HILO JACK-4N User manual

USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

USER MANUAL

MANUAL PALLET JACK

MODEL: JACK-4N, JACK-4S

USR Brands, Inc.

Phone: 800-764-1172 | www.usrestaurant.com | sales@usrestaurant.com

USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

Contents

1. Operation Manual

1.1 Range of Application

1.2 Operating Instruction

1.3 Safety Precautions

2. Description of truck

2.1 Applied Range

2.2 Illustration of Assembly Units & Operating Conditions

3. Using Functions

3.1 Test Run

3.2 Control Handle Knob Adjustment

3.3 Safe Parking

4.Safe Operation

4.1 Inspection of Hydraulic Oil

4.2 Air Extraction

4.3 Daily Maintenance

4.4 Possible Faults and trouble shooting

1. Operation Manual

1.1 Range of Application

Truck should be operated, used and maintained in accordance

with this manual. Other operation, which are not listed in this

manual, may cause hazards to people and truck, and may lead

to property loss. Please carefully read the nameplate first to

make sure the loading weight doesn’t exceed the truck’s

capacity. Overload and unbalanced load should be avoided.

Flammable explosive environment may cause explosion.

1.2 Operating Instruction

The truck can only be operated by staff who has been trained

well, has obtained a diver license, knows how to deal with

loading, is clear about the operating instructions and has

grasped operating skills.All the users should carefully read and

understand the content of this manual.

Failure to comply with the instructions will result in loosing

warranty. These rules apply equally to products that have been

unlawful exported without manufacture’s permission by

customers ( or third party ).

1.3 Safety Precautions

User should be responsible to the truck’s useful life. It is

forbidden to load people and let then stand on the forks to side.

When discover damage and other flaw, user should

immediately send report to supervisor.

USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

2 Description of truck

2.1 Applied Range

The truck can lift and carry goods on level ground by using fork.

It can also carry open type tray and transverse tray. User can

obtain the carrying capacity from the truck’s nameplate.

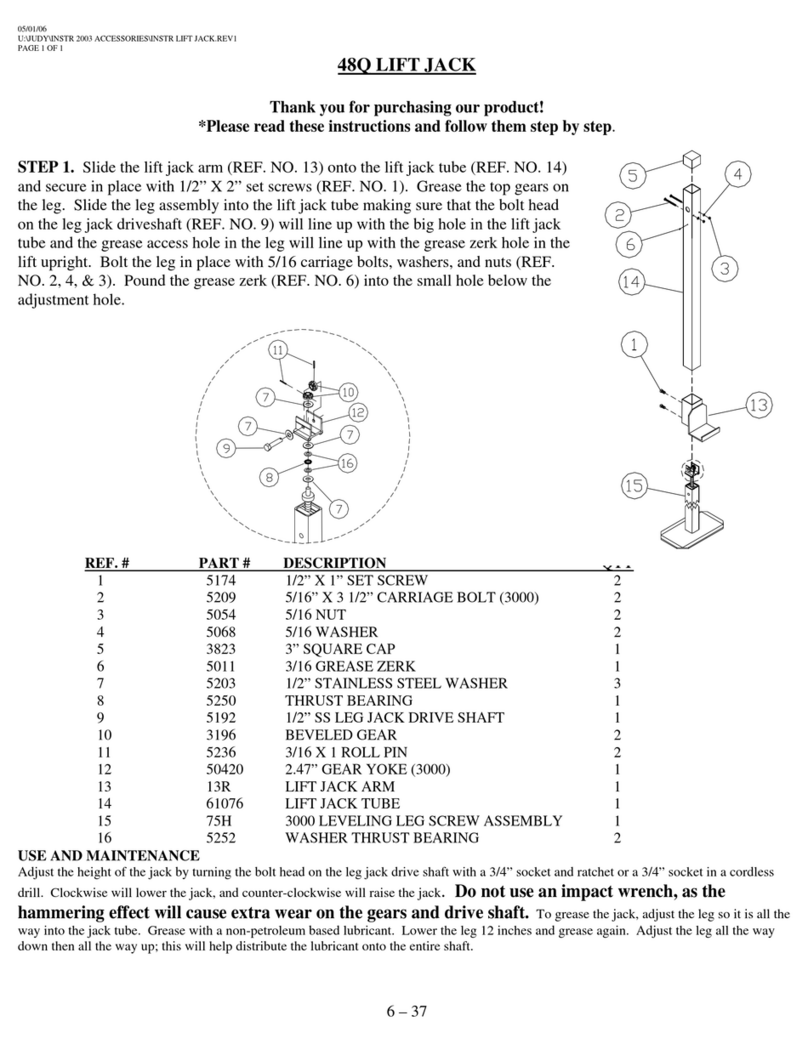

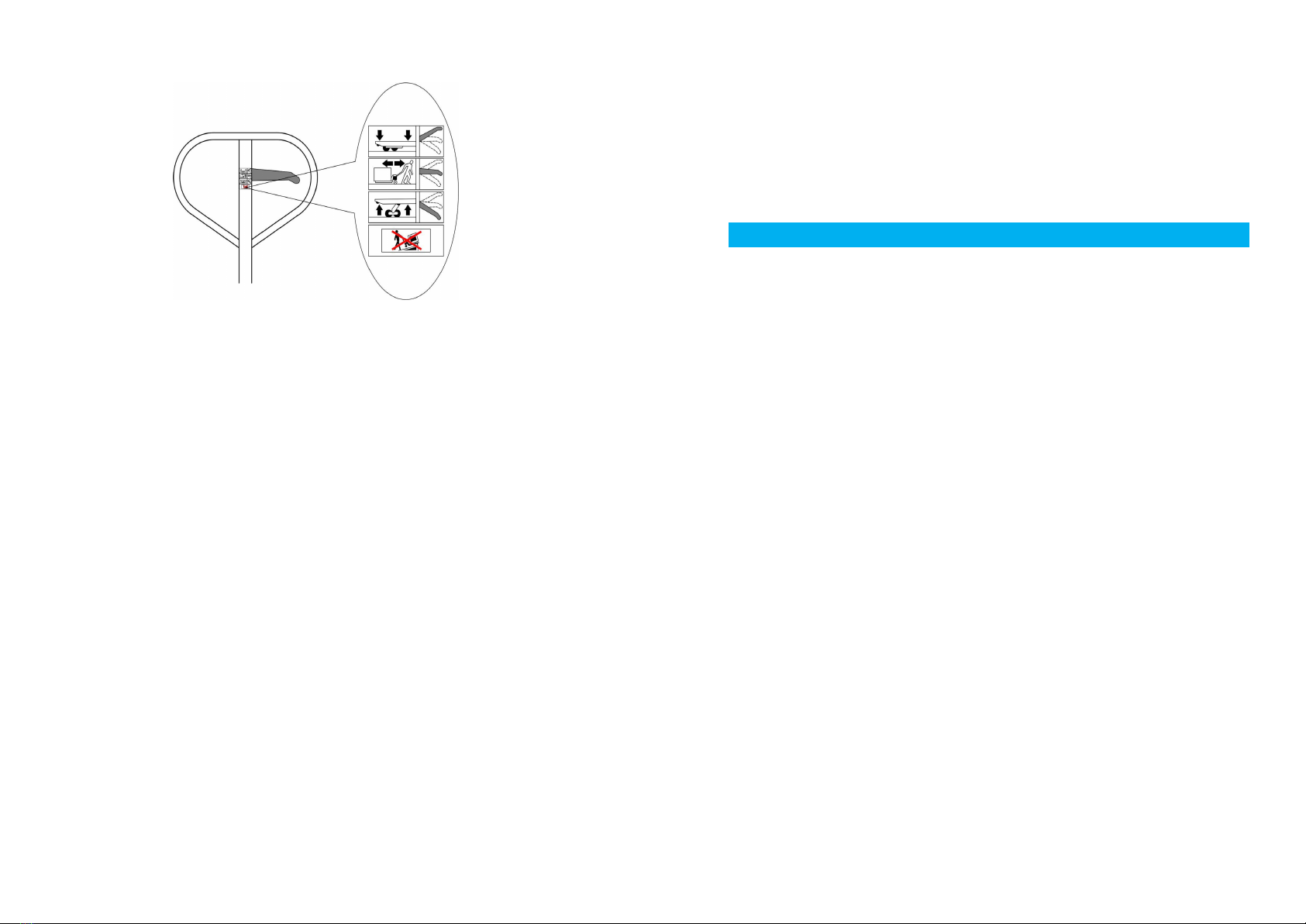

2.2 Illustration of Assembly Units & Operating

Conditions

3. Using Functions

3.1 Test Run

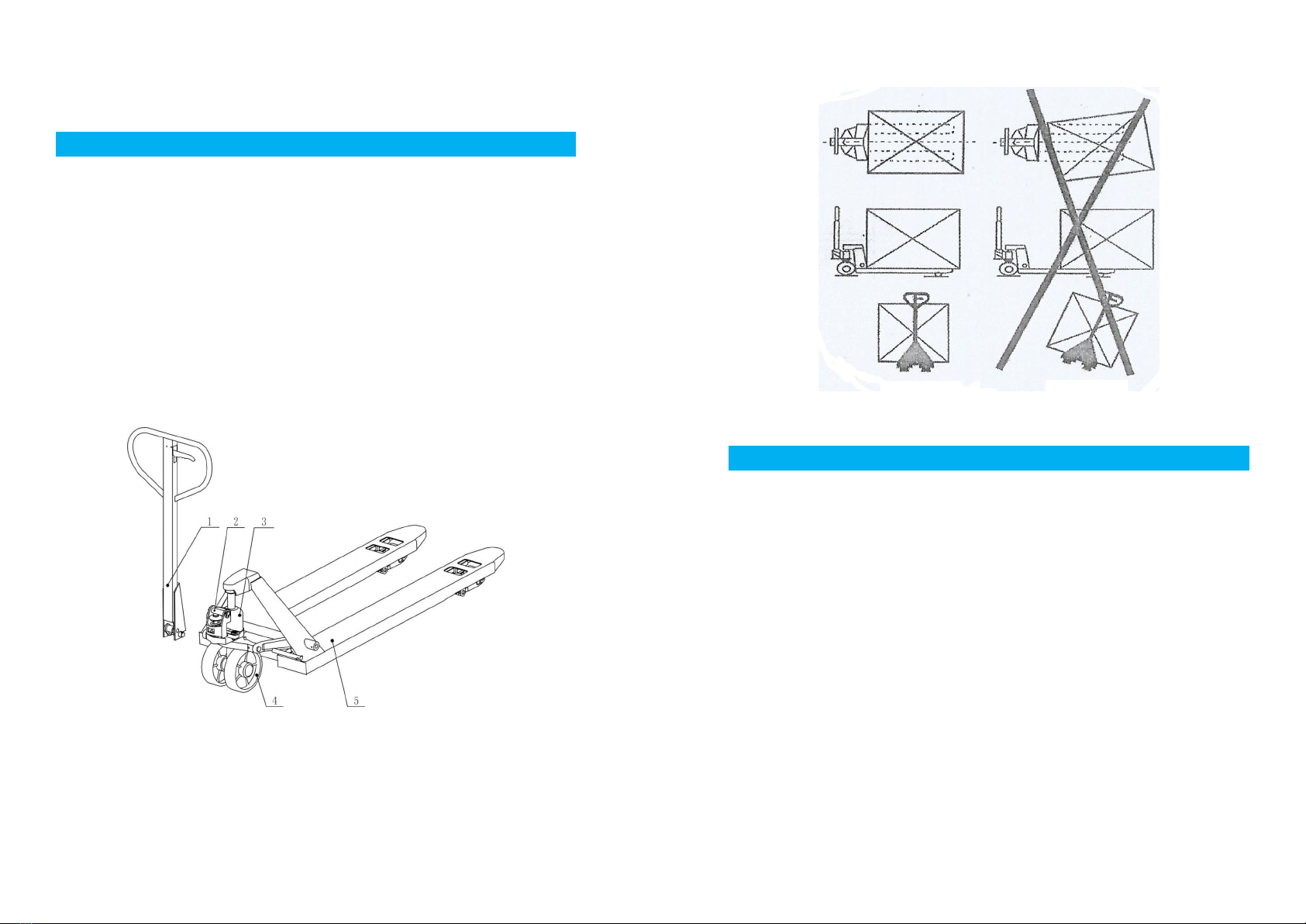

Loading goods at test run should be operated in the safe area

with staff only. The gravity center of the goods should be

positioned in the middle of the two forks. Do not put goods at

rear of the fork.The carrying capacity can be maximized when

weight is evenly distributed.

3.2 Control Handle Knob Adjustment

1. Handle

2. Pin roll

3. Oil pump

4. Big wheel

5. Fork frame

Correct

Wrong

USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

The control handle knob has three positions (up, middle, down).

Up Push the control handle knob to the lower position, then

bob up and down the handle to lift goods on fork.

Middle Keep the forklift in the middle position, then the fork will

not lift or decent. This mode is used to pull the truck.

Down Pull and keep the control handle knob to the upper

position, then the fork will descend. Release the control handle

knob, it will automatically get back to the middle position.

Lift Make sure the fork is fully into the bottom of the goods

before lifting the goods. When everything ready, push the

control handle knob to the lower position and rock the handle to

lift goods to the wanted height.

Descend When pull the control handle knob up, the fork will

descend. Release the control handle knob, it will automatically

get back to the middle position, and the fork will stop descend.

When moving truck, the control handle knob should be kept in

the middle position.

3.3 Safe Parking

Do not park the truck on an inclined plane. The truck forks

should be on the lowest position while parking.Wheels should

be fixed and fencing should be used to protect the truck when

using other vehicle to transport it.

4. Safe Operation

4.1 Inspection of Hydraulic Oil

Check the oil mass every six months. The total capacity is

about 0.3 L. Hydraulic oil type: L-HV46. Use under -20℃ ~

+40℃.

4.2 Air Extraction

Air will easily get into the oil tank because of transportation and

inversion. This will lead to the failure of lifting the fork when

push the control handle knob to the lower position. Method of

air extraction: Pull and keep the control handle knob to the

upper position, then rock the handle for several times.

4.3 Daily Maintenance

Daily maintenance can improve the truck’s service life.

Specially pay attention to the place between wheels and axis.

Make sure there is no yarn or other rags in order to keep all

wheels running with handiness. When the truck does not work,

make sure that the truck forks are on the lowest position.

Lowering

Netural gear

Raising

USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

4.4 Possible Faults and trouble shooting

Use the method listed in the following table (table 4.4). If the

fault can not be removed, please contact the supplier for an

advanced checking. The maintenance can only be done by

specialized persons. Person without specialized training

shouldn’t assemble and disassemble the truck.

Table 4.4 Possible Faults and trouble shooting

Fault

Description

Reason

Method

1

Fork cannot

reach the

wanted

height

·Lacking of hydraulic oil.

·Add hydraulic oil.

2

Fork cannot

rise

·Hydraulic oil is not pure.

·The relief valve is opened

because the adjustment nut

is too high or the screw is

too close.

·Air in the hydraulic oil.

·Change hydraulic oil.

·Readjust the position of

the adjustment nut or the

adjustment screw.

·Bob up and down the

handle to extract the air.

3

Fork cannot

descend

·The large piston or the

pump body is damaged

because of the unevenly

distributed weight on the fork

or overloading.

·The fork has been kept in

high position for a long time ,

and the large piston is

rusted.

·The adjustment nut or the

adjustment screw is in an

incorrect position.

·Change the large piston

or the pump body.

·Keep the fork in the

minimum height when

work is done. Pay attention

to lubricate the piston

lever.

·Readjust the position of the

adjustment nut or the

adjustment screw.

4

Oil leak

·Aging or damaging of

sealing element.

·Some elements are

crazed.

·Change the damaged

elements.

5

Fork

descend

without

operation

·The relief valve cannot

shut because of impure

hydraulic oil.

·Some of the hydraulic

system elements are

damaged or crazed.

·Air in the hydraulic oil.

·Aging or damaging of

sealing element.

·The adjustment nut or the

adjustment screw is in an

incorrect position.

·Change hydraulic oil.

·Check and change the

damaged elements.

·Extract thee air.

·Change the sealing

elements.

·Readjust the position of

the adjustment nut or the

adjustment screw.

This manual suits for next models

1

Table of contents