hilmor LDHD250 Troubleshooting guide

Table of contents

Other hilmor Security Sensor manuals

Popular Security Sensor manuals by other brands

B.E.G. LUXOMAT

B.E.G. LUXOMAT PD4-M-HCL-FC Application description

Johnson Controls

Johnson Controls PG9200AX user manual

optrel

optrel weldCap quick start guide

Afriso EURO-INDEX

Afriso EURO-INDEX LAG-14 ER operating instructions

ABB

ABB Busch-Watchdog 70 MasterLINE operating instructions

Satel

Satel AQUA manual

Yates

Yates Y-530 user manual

Orbis

Orbis EBR-2 Instructions for use

Honeywell

Honeywell IntelliSense FG-1625RFM installation instructions

Summit Treestands

Summit Treestands SOP STS Series instructions

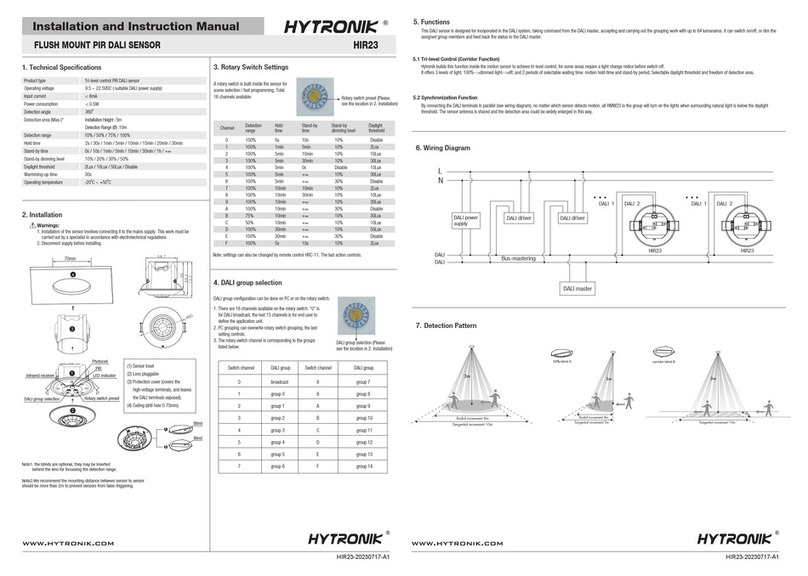

Hytronik

Hytronik HIR23 Installation and instruction manual

Datalogic

Datalogic S65-PA-5-M13 instruction manual

Halma

Halma BEA ACTIV8 THREE ON user guide

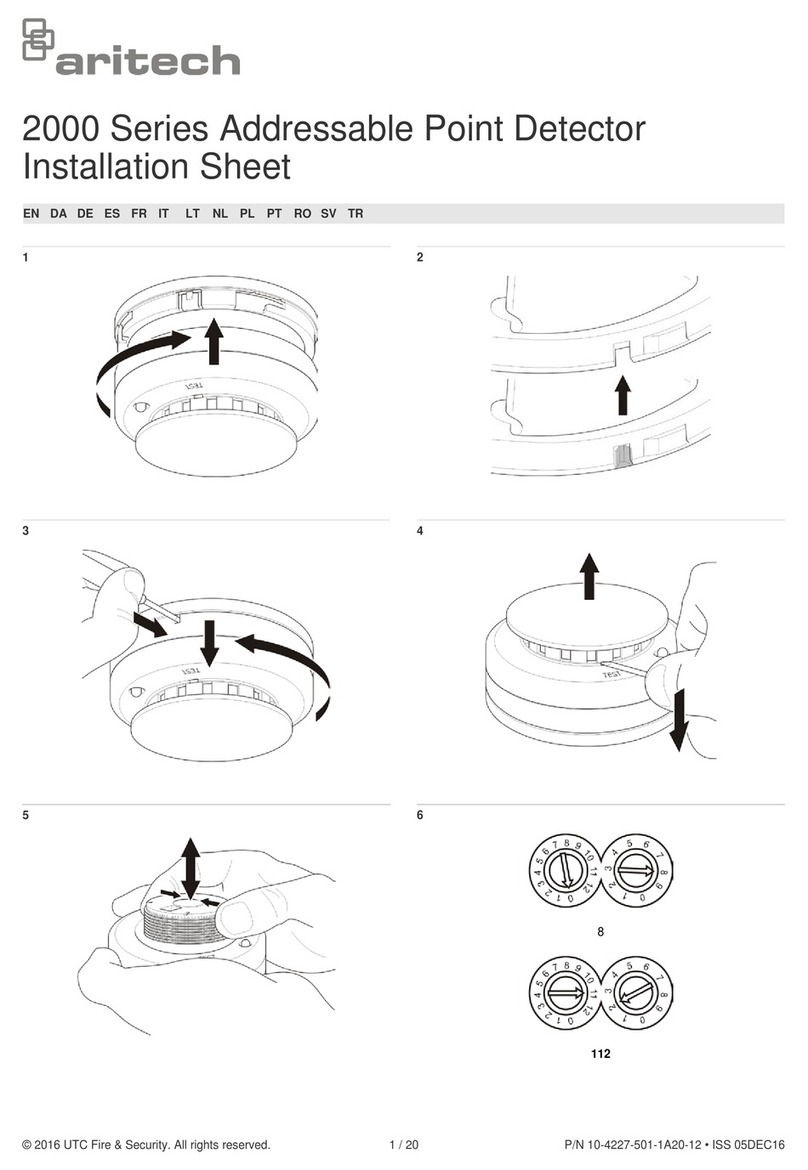

Aritech

Aritech 2000 Series Installation sheet

EMX Industries

EMX Industries IRB-MON2 instruction manual

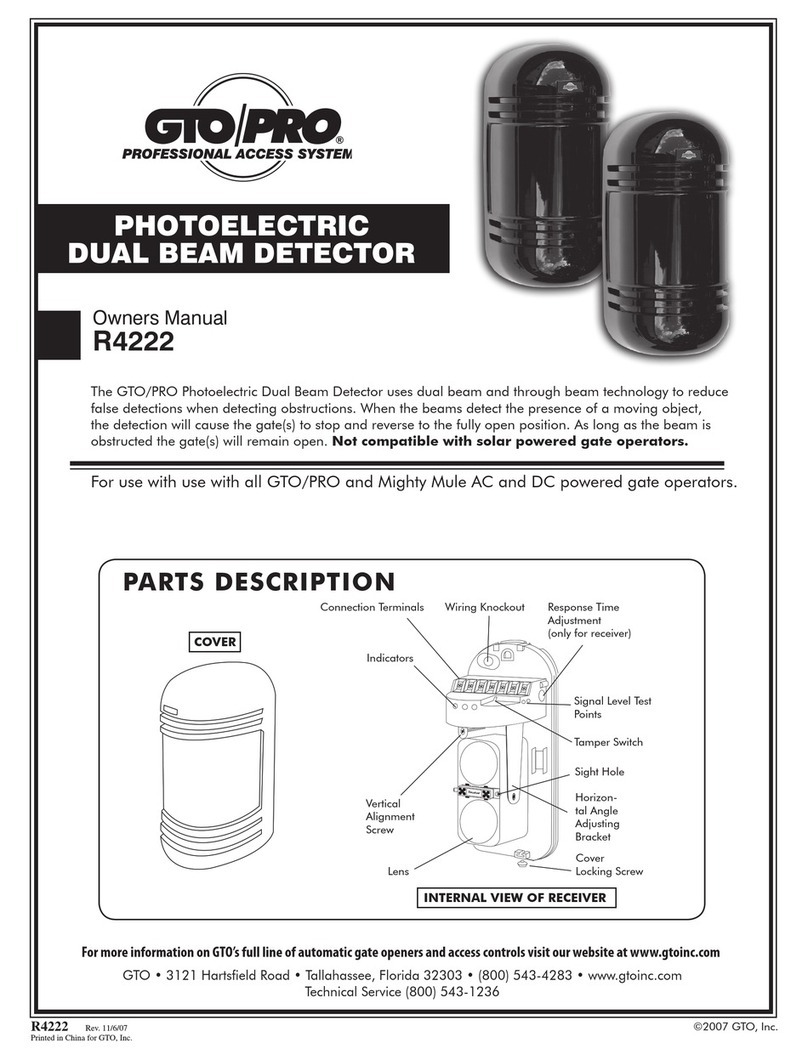

GTO

GTO R4222 owner's manual

Mustang Survival

Mustang Survival ELITE INFLATABLE PFD MD5153 owner's manual

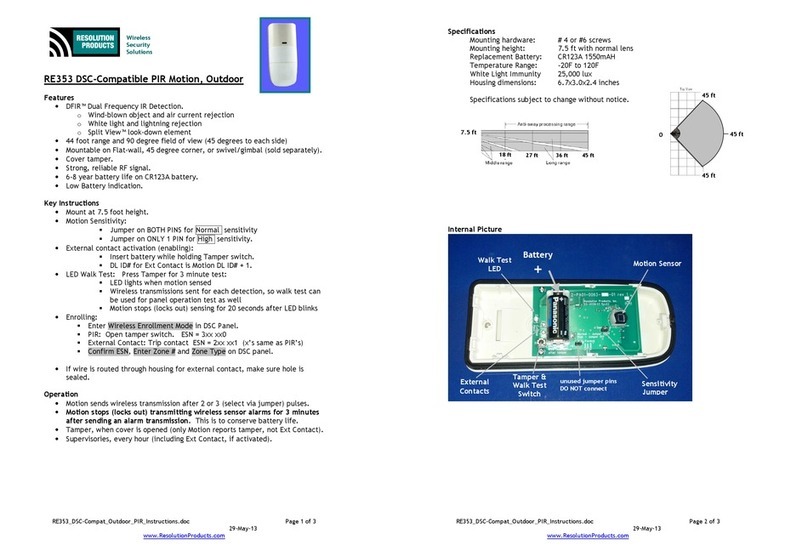

Resolution Products

Resolution Products RE353 instructions