MODEL H8092

31/2 Ton Double Pump

Garage Jack

COPYRIGHT © DECEMBER, 2006 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JC8823 PRINTED IN CHINA

Specifications

Maximum Lifting Capacity .....................7000 lbs.

Lifting Range .......................................51⁄4"–193⁄4"

Weight .......................................................84 lbs.

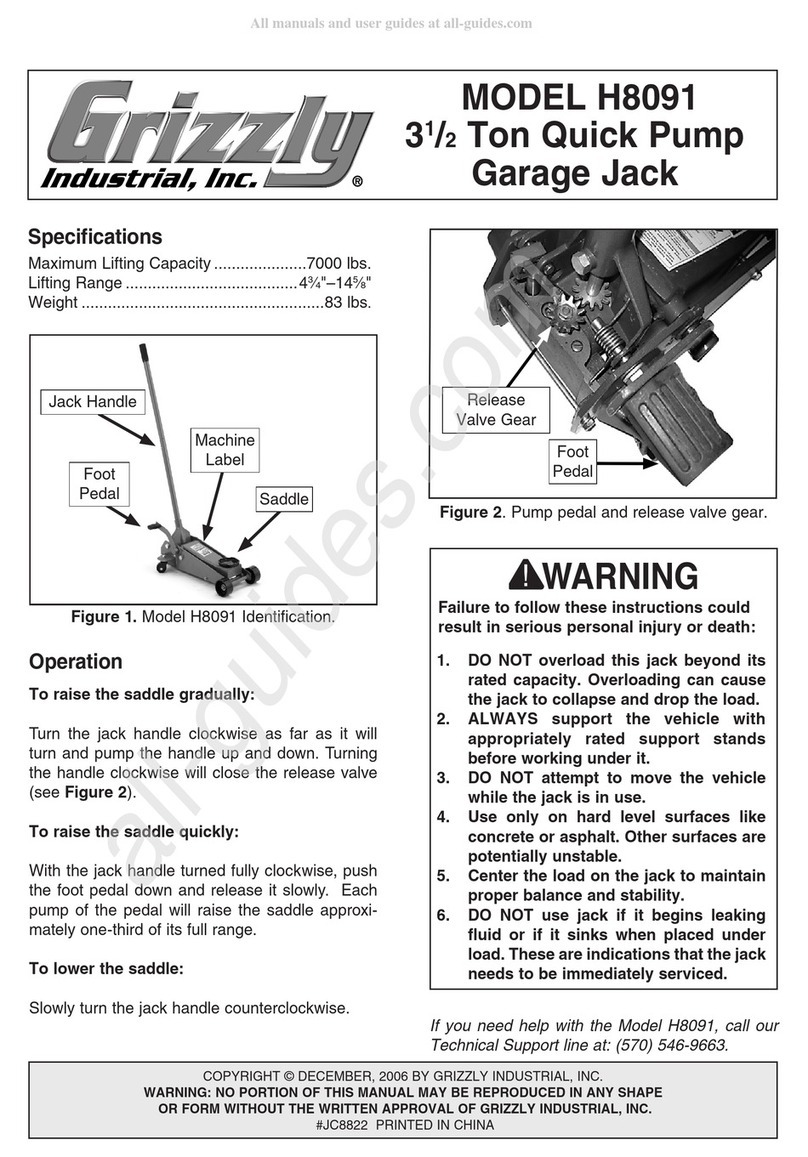

Figure 1. Model H8092 Identification.

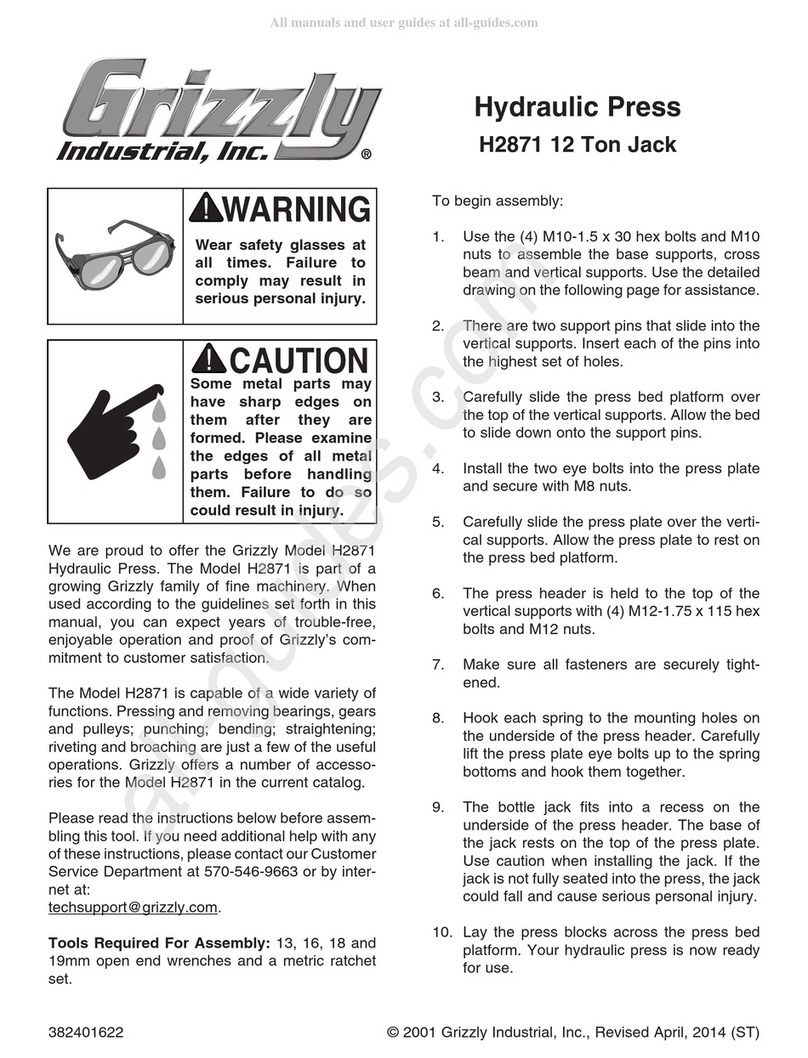

Figure 2. Pump pedal and release valve gear.

If you need help with the Model H8092, call our

Technical Support line at: (570) 546-9663.

Foot

Pedal

Jack Handle

Failure to follow these instructions could

result in serious personal injury or death:

To raise the saddle with the jack handle:

Turn the handle clockwise as far as it will turn

and pump the handle up and down. Turning the

handle clockwise will close the release valve (see

Figure 2).

To raise the saddle with the foot pedal:

With the jack handle turned fully clockwise, push

the foot pedal down and release it slowly. Each

pump of the pedal will raise the saddle approxi-

mately two inches.

To lower the saddle:

Slowly turn the jack handle counterclockwise.

Operation

Machine

Label

Saddle

Foot

Pedal

1. DO NOT overload this jack beyond its

rated capacity. Overloading can cause

the jack to collapse and drop the load.

2. ALWAYS support the vehicle with

appropriately rated support stands

before working under it.

3. DO NOT attempt to move the vehicle

while the jack is in use.

4. Use only on hard level surfaces like

concrete or asphalt. Other surfaces are

potentially unstable.

5. Center the load on the jack to maintain

proper balance and stability.

6. DO NOT use jack if it begins leaking

fluid or if it sinks when placed under

load. These are indications that the jack

needs to be immediately serviced.

Release

Valve Gear