Afriso EURO-INDEX LAG-14 ER User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

74363 Güglingen

Telefon

+49 7135 102-0

Service

+49 7135-102-211

Telefax

+49 7135-102-147

www.afriso.com

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

07.2019.1

854 001 0153

Operating instructions

Leak detector

LAG-14 ER

0123

MVV TB C 2,

App. C 2.15.16

2 LAG-14 ER

Table of contents

1This instruction manual ............................................................................................. 4

1.1 Precautions .................................................................................................... 4

2Safety ......................................................................................................................... 5

2.1 Intended use................................................................................................... 5

2.2 Predictable incorrect application ................................................................... 5

2.3 Safe handling ................................................................................................. 6

2.4 Qualification of personnel .............................................................................. 6

2.5 Modifications to the product........................................................................... 7

2.6 Usage of spare parts and accessories.......................................................... 7

2.7 Liability information ........................................................................................ 7

3Product description.................................................................................................... 8

3.1 Application area ...........................................................................................10

3.2 Function........................................................................................................10

3.3 Operating modes ......................................................................................... 12

3.4 Application examples...................................................................................12

4Technical data .........................................................................................................14

4.1 Approvals, tests and conformities ...............................................................16

5Transport and storage.............................................................................................17

6Mounting and commissioning..................................................................................17

6.1 Calculation fundamentals ............................................................................17

6.2 Installing the container for the leak detection fluid......................................20

6.3 Minimum distance ........................................................................................21

6.4 Pipe installation ............................................................................................22

6.5 Mounting the test valve................................................................................24

6.6 Mounting the control unit ............................................................................. 24

6.7 Electrical connection....................................................................................26

6.8 Commissioning the product .........................................................................30

7Operation .................................................................................................................31

7.1 Alarm condition ............................................................................................ 31

7.2 Function test.................................................................................................32

8Maintenance ............................................................................................................33

8.1 Maintenance times.......................................................................................33

8.2 Maintenance activities .................................................................................33

9Troubleshooting....................................................................................................... 34

10 Decommissioning, disposal.....................................................................................34

11 Spare parts and accessories...................................................................................36

LAG-14 ER 3

12 Leak detection fluids for leak detector ....................................................................37

13 Warranty...................................................................................................................37

14 Copyright..................................................................................................................37

15 Customer satisfaction..............................................................................................37

16 Addresses ................................................................................................................37

17 Appendix ..................................................................................................................38

17.1 Certification of specialised company (according to applicable water

regulations)...................................................................................................38

17.2 Approval documents ....................................................................................39

17.3 EU Declaration of Conformity ......................................................................40

17.4 Declaration of Performance (DoP) ..............................................................41

17.5 CE Marking...................................................................................................42

This instruction manual

4 LAG-14 ER

1 This instruction manual

These operating instructions are part of the product.

Read this manual before using the product.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING

WORD

Type and

source of the hazard are shown here.

Precautions to take in order to avoid the hazard are shown here.

There are three different levels of warnings:

Warning word Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or severe injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or severe injuries.

NOTICE Failure to observe the information may result in

damage to property.

Safety

LAG-14 ER 5

2 Safety

2.1 Intended use

The leak detector LAG-14 is a leak detector for liquid-based systems

as per EN 13160-1, class II (EN 13160-3).

The LAG-14 ER leak detector may only be used to monitor double-

walled containers (tanks) as per chapter 3.1, page 10 containing leak

detection fluid in the interstitial space and used for the aboveground

storage of:

•Water-polluting liquids

•Flammable liquids with a flash point of > or ≤55 °C.

Since July 2003, the LAG-14 ER leak detector may only be used for

replacement deliveries for underground, double-walled tanks as a re-

sult of the reclassification of water-polluting liquids in Germany.

Leaks in the container (tank) are detected and signalled when the

level of the leak detection fluid falls.

Only black containers may be installed in hazardous areas (Ex).

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

2.2 Predictable incorrect application

The control unit must never be used in the following cases:

•Hazardous area (Ex)

If the product is operated in hazardous areas, sparks may cause

deflagrations, fires or explosions.

The intrinsically safe circuit and the corresponding probe may be op-

erated in hazardous areas (EX), zone 0, zone 1 and zone 2.

White containers must not be installed in hazardous areas (Ex).

Safety

6 LAG-14 ER

2.3 Safe handling

The leak detector LAG-14 ER represents state-of-the-art technology

and is made according to the pertinent safety regulations. Each prod-

uct is subjected to a function and safety test prior to shipping.

Operate the leak detector LAG-14 ER only when it is in perfect

condition. Always observe the operating instructions, all perti-

nent local and national directives and guidelines as well as the

applicable safety regulations and directives concerning the pre-

vention of accidents.

DANGER

Severe burns or death caused by mains voltage (AC

230 V,

50

Hz) in the control unit.

Do not expose the control unit to water.

Disconnect the mains voltage supply before opening the control

unit or before performing maintenance and cleaning work and

make sure it cannot be switched on.

Do not tamper with the control unit in any way whatsoever.

Observe the instructions in DIN EN 60079-10-1.

Malfunctions which may have an adverse effect on safety must

be immediately repaired.

2.4 Qualification of personnel

The product may only be mounted, commissioned, operated, main-

tained, decommissioned and disposed of by specially qualified com-

panies. These are specialised companies as per § 3 of the German

Ordinance on Installations for Handling Water-Polluting Substances

April 18, 2017 (German Federal Law Gazette (BGBI.) I p. 377).

These activities do not have to be performed by specialised compa-

nies if this obligation does not apply according to the applicable local

directives or if AFRISO performs these activities with AFRISO's own,

trained staff.

If handling tanks containing liquids with a flash point of ≤55° C, the

staff must also be knowledgeable in fire and explosion protection.

Electrical work may only be performed by trained electricians and in

compliance with all applicable local and national directives, regula-

tions and electrical code requirements.

Safety

LAG-14 ER 7

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine spare parts and accessories of the manufac-

turer (see chapter 11, page 36).

2.7 Liability information

The manufacturer shall not be liable in any form whatsoever for

direct or consequential damage resulting from failure to observe the

technical instructions, guidelines and recommendations.

The manufacturer or the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this product, in particular in case of improper use of the

product, misuse or malfunction of the connection, malfunction of the

product or of connected products. The manufacturer or the sales

company shall not be liable for any damage whatsoever resulting

from any use other than the use explicitly permitted in this instruction

manual.

The manufacturer shall not be liable for misprints.

Product description

8 LAG-14 ER

3 Product description

The leak detector consists of a control unit, a probe and a container

for leak detection fluid (black LAG container).

The control unit and the probe are connected by means of a two-wire

signal cable with a maximum length of 50 m.

The probe is plugged into the top of the black LAG container. In the

case of a leak in the interstitial space, the leak detection fluid level in

the black LAG container falls. The electrode rods of the probe are no

longer submerged in the leak detection fluid. The control unit detects

the change in resistance and generates an alarm.

Fig. 1: Container for leak detection fluid (black LAG container) with

probe

a

Liquid level

d

Housing part

B

Company and approval mark

e

Electrode rods

c

Signal cable

Product description

LAG-14 ER 9

Probe

The probe consists of two metallic electrode rods which are installed

at a specific distance from each other.

The two electrode rods are contained in a housing with a diameter of

34 mm which also holds the probe in the black LAG container. The

probe is equipped with a two-wire signal cable, length 1 m.

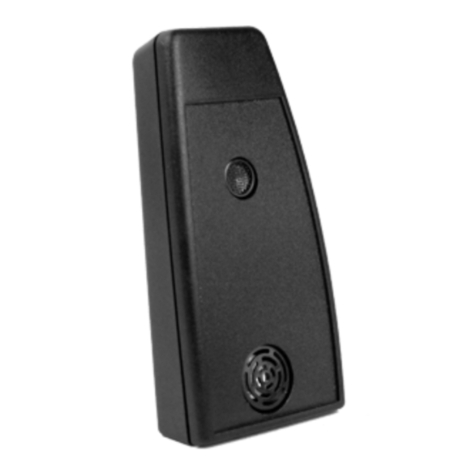

Control unit

The control unit SE2 contains the following elements in an impact-

resistant plastic housing: display elements and controls as well as all

electronic components for signal processing and conversion of the

probe signal into a digital output signal.

The output signal is available as a voltage-free relay contact.

a

Green pilot lamp

B

Test button

c

Red alarm lamp

d Acknowledge

button

e Without function

Fig. 2: Control unit

Product description

10 LAG-14 ER

3.1 Application area

Tanks

Only the following tanks are approved: double-walled containers

(tanks) which are operated under atmospheric conditions and which

comply with the standards DIN 6616 type A, DIN 6623-2, DIN 6624-

2, EN 12285-2 (type D) and EN 12285-1 (type D) or which have an

approval that the interstitial space is suitable for connection of a liq-

uid-based leak detection system.

The interstitial space volume of the system must not exceed 1 m³.

Stored liquids

Only the following liquids are approved:

•Water-polluting liquids.

•Flammable liquids with a flash point of > or ≤55 °C.

Approved storage media

If the containers (tanks) are operated under atmospheric conditions

and depending on the design of the containers (tanks), water-pollut-

ing liquids with the following densities may be stored in the contain-

ers (tanks):

•Tanks as per DIN 6616 type A, DIN 6623-2 and DIN 6624-2

≤2.5 m Ø permissible density ≤1.90 g/cm³

≤2.9 m Ø permissible density ≤1.85 g/cm³

CAUTION

Danger of reaction of leak detection fluid and stored liquid if un-

suitable leak detection fluid is used.

The leak detection fluid and the stored liquid may not react.

Proven compatibility is required.

Observe the information on the intended use in chapter 2.1,

page 5.

3.2 Function

The LAG-14 ER leak detector monitors the interstitial space of dou-

ble-walled tanks filled with leak detection fluid. In the case of a leak

in the inner or outer wall of the container (tank), above or below the

levels of the stored liquid or the ground water, the leak detection fluid

escapes. This causes the level of the leak detection fluid to fall. The

electrode rods of the probe are no longer submerged in the leak de-

tection fluid. The control unit detects the change in resistance, gener-

ates visual and audible alarms and actuates the output relay.

Product description

LAG-14 ER 11

Probe

The black LAG container is installed above the interstitial space. The

bottom side of the black LAG container is connected to the top of the

interstitial space via a hose. This way, the black LAG container is the

top part of the interstitial space. The interstitial space is filled with

leak detection fluid to the middle of the black LAG container. The

probe is installed from the top of the black LAG container so that the

electrode tips are covered by the leak detection fluid. Both electrodes

are connected to the control unit by a two-wire cable.

Control unit

The control unit continuously monitors the electrical resistance be-

tween the two electrodes of the probe. The green pilot lamp lights up

when the device is ready for operation. If the probe resistance is less

than 5 kΩ, there is no alarm condition: The red alarm lamp is off, the

relay is:

•De-energised (in the operating mode Eco)

•Energised (in the operating mode FailSafe)

If the resistance is greater than 5 kΩ, an alarm condition, i.e. a leak

has been detected by the control unit: The red alarm lamp and the

audible alarm are on and the relay is:

•Energised (in the operating mode Eco)

•De-energised (in the operating mode FailSafe)

The audible alarm can be muted with the "Acknowledge" button in

the case of an alarm.

No alarm is triggered in case of a power outage. When mains voltage

is restored, the product immediately resumes operation. If a leak has

occurred in the meantime, this is signalled.

The green pilot lamp lights up as soon as the leak detector is sup-

plied with mains voltage. The Test button allows you to simulate an

alarm condition in order to perform a function test.

Product description

12 LAG-14 ER

3.3 Operating modes

Eco:

The LAG-14 ER leak detector is equipped with an output relay to

transmit the alarm signal to additional external devices. If no error

condition is present, the relay is de-energised; in case of an alarm,

the relay is energised.

FailSafe:

The LAG-14 ER leak detector is equipped with an output relay to

transmit the alarm signal to additional external devices. If no error

condition is present, the relay is -energised; in case of an alarm, the

relay is de-energised.

The leak detector LAG-14 ER can be operated with or without addi-

tional external devices. External devices include units for audible and

visual alarm signal or remote alarm devices, building control sys-

tems, etc.

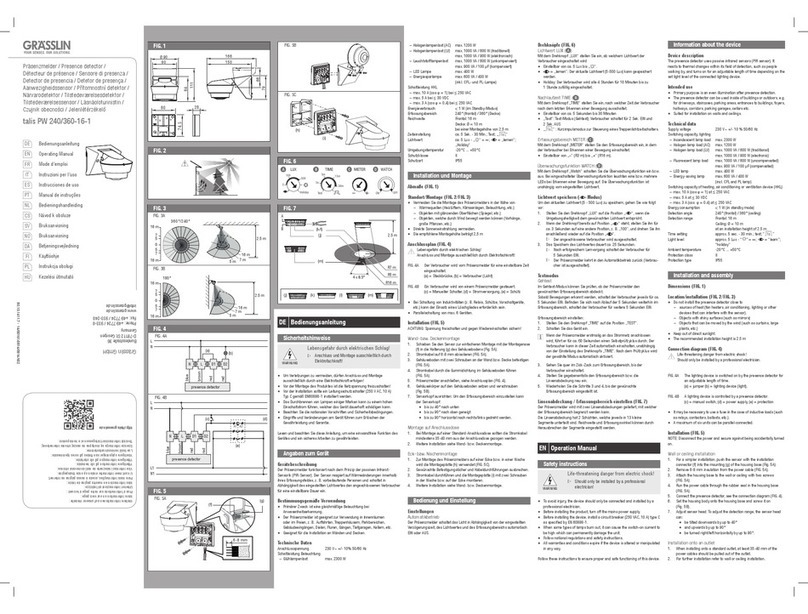

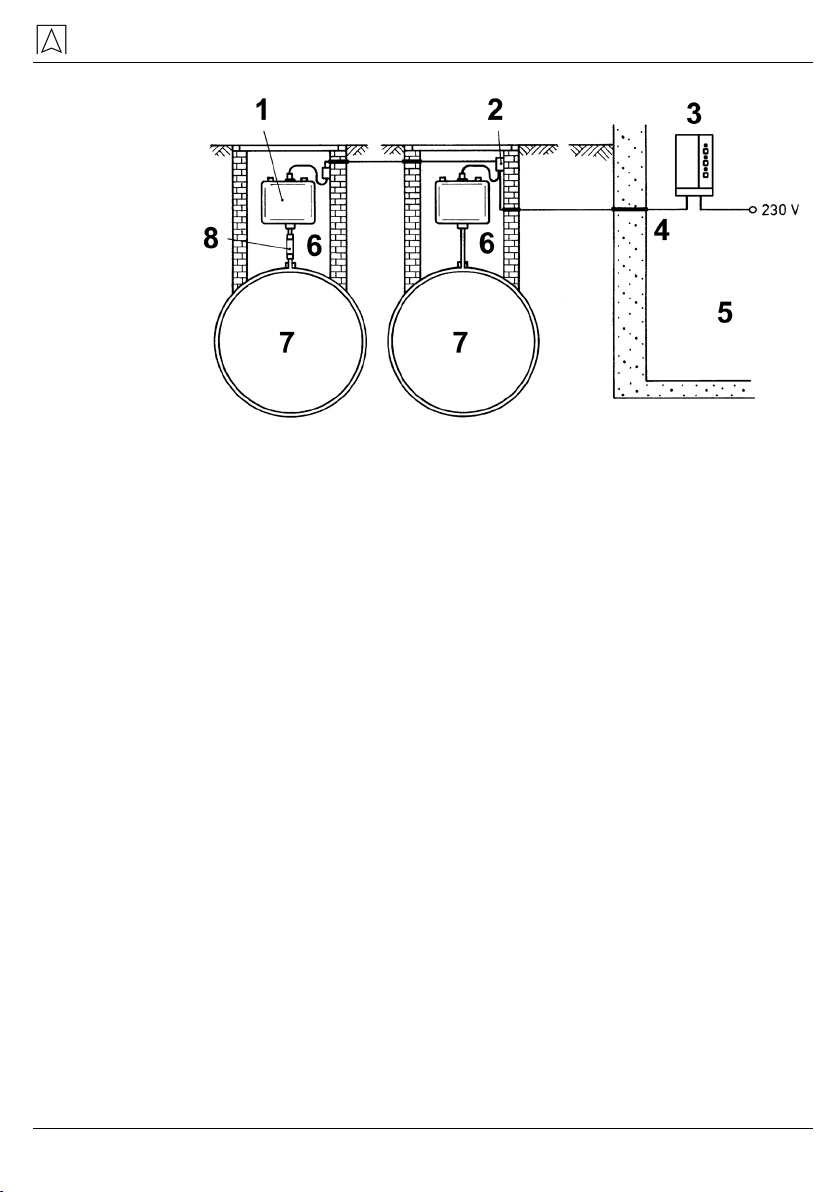

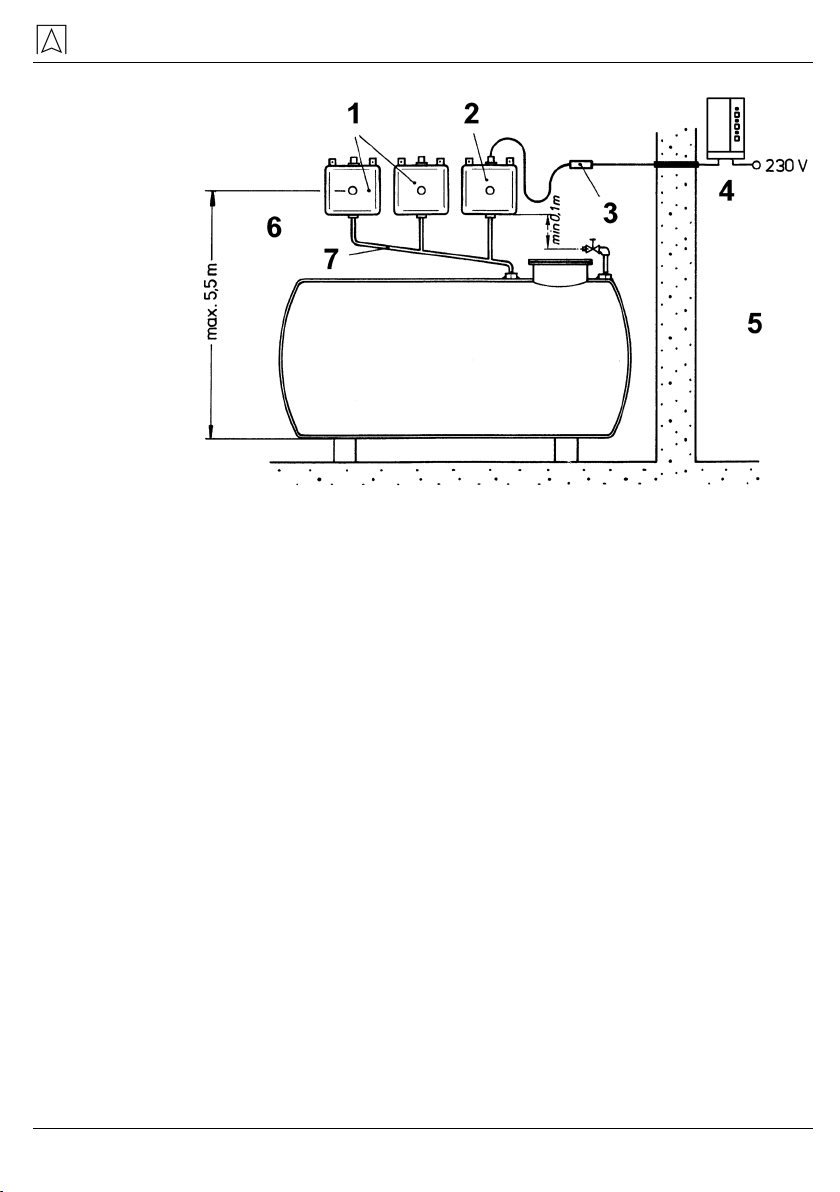

3.4 Application examples

1 Control unit

2 Probe cable

3 Black LAG con-

tainer

4 Probe

5 Connection line

6 Outer wall

7 Interstitial space

8 Inner wall

9 Test valve

Fig. 3: Standard application

Product description

LAG-14 ER 13

Fig. 4: Two black LAG containers at a single control unit (different

locations)

1 Black LAG containers, install

in recess, if possible

5 Non-hazardous (safe) area

2 Permanently installed junction

boxes, connect both probes in

series

6 Hazardous (Ex) area

3 Control unit 7 Stored liquid, compatible

with leak detection fluids

4 All ducts gastight in protective

pipe

8 Transparent piece, sealed

installation

No more than two black LAG containers with probes may be con-

nected in series to one control unit.

Technical data

14 LAG-14 ER

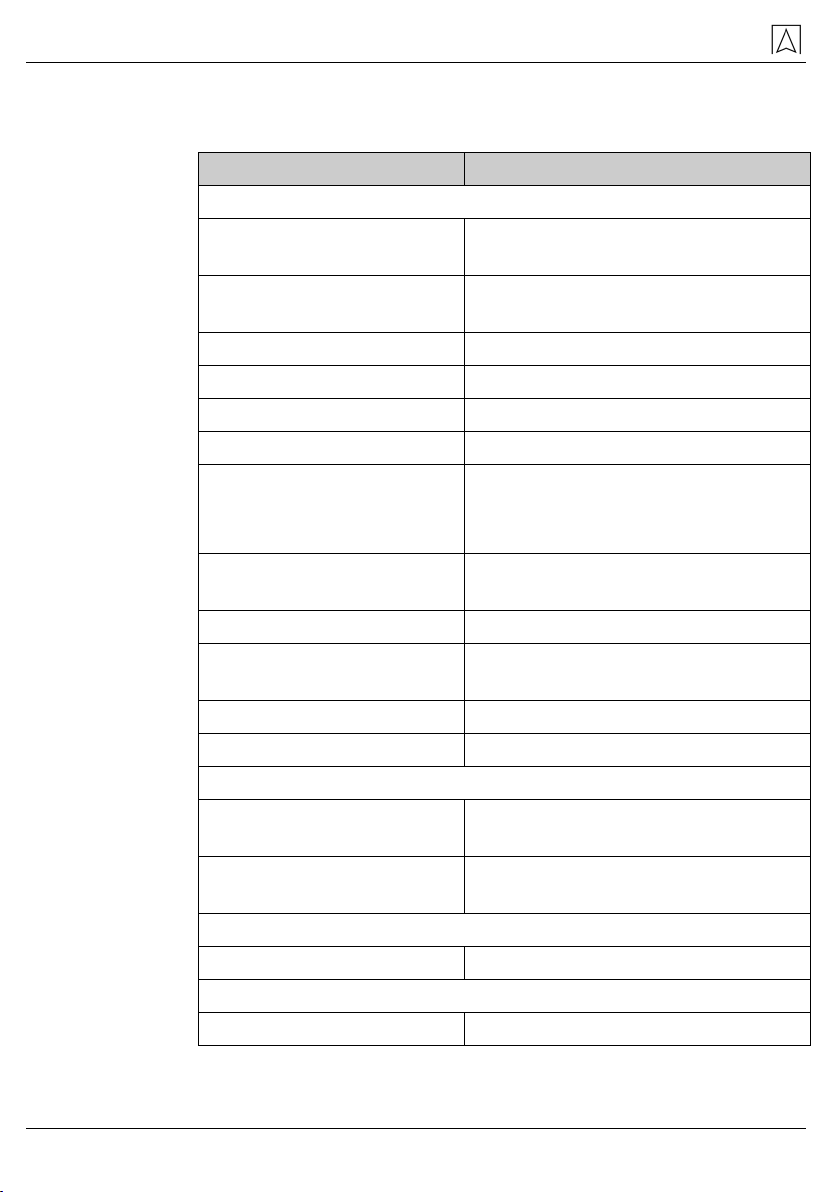

4 Technical data

Table 1: Technical specifications probe and container

Parameter Value

General specifications

Dimensions tank

(W x H x D)

300 x 325 x 145 mm

Space requirements

(W x H x D)

500 x 700 x 200 mm

Weight 1.0 kg

Electrode housing Plastic, Ø 34 mm

Electrode rods V 2 A, Ø 3 mm

Resistance Leak detection fluid

Connection cable:

Standard length

Max. length

H05VV-F, 2 x 1 mm²

1 m

50 m (shielded)

Container (conductive)

black

Hostalen / Vestolen

Surface resistance < 109Ohm as per DIN 53486

Active volume 4.5 litres

(electrode tip to liquid level)

Total volume 10 litres

Connecting hose EPDM hose 14 x 3 (ID 14)

Operating temperature range

Ambient -25 °C to +50 °C, depending

on mixing ratio

Storage -25 °C to +60 °C, depending

on mixing ratio

Supply voltage

Probe voltage Max. 17 V, AC

Electrical safety

Degree of protection IP 20 (EN 60529)

Technical data

LAG-14 ER 15

Table 2: Technical specifications control unit SE2

Parameter Value

General specifications

Dimensions housing

(W x H x D)

100 x 188 x 65 mm

Weight 0.4 kg

Equipment group

(2014/34/EU)

Category (2014/34/EU)

Type of protection

Protection class

Supply voltage

Safety-related maximum

voltage Um

Degree of protection

II

(1) G

[Ex ia] IIC

II

230 V, 50 Hz

253 V

IP 30

Response delay < 1 second

Additional connections 1 output relay (1 changeover contact)

Breaking capacity output

relay

Max. 250 V. 2 A, resistive load

Relay fuse T 2 A

Emissions The A-weighted sound level of the au-

dible alarm is at least 70 dB(A) at a

distance of one metre

Operating temperature range

Ambient -20 °C to +50 °C

Supply voltage

Nominal voltage AC 230 V ± 10 %, 50/60 Hz

Nominal power 5 VA

Mains fuse T 100 mA H (1.5 kA)

Electrical safety

Protection class II (EN 60730-1)

Degree of protection IP 30 (EN 60529)

Technical data

16 LAG-14 ER

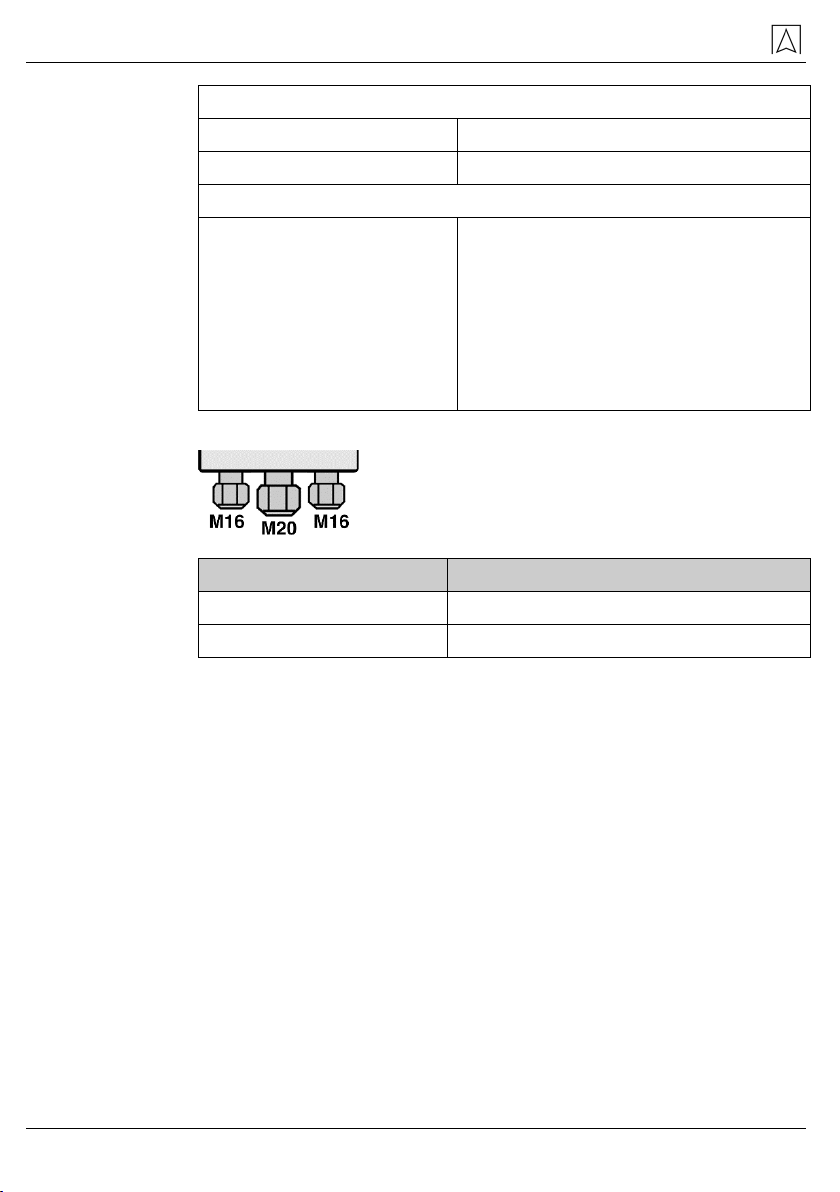

Electromagnetic compatibility (EMC)

Emitted interference EN 60730-1:2011

Noise immunity EN 60730-1:2011

Probe circuits

Probe circuit

Maximum values

for subgroup IIC

for subgroup IIB

Effective internal capaci-

tance and inductance

ia

U0= 16.8 V, Ik= 57 mA, P = 240 mW,

linear characteristic

C0180 nF; L01 mH

C0675 nF; L08 mH

Negligible

Cable glands at the control unit

The centre blind piece can be replaced with

a cable gland M20.

Cable gland Cable diameter

M16 4.0 - 8.8 mm

M20 8.0 - 12.5 mm

4.1 Approvals, tests and conformities

LAG-14 ER complies with the EMC Directive (2014/30/EU), the Low

Voltage Directive (2014/35/EU), the ATEX Directive (2014/34/EU),

the RoHS Directive (2011/65/EU), EC Type Examination Certificate

number EX5 11 02 15639 011 and the Construction Products Di-

rective 305/2011 (EN 13160-3:2003).

Transport and storage

LAG-14 ER 17

5 Transport and storage

CAUTION

Damage to the product due to improper transport.

Do not throw or drop the product.

Protect the product from wetness, humidity, dirt and dust.

CAUTION

Damage to the product due

to improper storage.

Protect the product from shock when storing it.

Store the product packaged in this film.

Store the product in a clean and dry environment.

Protect the product from wetness, humidity, dirt and dust.

Only store the product within the permissible temperature range.

6 Mounting and commissioning

6.1 Calculation fundamentals

LAG-14 ER at underground container (tank)

The effective capacity of the black LAG container is limited by the liq-

uid level screw in the centre of the container; it amounts to 4.5 litres.

For underground containers (tanks), 1 litre of leak detection fluid is

required in the black LAG container per 100 litres of interstitial space

volume.

The black LAG container is sufficient for 450 litres of interstitial space

volume. This corresponds to containers (tanks) with a storage vol-

ume of up to 60,000 litres.

Together with additional containers with an effective capacity of 4.5

litres each, the LAG14 ER leak detector can also be used for tanks

with a greater interstitial space volume.

The additional containers are connected to each other and to the

black LAG container by means of EPDM hoses.

Mounting and commissioning

18 LAG-14 ER

Leak detection fluid in the in-

terstitial space of the tank as

per nameplate on the tank

[litres]

Number of re-

quired black

LAG containers

with probe

Number of required

additional contain-

ers (without probe)

0-450 1 0

450-900 1 1

900-1350 1 2

1350-1800 1 3

1800-2250 1 4

In the case of new installations, the interstitial space volume of the

system must not exceed 1000 l.

LAG-14 ER at aboveground container (tank)

For aboveground containers (tanks), 1 litre of leak detection fluid is

required in the black LAG container per 35 litres of interstitial space

volume.

One black LAG container is sufficient for 157.5 litres of interstitial

space volume. This corresponds to containers (tanks) with a storage

volume of up to 20,000 litres.

Together with additional containers with an effective capacity of

4.5 litres each, the LAG-14 ER leak detector can also be used for

tanks with a greater interstitial space volume.

The additional containers are connected to each other and to the

black LAG container by means of EPDM hoses.

Leak detection fluid in the in-

terstitial space of the tank as

per nameplate on the tank

[litres]

Number of re-

quired black

LAG containers

with probe

Number of required

additional contain-

ers (without probe)

0-157.5 1 0

157.5-315 1 1

315-472.5 1 2

472.5-30 1 3

630-787.5 1 4

Mounting and commissioning

LAG-14 ER 19

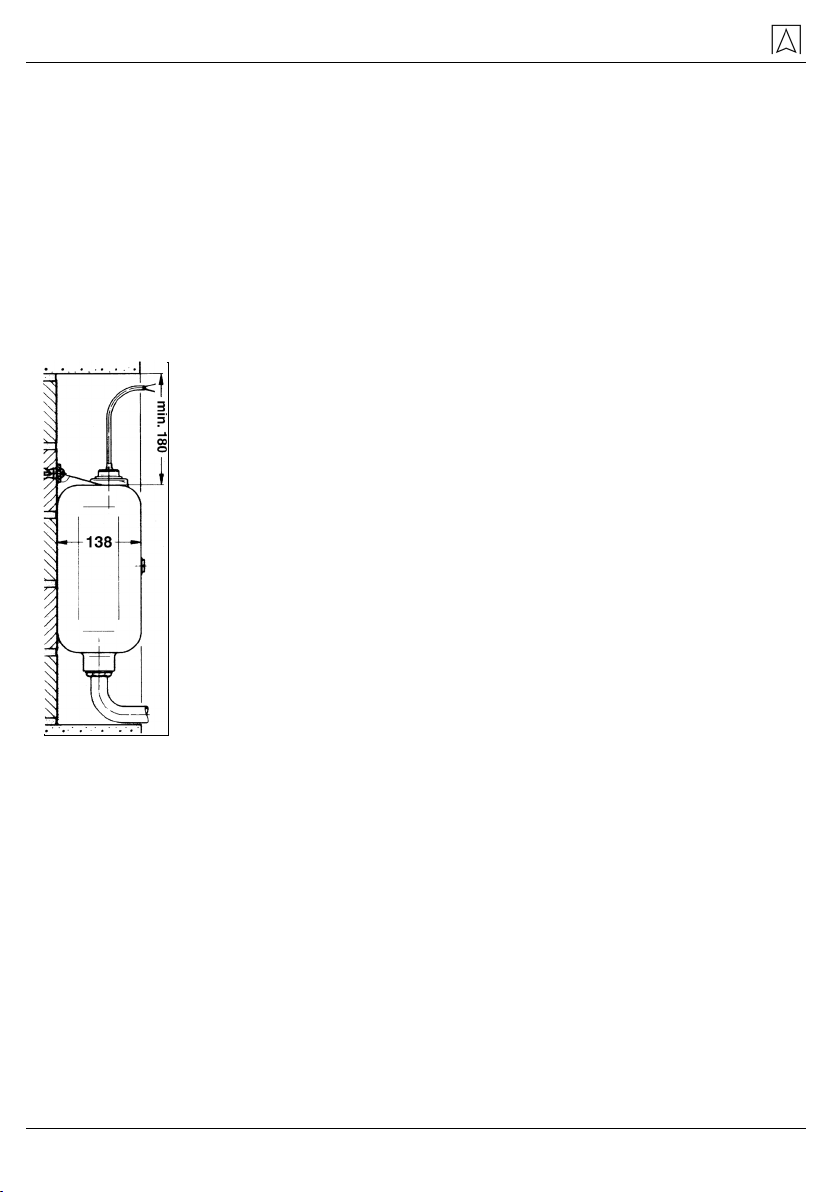

Fig. 5: Additional container

1

Additional black container 6 Hazardous (EX) area or

non-hazardous (safe) area

2

Black LAG container with probe

3 Junction box, permanently in-

stalled

7 Communicating

connection

4

Control unit

5 Non-hazardous

(safe) area

Mounting and commissioning

20 LAG-14 ER

Dasverknüpfte Bild kann nicht angezeigt werden. Möglicherweise wurde die Datei verschoben, umbenannt oder gelöscht. Stellen Sie sicher, dass die Verknüpfung auf die korrekte Datei und den korrekten Speicherort zeigt.

6.2 Installing the container for the leak detection fluid

Verify the volume of leak detection fluid required (check the

nameplate at the tank (container)) and determine the number of

required black LAG containers as described in chapter 6.1,

page 17).

The black LAG container can be mounted directly next to the control

unit or in the vicinity of the container (tank) to be monitored in haz-

ardous areas (Ex) zone 1 and zone 2 (e.g. in the manhole).

When installing the LAG container in the hazardous area (Ex),

in the manhole or outdoors, make sure neither surface water no

rain nor dirt nor airborne sand can get into the container or into

the cable junction box.

Mount the black LAG container high enough above the intersti-

tial space for the static pressure of the leak detection fluid to be

sufficient at all points of the interstitial space to cause the leak

detection fluid to escape and the leak detection fluid level in the

black LAG container to fall in the case of a leak so that an alarm

can be triggered.

The minimum distance between the tank top and the bottom of

the black LAG container primarily depends on the density of the

stored medium and, in the case of underground tanks, on the

possible level of the ground water or backflow above the tank

top. Mount the black LAG container at least 30 cm above the

tank top.

If the test pressure for the interstitial space of the tank is 0.6 bar,

the black LAG containers (with reference to the liquid level

screw) may be no higher than 5.5 m above the bottom of the

tank.

Table of contents

Other Afriso EURO-INDEX Security Sensor manuals

Popular Security Sensor manuals by other brands

Intelbras

Intelbras IVP 3000 PET user manual

DANLERS

DANLERS CBU-HBSP Installation

Monacor

Monacor IRS-200 quick guide

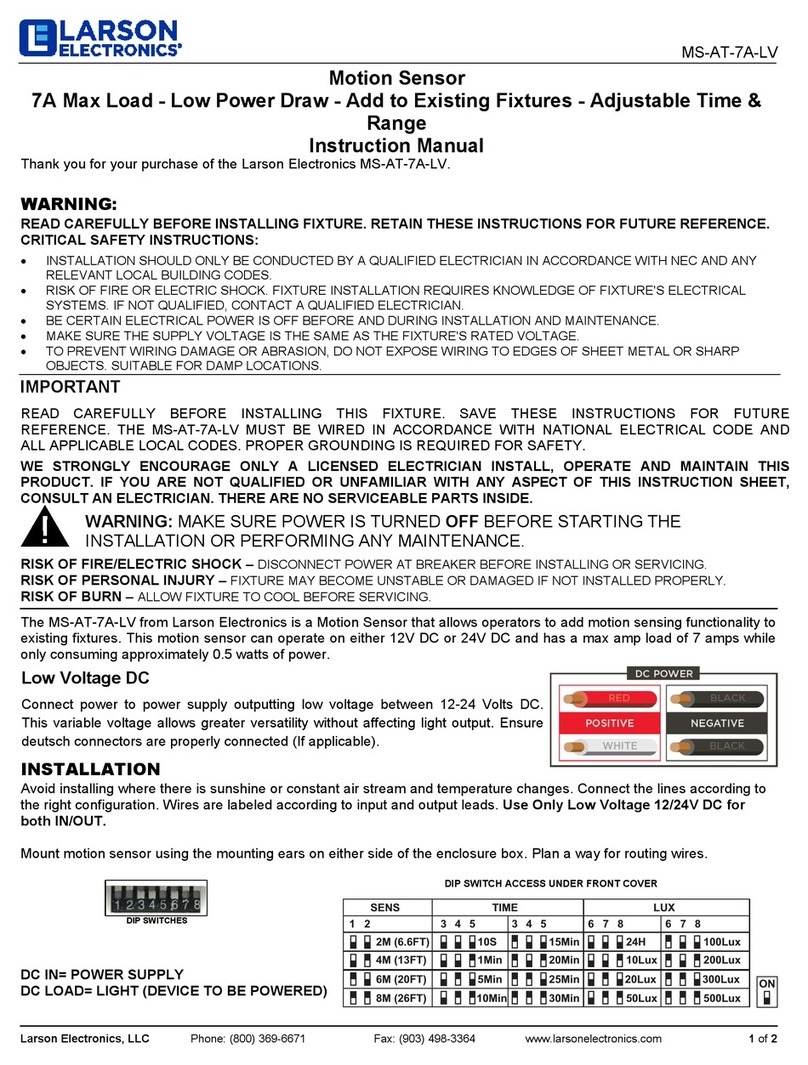

Larson Electronics

Larson Electronics MS-AT-7A-LV instruction manual

dtec

dtec GJD 350 Installation & setup guide

Thermo Scientific

Thermo Scientific Dionex UltiMate 3000 Series operating instructions