

37

20

13

4

15

21

10

8

7

CONTENTS

MAIN MACHINE COMPONENTS..........................................3

CONTENTS............................................................................4

1. GENERAL SAFETY REGULATIONS................................5

1. RECHARGING THE BATTERIES ............................................... 5

2. USING THE MACHINE ............................................................... 6

3. DEACTIVATION OF THE MACHINE........................................... 8

4. MAINTENANCE .......................................................................... 8

5. TRANSPORT .............................................................................. 9

2. SYMBOLS USED IN THE MANUAL ............................... 10

3. PURPOSE AND CONTENT OF THE MANUAL ..............10

4. TARGET GROUP.............................................................10

5. STORING THE USE AND MAINTENANCE MANUAL.... 10

6. ON CONSIGNMENT OF THE MACHINE ........................ 10

7. INTRODUCTORY COMMENT ......................................... 10

8. IDENTIFICATION DATA................................................... 10

9. TECHNICAL DESCRIPTION ........................................... 10

10. INTENDED USE.............................................................10

11. SAFETY..........................................................................10

12. SERIAL NUMBER PLATE ............................................. 10

13. TECHNICAL DATA ........................................................ 11

14. SYMBOLS USED ON THE MACHINE .......................... 12

15. SYMBOLS USED ON THE SERIAL NUMBER

PLATE .................................................................................. 12

16. MACHINE PREPARATION ............................................13

1. HANDLING THE PACKAGED MACHINE ................................. 13

2. HOW TO UNPACK THE MACHINE .......................................... 13

3. HOW TO MOVE THE MACHINE .............................................. 13

4. SECURING THE MACHINE...................................................... 14

5. TYPE OF BATTERY TO BE USED ........................................... 14

6. BATTERY MAINTENANCE AND DISPOSAL............................ 14

7. INSERTING THE BATTERIES INTO THE MACHINE............... 14

8. CONNECTING BATTERIES TO THE SYSTEM

OF THE APPLIANCE .................................................................... 14

9. RECHARGING THE BATTERIES ............................................. 14

10. ASSEMBLING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 15

11. ASSEMBLING THE SQUEEGEE BODY................................. 15

12. FILLING THE SOLUTION TANK............................................. 15

12. DETERGENT SOLUTION....................................................... 15

17. PREPARING TO WORK ................................................ 16

18. WORK ............................................................................16

1. SCRUBBING WITH DRYING .................................................... 16

2. SCRUBBING WITHOUT DRYING ............................................ 16

3. DRYING..................................................................................... 17

4. ADJUSTING THE DETERGENT SOLUTION

(VERSIONS WITHOUT HDC)....................................................... 17

5. AUTOMATIC DETERGENT MEASURING SYSTEM

(HDC VERSION) ........................................................................... 17

6. REVERSE GEAR ...................................................................... 17

7. EXTRA BRUSH HEAD PRESSURE ......................................... 17

8. ACOUSTIC SIGNALLING DEVICE ........................................... 17

9. WORKING HEADLIGHTS (OPTIONAL) ................................... 18

10. EMERGENCY BUTTON.......................................................... 18

11. HOUR METER......................................................................... 18

12. BATTERY CHARGE LEVEL INDICATOR ............................... 18

13. OVERFLOW DEVICE ............................................................. 18

19. AT THE END OF THE WORK........................................ 18

20. RECOMMENDED MAINTENANCE OPERATIONS ......19

1. EMPTYING THE RECOVERY TANK ........................................ 19

2. CLEANING THE SQUEEGEE BODY........................................ 19

3. CLEANING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 19

4. CLEANING THE RECOVERY TANK FILTERS ......................... 19

5. CLEANING THE RECOVERY TANK......................................... 20

6. EMPTYING THE SOLUTION TANK.......................................... 20

7. CLEANING THE WATER SYSTEM FILTER ............................. 21

8. CLEANING THE VACUUM TUBE............................................. 21

21. EXTRAORDINARY MAINTENANCE WORK ................21

1. REPLACING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 21

2. REPLACING THE SQUEEGEE BODY RUBBER BLADES...... 21

3. REPLACING THE SIDE SPLASH GUARD

RUBBER BLADES ........................................................................ 21

22. ADJUSTMENT INTERVENTIONS.................................22

ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES ....... 22

23. DISPOSAL .....................................................................22

24. CHOOSING AND USING BRUSHES ............................22

25. TROUBLESHOOTING...................................................23

4

The following symbols are used to indicate any potentially hazardous situations. Always read this information carefully

and take the necessary precautions to protect any people and/or objects that may be present.

Operator cooperation is paramount for accident prevention. No accident prevention programme can be eective

without the full cooperation of the person directly responsible for the machine's operation. Most accidents that occur

at the workplace, during work activities, or while in transit, are caused by the failure to respect the most basic safety

regulations. An attentive, careful operator is most eective guarantee against accidents and is fundamental in order

to implement any prevention programme.

DANGER: Indicates an imminent danger that could cause serious injury or death.

WARNING: Indicates a probable dangerous situation that could cause serious injury or death.

CAUTION: Indicates a probable dangerous situation that could cause minor injuries.

ATTENTION: Indicates a probable dangerous situation that could damage objects.

DANGER:

• If the battery charger power cable is damaged or broken, it should be replaced by the

manufacturer, by authorised service personnel or else by a qualied person, in order to protect

against hazards.

• The socket for the battery charger cable must have a prescribed earth connection.

• Keep sparks, ames, and incandescent materials at a safe distance from the batteries.

Explosive gases are emitted during normal use.

• highly explosive hydrogen gas is generated while charging the batteries. Keep the recovery

tank unit in a maintenance position during the entire battery recharging cycle, and only perform

the procedure in well-ventilated areas at a safe distance from any open ames.

• Before charging check that the electric cable that connects the battery charger to the batteries

is not damaged, and if it is damaged do not use it and contact technical assistance.

• Before starting to charge the batteries, check that there is no standing water or dampness in

the on-board battery charger socket.

• Before charging check that the electric cable that connects the battery charger to the mains is

not damaged, and if it is damaged do not use it and contact technical assistance.

• Do not disconnect the direct current cable of the battery charger from the socket of the machine

when the battery charger is operating. This is necessary in order to avoid electric arcs forming.

To disconnect the battery charger when it is charging, rst disconnect the alternating current

power cable.

WARNING:

• Do not use an incompatible battery charger since it could damage the batteries and potentially

cause a re.

• The batteries emit hydrogen gas. This gas can cause explosions or res. Keep a safe distance

from ames or sparks. keep the covers open when charging the batteries.

• Before using the battery charger, make sure that the frequency and the voltage values

indicated on the machine's data plate coincide with the network's values.

• Keep the battery charger's cable at a safe distance from any hot surfaces.

• Never smoke in the machine's vicinity while the batteries are charging.

• Carefully read the user manual of the battery charger that you want to use before starting the

charging operation.

1. GENERAL SAFETY REGULATIONS

1. RECHARGING THE BATTERIES

5

DANGER:

• In the event of danger, quickly press the emergency button in the electrical system panel near

the operator's seat.

• Never collect gases, explosive/inammable liquids or powders, nor acids and solvents! These

include gasoline, paint thinners and fuel oil (which, when mixed with the vacuum air, can form

explosive vapours or mixtures), and also non-diluted acids and solvents, acetones, aluminium

and magnesium powders. These substances may also corrode the materials used to construct

the machine.

• If the machine is used in dangerous areas (e.g. petrol stations), the relative safety standards

must be observed. It is forbidden to use the machine in environments with a potentially

explosive atmosphere.

WARNING:

• The machine can be used by children over the age of 8 and by people with limited physical,

sensorial or mental capacity, or people without experience or the required knowledge, as long

as they are supervised or have been instructed about safe machine use and the inherent

dangers. Children must not play with the machine. The cleaning and maintenance that should

be carried out by the user should not be done by unsupervised children.

• The machine must be exclusively used by authorised, trained personnel.

• Do not use the machine on surfaces with a slope greater than the one indicated on the serial

number plate.

• The machine is not suitable for cleaning rough or uneven oors. Do not use the machine on

slopes.

• In the event of a re, use a powder extinguisher. Do not use water.

• Adapt the speed to the adhesion conditions.

• In order to prevent the unauthorised use of the machine, the power supply must be

disconnected: switch the machine o using the main switch (by removing the key from the

block) and disconnect the battery's connector from the electrical system's connector.

• Do not use the machine if you do not have the requisite knowledge or authorisation.

• Do not use the machine if you have not read and understood the following user manual.

• Do not use the machine under the inuence of alcohol or drugs.

• Do not use the machine when using a mobile phone or other electronic devices.

• Do not use the machine if it is not working correctly.

• Do not use the machine in areas where there are inammable vapours or liquids or combustible

powders.

• Do not use the machine in areas that are too dark to see the controls or operate the machine

safely, unless the work lights or the front headlights are on.

• Do not use the machine in areas where there is a risk of falling objects, unless the machine is

equipped with an overhead guard (optional).

CAUTION:

• Children must be supervised to ensure they do not play with the machine.

• During the working of the machine, pay attention to other people and especially to children.

• The machine must only be powered with a voltage equal to that shown on the serial number

plate.

2. USING THE MACHINE

6

• Read the labels on the machine carefully. Do not cover them for any reason, and replace them

immediately if they become damaged.

• The machine must only be used and stored in an enclosed or covered environment.

• The machine must not be used or stored outdoors in damp conditions or directly exposed to

rain.

• The machine does not cause harmful vibrations.

• Use the machine only in the way described in this manual.

• Do not pick up anything that is burning or smouldering, like cigarettes, matches or glowing

embers.

• Reduce speed on slopes and dangerous corners.

• Reduce speed before making a turn.

• Keep all parts of your body inside when the machine is moving.

• Be careful when reversing.

• Do not transport passengers.

• Always follow the instructions for mixing, use and disposal on the containers of the chemical

substances.

ATTENTION:

• If the machine is to be used in the presence of other individuals, aside from the operator, the

beacon light must be utilized.

• Always take appropriate measures to protect any individuals and/or objects that may be

present while using this machine.

• Be careful to avoid collisions with shelving or scaolding, above all if there is a risk of objects

falling from heights.

• Do not place any liquid containers on the machine.

• The machine must only be used under temperature conditions ranging from 32 °F to +104 °F.

• When using detergents to clean the ooring, always follow the instructions and respect the

warnings indicated on the containers' labels.

• Always use appropriate gloves and protective equipment when handling the detergents used

to clean the oor.

• Do not use the machine as a means of transport.

• Avoid working with the brushes when the machine is standing still, so as not to damage the oor.

• In the event of a re, use a powder re extinguisher if possible, and avoid the use of water.

• Do not allow any objects to penetrate into the machine's openings. Do not use the machine is

the openings are obstructed.

• Keep the machine's openings free of any dust, lint, hairs, or any other foreign materials that

could reduce the airow.

• Do not remove or alter any labels axed to the machine.

• This machine has not been approved for use on public streets or roadways.

• Only use the brushes and pad holders that have been supplied with the machine or those

specied in the Use and Maintenance Manual. The use of other brushes or felt pads could

compromise the machine's safety conditions.

• Before starting to work check that there are no leaks.

• Before starting to work check that all the safety devices have been installed and are working

correctly.

• Before starting work check that the brakes and steering are working correctly.

• Before starting work adjust the seat and steering wheel, and also the seat belt if there is one.

7

WARNING:

• Always protect the machine against sunlight, rain, and other atmospheric agents, both while it is

stationary and while it is in function. Store the machine in a dry, sheltered place: this machine is only

designed for use under dry conditions, and must not be used or stored outdoors under humid conditions.

• Do not park the machine near combustible materials, powders, gases or liquids.

• Stop the machine on a at surface.

• Check that the electric brake is engaged, switch o the machine and remove the key from the

instrument panel, disconnect the battery connector from the electrical system connector.

• If the machine is left unattended, it must be protected from any accidental movements

ATTENTION:

• The machine must only be stored under temperature conditions ranging from 32 °F to

+104 °F. The humidity level must be between 30% and 95%.

3. DEACTIVATION OF THE MACHINE

DANGER:

• In order to avoid short-circuits when working in the vicinity of electrical components, do the

following: avoid the use of non-insulated tools; do not place or allow metallic objects to fall

upon the electrically powered components; remove any rings, watches and/or clothing with

metallic parts that might come into contact with the electrically powered components.

• do not work underneath the raised machine without adequate xed safety supports.

WARNING:

• Read all the relevant instructions carefully before performing any maintenance/repair

operations.

• If the machine does not work properly, check this is not caused by failure to carry out routine

maintenance. Otherwise, ask for intervention of the authorised technical assistance centre.

• Restore all electrical connections after any maintenance interventions.

CAUTION:

• When doing maintenance work, switch o the machine using the main switch. Remove the

key from the instrument panel and remove the battery connector from the electrical system

connector.

• Avoid contact with moving parts. Do not wear loose clothing or jewellery and tie long hair back.

• Block the wheels before lifting the machine.

• Lift the machine with equipment that can sustain the weight to be lifted.

ATTENTION:

• Never tamper with the machine's protection devices for any reason; always follow the supplied

routine maintenance instructions scrupulously.

• If the machine needs to be pushed for maintenance purposes (batteries absent; discharged

batteries; etc.), never exceed 2.49 mph.

• If any issues are encountered while using the machine, check to make sure that these are

4. MAINTENANCE

8

not due to a lack of proper maintenance. Otherwise, request the intervention of authorized

personnel or an Authorized service centre.

• If any parts need to be replaced, always request ORIGINAL spare parts from an authorized

Dealer or Retailer.

• In order to ensure the machine's safety and proper functionality, always have the scheduled

maintenance interventions (specied in the appropriate section of this Manual) performed by

authorized personnel or by an authorized Service Centre.

• Do not clean the machine with direct or pressurized jets of water, or with corrosive substances.

• If lead batteries (WET) have been installed on the machine, avoid tilting the machine beyond

30° with respect to the horizontal plane, as this could cause the highly corrosive liquid to leak

out of the batteries.

• Avoid contact with the battery acid.

• Keep all metal objects away from the batteries.

• Use a non-conductive device for removing the battery.

• Use a hoist and suitable equipment when lifting the batteries.

• The battery must be installed by qualied personnel.

• Always observe the safety measures of the site regarding removing the battery.

• Remove the batteries if the machine needs to be tilted in order to perform maintenance

procedures.

• Have the machine checked by an authorised technical assistance centre every year.

• When disposing of consumable materials, observe the laws and regulations in force. Once

the machine has reached the end of its service life, the materials contained within it must be

disposed of in an appropriate manner, keeping in mind that the machine itself has been built

using fully recyclable materials.

• Do not push or tow the machine without an operator on the seat who can control the machine.

• Do not wash the machine with pressurised water or wet the machine near electrical components.

• All repairs must be carried out by qualied personnel.

• Do not physically change the design characteristics of the machine.

• Use spare parts supplied by Hillyard or by Hillyard service centres.

• Wear personal protective equipment as required and as suggested in the manual.

WARNING:

• Drain both tanks before transport.

• Bring both the squeegee and the brushes to a working position before securing the machine

to the transport vehicle.

• Use a ramp, a truck or a trailer that can support the weight of the machine and the operator.

• To place the machine on the transport vehicle use a pulley. Do not drive the machine on or o

a truck or trailer.

• The ramp for placing the machine on the transport vehicle should have such a slope that the

machine does not get damaged.

• Check that the electric brake is correctly engaged after loading the machine onto the transport

vehicle.

ATTENTION:

• The machine must only be stored under temperature conditions ranging from 32 °F to

+104 °F. The humidity level must be between 30% and 95%.

5. TRANSPORT

9

Warning symbol:

Carefully read the sections preceded by this symbol meticulously following the

instructions indicated for the safety of the operator and the device.

Covered place symbol:

The operations preceded by this symbol must always be carried out in a dry, covered

area.

Danger symbol (moving carriages):

Indicates that the packed product should be handled with suitable carriages that

conform to legal requirements.

Disposal symbol:

Carefully read the sections marked with this symbol for disposing of the appliance.

Recycling symbol:

Tells the operator to carry out the operations in compliance with environmental

regulations in force in the place where the appliance is being used.

Symbol of the open book with i:

Indicates the need to consult the instruction manual.

The descriptions contained in this document are not binding. The company therefore reserves the

right to make any modications at any time to elements, details, or accessory supply, as considered

necessary for reasons of improvement or manufacturing/commercial requirements. The reproduction,

even partial, of the text and drawings contained in this document is prohibited by law.

The company reserves the right to make any technical and/or supply modications. The images

are shown as reference only and are not binding as to the actual design and/or equipment.

Symbol of the open book:

Tells the operator to read the user manual before using the device.

Symbol indicating the compulsory use of protective gloves:

Indicates that the operator should always wear protective gloves, to avoid the risk of

serious injury to his hands from sharp objects.

Mandatory room ventilation symbol:

Informs the operator that the room must be ventilated while the batteries are being

recharged.

Symbol indicating a treading ban:

Informs the operator that it is forbidden to tread on machine components, as this could

lead to serious injury.

Danger symbol (corrosive substances):

The operator should always wear protective gloves to avoid the risk of serious injury to

the hands caused by corrosive substances.

Danger symbol (battery acid leakage):

Indicates the danger of leaking acid or acid fumes from the batteries while they are

being recharged.

2. SYMBOLS USED IN THE MANUAL

Information symbol:

Indicates additional information for the operator, to improve the use of the device.

3. PURPOSE AND CONTENT OF THE MANUAL

4. TARGET GROUP

5. STORING THE USE AND MAINTENANCE MANUAL

6. ON CONSIGNMENT OF THE MACHINE

The aim of this manual is to provide customers with all the information needed to use the machine

in the safest, most appropriate and most autonomous way. This includes information concerning

technical aspects, safety, operation, downtime, maintenance, spare parts and scrapping. The operators

and qualied technicians must carefully read the instructions in this manual before carrying out any

operations on the machine. If in doubt about the correct interpretation of instructions, contact your

nearest Customer Service Centre to obtain the necessary clarications.

This manual is written both for operators and for qualied machine maintenance technicians. Operators

must not perform operations that should be carried out by qualied technicians. The manufacturer is not

liable for damages resulting from failure to comply with this veto.

The Use and Maintenance Manual must be stored in its special pouch close to the machine, protected

from liquids and anything else that could compromise its legibility.

When the machine is consigned to the customer, an immediate check must be performed to ensure all

the material mentioned in the shipping documents has been received, and also to check the machine

has not suered damage during transportation. If this is the case, the carrier must ascertain the extent

of the damage at once, informing our customer service oce. It is only by prompt action of this type that

the missing material can be obtained, and compensation for damage successfully claimed.

8. IDENTIFICATION DATA

For technical assistance or to request replacement parts, always give the model, the version and the

serial number (written on the relevant plate).

9. TECHNICAL DESCRIPTION

10. INTENDED USE

11. SAFETY

The TRIDENT R30 SC is a oor scrubbing machine that can work on various types of oor and dirt

thanks to the mechanical action of two or three brushes and the chemical action of a water-detergent

solution. As it advances, it collects the dirt removed, along with the detergent solution not absorbed by

the ooring itself. The machine must only be used for this purpose.

This scrubbing machine was designed and built for the cleaning (scrubbing and drying) of smooth,

compact ooring in the commercial, residential and industrial sectors by a qualied operator in proven

safety conditions. The scrubbing machine is not suitable for cleaning rugs or carpet oors. It is only

suitable for use in closed (or at least covered) places.

ATTENTION: the machine is not suitable for use in the rain, or under water jets.

IT IS FORBIDDEN to use the machine for picking up dangerous dusts or inammable liquids in

places with an explosive atmosphere. In addition, it is not suitable as a means of transport for

people or objects.

Operator cooperation is paramount for accident prevention. No accident prevention programme can

be eective without the full cooperation of the person directly responsible for machine operation. The

majority of occupational accidents that happen either in the workplace or whilst moving are caused by

failure to respect the most basic safety rules. An attentive, careful operator is most eective guarantee

against accidents and is fundamental in order to implement any prevention programme.

7. INTRODUCTORY COMMENT

Any oor scrubbing machine can only work properly and eectively if used correctly and kept in full

working order by performing the maintenance operations described in the attached documentation. We

therefore suggest you read this instruction booklet carefully and read it again whenever diculties arise

while using the machine. If necessary, remember that our assistance service (organised in collaboration

with our dealers) is always available for advice or direct intervention.

12. SERIAL NUMBER PLATE

The serial number plate is located at the rear of the steering column, and indicates the machine's

general characteristics, including its serial number. The serial number is a very important piece of

information and should always be provided together with any request for assistance or to purchase

spare parts.

10

13. TECHNICAL DATA

Remarks:

(1) Machine weight: refers to the overall weight of the machine, without the batteries or the

operator on board, and with both tanks empty.

(2) Machine weight during transport: refers to the overall weight of the machine with the batteries

on board, without the operator on board, and with both tanks empty.

(3) Machine weight during work operations: refers to the overall machine weight with the batteries

inserted, the solution tank full, the detergent canister full (valid for HDC versions), the recovery

tank empty, and the operator on board (theoretical weight 154 lb).

(4) Lateral brush associated with the scrubbing brush head.

(5) Lateral brush associated with the sweeping brush head.

11

TECHNICAL DATA US

cu

TRIDENT

R30 SC

Rated machine power W 2025

Working capacity up to sq.ft/h 43056

Working width in 29,7

Squeegee width in 30,7

Central brush head brushes (number -Ø external bristles) No. / in 2 - Ø15.75

Rpm of the individual brush on the central brush head rpm 140

Central brush head motor (voltage - nominal power rating) V / W 24 - 500

Down pressure on central brush head lb up to 220

Traction motor (voltage / rated power) V / W 24 - 600

Traction wheel (external Ø / width) in Ø11,8 - 3,3

Maximum slope during ascent and descent with the transport

programme (weight(3))% 14

Maximum slope during ascent and descent with the transport

programme (weight(2) + operator) % 18

Maximum slope during ascent and descent with the working

programme (weight(3))% 7

Maximum ambient temperature for machine operation °F 104

Minimum temperature for using the machine's scrubbing

functions °F 32

Front wheel (external Ø - width) in Ø 8,9 - 2,4

TECHNICAL DATA US

cu

TRIDENT

R30 SC

Maximum forward speed in transport mode mph 5

Vacuum motor (voltage - nominal power rating) V / W 24 - 424

Vacuum on vacuum head psi 1,71

Maximum solution tank capacity gal 28

Maximum recovery tank capacity gal 25

Turning radius in 38,35

Machine dimensions (length - width - height) in 62,6 - 31,5 - 49

Battery compartment dimensions (width - length - useful height) in 20,7 - 15 - 11,8

Recommended battery n° - V /

AhC5

4 - 6 / 200

Machine weight(1) lb 606

Machine weight during transport(2) lb 890

Machine weight during work operations(3) lb 1300

Maximum battery weight (recommended) lb 71

Sound pressure level (ISO 11201) - LpA dB (A) 63

Uncertainty KpA dB (A) 1.5

Hand vibration level (ISO 5349) m/s2<2,5

Body vibration level (ISO 2631) m/s2<0,5

Vibration measurement uncertainty 1,5%

Label for optional tank cleaning kit command:

Applied near the steering column to indicate the command button for

the optional tank cleaning kit.

Acoustic signalling device control label:

Applied in the vicinity of the steering column to indicate the acoustic

signalling device's control button.

Label for detergent solution adjustment selector (optional on HDC

versions):

Applied near the steering column to indicate the detergent solution

adjustment selector button.

Detergent solution recycle control button (FLR versions):

Applied in the vicinity of the steering column to indicate the detergent

solution recycle control button.

14. SYMBOLS USED ON THE MACHINE

Symbol of maximum temperature for lling the solution tank:

Applied to the left-hand side of the machine's solution tank to indicate

the maximum temperature of the water that can be used to safely ll

the solution tank.

Filter body position symbol:

Applied to the left-hand side of the machine to indicate the position of

the solution tank lter.

Main switch symbol:

Applied to the control panel, positioned on the front of the machine, to

indicate the main switch.

Label for detergent solution tap command:

Applied in the vicinity of the control column to identify the detergent

solution tap control lever.

Extra pressure activation/deactivation lever position symbol:

Applied to the central brush head's extra pressure activation/

deactivation lever.

Reverse gear activation/deactivation lever position symbol:

Applied to the reverse gear activation/deactivation lever.

Treading ban label:

Located on the machine, to identify the surfaces that must not be

trodden on (risk of personal injury or damage to the machine).

Label indicating the need to read the Use and Maintenance

Manual:

Applied in the vicinity of the steering column in order to remind the

operator to read the user and maintenance manual before using the

machine.

Label warning about the risk of crushed hands:

Indicates danger to hands due to crushing between two surfaces.

Recovery tank drainage hose symbol:

Applied to the back of the machine to identify the recovery tank's

drainage hose.

Solution tank drainage cap symbol:

Applied to the back of the machine to identify the solution tank's

drainage cap.

Warning label (versions with built-in battery charger):

Axed to the machine in order to warn the operator to read the user

and maintenance manual (this document) before using the machine

for the rst time. It also contains a summary of the procedures to be

applied in order to properly charge the batteries.

Label showing the permitted pH range for the detergent used

(optional HDC system):

Applied above the detergent tank cap to indicate the pH range allowed.

Warning label for the use of the water system (optional HDC

system):

Warns the operator of the need to read the Use and Maintenance

manual before using the machine with the automatic detergent solution

measuring system.

Label showing the percentage of use of the detergents (optional

HDC system):

Applied near the detergent tank to indicate the instructions for using

standard or concentrated detergents.

Warning label (versions with built-in battery charger):

Applied to the machine to remind the operator of the applicable

procedures for properly caring for the machine itself.

Solution tank lter daily care warning label:

Applied to the machine to remind the operator to clean the solution tank

after each use.

Warning label (versions without built-in battery charger):

Axed to the machine in order to warn the operator to read the user

and maintenance manual (this document) before using the machine

for the rst time. Also indicates the applicable procedures for properly

caring for the machine itself.

Brush head body working position symbol:

Applied to the steering column to indicate the brush head control lever

direction of rotation for bringing the brushes to their working position.

Brush head body standby position symbol:

Applied to the steering column to indicate the brush head control lever

direction of rotation for bringing the brushes to their standby position.

Squeegee body working position symbol:

Applied to the steering column to indicate the squeegee control lever

direction of rotation for bringing the squeegee to its working position.

Squeegee body standby position symbol:

Applied to the steering column to indicate the squeegee control lever

direction of rotation for bringing the squeegee to its standby position.

Battery connection symbol:

Applied beneath the recovery tank to indicate how to connect the 6V or

12V batteries in order to obtain a total voltage of 24V.

Vacuum motor lter label:

Applied inside the vacuum cover to identify the vacuum motor intake

air lter, and also serves to remind the operator to clean the lter after

each machine use.

Maximum gradient symbol:

Used on the machine serial number plate, to indicate the maximum

gradient that can be safely handled in working mode.

15. SYMBOLS USED ON THE SERIAL NUMBER PLATE

12

P

R

ATTENZIONE: il sistema di dosaggio è particolarmente indicato per pulizia di

manutenzione frequente.

E’ possibile utilizzare detergenti di manutenzione acidi o alcalini con valori di pH

compresitra 4 e 10 e che non contengano: agenti ossidanti, cloro o bromo, formaldeide,

solventi minerali.

I detergenti utilizzati devono essere idonei per impiego con lavasciuga.

Se il sistema non viene utilizzato quotidianamente, a fine lavoro lavare il circuito con

acqua. Il sistema è escludibile. In caso di utilizzo saltuario di detergenti con pH

compreso tra 1-3 o 11-14 utilizzare la lavasciuga nella modalità tradizionale

aggiungendo il detergente nel serbatoio acqua pulita ed escludendo il circuito di

dosaggio.

WARNING: the dosing system has been specially designed for frequent maintenance

cleaning.

It is possible to use acid and alkaline maintenance detergents with pH values within 4

and 10 and that do not contain: oxidant agents, chlorine or bromine, formaldehyde,

mineral solvents.

Detergents used must be suitable for scrubbing machines.

If the system is not daily used, wash the circuit with water at the end of work. The

system can be cut out. In case of occasional use of detergents with pH within 1-3 or

11-14,use the scrubbing machine in the traditional way adding the detergent in the

clean water tank and cutting out the dosing circuit.

+

Detergente standard

Standard detergent

0,5%

1%

1,5%

2%

2,5%

3%

3,5%

Detergente concentrato

Concentrated detergent

0,1%

0,2%

0,3%

0,4%

0,5%

0,6%

0,7%

MODALITÀ D’USO:

Versare direttamente il detergente nel

serbatoio da 15 litri in dotazione.

Selezionare, tramite il selettore sul

cruscotto, la % diluizione detergente

desiderata tra i valori indicati nella

tabella.

INSTRUCTIONS:

Pour directly the detergent into the 15

liter tank.

Select with the knob on the instrument

panel the dilution % you need among

the values indicated in the table.

MODALITÀ D’USO:

Versare3 litri di detergente concentrato

e riempire completamente di acqua il

serbatoio da 15 litri in dotazione.

Selezionare, tramite il selettore sul

cruscotto, la % diluizione detergente

desiderata tra i valori indicati nella

tabella.

INSTRUCTIONS:

Pour 3 liter concentrated detergent and

fill completely the equipped 15 liter

tank with water.

Select with the knob on the instrument

panel the dilution % you need among

the values indicated in the table.

X%

16. MACHINE PREPARATION

1. HANDLING THE PACKAGED MACHINE

The machine's overall weight including packaging is 685lb.

NOTE: it is recommended that all the packaging components be kept for any future machine

transportation.

DANGER: Move the packaged product with handling equipment that complies with legal

requirements regarding size and mass of the packaging.

2. HOW TO UNPACK THE MACHINE

The machine is shipped in specic packaging. To remove it, proceed as follows:

1. Place the lower part of the outer packaging in contact with the oor.

NOTE: use the pictograms printed on the box as a reference.

2. Remove the outer package.

WARNING: the machine is contained in specic packaging materials, whose elements (plastic

bags, staples, etc.) can pose potential hazards, and must not be left within reach of children,

disabled persons, etc.

3. Remove the boxes containing the disc brushes and squeegee body from the machine.

CAUTION: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

4. Insert a ramp in the rear part of the machine.

ATTENTION: the ramp gradient must not be such as to cause damage to the machine as it

comes down.

5. The machine is xed to the pallet with wedges (1) that block the wheels (Fig.1). Remove these

wedges.

6. Check to make sure that the main switch on the control panel has been set to its “0” position. If

this is not the case, turn the key (2) a quarter turn to the left (Fig.2). Remove the key from the

main switch.

7. Grip the handle (3) and raise the recovery tank to the maintenance position (Fig.3).

8. Connect the backup battery carriage's connector to the machine's main system connector

(Fig.4).

9. Grip the handle (3) and lower the recovery tank to its working position (Fig.5).

10. Sit on the driver’s seat.

11. Insert the key (1) into the main switch on the control panel. Set the main machine switch to its "I"

position, by turning the key a quarter turn to the right (Fig.6).

12. Turn the brush head control level (4) anti-clockwise (Fig.7); in this manner the brush head body

will be raised o the pallet.

13. Turn the squeegee control lever (5) clockwise (Fig.8) to raise the squeegee body o the pallet.

14. Engage the reverse gear using the reverse gear activation/deactivation lever (6) (Fig.9).

3. HOW TO MOVE THE MACHINE

To transport the machine safely, proceed as follows:

DANGER: before starting any task, make sure the current regulations concerning the safe

transport of dangerous substances are scrupulously observed.

1. Check to make sure that the solution tank and the recovery tank are empty. If this is not the case,

empty them (see the sections titled “EMPTYING THE SOLUTION TANK” and “EMPTYING THE

RECOVERY TANK”).

2. Sit on the driver’s seat.

3. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn to the right (Fig.1).

4. Turn the brush head control lever (2) anti-clockwise (Fig.2); in this manner the brush head body

will be raised o the oor.

5. Turn the squeegee control lever (3) clockwise (Fig.3) to raise the squeegee body o the oor.

6. Press the drive pedal (4) (Fig.4) to begin moving the machine.

7. Use a ramp to move the machine up onto the transport vehicle.

CAUTION: during this operation, check there are no people or objects near the machine.

NOTE: the ramp gradient must not be such as to cause damage to the machine as it goes up.

8. Position the machine on the means of transport, and set the main switch to its “0” position by

turning the key (1) a quarter turn anti-clockwise (Fig.5). Remove the key from the main switch.

9. Get o the machine.

10. Grip the handle (5) and raise the recovery tank to its maintenance position (Fig.6).

15. Press the drive pedal (7) (Fig.10) to begin moving the machine.

16. Drive the machine down the ramp.

ATTENTION: during this operation, check there are no people or objects near the machine.

17. Bring the main switch to its "0" position by turning the key (1) a quarter turn anti-clockwise

(Fig.2). Remove the key from the main switch.

18. Get o the machine.

19. Grip the handle (2) and raise the recovery tank to its maintenance position (Fig.3).

20. Disconnect the backup battery carriage's connector from the machine's main system connector

(Fig.4).

21. Grip the handle (4) and lower the recovery tank to its working position (Fig.5).

11. Disconnect the battery connector from the machine's main system connector (Fig.7).

12. Grip the handle (5) and lower the recovery tank to its working position (Fig.8).

WARNING: secure the device according to the directives in force in the country of use, so that

it cannot slide or tip over.

13

3

4

1

1

3

2

2

6

1

53

0

0

ON

ON

7 8

4

5

96

10

7

32 2

3

4

4

65

7 8 5

2

2

2

1

A55,91in

B40,31in

C69,29in

4. SECURING THE MACHINE

The procedure for securing the machine, thus allowing the operations to be performed under conditions

of complete safety, is as follows:

1. Make sure the solution tank is empty. If this is not the case, empty it (read "EMPTYING THE

SOLUTION TANK").

2. Make sure the recovery tank is empty. If this is not the case, empty it (read "EMPTYING THE

RECOVERY TANK").

3. Bring the main switch to its "0" position by turning the key (1) a quarter turn anti-clockwise (Fig.1).

Remove the key from the instrument panel.

4. Get o the machine.

5. Grip the handle (2) and raise the recovery tank to the maintenance position (Fig.2).

6. Disconnect the battery connector from the machine's main system connector (Fig.3).

7. Grip the handle (2) and turn the recovery tank to its working position (Fig.4).

5. TYPE OF BATTERY TO BE USED

Power to the machine must be supplied by four sealed traction batteries with gas recombination or

gel technology.

The batteries must meet the requirements laid out in the norms: CEI EN 60254-1:2005-12 (CEI 21-5)

+ CEI EN 60254-2:2008-06 (CEI 21-7). To ensure good results, you are advised to use four 6V MFP

210 Ah/C5batteries.

6. BATTERY MAINTENANCE AND DISPOSAL

For battery maintenance and recharging, respect the instructions provided by the battery manufacturer.

When the batteries reach the end of their service life, they must be disconnected by specialized and

properly trained personnel, and must be subsequently removed from the battery compartment using

suitable lifting devices.

NOTE: dead batteries are classied as dangerous waste and as such must be delivered to an

authorised body for disposal.

7. INSERTING THE BATTERIES INTO THE MACHINE

The batteries must be housed in the special compartment beneath the recovery tank and should be

handled using lifting equipment that is suitable in terms of both weight and its coupling system.

DANGER: make sure that you comply with the accident prevention regulations in force in the

country where you work or with DIN EN 50272-3 and DIN EN 50110-1, before any handling of

the batteries.

CAUTION: to prevent an accidental short circuit use insulated tools to connect the batteries, and

do not place or drop metal objects on the battery. Remove rings, watches and any clothing with

metal parts that may come into contact with the battery terminals.

The various phases for inserting the batteries in the battery compartment are as follows:

1. Make sure the machine is in a safe condition (read “SECURING THE MACHINE”).

2. Move to the left hand side of the machine and open the left lateral carter (1) (Fig.1).

3. Check to make sure that the electronic brake is engaged, and turn the lever on the rear left portion

of the machine (2) clockwise (Fig.2). Close the left lateral carter (1).

4. Grip the handle (3) and raise the recovery tank to the maintenance position (Fig.3).

NOTE: for battery maintenance and daily recharging, you must fully respect the indications

provided by the manufacturer or retailer.

CAUTION: all installation and maintenance operations must be carried out by specialised

personnel.

NOTE: before installing the battery, clean the battery compartment. Check that the connectors

on the cables supplied are functioning correctly.

ATTENTION: check that the characteristics of the battery that you are looking to use are

appropriate for the type of work to be performed. Check the battery charge and the condition of

the contacts on the battery.

NOTE: you are advised to only lift and move the batteries with lifting and transportation means

suitable for the specic weight and size

CAUTION: the lifting hooks must not damage the blocks, connectors or cables.

NOTE: before inserting the batteries, remember to cover the terminals with a little grease to

protect them against external corrosion.

5. House the batteries in the compartment, positioning the poles “+” and “-“ opposite each other.

8. CONNECTING BATTERIES TO THE SYSTEM OF THE APPLIANCE

The batteries should be connected so as to obtain a

total voltage of 24V.

ATTENTION: it is recommended that all installation

and maintenance operations be carried out by

expert personnel, trained at the specialised

assistance centre.

CAUTION: to prevent an accidental short circuit

use insulated tools to connect the batteries, and do

not place or drop metal objects on the battery.

Remove rings, watches and any clothing with

metal parts that may come into contact with the

battery terminals.

The various phases for inserting the batteries in the battery compartment are as follows:

1. Using the supplied jumper cable (1), connect the batteries to the "+" and "-" poles in sequence.

2. Connect the batteries' connector cable (2) to the “+” and “-“ poles to obtain a voltage of 24V at the

terminals.

3. Connect the electric system connector (3) to the battery connector (2).

9. RECHARGING THE BATTERIES

The batteries must be charged prior to rst use, and whenever they no longer provide sucient power.

ATTENTION: to avoid any permanent damage to the batteries, it is essential to avoid their

complete discharge; begin recharging them within a few minutes of noting the "discharged

batteries" signal.

ATTENTION: never leave the batteries completely discharged, even if the device is not being

used.

1. Bring the appliance to the zone where the batteries are charged.

2. Make sure the machine is in a safe condition (read “SECURING THE MACHINE”).

ATTENTION: park the machine in an enclosed place, on a at and level surface; near the

machine there must be no objects that could either damage it, or be damaged through contact

with it.

ATTENTION: the room used to recharge the batteries must be adequately ventilated to prevent

the accumulation of gases that leak from batteries.

3. Grip the handle (1) and raise the recovery tank to its maintenance position (Fig.1).

To recharge the batteries without the built-in battery charger, proceed as follows:

A. Disconnect the electrical system's connector (2) from the battery connector (3) (Fig.2).

ATTENTION: the following operations must be carried out by qualied personnel. An incorrect

connection of the connector may cause a malfunction of the device.

B. Connect the external battery charger cable to the battery connector.

NOTE: the coupling connector of the battery charger is consigned inside the bag containing this

instruction booklet, and must be assembled on the cables of the battery charger as indicated in

the instructions.

ATTENTION: before connecting the batteries to the battery charger, make sure it is suitable for

the batteries used.

NOTE: carefully read the use and maintenance instructions of the battery charger that is used

for charging.

CAUTION: keep the recovery tank open for the duration of the battery recharging cycle to allow

gas fumes to escape.

C. Once the recharge cycle has been completed, disconnect the battery charger's cable from the

battery connector.

D. Connect the electrical system's connector (2) to the battery connector (3) (Fig.2).

E. Grip the handle (1) and turn the recovery tank to its working position (Fig.3).

To recharge the batteries with the on-board battery charger proceed as follows:

ATTENTION: the following operations must be carried out by qualied personnel. An incorrect

connection of the connector may cause a malfunction of the device.

NOTE: carefully read the use and maintenance instructions of the battery charger that is used

for charging.

14

2

0

3

4

22

2

21 3 3

2

1

3

2

1

2

3

2

1131

1

I. Remove the cap (4) from the battery charger socket (Fig.4).

CAUTION: before connecting the batteries to the battery charger, make sure it is suitable for

the batteries used.

WARNING: Before inserting the battery charger's power cable into the socket (5), make sure

that no condensate or other types of liquid are present (Fig.5).

NOTE: the battery charger power cable is delivered inside the bag containing this instruction

booklet.

II. Connect the battery charger's power cable to the socket on the battery charger itself.

III. Plug the battery charger cable into the mains socket.

CAUTION: keep the recovery tank open for the duration of the battery recharging cycle to

allow gas fumes to escape.

IV. When the recharge cycle is complete, disconnect the battery charger cable from the mains.

V. Disconnect the battery charger's power cable from the socket on the battery charger itself.

VI. Apply the cap (4) to the battery charger's socket (Fig.4).

VII. Grip the handle (1) and turn the recovery tank to its working position (Fig.6).

10. ASSEMBLING THE BRUSH HEAD BRUSHES (SCRUBBING VERSION)

To assemble the brushes to bush head body, which for reasons of packaging are supplied dismantled

from the machine, proceed as follows:

1. Sit on the driver’s seat.

2. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn to the right (Fig.1).

3. Turn the brush head control lever (2) anti-clockwise (Fig.2); in this manner the brush head body

will be raised o the oor.

4. As soon as the brush head body has arrived in its resting position, perform the procedure for

securing the machine (see the section titled “SECURING THE MACHINE”).

CAUTION: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

5. Move to the left hand side of the machine and open the left lateral carter (3) (Fig.3).

6. Remove the side splash guard support (4) by loosening the knobs (5) on it (Fig.4).

7. With the brush head UP, insert the brush in the plate housing underneath the brush head, turning it

until the three buttons engage with the niches on the plate itself.

8. Turn in increments until the button is pushed towards the coupling spring and is locked in place

(Fig.5).

NOTE: as soon as you have tted the left-hand brush, go to the right side of the machine and

repeat the procedure for the right-hand brush. Image 4 indicates the direction of rotation for

coupling the left brush; the right brush must be turned in the opposite direction.

11. ASSEMBLING THE SQUEEGEE BODY

For packaging reasons, the squeegee body comes disassembled from the machine. In order to mount

it on the squeegee support, do the following:

1. Sit on the driver’s seat.

2. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (Fig.1).

3. Turn the squeegee control lever (2) anti-clockwise (Fig.2) to raise the squeegee body o the oor.

4. Once the squeegee body has arrived in its resting position, perform the procedure for securing the

machine (see the section titled “SECURING THE MACHINE”).

CAUTION: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

5. Unscrew the knobs (3) present in the squeegee body's pre-assembly (Fig.3).

6. First, insert the left pin (4) on the squeegee body into the left slit (5) in the squeegee support (Fig.4),

so that the bushing adheres to the walls of the slit in the squeegee support.

7. Repeat the same operation for the right pin.

8. Insert the vacuum tube (6) into the sleeve (7) in the squeegee body (Fig.5).

NOTE: Although the squeegee comes pre-adjusted, it is nevertheless recommended to read the

section titled “ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES”.

12. FILLING THE SOLUTION TANK

Before lling the solution tank, carry out the following steps:

1. Take the machine to the usual place for lling the solution tank.

2. Perform the procedure for securing the machine (see the section titled “SECURING THE

MACHINE”).

3. Check to make sure that the solution tank drainage cap (1) is closed. If this is not the case, close

it (Fig.1).

4. Check to make sure that the water system's lter cap (2), located on the rear left-hand side of the

machine, is closed, and close it if necessary (Fig.2).

The solution tank can be lled with water in two dierent ways:

• Removing the cap/measuring device (3) and lling the solution tank by means of a rubber hose or

a bucket (Fig.3).

• Using the ller hose (4) (Fig.3), which supports the water hose on its own. In this case, be sure to

remove the cap/measuring device (3) in order to allow the air to vent properly.

5. Fill with clean water, at a temperature not higher than 122°F and not lower than 50°F. The amount

inside the tank can be seen by means of the level pipe on the front left of the seat.

12. DETERGENT SOLUTION

After lling the solution tank with clean water add the liquid detergent to the tank in the concentration

and manner indicated on the detergent manufacturer's label. To prevent the formation of an excessive

amount of foam that could damage the vacuum motor, use the minimum percentage of detergent

required.

CAUTION: protective gloves should always be worn before handling detergents or acidic or

alkaline solutions, to avoid serious injury to the hands.

ATTENTION: always use detergents whose manufacturer's label indicates their suitability for

scrubbing machines. Do not use acid or alkaline products or solvents without this indication.

ATTENTION: always use low-foam detergent. To avoid the production of foam, put a minimum

quantity of antifoam liquid in the recovery tank before starting to clean. Do not use pure acids.

ATTENTION: The ller cap can be used as measuring device for the detergent to be added to

the solution tank; the cap features moulded notches identifying the percentage of detergent,

ranging from a minimum of 0.1% to a maximum of 0.5%.

For versions with HDC, ll the solution tank with clean water and then proceed as follows:

1. Make sure the machine is in a safe condition (read “SECURING THE MACHINE”).

CAUTION: protective gloves should always be worn before handling detergents or acidic or

alkaline solutions, to avoid serious injury to the hands.

2. Remove the detergent tank cap (1) (Fig.1).

3. Fill the tank with the required detergent.

NOTE: there is a level indicator (2) in the rear left part of the detergent tank (Fig.1).

ATTENTION: always use detergents whose manufacturer's label indicates their suitability for

scrubbing machines. Do not use acid or alkaline products or solvents without this indication.

15

54

4 5

61

3

4 5

21

1

2

3

5

4

ON

3

4

2

5

1

12

7

6

3

5

4

ON

2 31

1 2

3

4

ATTENTION: the dosing system is suitable for frequent maintenance cleaning. Acid or alkaline

maintenance detergent tank be used with pH values between 4 and 10 and that do not contain:

oxidising agents, chlorine or bromine, formaldehyde, mineral solvents. The detergents used

must be suitable for use with scrubbing machines. Wash the circuit with water after use if the

system is not used daily. The system can be excluded. In case of sporadic use of detergents with

pH between 1-3 or 11-14, use the oor scrubbing machine in the traditional way by adding the

detergent in the clean water tank and excluding the dosing circuit.

ATTENTION: always use low-foam detergent. To avoid the production of foam, put a minimum

quantity of antifoam liquid in the recovery tank before starting to clean. Do not use pure acids.

4. Close the cap (1) correctly to prevent liquid leaking out when working (Fig.2).

Before beginning to work, it is necessary to:

1. Make sure the recovery tank is empty. If this is not the case, empty it (read “EMPTYING THE

RECOVERY TANK”).

2. Check that the amount of detergent solution present in the solution tank is sucient for the type

of work to be performed. If this is not the case, top up the solution tank (see the sections titled

“FILLING THE SOLUTION TANK” and “DETERGENT SOLUTION”).

3. Check that the squeegee rubbers are in good working condition. If not, carry out maintenance (see

“REPLACING THE SQUEEGEE BODY RUBBER BLADES”).

4. Check that the status of the brushes is suitable for the work to be performed. If this is not the case,

take appropriate measures to have them serviced.

5. Check that the main switch (1) on the control panel has been set to its “0” position (Fig.1). If this

is not the case, turn the key a quarter turn anti-clockwise. Remove the key from the instrument

panel.

6. Grip the handle (2) and raise the recovery tank to the maintenance position (Fig.2).

7. Connect the battery connector (3) to the machine's main system connector (4) (Fig.3).

8. Grip the handle (2) and lower the recovery tank to its working position.

9. Check that the electronic brake is engaged. If this is not the case, turn the lever (5) anti-clockwise.

The traction gearmotor is located on the rear left-hand side of the machine (Fig.4)

17. PREPARING TO WORK

18. WORK

1. SCRUBBING WITH DRYING

To carry out “SCRUBBING AND DRYING” tasks, proceed as follows:

1. Make all the checks listed in “PREPARING TO WORK”.

2. Sit on the driver’s seat.

3. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (Fig.1).

NOTE: As soon as the machine turns on, the control board will perform a diagnostics procedure,

during which the red LED indicator (2) on the control panel (Fig.2) will remain on.

NOTE: If the control board's diagnostics procedure returns a positive outcome, the red LED

indicator (2) on the control panel (Fig.2) will turn o, and an acoustic signal will sound indicating

that the work operations may be initiated.

4. Lower the brush head body by turning the brush head control lever (3) on the rear part of the

steering column (Fig.3).

5. Lower the squeegee body by turning the squeegee control lever (4) on the rear part of the steering

column (Fig.4).

6. Check to make sure that the detergent solution tap is completely open. If this is not the case, adjust

the lever (5) on the left-hand side of the steering column (Fig.5).

7. Press the drive pedal (6) (Fig.6) to begin moving the machine.

NOTE: Once the drive pedal is pressed, the brush head body and the squeegee body will begin

to descend into their working positions.

NOTE: Once the brush head body and the squeegee body have reached their working positions,

the relative motors will enter into function, and the solenoid valve will dispense the detergent

solution.

8. During the rst few meters, check that the detergent solution coming out is appropriate to the work

to be carried out; if not, adjust it after reading the section "ADJUSTING DETERGENT SOLUTION”.

The appliance will now begin to work with full eciency until the battery is at or until the detergent

solution has nished. During the rst few metres, check that there is sucient solution and that the

squeegee is drying correctly.

NOTE: If the drive pedal is released during the scrubbing/drying operation, the brush motor and

the solenoid valve will be deactivated, and the vacuum motor will continue to function for a few

seconds in order to ensure that all the liquid present in the vacuum hose is extracted.

NOTE: when lling the solution tank, it is good practice to empty the recovery tank using the

special drainage hose.

2. SCRUBBING WITHOUT DRYING

To carry out “SCRUBBING WITHOUT DRYING” tasks, proceed as follows:

1. Make all the checks listed in “PREPARING TO WORK”.

2. Sit on the driver’s seat.

3. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (Fig.1).

NOTE: As soon as the machine turns on, the control board will perform a diagnostics procedure,

during which the red LED indicator (2) on the control panel (Fig.2) will remain on.

NOTE: If the control board's diagnostics procedure returns a positive outcome, the red LED

indicator (2) on the control panel (Fig.2) will turn o, and an acoustic signal will sound indicating

that the work operations may be initiated.

4. Lower the brush head body by turning the brush head control lever (3) on the rear part of the

steering column (Fig.3).

5. Check to make sure that the detergent solution tap is completely open. If this is not the case, adjust

the lever (4) on the left-hand side of the steering column (Fig.4).

6. Press the drive pedal (5) (Fig.5) to begin moving the machine.

NOTE: Once the drive pedal has been pressed, the brush head body will begin to descend into

its working position.

NOTE: Once the brush head body has reached its working position, the brush gearmotors will

enter into function and the solenoid valve will begin to dispense the detergent solution.

7. During the rst few meters, check that the detergent solution coming out is appropriate to the work

to be carried out; if not, adjust it after reading the section "ADJUSTING DETERGENT SOLUTION”.

The appliance will now begin to work with full eciency until the battery is at or until the detergent

solution has nished. During the rst few metres, check that there is sucient solution.

NOTE: If the drive pedal is released during the scrubbing without drying operation, the brush

motor and the solenoid valve will be deactivated.

NOTE: when lling the solution tank, it is good practice to empty the recovery tank using the

special drainage hose.

16

1 2

2

1 1

1

1

1

1

1

1

223

4

3

0

ON

ON

4

2

2 3

2

3

4

4

6

6

2 3

2

3

5

4

5

4

5

5

3. DRYING

To carry out “DRYING WITHOUT SCRUBBING” tasks, proceed as follows:

1. Make all the checks listed in “PREPARING TO WORK”.

2. Sit on the driver’s seat.

3. Insert the key (1) into the main switch on the control panel. Bring the main switch to its "I" position

by turning the key (1) a quarter turn clockwise (Fig.1).

NOTE: As soon as the machine turns on, the control board will perform a diagnostics procedure,

during which the red LED indicator (2) on the control panel (Fig.2) will remain on.

NOTE: If the control board's diagnostics procedure returns a positive outcome, the red LED

indicator (2) on the control panel (Fig.2) will turn o, and an acoustic signal will sound indicating

that the work operations may be initiated.

4. Lower the squeegee body by turning the squeegee control lever (3) at the rear of the steering

column (Fig.3).

5. Press the drive pedal (4) (Fig.4) to begin moving the machine.

NOTE: Once the drive pedal has been pressed, the squeegee body will begin to descend into its

working position.

NOTE: Once the squeegee body has reached its working position, the vacuum motor will enter

into function.

The machine will now work at its maximum eciency level until the batteries run down.

NOTE: If the drive pedal is released during the drying operation, the vacuum motor will continue

to operate for a few seconds in order to ensure that all the liquid present in the vacuum hose is

extracted.

The drying without scrubbing operation should only be carried out if the

machine was previously used to carry out a scrubbing without drying

operation.

4. ADJUSTING THE DETERGENT SOLUTION (VERSIONS WITHOUT HDC)

To adjust the amount of detergent solution on the brush, proceed as follows:

1. Open the tap's output ow to maximum, and shift the knob on the left hand side of the steering

column (1) (Fig.1) upward.

2. When the drive pedal is pressed (2) (Fig.2), the brush gearmotors will enter into function and the

solenoid valve will distribute detergent solution to the brushes.

3. During the rst few metres, check to make sure that the quantity of solution is sucient to wet the

oor, but not so much as to come out of the splash guard. The detergent leakage can be adjusted

using the knob (1) on the steering column.

ATTENTION: When the knob (1) (Fig.1) is moved upwards, the amount of detergent solution

distributed to the brushes increases. When the knob (1) (Fig.3) is moved downwards, the

amount of detergent solution distributed to the brushes decreases.

5. AUTOMATIC DETERGENT MEASURING SYSTEM (HDC VERSION)

Upon request, the machine can be tted with a system that measures out the detergent separately from

the water in the solution tank.

To start it do as follows.

1. With the machine active, press the HDC system ON/OFF button (1) on the left-hand side of the

steering column (Fig.1).

2. Press the detergent solution adjustment button (2) to select the level you want to use for the task

in hand (Fig.2).

If you press the button (2) (Fig.2), the command display will show a code indicating the amount of

detergent in the machine water system (Fig.3). Press the button gradually to cyclically alter the amount

of detergent; there are four possible settings (from 0 to 3).

If the command display shows the code H2O 0, the machine doesn't dispense detergent (Fig.4).

This mode is used when the oor is already wet or in general when the chemical action of water and

detergent solution is not necessary.

With each press of the button (2), the amount of solution released into the machine water system will

increase by one level. Once the maximum level has been reached, a further press on the button will

return you to level 0 (no solution dispensed).

ATTENTION: Passing from one step to another is a continuous cycle - it is not possible to go

back except by continuing to the end of the scale and starting again from zero. If the machine is

switched o via the main switch, the ow of detergent will return to step -03.

ATTENTION: if this system is used, the water adjustment tap must always be at its maximum

setting (Fig.4).

6. REVERSE GEAR

This machine is equipped with electronic traction control. To reverse, proceed as follows:

1. Engage the “REVERSE GEAR ACTIVATION/DEACTIVATION” lever (1) underneath the steering

wheel (Fig.1).

2. Press the drive pedal (2) (Fig.2) to start the machine moving in reverse.

CAUTION: the reverse speed is lower than the forward speed to comply with current health and

safety standards.

NOTE: In order to disengage the reverse gear, disengage the lever (1) underneath the steering

wheel (Fig.1).

NOTE: Once the lever has been engaged (1), the acoustic signalling device will be activated in

order to signal that the machine's reverse gear has been engaged.

NOTE: If the reverse gear is engaged with the squeegee in its working position, once the drive

pedal is pressed, the machine will begin to move in reverse and the squeegee body will be

raised into its resting position.

NOTE: If the reverse gear is engaged with the brush head in its working position, once the drive

pedal is pressed, the machine will begin to move in reverse and the brush head will remain in its

working position, but the solenoid valve will stop dispensing detergent solution to the brushes.

7. EXTRA BRUSH HEAD PRESSURE

This machine is capable of increasing the pressure exerted upon the brushes during the work cycle.

This can be done in the following manner:

1. Check to make sure that the brush head body is in contact with the oor. If this is not the case, adjust

the brush head control lever (1) on the steering column (Fig.1).

2. Engage the “EXTRA-PRESSURE ACTIVATION/DEACTIVATION” lever (2) underneath the steering

wheel (Fig.2).

3. Press the drive pedal (3) (Fig.3) to initiate the machine's working cycle.

NOTE: Once the lever (2) (Fig.4)has been engaged, the red indicator light (4) on the steering

column will turn on to indicate that the extra-pressure function has been enabled.

8. ACOUSTIC SIGNALLING DEVICE

The machine is equipped with an acoustic signalling device. If an acoustic signal needs to be emitted,

simply press the button (1) on the control panel (Fig.1).

17

2 3

4

1

1

2

4

3

ON

3

21

4

1

1 1

1

1

1

1 2

3

2

21

1 2

2 3

4

1

1

2 3

4

1

1

9. WORKING HEADLIGHTS (OPTIONAL)

Upon request, the machine can be equipped with front and rear working lights.

These lights can be turned on by setting the main switch to its “I” position, or rather by turning the key

a quarter turn to the right (Fig.1).

10. EMERGENCY BUTTON

If any problems are encountered during the work operations, press the emergency button (1) on the

electrical system's cover carter (Fig.1).

CAUTION: This command interrupts the electrical circuit between the batteries and the machine

system.

NOTE: After having stopped and resolved the problem, the work operations can be resumed by

doing the following:

• Bring the main switch to its "0" position by turning the key (2) a quarter turn anti-clockwise

(Fig.2).

• Disengage the mushroom-head emergency button (1) (Fig.3).

• Bring the main switch to its "I" position by turning the key (2) a quarter turn clockwise (Fig.4).

12. BATTERY CHARGE LEVEL INDICATOR

The control panel is equipped with a control display.

The graphic symbol that identies the charge level of batteries appears at the bottom of the control

display.

The indicator consists of charge level symbols (2).

When the minimum remaining charge is reached, the graphic symbol (2) will start to blink, and will

turn o after a few seconds, after which the symbol (3) will start to blink. Under these conditions, the

machine must be brought to the battery charging area.

NOTE: A few seconds after the battery charge reaches the critical level (2), the brush gearmotors