hilmor LDIR150 Troubleshooting guide

Model

LDIR150

Infrared Refrigerant

Leak Detector

Operation and Maintenance Instructions

2

TABLE OF CONTENTS

Introduction ............................................................................................3

Key Features...........................................................................................4

Safety ...................................................................................................5-6

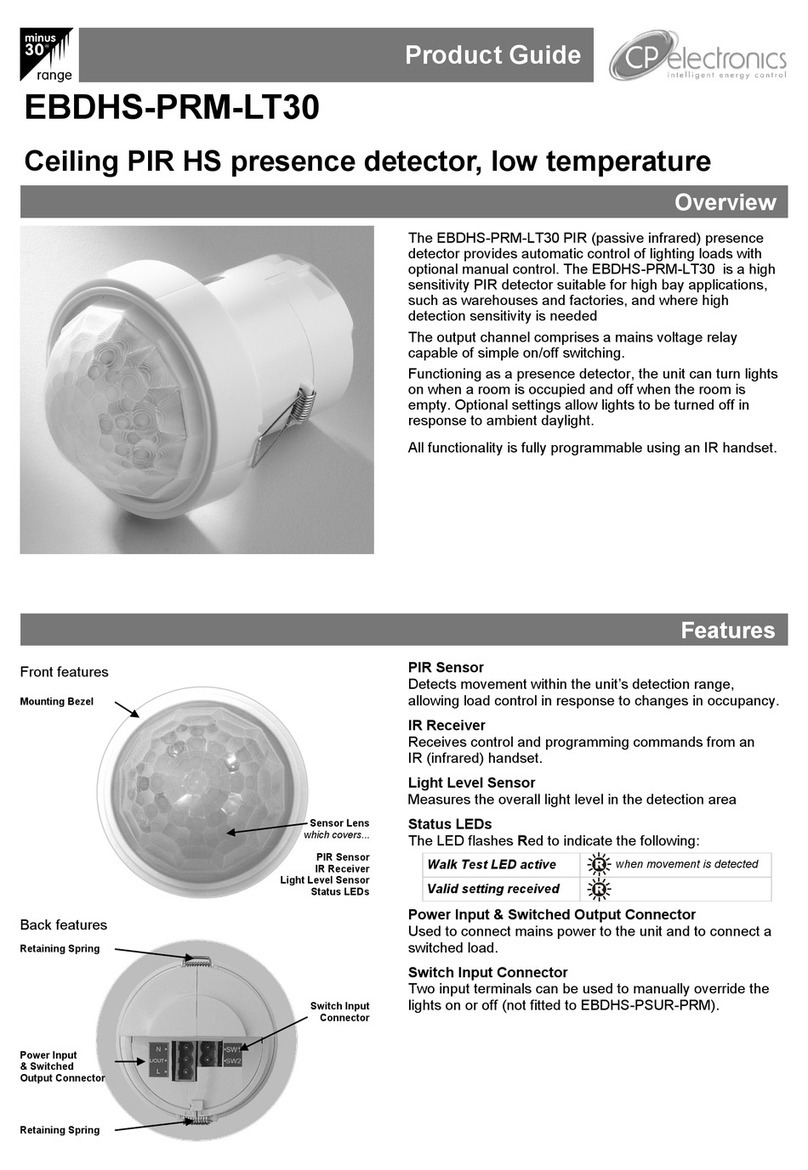

Leak Detector Components..............................................................7

Features ..............................................................................................8-9

Operating Instructions......................................................................10

Technical Specifications ................................................................... 11

3

INTRODUCTION

The hilmor Infrared Refrigerant Leak Detector is a hand-held leak detector

that uses the infrared detection method. Compared with the traditional

leak detector, its sensor has a longer life, higher detection accuracy,

greater ease of use, and detects a wider range of refrigerants. The LDIR150

is equipped with a large, easy to read TFT LCD screen.

WARNING

It is important to read the entire instruction manual carefully for a complete

understanding of the hilmor Infrared Refrigerant Leak Detector features,

limitations and specifications before use. hilmor products are designed

and manufactured to be used by trained and licensed technicians.

Incorrect use may result in accidents, injuries or death. Refer to page 5-6

for safety warnings.

4

KEY FEATURES

EXTRA CONFIDENCE

•Built to last with a 10-year sensor life.

EASY TO READ

•The TFT LCD screen provides a clear visual confirmation of the leak

location.

ADDED CONVENIENCE

•Audible and visual notification for leak detection.

ADDED VERSATILITY

• Works on all halogenated refrigerants.

5

SAFETY

SAFETY PRECAUTIONS

To prevent personal injury, please read the operating manual carefully and

operate only as instructed by following the guidelines listed below.

1. Wear safety glasses, gloves and all other recommended safety gear

when working with refrigerants. Contact with refrigerants may cause

injury. Please see any warnings associated with refrigerants.

2. Avoid the inhalation of refrigerant. High concentrations of refrigerants are

harmful to humans and can cause serious injury.

3. Do not allow probe to come in contact with electrically charged objects

or high voltage.

4. Before each use, make sure the filter is clean. Do not allow any liquids to

enter the probe tip; doing so will damage the unit.

SAFETY HAZARD WARNINGS FOR LITHIUM ION BATTERIES

Rechargeable Lithium Ion batteries are potentially hazardous and can

present a serious FIRE HAZARD if damaged, defective or improperly

used. Larger Lithium batteries and those used for industrial use involving

high discharge current and frequent full discharge cycles require special

precautions.

The LDIR150 has a built in rechargeable lithium battery, which is NOT

user replaceable, and should be charged ONLY with the provided LDIR150

charger.

A FIRE IS MOST LIKELY TO OCCUR DURING THE CHARGING PROCESS

UNDER THE FOLLOWING CIRCUMSTANCES:

• THE BATTERY HAS BEEN FULLY DISCHARGED AND IS NOT RECHARGED

SHORTLY AFTERWARD. This potential is aggravated if batteries are

damaged, contain an undetected factory defect, are used or stored at

temperature extremes, or are approaching the end of their useful life.

Ideally, batteries should be recharged within 24 hours of a full discharge.

• CHARGING IS ATTEMPTED AT TEMPERATURES BELOW 40°F (4°C) Charging

below 40°F (4°C), causes a chemical reaction in the battery cells that can

cause permanent damage and the possibility of fire or explosion during

charging.

6

SAFETY(CONT.)

•THE BATTERYHAS BEENEXPOSED TO LIQUIDS, ESPECIALLY SALTWATER.

Exposure to liquids can cause internal corrosion or damage to the cells or

to the Battery Management System (BMS). The BMS protects the battery

from overcharging, high self- discharge or imbalanced charging of the

cells, any of which can present the possibility of fire during recharging.

• OPERATING OR CHARGING A BATTERY THAT HAS BEEN DAMAGED FROM

DROPPING OR FROM SHIPPING DAMAGE.

• USING A CHARGER OTHER THAN SPECIFICALLY DESIGNATED FOR THE

PARTICULAR BATTERY. Lithium Ion battery chargers provide a specific

charging voltage and microprocessor current and voltage control. They

are fundamentally dierent than chargers for SLA, NiCd, NiMH, or other

rechargeable batteries. Chargers for LiNiMnCoO2 (NMC) batteries

(VML) and LiFePO4 batteries (VLX) are not interchangeable, and require

dierent charging voltages.

7

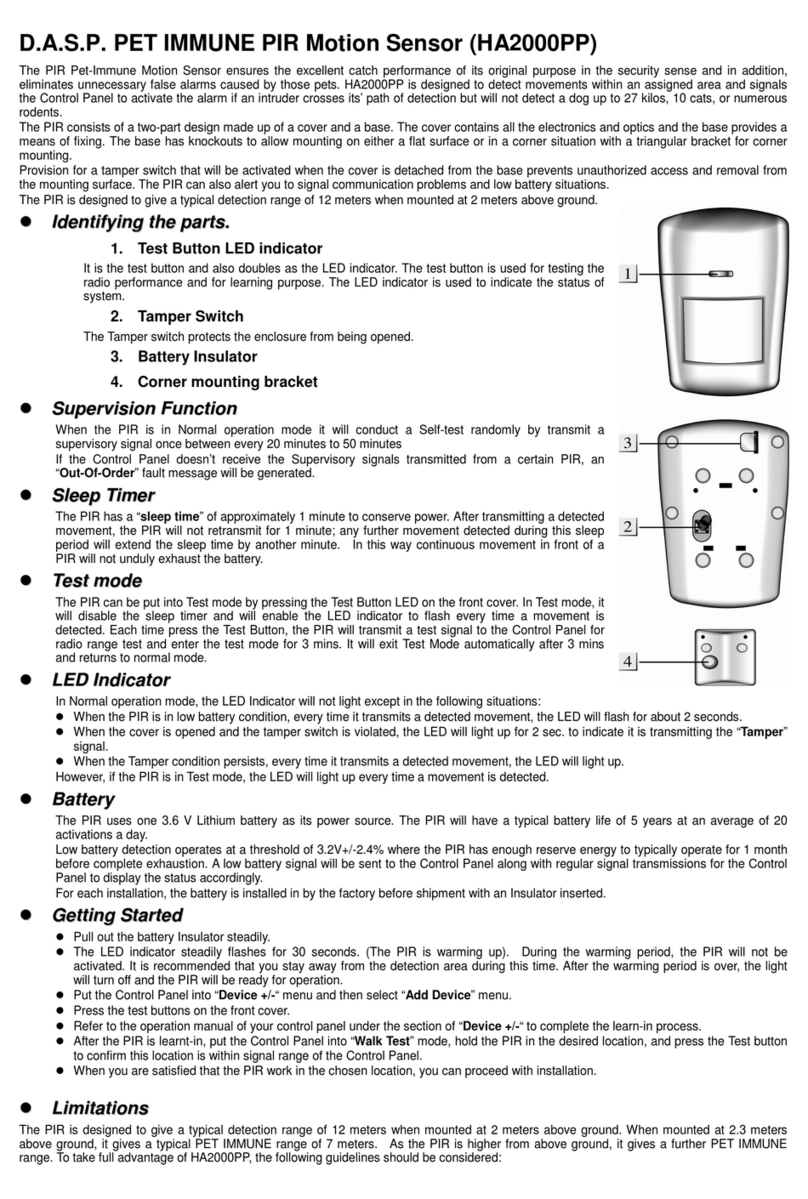

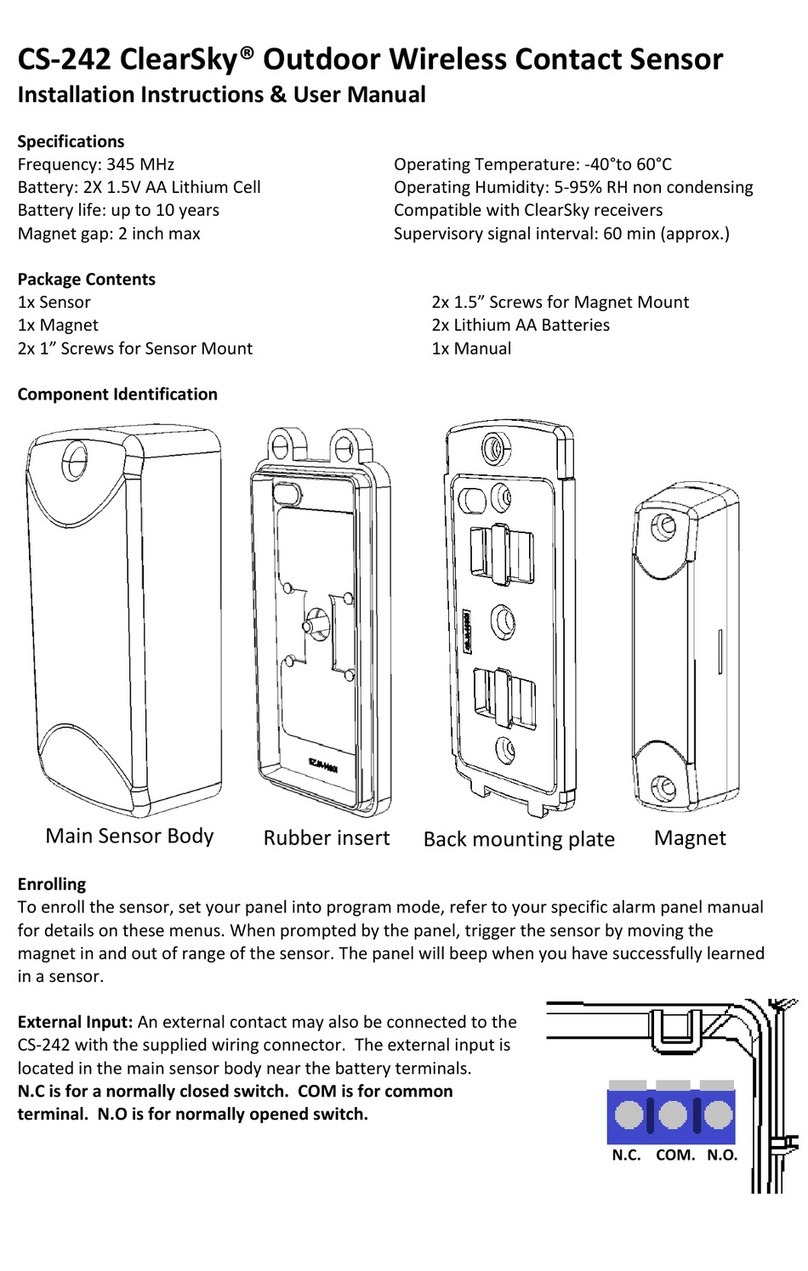

1

Flexible Probe

2

SENS (L, M, H) Button

3

RESET Button

4

Charging Port

5

Alarm Headphone Jack

6

Status Display Zone

7

PEAK Button

8

ON/OFF Button

9

MUTE Button

10

Charging Indicator Battery

11

Maximum Leak Record

14

Real Time Detection Indicator

12

Audio MUTE Indicator

15

Peak Function Status: When

displayed as ON above the

PEAK on the display, it is

active

13

Battery Voltage Indicator

16

Sensitivity Level Indicator

(FIG. 1)

(FIG. 2)

1

5

16

6

15

7

14

9

12

8

13

10

11

LEAK DETECTOR COMPONENTS

8

FEATURES

FUNCTIONS AND FEATURES

Please refer to FIG. 1 and FIG. 2 to familiarize yourself with the indicators

and keypad controls as you proceed through this section.

BATTERY VOLTAGE INDICATOR

The Battery Voltage Indicator shows battery level. 4 bars in the battery

icon indicate full battery; one bar indicates low battery.

SENSITIVITY ADJUSTMENT

The unit provides three levels of sensitivity adjustment. When the unit

is switched on, it is set to the lowest sensitivity position. To change the

sensitivity, press the SENS button; The LED screen will display the corre-

sponding sensitivity level: L for Low, M for Medium and H for High.

SENSOR STATUS INDICATOR

The unit automatically diagnoses and indicates the sensor’s status. When

switched on, the circuit automatically senses the condition of the sensor,

indicating a failed or missing sensor.

FAILED SENSOR INDICATION

If the circuit detects a failed or missing sensor,

(FIG. 3) is displayed and the leak detector will stop

working.

AUDIBLE / VISUAL ALARMS – MUTE FEATURE

The unit features two indications – an internal speaker audible alarm,

and TFT LCD display visual notification. When refrigerant is detected, the

detectors shows leakage level in bar chart form. Green indicates “no re-

frigerant detected / no leak”, and Red indicates detection of refrigerant

in high concentration. When the unit is switched on, the audible alarm is

activated by default. The audible alarm may be disabled by pressing the

MUTE button. Press the MUTE button again to allow audio as well as visu-

al notification. The audio notification may also be heard via headphones

plugged into the 3.5mm headphone jack.

(FIG. 3)

9

FEATURES (CONT.)

BATTERY CHARGING INSTRUCTIONS

1. Avoid completely discharging the battery to maximize its useful life.

2. The battery is partially charged when packaged. Fully charge the battery

before first use.

3. Only use the supplied charger and cable.

4. Never replace the battery and with proper care it will last the life of the

device (10 years).

5. Battery Charging Indicator displays red while charging, blue when

charging is complete.

BATTERY CARE

1. Do not expose the unit to temperatures higher than 140°F (60°C).

2. Do not charge the battery in or nearby heated places, such as fire, hot

vehicles, or direct sunlight.

3. Stop using the unit immediately if it emits an odor or shows signs of

damage or other abnormality.

4. Storage

a. The battery should have a 40%-50% charge during prolonged stor-

age of a month or longer.

b. Battery life is dramatically reduced if the battery is stored fullycharged

and/or at high temperatures.

5. Charging parameters: 5 VDC 1A

FILTER REPLACEMENT:

Warning: Turn the power o before replacing filter.

1. Unscrew probe tip.

2. Remove and discard old filter.

3. Insert new filter

4. Replace probe tip.

5. Replace filter whenever it becomes visibly dirty or every two to three

months depending on use.

BUTTON OPERATION

ON/OFF Press and hold for 2 seconds to turn the device “on”

and “o”.

RESET Reset sensitivity benchmark to improve stability and

sensitivity.

MUTE Press to toggle the audible alarm “on” and “o”.

SENS Press button to cycle through three levels of sensitivity,

low, medium, and high.

PEAK Press to turn peak function “on” and “o”. The maximum

value is cleared when turned o.

10

OPERATING INSTRUCTIONS

This unit detects relative concentrations of refrigerant, the sensor tip must

always be in motion. Keep the unit away from moisture and high voltages.

To detect leakage in a refrigeration system, the system must operate at a

minimum of 50 PSI. Environmental temperatures lower than 59°F (15°C)

may further reduce a system’s operating pressure, causing a leak to be-

come more dicult to detect. In such cases, “No Leak” may be falsely in-

dicated, requiring an alternate diagnostic means.

1. Turn on the unit by pressing and holding for 2 seconds and releasing the

ON/OFF button.

2. Ensure battery is suciently charged for operation by looking at the Bat-

tery Voltage Indicator. If not, please see Battery Charging Instructions.

3. The unit takes approximately 30 seconds to warm up and calibrate after

the ON/OFF button has been pressed. Keep the LDIR150 away from any

areas of potential refrigerant leakage until the warm-up and calibration

period is over. If there is an error, replace the filter. See Filter Replace-

ment on page 9 for instructions. To avoid false indications, allow the

LDIR150 to fully warm-up before using. The unit is actively reading when

the bar chart is displayed.

4. Press MUTE button to disable audible indication if desired, when audio

indication is enabled, a paced beep will be emitted.

5. After the unit has warmed up, select desired sensitivity by pressing the

SENS button.

6. Slowly move the probe (approximately 3”/sec or 75 mm/sec) at a dis-

tance of 0.25” (0.63 mm) from the suspected leak area. A closer probe

position and slower “sweep” will usually raise the probability of finding

leaks. Once the device indicates a change in concentration, note the

location and keep the tip moving past the potential leak to refresh the

air as this device measures changes in concentration and moving to

“cleaner” air will help detect leaks.

7. Return the tip back to, and past, the first location. When the device indi-

cates a second change, note that location. The source of the leak will be

near the midpoint between the two noted locations.

11

TECHNICAL SPECIFICATIONS

Sensor Type: Infrared Spectrum Absorbtion

Sensor Life: 10 Years (Typical)

Maximum Sensitivity: 4 grams/year

Response Time: ~3 seconds

Warm-Up Time: ~30 seconds

Operating Environment:

32°F (0°C) ~ 104°F (40°CF ) at < 75% RH (non-condensing)

Display Method: TFT LCD display

Notification Mode: TFT LCD display and audio

Battery: Built in rechargeable lithium battery: 3.7V, 3000mAh

Battery Saver: Automatic shutdown after 10 minutes of inactivity

Working Time: ~ 6 hours

Charging Time: ~ 4 hours

Certifications: SAE J1627, SAE J2791, SAE J2913, EN14624: 2012

Refrigerants Detected: It will detect all halogenated (including Chlorine of Fluorine)

refrigerants. This includes, but is not limited to:

CFC: R12, R11, R500, R503

HCFC: R22, R123, R124, R502

HFC: R134A, R404A, R410A, R407C

CH R600A

Weight: 14.6 oz. (415g)

Size: 7.9" x 3.3" x 1.5" (201 mm x 86 mm x 38 mm)

hilmor.com + 1-800-995-2222

©2019 hilmor

Table of contents

Other hilmor Security Sensor manuals

Popular Security Sensor manuals by other brands

Comelit

Comelit DT02CW Technical manual

Ecco

Ecco Reflex 7160 Series Installation and operation instructions

Kopp

Kopp 3238.0009.3 Operation manual

Guardian

Guardian 00235 instruction manual

Ecolink

Ecolink ClearSky CS-242 Installation instructions & user manual

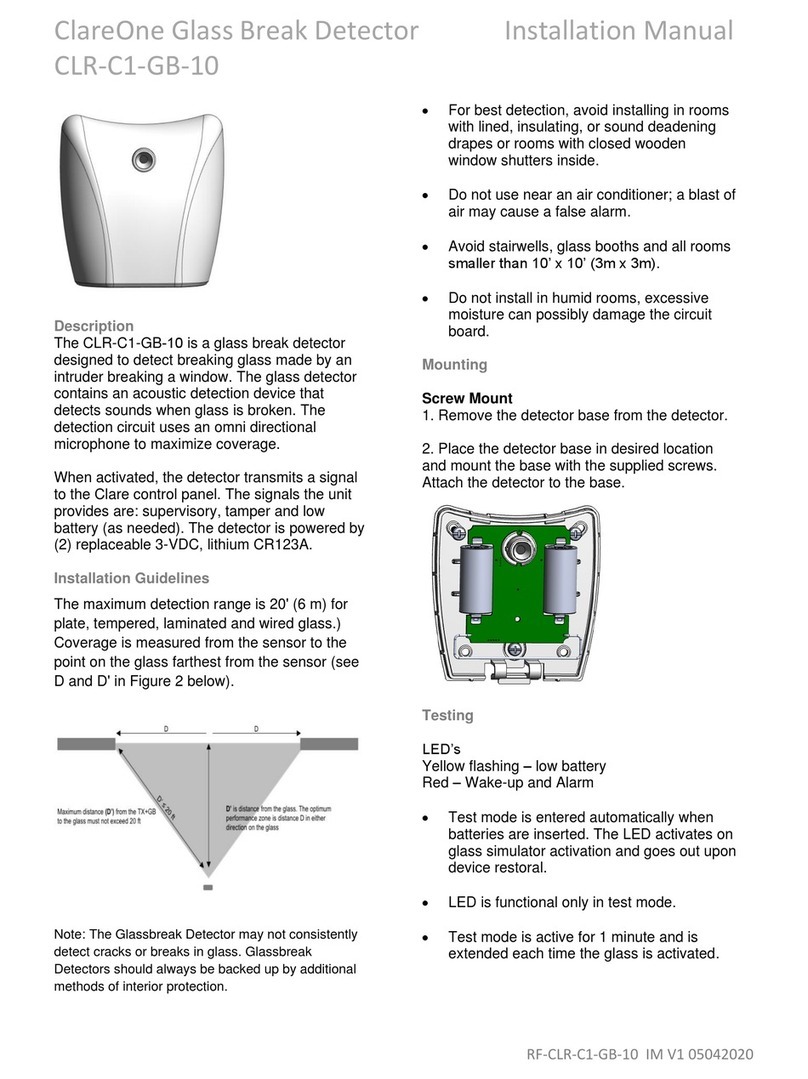

ClareOne

ClareOne CLR-C1-GB-10 installation manual